Exercise 6.1

Subject:

Given:

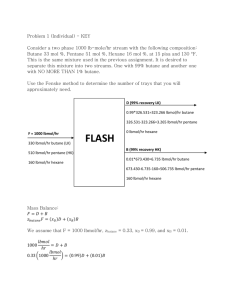

Simultaneous absorption and stripping.

Fig. 6.1 in which simultaneous absorption and stripping occur.

Find: Whether absorption and stripping is more important.

Analysis:

Stripping of water = 22 kmol/h

Absorption of acetone = 10.35 kmol/h

Therefore, more stripping than absorption occurs.

However, the operation is primarily absorption because a very large percentage, 99.5%, of the

acetone is absorbed. Only a very small fraction of the water is stripped.

Exercise 6.2

Subject:

Given:

Column packings since 1950.

History of the development of column packings.

Find: Advantages of new packings. Advances in packing design and fabrication. Need for

structured packings.

Analysis: The newer packings provide more surface area for mass transfer, a higher flow

capacity, and a lower pressure drop. They provide more effective through flow. Many are

plastics made from molds or thin metal strips that can be inexpensively fabricated into intricate

shapes. Structured packings largely eliminate the problems of channeling and at the same time

give improvement in efficiency, capacity, and pressure drop.

Exercise 6.3

Subject:

Advantages of bubble-cap trays

Given: Characteristics and performance of bubble-cap trays

Find: Characteristics that give bubble-cap trays a very high turndown ratio.

Analysis: Unlike sieve and valve trays, bubble-cap trays do not allow liquid to weep.

Therefore, bubble-cap trays can be operated at very low liquid flow rates. Also, bubble caps

force the vapor to flow out sideways, rather than vertically up, thus allowing a relatively high

vapor rate.

Exercise 6.4

Subject:

Given:

Selection of alternative absorbent for Example 6.3

Flow rate, density, and MW of three potential absorbents listed below.

Find: Select the best absorbent with reasons why. Are any of the absorbents unacceptable?

Analysis: In Example 6.3, the rich gas contains C1 to nC6 hydrocarbons, with mostly C3. Object

of absorber is to absorb most of the nC4. The absorbent is an oil of 250 MW and 21oAPI, at a

flow rate, L, of 368 lbmol/h. An alternative absorbent must also be of higher molecular weight

than nC4 and must have a flow rate of at least 368 lbmol/h. If its molecular weight is too low, a

significant amount of it will be stripped. This can be judged by its K-value and stripping factor,

S=KV/L. The entering gas rate, V, is 946 lbmol/h. Column operating conditions are about 94

psia and a maximum temperature of 126oF.

Pertinent properties and factors for the three potential absorbents are:

Absorbent

C5 s

light oil

medium oil

gpm

115

36

215

ρ, lb/gal

5.24

6.0

6.2

lb/h

36,200

13,000

80,000

MW

72

130

180

lbmol/h

500

100

440

K-value

0.9

0.005

0.0005

S=KV/L

2.3

0.013

0.0013

The light oil can not be used because its flow rate of 100 lbmol/h is much lower than the

necessary 368 lbmol/h. The C5s can not be used because their stripping factor is very high. The

only possible alternative is the medium oil.

Exercise 6.5

Subject:

Stripping of VOCs from water effluents by air and water

Given: Packed tower for stripping

Find:

Advantages and disadvantages of air over steam

Analysis:

Advantages:

Air is available anywhere.

Air is inexpensive.

Disadvantages: Air can form a flammable or explosive mixture with the VOC.

With steam, the exit gas can be condensed and the VOC

recovered as a liquid.

Exercise 6.6

Subject:

Preferred operating conditions for absorbers and strippers.

Find: Best conditions of temperature and pressure, and the trade-off between number of stages

and flow rate of separating agent, using equations.

Analysis: Absorbers:

For high performance, want a large absorption factor, A = L/KV

Therefore, want a small K-value.

Assume that:

γ iL Pi s

Ki =

P

s

Pi = vapor pressure, which increases with increasing temperature

Therefore, operate at a high pressure and a low temperature.

Strippers:

For high performance, want a large stripping factor, S = KV/L

Therefore, want a large K-value.

Therefore, operate at low pressure and a high temperature.

For the tradeoff between number of equilibrium stages, N, and flow rate of mass separating

agent, L or V. Consider absorption. The fraction of a component absorbed is given from a

modification of Eq. (5-48),

A −1

A N +1 − A

1 − φ A = 1 − N +1

= N +1

A −1 A −1

Thus, a large fraction absorbed can be achieved with either N or A = L/KV. The tradeoff is most

clearly shown in Fig. 5.9. For low fractions absorbed (i.e. high φA), N has little effect and (1 φA) is approximately equal to A. But for high fractions absorbed, the larger the value of N, the

smaller the required value of A, and, thus, the smaller the required value of the flow rate of the

liquid separating agent, L.

The tradeoff for stripping is similar. The fraction of a component stripped is given by a

modification of Eq. (5-51),

S −1

S N +1 − S

1 − φ S = 1 − N +1

= N +1

S −1 S

−1

Thus, a large fraction stripped can be achieved with either N or S = KV/L. The tradeoff is most

clearly shown in Fig. 5.9. For low fractions stripped (i.e. high φS), N has little effect and (1 - φS)

is approximately equal to S. But for high fractions absorbed, the larger the value of N, the

smaller the required value of S, and, thus, the smaller the required value of the flow rate of the

vapor separating agent, V.

xercise 6.7

Subject:

Absorption of CO2 from air at 25oC by 5-N aqueous triethanolamine

Given: Feed gas containing 10 mol% CO2 and 90 mol% air. Absorbent of 5N aqueous

triethanolamine containing 0.04 moles of CO2 per mole of amine solution. Column with 6

equilibrium stages. Exit liquid to contain 78.4% of the CO2 in the feed gas. Therefore, exit gas

contains 21.6% of the CO2 in the entering gas. Equilibrium data for CO2 at 25oC in terms of

mole ratios.

Assumptions: Negligible absorption of air and stripping of amine and water.

Find: (a) Moles of amine solution required per mole of feed gas.

(b) Exit gas composition.

Analysis: Use the nomenclature and type of plot shown in Fig. 6.11(a). Therefore, for CO2,

X0 = 0.04 mol CO2/mol amine solution

YN+1 = Y7 = 10/90 = 0.1111 mol CO2/mol air

Y1 = 0.216(10)/90 = 0.024 mol CO2/mol air

(b) Therefore, the exit gas composition is 0.024 mol CO2/mol air or 0.024/(1 + 0.024) x 100% =

2.34 mol% CO2 and 97.66 mol% air.

(a) A plot of the equilibrium data as Y vs. X is given below. The operating point (X0, Y1) at the

top of the column is included. A straight operating line through this point is found by trial and

error to give 6 equilibrium stages, when using Y7 = 0.1111. The resulting XN = X6 = 0.085.

From Eq. (6-3), the slope of the operating line = L'/V' = (0.1111 - 0.024)/(0.085 - 0.04) = 1.936

mol triethanolamine solution/mol air. The feed gas contains 9 mol air/10 mol feed gas.

Therefore, mols of amine solution/mol feed gas = 1.936(0.9) = 1.74.

See plot on next page.

Exercise 6.7 (continued)

Exercise 6.8

Subject:

Absorption of acetone from air by water at 20oC and 101 kPa (760 torr) in a

valve-tray column.

Given: 100 kmol/h of feed gas containing 85 mol% air and 15 mol% acetone. Pure water is

the absorbent. Overall tray efficiency is 50%. Absorb 95% of the acetone. Equilibrium p-x data

for acetone are given as listed below.

Assumptions: Negligible absorption of air and stripping of water.

Find: (a) Minimum ratio, L'/V' of moles of water/mole of air.

(b) Number of equilibrium stages for L'/V' = 1.25 times minimum.

(c) Concentration of acetone in the exit water.

