International Journal of Trend in Scientific Research and Development (IJTSRD)

Volume 5 Issue 4, May-June 2021 Available Online: www.ijtsrd.com e-ISSN: 2456 – 6470

Analysis of Technological Schemes for Producing

Bars by Forging on Radial Crimping Machines

Tilavov Yunus1, Danilenko Anjela2, Urokov Komol1, Elmurodov Nuriddin1

1Karshi

2Belgorod

State University, Karshi, Uzbekistan

State National Research University, Belgorod, Russia

How to cite this paper: Tilavov Yunus |

Danilenko Anjela | Urokov Komol |

Elmurodov Nuriddin "Analysis of

Technological Schemes for Producing

Bars by Forging on Radial Crimping

Machines" Published

in

International

Journal of Trend in

Scientific Research

and

Development

(ijtsrd), ISSN: 24566470, Volume-5 |

IJTSRD42586

Issue-4, June 2021,

pp.1509-1512,

URL:

www.ijtsrd.com/papers/ijtsrd42586.pdf

ABSTRACT

This article examines the analysis of technological schemes for the production

of rods by forging on radial swaging machines that allows you to select the

structural material and geometric dimensions of the workpiece and tool and

technological parameters, the feed rate of the workpiece, the parameters of

the reduction cycle of the forging process of refractory metals on radial

swaging machines that ensure the production of bars good quality, sufficiently

high plasticity.

KEYWORDS: bar, billet, technological schemes, recrystallization, annealing,

drawing

Copyright © 2021 by author (s) and

International Journal of Trend in Scientific

Research and Development Journal. This

is an Open Access article distributed

under the terms of

the

Creative

Commons Attribution

License

(CC

BY

4.0)

(http: //creativecommons.org/licenses/by/4.0)

1. INTRODUCTION

In order to determine the optimal design parameters of the

technological tool of the radial crimping machine (ROMe)

and the choice of its material, which ensures reliable

performance during deformation of bars made of refractory

metals, the authors have developed a mathematical model of

the thermal and thermally stressed state of the workpiecetool system.

2. Methods

It is known that during the deformation of refractory metals

and alloys based on them (for example, molybdenum and its

alloys are deformed at 1000-1100 0С) on radial crimping

machines, the technological tool is exposed to large thermal,

mechanical and dynamic loads, which often cause the

destruction of the tool [1 , 2]. In this regard, the use of

computational methods [3, 4] for determining the stress

state, choosing the material of the tool and assessing its

performance is of great scientific importance.

3. Results and Discussion

Hot-pressed rods of molybdenum grades MChVP and MCh

with a diameter of 52-65 mm and a length of 350-400 mm,

pre-annealed at a recrystallization temperature (Tm = 10001100 0C for 1 hour), are used as initial blanks for obtaining

rods with a diameter of 12-16 mm. It is recommended to

forge the initial blanks at a heating temperature of 900 ±

500C, and with a diameter of 25-30 mm at 600 ± 500C. Before

forging at Tn = 600 ± 500C, the rods should be subjected to

recrystallization annealing in a hydrogen atmosphere for 40@ IJTSRD

|

Unique Paper ID – IJTSRD42586

|

60 minutes. The basic technological scheme for forging

molybdenum rods with a diameter of 52-65 mm to rods with

a diameter of 12-16 mm on a radial crimping machine

(POMe) is shown in table 1.

The authors proposed a methodology and performed

calculations of energy-force and deformation parameters for

forging molybdenum blanks on a VV4032Ts radial crimping

machine, the equipment of which is currently installed at the

Moscow Refractory Metals and Hard Alloys Plant [1, 2].

The total force P at radial compression is recommended to

be determined by the formula:

P = q⋅F

(1)

where, q − specific effort, F − contact area of the striker

with the workpiece, and the specific effort q according to

the following formula:

2 l

q = σ s 1 + µ 0

3 dn

where,σ s − tensile

(2)

strength

at

compression

temperature, µ − coefficient of friction,

l o − length of the

deforming part of the striker,

Volume – 5 | Issue – 4

|

d n − forging diameter.

