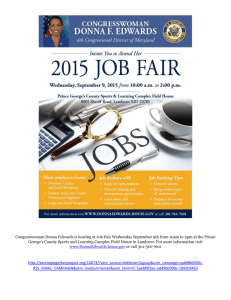

8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Search a a a IPC Class 2 VS Class 3: The Different Design Rules by Lucy Iantosca | Jul 21, 2020 | 6 comments As a circuit board manufacturer, designers often ask us about the difference between IPC Class 2 and Class 3. Class 1 does exist although https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign=… 1/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits we rarely produce boards that fall into this classification. Most of the times, even if the end-use of the product only requires Class 1, we will make it Class 2 just to ensure a better performance. This article will help you understand the different design rules for IPC Class 2 and Class 3 circuit boards. There are four IPC classifications. Class 1 is assigned to general electric boards with a limited life and a “simple” function, such as the ones you can find in remote controls. Class 2 is for dedicated service electronic products. This means that you expect the board to have an extended life so you can place it in a television, a computer, or an air conditioner. Class 3 PCBs are tighter in tolerances as opposed to Class 1 and Class 2 boards. John Perry, Director of Printed Board Standards and Technology at IPC, explained: “Class 3 includes products where continued high performance or performance-on-demand is critical, product downtime cannot be tolerated, end-use environment may be uncommonly harsh, and the product must function when required.” These circuit boards are highly reliable. They are used to achieve high performances in the military or in medical, for instance. IPC-6012DS Class 3A includes space and military avionics. It is the highest class for printed circuit boards. https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign=… 2/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Contents [ hide ] 1 Class 1 – General electronic products 2 Class 2 – Dedicated service electronic products 3 Class 3 – High-performance electronic products 4 IPC 6012 Class 3/A 5 What are the differences between Class 2 and Class 3 for assembly? 6 What are the differences between Class 2 and Class 3 for PCB manufacturing? 6.1 Annular ring and drill breakout 6.1.1 IPC annular ring acceptance criteria 6.2 What are the design rules for annular rings? 6.2.1 IPC Class 2 Drill & Pad Diameter for 1/2 oz Copper 6.2.2 IPC Class 3 Drill & Pad Diameter for 1/2 oz Copper 6.3 PCB dielectric requirement 6.4 PCB through-hole plating requirement 7 PCB cross-section to verify the spec requirement 8 Inspection and acceptance criteria 8.1 Documentation Class 1 – General electronic products Class 1 boards are assigned to general electronic boards with a limited life and a simple function. This class includes most typical everyday products. The class 1 boards allow various cosmetic defects as long as it doesn’t affect the functioning of the board. The reliability of the product isn’t a critical factor in these types of boards. For instance, they can be found in TV remote controls, LED lights, kids’ toys, etc. They are the most inexpensive boards to manufacture in the industry but they come with a limited life expectancy. https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign=… 3/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Class 2 – Dedicated service electronic products Class 2 boards have higher reliability and extended life. They follow more stringent standards than class 1 but allow some cosmetic imperfections. Here, uninterrupted service is preferable, but not critical. The class 2 products aren’t exposed to extreme environmental conditions. The board is expected to run continuously but its operation is not extremely critical. These kinds of boards are implemented in your laptops, smartphones, tablets, communication equipment, etc. Class 3 – High-performance electronic products Class 3 boards must provide a continued performance or performance on demand. There can be no equipment downtime, and the end-use environment may be exceptionally harsh. High levels of inspection and testing are performed on these boards with stringent standards. This makes the class 3 boards highly reliable. This category includes critical systems such as life support systems, military equipment, electronic monitoring systems, automotive PCB, etc. https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign=… 4/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits IPC 6012 Class 3/A The IPC-6012 class 3/A is relatively a new class that includes space and military avionics. This is the highest class for printed circuits. The class 3/A boards call for very stringent manufacturing criteria since the boards should remain operational in critical conditions such as Outerspace, etc. These boards are