Analysis: Use the nomenclature and type of plot shown in Fig. 6.11(a). Then, the operating line

will be straight. For acetone,

X0 = 0.0 mol acetone/mol entering water

YN+1 = 0.15/0.85 = 0.1765 mol acetone/mol air in entering gas

Flow rate of acetone in exit gas = (1 - 0.95)(15) = 0.75 kmol/h. With 85 kmol/h of air,

Y1 = 0.75/85 = 0.00882 mol acetone/mol air

Convert the p-x equilibrium data to mole ratio, Y-X data, using y = p/P, Y = y/(1- y), X = x/(1-x)

p, torr

x

y

X

Y

30.0 0.033 0.0395 0.0341 0.0411

62.8 0.072 0.0826 0.0776 0.0901

85.4 0.117 0.1124 0.1325 0.1266

103.0 0.171 0.1355 0.2063 0.1568

(a) With the type of curvature in the Y-X equilibrium curve, shown below, the minimum

absorbent rate is determined by a straight operating line that passes through the point (Y1 , X0 )

and is drawn tangent to the equilibrium curve, as shown. From Eq. (6-3), the slope of the

operating line = L'/V' = 1.06 mol water/mol of air on an acetone-free basis = minimum ratio.

(b) For 1.25 times minimum, L'/V' = 1.25(1.06) = 1.325. Now a straight operating line that

passes through the point (Y1 = 0.00882 and X0 = 0.0) is drawn as shown below, where

equilibrium stages are stepped off, as in Figs. 6.11(a) and 6.12, until the steps reach or exceed the

required value of YN+1 = 0.1765. As seen, in the figure below, the determined number of

equilibrium stages is approximately 9.

(c) The concentration of acetone in the exit liquid, XN is the point on the operating line for Part

(b), where YN+1 = 0.1765. From Eq. (6-3), for the operating line for an absorber,

Y −Y

0.1765 − 0.00882

X N = N +1 1 + X 0 =

+ 0.0 = 0.127 mol acetone/mol water

L′

1.325

V′

or an exit mole fraction of acetone in the water of 0.127/(1.127) = 0.113

Analysis: (continued)

Exercise 6.8 (continued)

Exercise 6.9

Subject:

Absorption-stripping system for benzene (B) removal from gas by oil and

subsequent stripping of benzene from oil by steam.

Given: Plate column absorber and stripper. Feed gas containing 0.06 mol B/mol B-free gas.

Absorbent oil containing 0.01 mol B/mol B-free oil. Liquid leaving absorber contains 0.19 mol

B/mol B-free oil. 90% of B in the gas stream is absorbed. Liquid leaving stripper contains 0.01

mol B/mol oil. Flow ratio of B-free oil-to-B-free steam = 2.0. Molecular weights are 200, 78,

and 32 for oil, benzene, and gas, respectively. Equilibrium X-Y data given for absorber (25oC)

and stripper (110oC).

Assumptions: Gas is not soluble in oil and oil is not volatile.

Find: (a) Molar flow rate ratio of B-free oil to B-free gas in the absorber.

(b) Number of equilibrium stages in the absorber.

(c) Minimum steam flow rate in the stripper per mol of B-free oil.

Analysis: A flow diagram of the absorber-stripper system is shown in Fig. 5.10(a), except that

there is no makeup absorbent oil because the oil is assumed to be non-volatile.

(a) Consider just the absorber. Take a basis of V ' = 1 mol/h of B-free gas entering the absorber.

Because YN+1 = 0.06 mol B/mol B-free gas, we have 0.06 mol/h of B in entering gas. With 90%

absorption, 0.06(0.9) = 0.054 mol/h of B absorbed, leaving 0.006 mol/h of B in the exiting gas.

In the entering absorbent oil, X0 = 0.01 mol B/mol B-free oil. In the liquid leaving the absorber,

XN = 0.19 mol B/mol B-free oil. A material balance around the absorber on the benzene gives:

′ + X N L′

YN +1V ′ + X 0 L′ = YV

Therefore,

1

0.06(1.0)+0.01L′ = 0.006 + 0.19 L′

(1)

Solving Eq. (1), L' = 0.30 mol/h of B-free oil, giving L'/V’' = 0.30 mol B-free oil to B-free gas.

(b) Use a graphical method to determine the number of equilibrium stages in the absorber, using

Y-X coordinates to give a straight operating line. Data for the equilibrium curve of the absorber

are given and the operating line is obtained from terminal values of Y and X. The results are

given in the plot below. As seen, between 9 and 10 equilibrium stages are needed.

(c) The equilibrium curve for the stripper is shown in the plot below. With the type of curvature

in the Y-X equilibrium curve the minimum stripping gas rate is determined by a straight

operating line that passes through the operating point (Y0 = 0 , X1 = 0.01) at the bottom of the

column, as shown in Fig. 6.11(b) and is drawn tangent to the equilibrium curve, as shown. From

Eq. (6-5), the slope of the operating line = L'/V' = 3.0 mol B/mol of steam on a B-free basis.

Therefore,

(V’')min/L' = 0.33. This is compared to the given operating value of L'/V' = 2.0 or V'/L' = 0.5.

Analysis: (continued)

(a) Plot of results:

(b) Plot of results:

Exercise 6.9 (continued)

Exercise 6.10

Subject:

Stripping of benzene (B) from straw oil by steam at 1 atm (101.3 kPa).

Given: Oil enters stripper with 8 mol% benzene. 75% of B is stripped. Pure steam enters.

Steam exits with 3 mol% B. Sieve-plate column. Henry's law holds with a B partial pressure of

5.07 kPa when benzene mole fraction in the oil is 10 mol%.

Assumptions: Straw oil is not volatile and steam does not condense. Dalton's law.

Find: (a) Number of equilibrium stages required.

(b) Moles of steam required per 100 moles of benzene-oil feed to stripper.

(c) Number of equilibrium stages needed if 85% of B is stripped with same amount of

steam as in Part (b).

Analysis: With reference to the stripper in Fig. 6.11(b),

XN+1 = 8/92 = 0.087 mol B/mol B-free oil

Y0 = 0.0 mol B/mol B-free steam

YN = 3/97 = 0.0309 mol B/mol B-free steam

(b) For 100 moles of benzene-oil feed mixture, have 8 moles of benzene. Amount of benzene

stripped = 0.75(8) = 6 moles. Because the exit gas contains 0.0309 mol B/mol B-free steam, the

steam rate = 6/0.0309 = 194 moles.

Therefore, moles of steam/100 moles of benzene-oil feed = 194

Also, X1 = (8 - 6)/92 = 0.0217 mol B/mol B-free oil

(a) Assume Henry's law is given by Eq. (4-32), pB = HxB.. Because pB = 5.07 kPa when xB =

0.10, H = 5.07/0.1 = 50.7 kPa. Convert this to an a Y-X equilibrium equation. For a pressure of

101.3 kPa, assuming Dalton's law, yB = pB/P = 50.7xB/101.3 = 0.5xB . From Eq. (6-1), dropping

the benzene subscript, B, and noting that KB = 0.5,

KB = 0.5 =

Y / (1 + Y )

X / (1 + X )

Solving, Y =

0.5 X

1 + 0.5 X

(1)

The Y-X plot includes the equilibrium curve given by Eq. (1), and a straight operating line that

connects the column terminal points (Y0 = 0.0, X1 = 0.0217) and (YN = 0.0309, XN+1 = 0.087).

The corresponding slope of the operating line is (0.0309 - 0.0)/(0.087 - 0.0217) = L'/G' = 0.474.

From the plot below, stepping off stages as in Fig. 6.11(b), required N = approximately 3 stages.

(c) For 85% stripping of B, amount of B stripped = 0.85(8) = 6.8 moles B. Not stripped is1.2

moles B. Therefore, for the same B-oil and steam feeds, X1 = 1.2/92 = 0.01304 mol B/mol oil

and YN =6.8/194 = 0.03505 mol B/mol steam. The Y-X plot for this case is also given below,

where the equilibrium curve is the same as in Part (a), and a straight operating line connects the

column terminal points (Y0 = 0.0, X1 = 0.01304) and (YN = 0.03505, XN+1 = 0.087). The

corresponding slope of the operating line is (0.03505 - 0.0)/(0.087 - 0.01304) = L'/G' = 0.474

(same as in Part (a)). From the plot below, stepping off stages as in Fig. 6.11(b), required N =

between 5 and 6 stages.