May-June 2021

Page 1509

International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470

When forging with cut radius strikers, there are two zones of

contact areas of the forging with four strikers:

a) for the conical deforming zone of the striker

Fд =

(

)

sin

θ

1 2

2

D3 − d n2

4

tgβ

(3)

where, θ − angle / coverage / working radius surface of the

striker from the workpiece being processed;

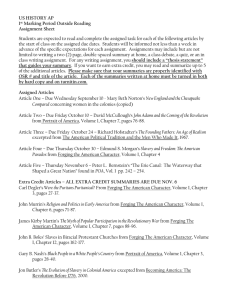

T abl e 1 .Flow chart for the production of cast molybdenum rods using the forging process at POM.

Electric arc melting

Preparation of blanks and forging at ROM

Cut to length. Heat treatment, mechanical

processing

Mechanical restoration

Heating the workpiece in a vacuum

or hydrogen atmosphere

Тn=1300÷1350 0C

Heating billets up to 900 0С and forging

on POM from Ø 36÷44 mm→25÷30 mm

Ingot pressing

Тn=1200÷1250 0C

µ= 4

VTGP

Тn=800÷1150 0C

µ= 6÷12

dno= 16÷40 mm

Mechanical processing

hammer forging

Тn=1250±50 0C

Annealing the bars

Rotary forging at

Тn=1250±50 0C

Ø20…10 mm

Cut to length

OTK

Annealing the rods at Тn=900±1000

0C for 40-60 min. Heating at 600±50

0C and forging at POM

from Ø 25÷30 mm→ Ø 18÷22 mm

Heating of workpieces up to 600±50

0C. Forging on ROM

from Ø 18÷22 mm→ 12÷16 mm

Mechanical processing, trimming of

ends, cutting to length.

b) for the calibrating cylindrical area of the striker

Fк = d nlk sin

θ

(4)

2

Specific effort q is determined:

- for the conical deforming zone of the striker

2 D −d

2

n

q = Ơ s 1 − µ 3

⋅

2

3

2tgβ

D3 − d n2

(5)

- for the calibrating cylindrical area of the striker

2 l

qk = Ơ s 1 + µ k

3 dk

(6)

The total force at radial compression of molybdenum by four strikers is determined from the expression:

P = q Д ⋅ F Д + q K ⋅ FK

(7)

At the indicated heating temperatures of workpieces (molybdenum at Тn = 900 0С and Тp = 600 0С equal to 90-110 kN and

single reductions from 30% to 75%, the total force is 1000-1600 kN) [3, 4].

To ensure that the specific loads on the strikers do not exceed the limiting values (80-85 kN), it is advisable to forge

molybdenum rods at 300 0C in two passes with hoods µ = 2,0 − 2,5 , and at a heating temperature of 600 ± 50 0C - with hoods

µ = 1,37 − 2,0 .

The maximum permissible feed rate of the workpiece into the strikers is calculated by the formula:

Vn =

π ⋅ n ⋅ H ⋅ (1 − cosϕ 0 )

60 ⋅ (2π − ϕ 0 )tgβ

@ IJTSRD

|

Unique Paper ID – IJTSRD42586

(8)

|

Volume – 5 | Issue – 4

|

May-June 2021

Page 1510

International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470

where, n-striker strokes frequency per minute, n = 800 rpm, H-full stroke of the striker, mm; H=6 mm, ϕ 0

the crank shaft, the limiting value of which is 30-400, ϕ 0

− loading angle of

= 400, β − the angle of the lead-in cone of the striker, which is equal

to 120.

For forging molybdenum rods, the feed rate of the workpiece into the strikers should not exceed the values:

π ⋅ n ⋅ H ⋅ (1 − cos ϕ 0 ) 3,14 ⋅ 800 ⋅ 6(1 − cos 40 0 ) 15072(1 ⋅ 0,8) 3014,4

Vn =

=

=

=

= 40,52 mm ;

s

60 ⋅ (2π − ϕ 0 )tgβ

74,4

60 ⋅ (2 ⋅ 3,14 − 40 0 )tg12 0 60 ⋅ 6,2 ⋅ tg12 0

The working speed of rapprochement of the strikers is determined by the formula:

π ⋅ n ⋅ H (1 − cos ϕ0 )

60(2π − ϕ 0 )

Vc =

(9)

When forging molybdenum, the working speed of drawing the strikers together is 8.1 mm/s, and the maximum permissible

speeds for POM VV4032Ts at and will be equal;