expensive to manufacture compared to the other classes since they need to be close to perfection. They are found in aerospace, military airborne systems, and missile systems. The major difference between all these classes is the degree of inspection. The classes define the permissible defects while manufacturing the boards. What are the differences between Class 2 and Class 3 for assembly? https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign=… 5/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Umut Tosun, Application Technology Manager at Zestron America, explained, “The major differences between Class 2 and Class 3 are found in component placement for surface-mount components, cleanliness requirements based on residual contaminants on the assemblies, plating thicknesses as defined in plating through-hole and on the surface of PCBs.” During assembly, surface-mount components might be slightly placed off pad. This is what we call a visual defect since it does not usually affect the electrical and mechanical performance. It, therefore, does not matter for Class 2 circuit boards. However, Class 3 does not accept any imperfection and this type of assembly misstep will cause the circuit board to fail the inspection. The amount of barrel fill required for through-hole leads is 50% for Class 2 and 75% for Class 3. As it can be delicate to get the paste into small plated through-holes (PTH), Sierra’s advice is to design your PTH 15 mils over the diameter of the lead. This way, you will have 7.5 mils on each side, which will make it easier for the paste to fill the barrel. Factors Class 2 Class 3 Surface- Can be slightly placed off pad. Imperfections are mount (Considered as a visual defect, not acceptable components doesn’t affect the electrical and including visual mechanical performance) flaws. This kind of imperfection will cause the circuit board to fail the inspection Amount of barrel fill Through-hole leads 50% Through-hole leads 75% https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign=… 6/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits What are the differences between Class 2 and Class 3 for PCB manufacturing? Annular ring and drill breakout 90 degrees annular breakout Another topic Class 2 and Class 3 differ on is drill breakouts. Class 2 allows breakouts from the annular ring whereas Class 3 does not accept any lifted or fractured annular rings. Class 3 boards need to be highly reliable and when there is a breakout, it is too difficult to find out how much is really broken out and how much it really affects the connection with the pad. For Class 2, 90 degrees breakout of the hole from land is allowed provided minimum lateral spacing is maintained. IPC Class 3 acceptable annular ring https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign=… 7/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Conductor to land junction area The conductor junction cannot be reduced by more than 20% of the minimum conductor width specified on the engineering drawing. The conductor junction should never be less than 2 mils or the minimum line width, whichever is smaller. For Class 3, the minimum internal annular ring cannot be less than 1 mil. The external annular ring cannot be less than 2 mils. It is measured from the inside of the PTH barrel to the edge of the land pad and may have a 20% reduction of the minimum annular ring in isolated areas due to defects, like pits, nicks, pinholes, or dents. https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign=… 8/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits There will be a difference between the designed annular ring and the manufactured / actual annular ring. This is due to shifting in materials during the circuit board manufacturing process. To meet the Class 3 requirements, Sierra uses Pluritec machines to discover the shift in material, software to re-scale the drill locations, and vision drilling to accurately place the drills. IPC annular ring acceptance criteria Feature Class 1 Class 3 Class 3 https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign=… 9/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Feature Class 1 Class 3 Class 3 Plated- 180⁰ annular ring 90⁰ annular ring The minimum through breakout from the breakout from the annular ring hole land is acceptable land is acceptable should not be provided the provided the less than minimum lateral minimum lateral 0.05mm. spacing is spacing is maintained. maintained. The minimum external annular The land/conductor The land/conductor ring may have a junction should not junction should not 20% reduction of be reduced by more be reduced by more the minimum than 30% of the than 20% of the annular ring. minimum conductor minimum conductor width. width. The conductor junction should