Exercise 6.10 (continued)

Analysis: (continued)

(a) Plot of results:

(b) Plot of results:

Exercise 6.11

Subject:

Stripping of VOCs from water by air in a trayed tower to produce drinking water.

Given: 1,500 gpm of groundwater containing ppm amounts of DCA, TCE, and TCA given

below. Stripping at 1 atm and 25oC to reduce the ppm amounts to the very low levels below.

K-values of VOCs given below.

Assumptions: No stripping of water and no absorption of air. System is dilute with respect to

the VOCs.

Find: Minimum air flow rate in scfm (60oF and 1 atm).

Number of equilibrium stages for 2 times the minimum air flow.

Composition in ppm for each VOC in the resulting drinking water.

Analysis: Flow rate of water = L = (1,500 gpm)(8.33 lb/gal)/18.02 lb/lbmol = 693 lbmol/min

% stripping of a VOC = (inlet ppm - outlet ppm)/inlet ppm)

VOC

K-value Inlet ppm Outlet ppm % stripping

DCA

60

85

0.005

99.994

TCE

650

120

0.005

99.996

TCA

275

145

0.200

99.862

Because of its high % stripping and a K-value that is much lower than for the other two VOCs,

the stripper is likely to be controlled by DCA. So base the calculations on DCA and then check

to see that the % stripping for TCE and TCA exceed the above requirements. Because of the

dilute conditions, use Kremser's method.

693

L

From Eq. (6-12),

Vmin = (fraction stripped) =

(0.99994) = 11.55 lbmol./min

K

60

or minimum air flow rate = 11.55 (379 scf/lbmol) = 4,377 scfm at 60oF and 1 atm

For 2 times the minimum value, V = 2(11.55) = 23.1 lbmol/min.

K V 60(23.1)

The stripping factor, given by Eq. (6-16), is for DCA, S DCA = DCA =

= 2.0

L

693

S N +1 − S 2 N +1 − 2

From Eq. (6-14), Fraction stripped = 0.99994 = N +1

=

(1)

S

− 1 2 N +1 − 1

Solving Eq. (1), N = 13 stages.

Now, for V = 11.55 lbmol/min and N = 13 stages, compute the fraction stripped for TCE and

TCA from Eq. (6-14) with the stripping factor from Eq. (6-16). The results are:

VOC

S Fraction

stripped

DCA

2.0 0.99994

TCE

21.6 1.00000

TCA

9.17 1.00000

The drinking water contains 0.005 ppm of DCA and essentially zero ppm of TCE and TCA.

Exercise 6.12

Subject:

Stripping of a solution of SO2, butadienes, and butadiene sulfone with nitrogen.

Given: 120 lbmol/h of liquid containing in lbmol/h,10.0 SO2, 8.0 1,3-butadiene (B3), 2.0 1,2butadiene (B2), and 100.0 butadiene sulfone (BS). Liquid effluent to contain < 0.05 mol% SO2

and < 0.5 mol% (B3 + B2). Stripping agent is pure nitrogen. Stripping at 70oC and 30 psia. Kvalues are 6.95 for SO2, 3.01 for B2, 4.53 for B3, and 0.016 BS.

Assumptions: Negligible stripping of BS because of its low K-value. No absorption of N2.

Find: Flow rate of nitrogen. Number of equilibrium stages.

Analysis: Assuming no stripping of BS, the exiting liquid will contain 0.05 mol% SO2, 0.50

mol% (B3 + B2), and 99.45 mol% BS, or in lbmol/h, 100.0 BS, 0.0503 SO2, and 0.503 (B3 +

B2). Therefore, % stripping of SO2 = (10.0 - 0.0503)/10.0 = 0.99497 and % stripping of (B3 +

B2) = (8.0 + 2.0 - 0.503)/(8.0 + 2.0) = 0.9497.

The minimum stripping agent flow rate is given by Eq. (6-12). Assume that because the Kvalue of B2 is the lowest of SO2, B2, and B3, that B2 controls. Further assume that essentially

all of the B3 is stripped so that the 0.5 mol% of (B2 + B3) is entirely B2. The solute-free liquid

rate = flow rate of BS = L' = 100 lbmol/h and the fraction of B2 stripped = (2.0 - 0.503)/2.0 =

0.748

L'

100

'

(fraction stripped) =

(0.748) = 24.9 lbmol/h

Vmin =

KSO2

3.01

Now use this value to compute the values of fraction stripped of SO2 and B3.

KV ' 6.95(24.9)

=

> 1.0

100

L'

KV ' 4.53(24.9)

Fraction stripped of B3 = ' =

> 1.0

L

100

Fraction stripped of SO 2 =

Therefore, the assumption that B2 controls is correct at the minimum stripping gas rate.

Assume an operational nitrogen flow rate of 1.5 times minimum. Therefore V’ =1.5(24.9) = 37.4

lbmol./h. The stripping factor, given by Eq. (6-16), is for B2,

S B2 =

K B2V ' 3.01(37.4)

=

= 1.13

L'

100

Using Eq. (6-14), Fraction B2 stripped = 0.748 =

Solving, N = 2.4 equilibrium stages.

S N +1 − S 113

. N +1 − 113

.

=

N +1

N +1

S

−1

113

.

−1

Analysis: (continued)

Exercise 6.12 (continued)

Fraction B3 stripped =

S N +1 − S 1.7 2.4 +1 − 17

.

=

= 0.863

N +1

2 . 4 +1

−1

S −1

17

.

Fraction SO 2 stripped =

S N +1 − S 2.612.4 +1 − 2.61

=

= 0.936

S N +1 − 1

2.612.4 +1 − 1

These fractions do not meet specifications. Therefore, the number of stages and/or the nitrogen

flow rate must be increased.

First try increasing the number of stages.

S = KV/L

Fraction stripped:

N=5

N=7

N = 10

SO2

2.61

B2

1.13

B3

1.7

0.995

0.9993

0.99996

0.880

0.922

0.954

0.970

0.990

0.998

For N = 5 stages, have in the exit liquid in lbmol/h, 0.05 SO2, 0.24 B2, and 0.24 B3. These

values correspond to a total of 100.53 lbmol/h of exit liquid. This results in 0.05 mol% SO2 and

0.48% (B2 + B3). Therefore, N = 5 stages is sufficient with a feed gas rate, V' , of 37.4 lbmol/h.

Other combinations of N and V' could be used..

Exercise 6.13

Subject:

Absorption of a light hydrocarbon gas mixture by n-decane as a function of

pressure and number of equilibrium stages at 90oF.

Given: Light hydrocarbon gas containing in lbmol/h, 1,660 C1, 168 C2, 96 C3, 52 nC4, and 24

nC5 for a total of 2,000 lbmol/h = V. Absorbent of L = 500 lbmol/h of nC10. K-value of nC10 =

0.0011.

Find: Component flow rates in the lean gas and rich oil for:

(a) N = 6 and P = 75 psia.

(b) N = 3 and P = 150 psia.

(c) N = 6 and P = 150 psia.

Analysis: Use the Kremser method with Eqs. (5-48) for fraction not absorbed, φA, (5-50 for

fraction not stripped, φA ,(5-38) for absorption factor, A, (5-51) for stripping factor, S , (5-45) and

(5-53) for component flow rates in the exit gas, υ1 , and (5-44) and (5-52) for component flow

rates in the exit liquid, lN, since no light hydrocarbons enter with the absorbent. Use Fig. 2.8 or

other source for K-values of C1 through nC5. For nC10 , assume the K-value is inversely

proportional to pressure.