Vn =

(

)

n ⋅ H ⋅ (1 − cos ϕ 0 ) 800 ⋅ 6 1 − cos 40 0

4800 ⋅ 0,2

=

=

= 49,52 mm ;

s

ϕ0

40

0

,

8

60 2 − tg12 0

60 ⋅ 2 − tgβ

60 2 ⋅

⋅ 02

π

π

3,14

(

)

n ⋅ H ⋅ (1 − cos ϕ 0 ) 800 ⋅ 6 1 − cos 40 0

and Vс =

=

= 10,53 mm ;

s

ϕ0

40 0

60 ⋅ 2 −

60 2 −

π

3,14

the average speed of the strikers convergence should always be less than the average speed of the striker Vδ

=

n⋅ H

because

60

forging of the workpiece is carried out by the flywheel drive-stroke of the striker, and not by bringing it together.

Vδ =

n ⋅ H 800 ⋅ 6

=

= 80 мм

с

60

60

Vδ ⟩ Vc

Selecting the angular velocity of the workpiece.

In the general case, the angular velocity of the workpiece during its processing is determined by the dependence

W=

θ

tц

=

where, n3

π ⋅ n3

(10)

30

n ⋅θ

n ⋅θ

and n3 = C ⋅ П

2π

2π

=

θ − the angle of coverage by the striker of the workpiece at the end of the stroke, n3 − workpiece revolutions. С – the

coefficient of overlap of the deformed surface, which is taken equal to 0.1-0.6.

θ≤

360 360

=

= 90 C-takes =0,2.

Ζ

4

where, Ζ − number of strikers in the car Ζ

n3 =

W=

= 4.

800 ⋅ 90 72000

=

= 11465 rpm

2 ⋅ 3,14

6,28

π ⋅ n3

30

⋅C =

3,14 ⋅ 11465 ⋅ 0,2 7200

=

= 240 s −1 .

30

30

The number of revolutions of the workpiece during processing in the hot state is taken in the range nз.г=(0.125…0.05) rpm, nз.г

= 0.1x11465 = 1146.5 rpm.

This technology for the production of rods from molybdenum and the method for calculating the forging forces, as well as the

thermo mechanical parameters of forging of molybdenum blanks, adopted for implementation at the Moscow Refractory Metals

and Hard Alloys Plant and will be implemented with the commissioning of a radial swaging machine model VV4032Ts.

@ IJTSRD

|

Unique Paper ID – IJTSRD42586

|

Volume – 5 | Issue – 4

|

May-June 2021

Page 1511

International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470

4. Conclusions

1. A new highly efficient process and thermomechanical

modes of forging on a radial swaging machine have been

developed to produce small-diameter bars from

refractory metals, which provides an increase in product

quality, an increase in equipment productivity and an

improvement in working conditions.

2.

A highly efficient technology for the production of rods

from molybdenum ingots has been created, which

includes hot pressing, high-temperature hydro-pressing

and forging on a radial crimping machine, provides the

production of small-diameter rods with a welldeveloped structure, improved quality and with an

increased (by 15-20%) level of mechanical properties.

References

[1] Tilavov Y. S. Development and implementation of lowwaste technology for the production of rods from

molybdenum and niobium. - Diss. for the degree of

candidate of technical sciences. - M .: 1994. 285 p.

@ IJTSRD

|

Unique Paper ID – IJTSRD42586

|

[2]

А. P. Kolikov, Yu. S. Tilovovidr. Matematicheskaya

model

termonapryajennogosostyaniyatexnologicheskogoins

trumentaprikovketrudnodeformiruyemixmaterialov.

Dep. VINITI. № 5. 1994.

[3]

А. P. Kolikov, I. А. Levitskiy, Yu. S. Tilovovidr.

Matematicheskaya

model

teploobmenaitermonapryajennogosostyaniya

v

sistemezagotovka

–

rabochiyinstrumentapriobrabotketugoplavkixmetallo

v. Izv. Vuzov. Chernayametallurgiya. – 1994. № 9.

[4]

А. А. Vardiyashvili, Yu. S. Tilovov, К. Х. Urokov.

Аnalizrezultatovraschetaparametrovtemperaturnogoi

termonapryajennogosostoyaniyavsistemezagotovkainstrumentpriradialnoykovke.

Nauchno–

texnicheskiyjurnalFerPI. 2020., Tom 24. №5. s. 213216.

Volume – 5 | Issue – 4

|

May-June 2021

Page 1512