not be less than 0.05mm or the minimum line width, whichever is smaller. What are the design rules for annular rings? To achieve acceptance for Class 2 and Class 3, follow the tables below published by Altium. The first one gives the annular ring requirements for mechanically drilled blind, buried, and through holes on ½ oz copper: IPC Class 2 Drill & Pad Diameter for 1/2 oz Copper Drill Pad Anti-Pad PCB Thickness Aspect Ratio 0.006'' 0.016'' 0.026'' Up to 0.039'' 6.5:1 0.008'' 0.018'' 0.028'' Up to 0.062'' 7.75:1 0.010'' 0.020'' 0.030'' Up to 0.100'' 10:01 0.012'' 0.022'' 0.032'' Up to 0.120'' 10:01 0.0135'' 0.024'' 0.034'' Up to 0.135'' 10:01 IPC Class 3 Drill & Pad Diameter for 1/2 oz Copper https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign&#61… 10/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Drill Pad Anti-Pad PCB Thickness Aspect Ratio 0.008'' 0.023'' 0.033'' Up to 0.062'' 7.75:1 0.010'' 0.025'' 0.035'' Up to 0.100'' 10:01 0.012'' 0.027'' 0.037'' Up to 0.120'' 10:01 0.0135'' 0.028'' 0.038'' Up to 0.135'' 10:01 And these tables are for various copper thicknesses: Drill & Pad Diameter 8 Layers or Less >8 Layers IPC Class 2 Pad Diameter Over Pad Diameter Over Drill Drill 1/4 oz Copper 0.010'' 0.010'' 3/8 oz Copper 0.010'' 0.010'' 1/2 oz Copper 0.010'' 0.010'' 1 oz Copper 0.012'' 0.012'' 2 oz Copper 0.014'' 0.014'' 3 oz Copper 0.016'' 0.016'' 4 oz Copper 0.018'' 0.018'' Drill & Pad Diameter 8 Layers or Less Drill & >8 Layers Pad Diameter 8 Layers or Less >8 Layers IPC Class Pad Pad IPC Class Pad Pad 2 Diameter Diameter 3A Diameter Diameter Over Drill Over Drill Over Drill Over Drill 0.013'' 0.015'' 0.013'' 0.015'' 0.013'' 0.015'' 0.013'' 0.015'' 1/4 oz Copper 3/8 oz Copper 1/2 oz Copper 1/2 oz Copper https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign&#61… 11/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Drill & Pad Diameter 1 oz 8 Layers or Less 0.015'' Drill & >8 Layers Diameter 0.017'' Copper 2 oz 1 oz 8 Layers or Less >8 Layers 0.015'' 0.017'' 0.016'' 0.018'' Copper 0.016'' 0.018'' Copper 3 oz Pad 2 oz Copper 0.019'' 0.021'' 0.022'' 0.024'' Copper 4 oz Copper PCB dielectric requirement The minimum dielectric for Class 2 and Class 3 is 3.5 mils. PCB through-hole plating requirement Class 3 requirements are as well more astringent for voids in copper. On Circuitnet, Paul Reid, Program Coordinator at PWB Interconnect Solutions, said, “A copper void is where the copper plating in the barrel of the hole is missing exposing the dielectric material of the drilled hole. Class 2 allows one void in 5% of the holes. Class 3 and 3/A allows no voids.” The plating thickness requirement for Class 2 is 0.8 mil as opposed to 1 mil for Class 3. These are just a few requirements that differ between Class 2 and Class 3. As usual, the best advice we can give you is to communicate with your PCB manufacturer. They will guide you and help you get it right the first time. You should also request a cross-section of your board to make sure that your shop met your Class 2 or Class 3 requirements. For a more detailed explanation read our post on 6 DFM issues. https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign&#61… 12/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits PCB cross-section to verify the spec requirement Visual and X-ray inspections are not always enough to ensure the integrity of a board. To make sure that your PCB manufacturer met your requirements, ask for a cross-section analysis. This destructive technique is the best way to verify your PCB internal structure, mostly using a microscope. The test can check for various aspects, such as cracks, voids in solder joints, through-hole filling, etc. Below is a cross-section of a Class 2 circuit board: And this is a cross-section of a Class 3A board: https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign&#61… 13/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits At Sierra, we do in-process cross-sections for every circuit board we manufacture at each step of the building process. We check for dielectric, plasma etch, solder mask thickness, copper, plating, etc. And if we don’t meet the customer’s requirements, we reject the board and build another one. If you need a report, you can ask for a final crosssection. We will send you a document with everything we tested and the results. The micro section analysis report looks like this: https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign&#61… 14/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Inspection and acceptance criteria After the end-use of the product, the degree of inspection is what you should take into account when choosing which classification your PCB should fall into. Keep in mind that inspection is one of the factors that drive up the cost when an