(a)

N = 6 and P = 75 psia:

Component

C1

C2

C3

nC4

nC5

nC10

Total

(b)

K-value

2.9

6.5

1.95

0.61

0.19

0.0011

A

0.0086

0.0385

0.1282

0.4098

1.3160

S

0.0044

φA

0.9914

0.9615

0.8718

0.5916

0.0541

φS

0.9956

υ1

l6

lbmol/h

14.0

6.5

12.3

21.2

22.7

497.8

574.5

υ1

l3

lbmol/h

30.0

12.0

22.6

33.2

22.9

498.9

619.6

lbmol/h

1,646.0

161.5

83.7

30.8

1.3

2.2

1,925.5

N = 3 and P = 150 psia:

Component

K-value

A

C1

C2

C3

nC4

nC5

nC10

Total

14.0

3.5

1.05

0.33

0.105

0.00055

0.0179

0.0714

0.2381

0.7576

2.3810

S

0.0022

φA

0.9821

0.9284

0.7644

0.3615

0.0443

φS

0.9978

lbmol/h

1,630.0

156.0

73.4

18.8

1.1

1.1

1,880.4

Exercise 6.13 (continued)

Analysis: (continued)

(c)

N = 6 and P = 150 psia:

Component

C1

C2

C3

nC4

nC5

nC10

Total

K-value

14.0

3.5

1.05

0.33

0.105

0.00055

A

0.0179

0.0714

0.2381

0.7576

2.3810

S

0.0022

φA

0.9821

0.9284

0.7619

0.2829

0.0032

φS

0.9978

υ1

lbmol/h

1,630.0

156.0

73.1

14.7

0.1

1.1

1,875.0

l6

lbmol/h

30.0

12.0

22.9

37.3

23.9

498.9

625.0

Exercise 6.14

Subject:

Absorption of a light hydrocarbon gas by nC10.

Given: 1,000 kmol/h of rich gas at 70oF with, in kmol/h, 250 C1, 150 C2, 200 C3, 200 nC4, and

150 nC5. 500 kmol/h of nC10 at 90oF. Absorber operates at 4 atm. K-value of nC10 at 80oF and

4 atm = 0.0014.

Assumptions: Using the Kremser method, use V = 1,000 kmol/h and L = 500 kmol/h, with an

average temperature of 80oF for K-values from Fig. 2.8 or other source.

Find: Percent absorption of each component for 4, 10, and 30 equilibrium stages.

Analysis: The K-values and absorption factors, from Eq. (6-15), A = L/KV, are:

Component

C1

C2

C3

nC4

nC5

K-value

38

7.6

2.25

0.64

0.195

A

0.0132

0.0658

0.2222

0.7813

2.564

For each component in the feed gas, the percent absorption is given by Eq. (6-13) x 100%,

A N +1 − A

Percent absorbed = N +1

× 100%

A −1

(1)

Using Eq. (1) with the values of A from the above table, the results are:

Component

C1

C2

C3

nC4

nC5

Percent absorbed:

for N = 4

for

1.32

6.58

22.03

65.14

96.30

N = 10

1.32

6.58

22.22

76.58

99.995

for N = 30

1.32

6.58

22.22

78.12

100.00

The number of stages affects only the heavier hydrocarbons that are absorbed to the greatest

extent.

Exercise 6.15

Subject: Back calculation of tray efficiency from performance data on absorption of propane.

Given: Large commercial absorber with Na = 16 actual plates. From Example 6.3, average

total liquid rate, L, is 446.7 lbmol/h, average total gas rate, V, is 866.5 lbmol/h. Propane in gas

feed = 213.8 lbmol/h. Propane in exit liquid = 43 lbmol/h. P = 93.7 psia. Average T = 111oF.

Find: Tray efficiency from performance data. Estimated tray efficiency from DrickamerBradford and O'Connell correlations.

Analysis: Fraction of propane absorbed = 43/213.8 = 0.20

From Fig. 2.8, for propane, K-value = 2.0

From Eq. (6-15), A = L/KV = 446.7/(2.0)(866.5) = 0.258

From Eq. (6-13),

A N +1 − A 0.258 N +1 − 0.258

Fraction absorbed = 0.20 = N +1

=

A −1

0.258 N +1 − 1

(1)

Solving Eq. (1), N = Nt = 0.93

From Eq. (6-1), Eo = Nt /Na = 0.93/16 = 0.058 or 5.8%

From Drickamer-Bradford correlation, Eq. (6-22), with µ L = 1.4 cP from Example 6.3,

Eo , % = 19.2 - 57.8 log µL = 19.2 - 57.8 log(1.4) = 10.8 %

From O'Connell correlation, Eq. (6-23), with ML = 250, ρL = 57.9 lb/ft3 from Example 6.3,

log E o = 1587

.

− 0.199 log C − 0.0896 log C

where, C =

2

KM L µ L

(2.0)(250)(1.4)

=

= 12.1

ρL

57.9

Therefore, from Eq. (2),

2

log E o = 1587

.

− 0.199 log 12.1 − 0.0896 log 12.1 = 1277

.

which gives Eo = 18.9%

The propane tray efficiency is lower than predicted.

(2)

Exercise 6.16

Subject:

Oil absorption of a gas to produce 95% hydrogen

Given: 800,000 scfm (0oC, 1 atm) of fuel gas containing 72.5% H2, 25% CH4, and 2.5% C2H6.

Absorbent of nC8. Absorber operates at 400 psia and 100oF. Exiting gas is to contain at least

80% of the entering H2 at a H2 purity of 95 mol%.

Assumptions: Ideal gas law.

Find: (a)

(b)

(c)

(d)

(e)

(f)

(g)

Minimum absorbent rate in gpm.

Actual absorbent rate at 1.5 times minimum.

Number of theoretical stages.

Stage efficiency of each component from O'Connell correlation.

Number of actual trays needed.

Composition of exit gas, accounting for stripping of octane.

Annual cost of lost octane.

Analysis: At 0oC and 1 atm, have 359 scf/lbmol. Therefore, entering V = 800,000/359 = 2,230

lbmol/min, with 0.725(2,230) = 1,616 lbmol/min H2, 558 lbmol/min CH4, 56 lbmol/min C2H6 .

From Fig. 2.8, at 400 psia, 100oF, K-values are: 30 for H2 , 7 for CH4 , and 1.75 for C2H6 .

(a) Assume the key component is CH4. If we neglect stripping of octane and assume

complete absorption of C2H6, with 20% absorption of H2, then exit gas will be 0.8(1,616) =

1,293 lbmol/min H2 and the exit liquid will contain 1,616 - 1,293 = 323 lbmol/min H2. For a

purity of 95 mol% H2, then will have 5 mol% CH4 or 1,293(5/95) = 68 lbmol/min of CH4 in the

exit gas and 558 - 68 = 490 lbmol/min of CH4 in exit liquid. Can not use Eq. (6-11) to compute

the minimum absorbent rate because we do not have a dilute system. Instead, for infinite stages,

assume the exiting rich oil is in equilibrium with the inlet gas. Then, for CH4, K = 7 = y/x. But y

for the inlet gas = 0.25. Therefore, x in the exiting oil = 0.25/7= 0.0357. Therefore, with 490

lbmol/min of CH4 in this oil, the total exiting oil = 490/0.0357 = 13,700 lbmol/min. Therefore,

the entering oil is 13,700 - 323 - 490 - 56 = 12,831 lbmol/min of nC8 = Lmin. For nC8 , MW =

114 and from Perry's Handbook, SG = 0.703. Therefore, liquid density = 0.703(8.33) = 5.86

lb/gal. Therefore, Lmin = 12,831(114)/5.86 = 250,000 gpm.

(b) For 1.5 times minimum, inlet absorbent rate = 19,200 lbmol/min = 375,000 gpm.

(c) Calculate the number of equilibrium stages from the Kremser equation based on CH4

absorption, inlet vapor and liquid flow rates. From Eq. (6-15),

ACH 4 = L / KV = 19,200 / (7)(2,230) = 123

.

From Eq. (6-13), for CH4, with a fraction absorbed = 490/558 = 0.878,

fraction of CH4 absorbed = 0.878 =

N +1

ACH

− ACH 4

4

N +1

ACH

−1

4

123

. N +1 − 123

.

=

N +1

1.23 − 1

(1)

Analysis: (c) (continued)

Exercise 6.16 (continued)

Solving Eq. (1), N =4.1 stages.

Check absorption of H2. Absorption factor = A = 19,200/(30)(2,230) =0.287

AHN2+1 − AH 2 0.287 4.1+1 − 0.287

From Eq. (6-13, fraction of H2 absorbed =

=

= 0.286

0.287 4.1+1 − 1

AHN2+1 − 1

This exceeds the minimum 20% specified. Actually, this problem is overspecified. The

absorber can be designed for 95 mol% purity of H2 in the exit gas or 20% absorption of H2. In

this problem, we can not achieve both specifications, unless the plate efficiency for H2 is much

less than that for CH4. Check this next.

(d) From the O'Connell correlation, Eq. (6-23), with ML = 114, ρL = 44 lb/ft3, and µL= 0.47 cP

from Perry's Handbook,

log E o = 1587

.

− 0.199 log C − 0.0896 log C

where, for H2, C =

2

(2)

KM L µ L

(30)(114)(0.47)

=

= 36.5

ρL

44

Therefore, from Eq. (2),

2

log E o = 1587

.

− 0.199 log 36.5 − 0.0896 log 36.5 = 1057

.

which gives Eo = 11.4 % for H2. Similarly, Eo = 21.1 % for CH4, and Eo = 32.5 % for C2H6.

(e) From Eq. (6-21), using CH4, Na = Nt /Eo = 4.1/0.211 = 19.4 or say 20 trays.

(f) For the stripping of nC8, from Fig. 2.8 by extrapolation, K = 0.003. From Eq. (2), Eo = 0.35.

Therefore, if 20 trays, have 20(0.35) = 7 equilibrium stages. From Eq. (6-16),

S = KV/L =0.003(2,230)/19,200 = 0.00035. From Eq. (6-14) for 7 stages,

S N +1 − S 0.000357 +1 − 0.00035

fraction stripped = N +1

=

= 0.00035

0.000357 +1 − 1

S −1

Therefore, 0.00035(19,200) = 7 lbmol/h of nC8 leaves in the exit gas.

For H2 , with 20 trays and Eo = 0.114, we have (0.114)(20) = 2.3 equilibrium stages. From Eq.

AHN2+1 − AH 2 0.287 2.3+1 − 0.287

(6-13), with A = 0.287, fraction H2 absorbed =

=

= 0.275

AHN2+1 − 1

0.287 2.3+1 − 1

Therefore, we can not meet the specification of less than 20% absorbed.

For C2H6, with 20 trays and Eo = 0.325, we have (0.325)(20) = 6.5 equilibrium stages.

From Eq. (6-13), with A = (19,200)/(1.75)(2,230) = 4.92,

A N +1 − A 4.92 6.5+1 − 4.92

fraction C2H6 absorbed =

=

= 0.999975

A N +1 − 1

4.92 6.5+1 − 1

Composition of exit gas in lbmol/min is 1,172 H2 , 68 CH4 , and 7 nC8 . H2 purity = 94%

(g) Cost of lost oil = 7(114)(60)(7,900)($1.00)/(5.86 lb/gal) = 64.6 million $/year.

Exercise 6.17

Subject:

Scale-up of absorber using Oldershaw column efficiency.

Given: Absorption operation of Examples 6.1 and 6.4 with a column diameter of 3 ft. New

column with 11.5 ft diameter. New tray with Oldershaw-column efficiency of 55% (EOV = 0.55).

Liquid flow path length from Fig. 6.16. Value of u/DE = 6 ft-1. From Example 6.4, λ = 0.68.

Assumptions: Straight operating line and equilibrium line as stated in Example 6.4

Find: Efficiencies EMV and Eo .

Analysis: Consider three cases: (a) complete mixing, (b) plug flow, and (c) partial mixing.

(a) From Eq. (6-31), EMV = EOV = 0.55. From Eq. (6-37),

log [1 + EMV (λ − 1) ] log [1 + 0.55(0.68 − 1) ]

=

Eo =

= 0.50

log λ

log 0.68

(b) From Eq. (6-32),

1

1

EMV = eλEOV − 1 =

( e(0.68)(0.55) − 1) = 0.67

λ

0.68

(

)

From Eq. (6-37),

log [1 + EMV (λ − 1) ] log [1 + 0.67(0.68 − 1) ]

=

Eo =

= 0.63

log λ

log 0.68

(c) To use Fig. 6.16, we need an estimate of the liquid flow rate. For the 3 ft diameter

column of Examples 6.1 and 6.4, liquid rate = 151.5 kmol/h of water. Assume the liquid rate is

proportional to the column cross-sectional area. Thus, for the 11 ft diameter, the liquid rate =

151.5(11/3)2 = 2,037 kmol/h = 162 gpm. From Fig. 6.16, a single-pass tower is adequate.

Assume liquid flow path = ZL = 7 ft. Eq. (6-34) is used to compute EMV, which requires the

Peclet number, given by Eq. (6-36),

Z u

N Pe = L = 7(6) = 42

DE

N

From Eq. (6-35), η = Pe

2

4 λEOV

1+

N Pe

1/ 2

−1 =

42

2

1+

4(0.68)(0.55)

42

1/ 2

− 1 = 0.37

From Eq. (6-34), EMV/EOV = 1.20. Therefore, EMV = 1.20(0.55) = 0.66

From Eq. (6-37),

log [1 + EMV (λ − 1) ] log [1 + 0.66(0.68 − 1)]

Eo =

= 0.62

=

log λ

log 0.68

From these results, we see that the column is operating closely to plug flow for the liquid.

Exercise 6.18

Subject: Estimation of column diameter based on conditions at bottom tray of a reboiled

stripper.

Given: Vapor and liquid conditions at bottom tray given in Fig. 6.48. Valve trays with 24-inch

spacing.

Find: Column diameter for 80% of flooding.

Analysis: Use entrainment flooding correlation of Fig. 6.24, where the abscissa is,

1/ 2

LM L ρG

FLV =

VM G ρ L

From Fig. 6.48, V = 546.2 lbmol/h and L = 621.3 lbmol/h

(1)

Average molecular weights of the gas and liquid are computed from M =

C

i =1

zi Mi ,

Component

M

y

My

x

Mx

Ethane

30.07 0.000006

0.0 0.000010

0.0

Propane

44.10 0.004817

0.2 0.001448

0.1

n-Butane

58.12 0.602573 35.0 0.391389 22.7

n-Pentane

72.15 0.325874 23.5 0.430599 31.1

n-Hexane

86.18 0.066730

5.8 0.176563 15.2

Total

64.5

69.1

Therefore, MV = 64.5 and ML = 69.1

Gas volumetric flow rate = QV = 6.192 ft3/s.

Therefore, ρV = VMV /QV = (546.2)(64.5)/(6.192)(3,600) = 1.58 lb/ft3

Liquid volumetric flow rate = 171.1 gpm = (171.1)(60)/7.48 = 1,372 ft3/h

Therefore, ρL = LML /QL = (621.3)(69.1)/1,372 = 31.3 lb/ft3

1/ 2

621.3(69.1) 158

.

From Eq. (1), FLV =

= 0.274

546.2(64.5) 31.3

Assume 24-inch tray spacing. From Fig. 6.24, CF = 0.24 ft/s

From relations below Eq. (6-44), since FLV is between 0.1 and 1.0,

F − 0.1

0.274 − 01

.

Ad

= 0.1 + LV

= 01

. +

= 0.119

A

9

9

From Perry's Handbook, surface tension = σ = 7 dyne/cm

From relation below Eq. (6-42), FST = (σ/20)0.2 = (7/20)0.2 = 0.8. FF = 1.0 , FHA = 1.0

From Eq. (6-42), C = FST FF FHA CF = (0.8)(1.0)(1.0)(0.24) = 0.192 ft/s

From Eq. (6-40), U f = C ( ρ L − ρV ) / ρV

1/ 2

= 0.192 ( 31.3 − 1.58 ) /1.58

1/ 2

= 0.833 ft/s

Exercise 6.18 (continued)

From Eq. (6-44),

4VM V

DT =

fU f π (1 − Ad / A ) ρV

1/ 2

4(546.2 / 3, 600)(64.5)

=

0.80(0.833)(3.14)(1 − 0.119)(1.58)

1/ 2

= 3. 56 ft

Exercise 6.19

Subject:

Estimation of column diameter based on conditions at the top tray of an absorber.