assembly goes from Class 2 to Class 3. When you think about it, PCBA (Printed Circuit Board Assembly) is not a simple task. The board needs to properly function once assembled with all its components, materials, and the solder to hold them together. Depending on which class your board falls into, the requirements you will have to meet for inspection will differ. This is when some IPC documents come in handy to set the level of acceptance criteria for each class of products. Documentation https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign&#61… 15/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits On Circuitnet, Leo Lambert, Vice President of EPTAC, made a list of the most significant documents, which are “the IPC 2220 series for circuit board design and fabrication, the IPC 6010 series documents for board performance and quality, IPC-A 600 for board Acceptability requirements, J-STD-001 for soldering requirements and IPC-A-610 for Acceptability requirements.” There is a misconception that links Class 3 boards only to the aerospace field. It is often true but Class 3 is not exclusive to aerospace or any other industry. The criteria for the four IPC classes are based upon the application of the product. Therefore, Class 3 can also be the criteria for avionics, military, industrial, and medical applications. It makes sense that a lot of Class 3 boards are for aerospace. The products launched into space have to be highly reliable to prevent any failure that could be critical. And the additional inspection is just too pricey for the commercial and consumer market. When you require a Class 3 circuit board, it implies that the product has to be built according to the complete IPC criteria. This means that the design and manufacture teams must take into account laminate selection, plating thickness, annular ring requirements, manufacturing processes, material qualifications, facilities arrangements, inspection criteria, etc. in order to produce the board that meets all the Class 3 requirements. For more design information, check with our DESIGN SERVICE team. In another article, we will discuss Class 3 for flex according to IPC-6013, the document about the qualification and performance specification for flexible PCBs. Meanwhile, you can read our article about IPC-2581 set to retire Gerber files and IPC-6012 or IPC-A-600, which standard should you use? DOWNLOAD OUR IPC CLASS 3 DESIGN GUIDE: https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign&#61… 16/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits 6 Comments BEST Inc on January 15, 2019 at 6:01 AM Very Informative blog! Thanks for sharing the differences between Class 2 and Class 3 for PCB assembly. However, here my eagerness increases to know about the IPC-6013 standard. As I have already aware of other courses like IPC 610, IPC 620, IPC J STD-001 etc but not about IPC 6013 and its design rules. Reply Adrian Adamson on July 2, 2019 at 11:34 AM It looks like the cross-section figures for both your Class-2 example and your class-3A example meet the Class-3 critiera. Does your class-2 example have any class-3 violations? Reply Steve Selby on December 3, 2019 at 6:23 AM I have a question concerning the requirements for Class 3 when it comes to connector mechanical holding assists which could be plastic or metal snap designs intended for holding connector in place for soldering process. My question is if you utilize a metal snapping component which does not have any electrical connections and the interface holes have copper through hole and annular ring top and bottom do they have to be soldered? If yes what is the criteria for acceptance to meet class 3? Reply https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign&#61… 17/18 8/1/2021 IPC Class 2 VS Class 3: The Different Design Rules | Sierra Circuits Lucy Iantosca on December 9, 2019 at 12:55 AM At this location, soldering is not required. You can simply attach the component bodies with screws and nuts. Reply HealthyBooklet.com on October 7, 2020 at 11:15 AM December 11, 2019 Class 2 vs. Class 3 Where are the mayor differences in class 2 and class 3 other than in the IPC-A-610 standard? In which standards is the difference most significant and notable? A.M Reply Ronald Smith on October 21, 2020 at 5:22 AM This is an important post which takes me to a quick look at the difference between IPC-A-610 Class 2 and Class 3 and also explains the various classes of boards as well and their working. Reply HOME | SITEMAP | TERMS & CONDITIONS | PRIVACY POLICY © 2021 SIERRA CIRCUITS, INC 1990-2021 ALL RIGHTS RESERVED ATTENTION CALIFORNIA RESIDENTS: CCPA COMPLIANCE 2020 https://www.protoexpress.com/blog/ipc-class-2-vs-class-3-different-design-rules/?utm_source#61;drift&utm_medium=blog&utm_campaign&#61… 18/18