Given: Vapor and liquid conditions at the top tray. Valve trays with 24-inch spacing.

Find:

Flooding velocity and column diameter for 85% of flooding (f = 0.85)

Analysis: Use entrainment flooding correlation of Fig. 6.24, where the abscissa is,

FLV

LM L ρV

=

VM V ρ L

1/ 2

889(109) 1.924

=

530(26.6) 41.1

1/ 2

= 1.487

(1)

For 24-inch tray spacing, from Fig. 6.24, CF = 0.082 ft/s

From relations below Eq. (6-44), since FLV is < 0.1, Ad/A = 0.1

From relation below Eq. (6-42), FST = (σ/20)0.2 = (18.4/20)0.2 =0.98. FF = 0.75 , FHA = 1.0

From Eq. (6-42), C = FST FF FHA CF = (0.98)(0.75)(1.0)(0.082) = 0.0603 ft/s

From Eq. (6-40), U f = C ( ρ L − ρV ) / ρV

1/ 2

4VM V

From Eq. (6-44), DT =

fU f π (1 − Ad / A ) ρV

= 0.0603 ( 41.1 − 1.924 ) /1.924

1/ 2

1/ 2

= 0.272 ft/s

4(530 / 3, 600)(26.6)

=

0.85(0.272)(3.14)(1 − 0.1)(1.924)

1/ 2

= 3. 53 ft

Exercise 6.20

Subject:

Hydraulic calculations for bottom tray of a sieve-tray column

Given: Absorber of Exercise 6.16 with an absorbent flow rate of 40,000 gpm of nC8. Sieve

trays on 24-inch spacing , with a weir height of 2.5 inches and 1/4-inch holes. Foaming factor =

0.80 and fraction flooding = 0.70.

Find: (a)

(b)

(c)

(d)

(e)

(f)

Column diameter at bottom.

Vapor pressure drop/tray.

Whether weeping will occur.

Entrainment rate.

Fractional decrease in Murphree efficiency due to entrainment.

Froth height in downcomer.

Analysis: From Exercise 6.16, V = 800,000/359 = 2,230 lbmol/min of entering gas.

Average MW of gas = 0.725(2.016) + 0.25(16.04) + 0.025(30.05) = 6.22

Assuming ideal gas law for gas at 400 psia and 100oF,

ρV = PM/RT = (400)(6.22)/(10.73)(560) = 0.414 lb/ft3

For the liquid, neglect absorbed components. ρL = 43.9 lb/ft3 = 5.86 lb/gal

MW of nC8 = 114. Therefore, L = 40,000(5.86)/114 = 2,056 lbmol/min

(a) Use entrainment flooding correlation of Fig. 6.24, where the abscissa is,

FLV

LM L ρV

=

VM V ρ L

1/ 2

=

2, 056(114) 0.414

2, 230(6.22) 43.9

1/ 2

= 1.64

(1)

From Fig. 6.24, for 24-inch tray spacing, CF = 0.08. Because FLV > 1, Ad /A = 0.2.

FHA = 1.0, FF = 0.8, and since σ = 20 dynes/cm, FST = 1.0.

From Eq. (6-24), C = FSTFFFHACF = (1)(0.8)(1)(0.08) = 0.064 ft/s

From Eq. (6-40), U f = C ρ L − ρV / ρV

1/ 2

= 0.064 43.9 − 0.414 / 0.414

4VM V

From Eq. (6-44), DT =

fU f π (1 − Ad / A ) ρV

1/ 2

1/ 2

= 0.66 ft / s

4(2, 230 / 60)(6.22)

=

0.70(0.66)(3.14)(1 − 0.2)(0.414)

1/ 2

= 44 ft

This is a very large diameter. Would probably use two parallel columns of 31 ft each, but

continue with 44 ft diameter.

(b) Vapor pressure drop per tray is given by Eq. (6-49), ht = hd + hl + hσ

(2)

From the continuity equation, m = uAρ , hole velocity for 10% hole area =

uo = (2,230/60)(6.22)/(3.14/4)(44)2(0.414)(0.1) = 3.68 ft/s and superficial velocity = 0.368 ft/s

uo2 ρV

3.682 0.414

From Eq. (6-50), hd = 0186

.

=

0186

.

= 0.045 in. of nC8

Co2 ρ L

0.732

43.9

Analysis: (continued)

Exercise 6.20 (continued)

Active bubbling area for Ad /A = 0.2 is Aa = A - 2Ad = 0.6 A. So, Ua = 0.368/0.6 = 0.61 ft/s

From Eq. (6-53), Ks = U a

ρV

ρ L − ρV

1/ 2

1/ 2

0.414

= 0.61

43.9 − 0.414

= 0.06 ft/s

From Eq. (6-52), φe = exp(-4.257Ks0.91) = exp[-4.257(0.06)0.91] = 0.72

From Eq. (6-54), C = 0.362 + 0.317 exp( −35

. hw ) = 0.362 + 0.317 exp[ −3.5(2.5)] = 0.362

Take weir length, Lw = 0.73DT = 0.73(44) = 32.1 ft = 385 in.

2/3

qL

From Eq. (6-51), hl = φ e hw + C

Lw φ e

40,000

= 0.72 2.5 + 0.362

385 0.72

2/3

= 9.0 in. of nC8

From Eq. (6-55), with maximum bubble size of 1/4 inch = 0.00635 m,

hσ = 6σ / gρ L DBmax = 6(20 / 1000) / (9.8)(703)(0.00635) = 0.00274 m = 0.11 in. nC8

From Eq. (2), ht = hd + hl + hσ = 0.045 + 9.0 + 0.11 = 9.2 in. nC8 = 0.23 psi/tray. Excessive!

(c) Apply criterion of Eq. (6-64). hd + hσ = 0.045 + 0.11 = 0.155 in. < hl = 9.0 in.

Therefore, weeping will occur.

(d) From Fig. 6.28, since FLV = 1.64, entrainment will be very low.

(e) Because entrainment is very low, EMV will not decrease.

(f) From Eqs. (6-70) and (6-72), hdf =(ht + hl + hda) / 2

(3)

Area of downcomer opening = Ada = Lwha Take ha = 2 in., Ada = (32.1)(2/12) = 5.4 ft2

qL

From Eq. (6-71), hda = 0.03

100 Ada

2

40, 000

= 0.03

100(5.4)

2

=164 in.

Very excessive

Exercise 6.21

Subject: Column performance for 40% of flooding.

Given: Data in Examples 6.5, 6.6, and 6.7.

Find: (a) Column diameter in Example 6.5 for f = 0.4.

(b) Vapor pressure drop in Example 6.6 for f = 0.4.

(c) Murphree vapor-point efficiency in Example 6.7 for f = 0.4

Analysis: (a) Example 6.5:

In this example, a value of f = 0.80 was used, giving DT = 2.65 ft

From Eq. (6-44), by ratioing values of f,

0.80

DT = 2.65

0.40

1/ 2

= 3.75 ft = 1.15 m

(b) Example 6.6:

In this example, a tower diameter of 1 m gives a vapor pressure drop = 0.093 psi/tray,

with a vapor hole velocity of 47.9 ft/s, a weir length of 0.73 m, an active area vapor velocity of

5.99 ft/s, and Ks = 0.265 ft/s.

Vapor hole velocity varies inversely with the square of the column diameter. Therefore,

uo = 14.6(1/1.15)2 = 11.0 m/s = 36 ft/s

From Eq. (6-50), hd is directly proportional to hole velocity squared. Therefore,

hd = 1.56(36/47.9)2 = 0.88 in. of liquid

Weir length is proportional to column diameter. So, Lw = 0.73(1.15/1) = 0.84 m = 0.33 in.

Vapor velocity based on active area varies inversely with the square of column diameter.

Therefore, Ua = 5.99(1/1.15)2 = 4.53 ft/s.

From Eq. (6-53), Ks is proportional to Ua. Thus, Ks = 0.265(4.53/5.99) = 0.20 ft/s

From Eq. (6-52), φe = exp(-4.257Ks0.91) = exp[-4.257(0.20)0.91] = 0.37

The value of C in Eq. (6-51) remains at 0.362.

From Eq. (6-51),

qL

hl = φ e hw + C

Lw φ e

2/3

12.9

= 0.37 2 + 0.362

33 0.37

2/3

= 0.88 in.

hσ = 0.36 in. (no change from Example 6.6)

From Eq. (6-49), ht = hd + hl + hσ = 0,88 + 0.88 + 0.36 = 2.12 in.

Tray pressure drop = htρL = 2.12(0.0356) = 0.076 psi/tray

(c) Example 6.7:

In this example, a tower diameter of 1 m gives a EOV = 0.77. Must redo all calculations.

DT = 1.15 m, A = 1.038 m2 = 10,380 cm2, Aa = 0.8(1.038) = 0.83 m2 = 8,300 cm2

Lw = 33 in. = 0.84 m, φe = 0.37, hl = 0.88 in. = 2.24 cm

Ua = 4.53 ft/s = 137 cm/s, Uf = 10.2 ft/s, f = Ua/Uf = 4.53/10.2 = 0.44

Analysis: (c) (continued)

Exercise 6.21 (continued)

F = UaρV0..5 = 1.37(1.92)0.5 = 1.90 (kg/m)0.5/s ,

From Eq. (6-64), t L =

From Eq. (6-65), t G =

qL = 812 cm3/s

hl Aa 2.24(10,380)

=

= 28.6 s

qL

812

1 − φ e hl (1 − 0.37)2.24

=

= 0.028 s

φ eU a

0.37(137)

From Eq. (6-67), k L a = 78.8 DL0.5 ( F + 0.425) = 78.8(181

. × 10−5 )(190

. + 0.425) = 0.78 s-1

From Eq. (6-66),

kG a =

1,030 DV0.5 f − 0.842 f 2

0.5

l

h

=

1,030(7.86 × 10 −2 ) 0.5 0.44 − 0.842 0.44

2.24

0.5

2

= 53.4 s-1

From Eq. (6-63), N L = k L at L = 0.78(28.6) = 22.3

From Eq. (6-62), N G = k G at G = 53.4(0.28) = 15

.

From Example 6.7, KV/L = 0.662

1

1

1

From Eq. (6-61), N OG =

=

=

= 144

.

1

KV / L

1 0.662 0.667 + 0.030

+

+

NG

NL

15

.

22.3

Mass transfer is controlled by the vapor phase.

From a rearrangement of Eq. (6-52), EOV = 1 − exp(− N OG ) = 1 − exp(−1.44) = 0.76 or 76%.

Exercise 6.22

Subject:

Sizing, hydraulics, and mass transfer for an acetone absorber

Given: Acetone absorber of Fig. 6.1, using sieve trays with 10% hole area, 3/16-inch holes, and

an 18-inch tray spacing. Foaming factor = 0.85.

Find: (a) Column diameter for 75% of flooding.

(b) Vapor pressure drop per tray.

(c) Number of transfer units.

(d) Number of overall transfer units.

(e) Controlling resistance to mass transfer.

(f) Murphree point vapor efficiency

If 30 trays are adequate.

Analysis: (a) Base column diameter on the top tray, where pressure is the lowest and gas flow

rate is the highest. Use data in Fig. 6.1. L = 1,943 kmol/h, ML = 18, ρL = 1,000 kg/m3

V = 6.9 + 144.3 + 536.0 + 22.0 + 0.1 = 709.3 kmol/h, MV = 28.8, P = 90 kPa, T = 25oC

From the ideal gas law, ρV = PM/RT = (90)(28.8)/(8.314)(298) = 1.05 kg/m3

Use entrainment flooding correlation of Fig. 6.24, where the abscissa is,

1/ 2

1/ 2

LM L ρV

1,943(18) 105

.

FLV =

=

= 0.056

VMV ρ L

709.2(28.8) 1,000

From Fig. 6.24, for 18-inch tray spacing, CF = 0.28 ft/s. Because FLV < 1, Ad /A = 0.1.

FHA = 1.0, FF = 0.85, and since σ = 70 dynes/cm, FST = (70/20)0.2 = 1.285

From Eq. (6-24), C = FSTFFFHACF = (1.285)(0.85)(1)(0.28) = 0.306 ft/s

From Eq. (6-40), U f = C ρ L − ρV / ρV

From Eq. (6-44),

4VM V

DT =

fU f π (1 − Ad / A ) ρV

1/ 2

1/ 2

= 0.306 1,000 − 105

. / 105

.

1/ 2

4(709.2 / 3, 600)(28.8)

=

0.75(9.44 / 3.28)(3.14)(1 − 0.1)(1.05)

= 9.44 ft / s

1/ 2

= 1.89 m = 6.2 ft

(b) Vapor pressure drop per tray is given by Eq. (6-49), ht = hd + hl + hσ

(1)

From the continuity equation, m = uAρ , hole velocity for 10% hole area =

uo = (709.2/3,600)(28.8)/(3.14/4)(1.9)2(1.05)(0.1) = 19.0 m/s =62.3 ft/s

Superficial velocity = (0.1)(19.0) = 1.90 m/s = 6.23 ft/s

uo2 ρV

62.32 105

.

From Eq. (6-50), hd = 0186

.

=

0186

.

= 142

. in. of liquid

2

2

Co ρ L

0.73 1,000

Active bubbling area for Ad /A = 0.1 is Aa = A - 2Ad = 0.8 A. So, Ua = 6.23/0.8 = 7.8 ft/s

From Eq. (6-53), Ks = U a

ρV

ρ L − ρV

1/ 2

1.05

= 7.8

1,000 − 105

.

1/ 2

= 0.253 ft/s

From Eq. (6-52), φe = exp(-4.257Ks0.91) = exp[-4.257(0.253)0.91] = 0.30

Assume a 2-inch weir height = hw

Exercise 6.22 (continued)

Analysis: (b) (continued)

. hw ) = 0.362 + 0.317 exp[ −35

. (2.0)] = 0.362

From Eq. (6-54), C = 0.362 + 0.317 exp( −35

Take weir length, Lw = 0.73DT = 0.73(6.2) = 4.52 ft = 54.3 in.

Volumetric liquid rate = qL = m/ρL = (1,943/60)(18)/(1,000)(0.003785 m3/gal) = 154 gpm

2/3

qL

From Eq. (6-51), hl = φ e hw + C

Lw φ e

154

= 0.30 2 + 0.362

54.3 0.30

2/3

= 1.09 in. of liquid

From Eq. (6-55), with maximum bubble size of 3/16 inch = 0.00476 m,

hσ = 6σ / gρ L DBmax = 6(70 / 1000) / (9.8)(1,000)(0.00476) = 0.009 m = 0.35 in. of liquid

From Eq. (2), ht = hd + hl + hσ =1.42 + 1.09 + 0.35 = 2.86 in. liquid = 0.103 psi/tray =

0.7 kPa/tray

(c) DT = 1.89 m, A = 2.804 m2 = 28,040 cm2, Aa = 0.8(2.804) = 2.24 m2 = 22,400 cm2

φe = 0.30, hl = 1.09 in. = 2.77 cm

Ua = 7.8 ft/s = 238 cm/s, Uf =9.44 ft/s, f = Ua/Uf = 7.8/9.44 = 0.826

F = UaρV0..5 = 2.38(1.05)0.5 = 2.44 (kg/m)0.5/s , qL = 154 gpm = 9,716 cm3/s

hA

2.77(22,400)

From Eq. (6-64), t L = l a =

= 6.39 s

qL

9,716

1 − φ e hl (1 − 0.30)2.77

=

= 0.027 s

φ eU a

0.30(238)

From the Wilke-Chang Eq. (3-39), DL = 1.12 x 10-5 cm2/s

. × 10−5 )(2.44 + 0.425) = 0.756 s-1

From Eq. (6-67), k L a = 78.8 DL0.5 ( F + 0.425) = 78.8(112

From Perry's Handbook, with a temperature correction based on Eq. (3-36), DV = 0.127 cm2/s

From Eq. (6-66),

From Eq. (6-65), t G =

kG a =

1,030 DV0.5 f − 0.842 f 2

hl0.5

=

1,030(0127

. ) 0.5 0.826 − 0.842 0.826

2.77 0.5

2

= 55.4 s-1

From Eq. (6-63), N L = k L at L = 0.756(6.39) = 4.83

From Eq. (6-62), N G = kG atG = 55.4(0.027) = 1.5

(d) From p. 271, for acetone, A = L/KV = 1.38. Therefore, KV/L = 1/1.38 = 0.725

1

1

1

From Eq. (6-61), N OG =

=

=

= 122

.

1

KV / L

1 0.725 0.667 + 0150

.

+

+

NG

NL

15

.

4.83

(e) Mass transfer is controlled by the vapor phase.

(f) From a rearrangement of Eq. (6-56), E OV = 1 − exp( − N OG ) = 1 − exp( −122

. ) = 0.705 or 70 %

Now, the separation requires 10 equilibrium stages. Assume the liquid on a tray is well mixed.

Then, from Eq. (6-31), EMV = EOV = 0.70. From below Eq. (6-33), take λ=KV/L=0.725.

log 1 + E MV ( λ − 1) log 1 + 0.70(0.725 − 1)

From Eq. (6-37), Eo =

=

= 0.66 (worst case)

log λ

log 0.725

Therefore, at most, we need from Eq. (6-21), Na =Nt /Eo = 10/0.66 = 15. Therefore, 30 okay.

Exercise 6.23

Subject: Design of a column to strip VOCs from water by air at 15 psia and 70oF.

Given: Conditions in Example 6.2 except that entering flow rates are twice as much.

Assumptions: Dilute system such that changes in vapor and liquid rates in the column are

negligible. Sieve trays on 24-inch spacing, with 10 % hole area of 3/16-inch holes, FF = 0.9,

FHA = 1.0 and f = 0.80.

Find: (a)

(b)

(c)

(d)

(e)

Number of equilibrium stages required.

Column diameter for sieve trays.

Vapor pressure drop per tray.

Murphree vapor-point efficiency from Chan-Fair method.

Number of actual trays.

Analysis: (a) Need 3 equilibrium stages, as determined in Example 6.2 and which is unchanged

when flow rates are doubled.

(b) liquid rate = 2(500) = 1,000 gpm or 1,000(60)(8.33)/18.02 = 27,800 lbmol/h = L

vapor rate = 2(3,400) = 6,800 scfm or 6,800(60)/379 = 1,077 lbmol/h = V

ρL = 62.4 lb/ft3. From ideal gas law, ρV = PM/RT = (15)(29)/(10.73)(530) = 0.0765 lb/ft3

Use entrainment flooding correlation of Fig. 6.24, where the abscissa is,

FLV

LM L ρV

=

VMV ρ L

1/ 2

27,800(18) 0.0765

=

1,077(29) 62.4

1/ 2

= 0.56

From Fig. 6.24, for 24-inch tray spacing, CF = 0.18 ft/s.

Because 0.1 < FLV > 1, from below Eq. (6-44), Ad /A = 0.1 + (FLV - 0.1)/9 = 0.15

FHA = 1.0, FF = 0.9, and since σ = 80 dynes/cm, FST = (80/20)0.2 = 1.32

From Eq. (6-24), C = FSTFFFHACF = (1.32)(0.9)(1)(0.18) = 0.21 ft/s

From Eq. (6-40), U f = C ρ L − ρV / ρV

From Eq. (6-44), for f = 0.80,

4VM V

DT =

fU f π (1 − Ad / A ) ρV

1/ 2

1/ 2

= 0.21 62.4 − 0.0765 / 0.0765

1/ 2

= 6.0 ft / s

4(1, 077 / 3, 600)(29)

=

0.80(6.0)(3.14)(1 − 0.15)(0.0765)

(c) Vapor pressure drop per tray is given by Eq. (6-49), ht = hd + hl + hσ

From the continuity equation, m = uAρ . Hole velocity for 10% hole area =

uo = (1,077/3,600)(29)/(3.14/4)(6)2(0.0765)(0.1) = 40 ft/s

Superficial velocity = (0.1)(40) = 4 ft/s

1/ 2

= 6.0 ft

(1)

Exercise 6.23 (continued)

Analysis: (c) (continued)

uo2 ρV

402

0.0765

=

0186

.

= 0.68 in. of liquid

2

2

Co ρ L

0.73

62.4

Active bubbling area for Ad /A = 0.15 is Aa = A - 2Ad = 0.7 A. Therefore, Ua = 4/0.7 = 5.7 ft/s

From Eq. (6-50), hd = 0186

.

ρV

ρ L − ρV

From Eq. (6-53), Ks = U a

1/ 2

0.0765

= 5.7

62.4 − 0.0765

1/ 2

= 0.20 ft/s

From Eq. (6-52), φe = exp(-4.257Ks0.91) = exp[-4.257(0.20)0.91] = 0.37

Assume a 2-inch weir height = hw

. hw ) = 0.362 + 0.317 exp[ −35

. (2.0)] = 0.362

From Eq. (6-54), C = 0.362 + 0.317 exp( −35

Take weir length, Lw = 0.73DT = 0.73(6)(12) = 53 in.

qL

From Eq. (6-51), hl = φe hw + C

Lw φe

2/3

1, 000

= 0.37 2 + 0.362

( 53) 0.37

2/3

= 2. 58 in. of liquid

From Eq. (6-55), with maximum bubble size of 3/16 inch = 0.00476 m,

hσ = 6σ / gρ L DBmax = 6(80 / 1,000) / (9.8)(1,000)(0.00476) = 0.0103 m = 0.40 in. of liquid

From Eq. (2), ht = hd + hl + hσ =0.68 + 2.58 + 0.40 = 3.66 in. liquid = 0.13 psi/tray

(d) DT = 6 ft, A = 28.3 ft2, Aa = 0.7(28.3) = 19.8 ft2 = 18,390 cm2

φe = 0.37, hl = 2.58 in. = 6.55 cm, ρG = 0.0765 lb/ft3 = 1.23 kg/m3

Ua = 5.7 ft/s = 1.74 m/s , Uf =6.0 ft/s, f = Ua/Uf = 5.7/6.0 = 0.95

F = UaρV0..5 =1.74(1.23)0.5 = 1.93 (kg/m)0.5/s , qL = 1,000 gpm = 63,100 cm3/s

hA

6.55(18,390)

From Eq. (6-64), t L = l a =

= 19

. s

qL

63,100

1 − φ e hl (1 − 0.37)6.55

=

= 0.064 s

φ eU a

0.37(174)

From the Wilke-Chang Eq. (3-39), DL = 0.96 x 10-5 cm2/s

From Eq. (6-67), k L a = 78.8 DL0.5 ( F + 0.425) = 78.8(0.96 × 10−5 )(193

. + 0.425) = 0.58 s-1

From Perry's Handbook, with T and P corrections based on Eq. (3-36), DV = 0.086 cm2/s

From Eq. (6-65), t G =

From Eq. (6-66),

kG a =

1, 030 DV0.5 ( f − 0.842 f 2 )

0.5

l

h

=

1, 030(0.086)0.5 0.95 − 0.842 ( 0.95 )

From Eq. (6-63), N L = k L at L = 0.58(1.9) = 1.1

6.55

0.5

2

= 2. 56 s-1

Analysis: (continued)

Exercise 6.23 (continued)

From Eq. (6-62), N G = kG atG = 2.56(0.064) = 0.16

(d) From Example 6.2, for benzene, S = KV/L = 9.89

1

1

1

From Eq. (6-61), N OG =

=

=

= 0.066

1

KV / L

1

9.89 6.25 + 8.99

+

+

NG

NL

016

.

11

.

From a rearrangement of Eq. (6-52), EOV = 1 − exp(− N OG ) = 1 − exp(−0.066) = 0.064 or 6.4%

(e) From Example 6.2, the separation requires 3 equilibrium stages.

If we assume the liquid on a tray is well mixed. Then, from Eq. (6-31), EMV = EOV = 0.064.

From Eq. (6-21), Na =Nt /Eo = 3/0.064 = 47 trays.

If we assume plug flow of liquid on a tray, then, if we take, below Eq. (6.33), λ=KV/L=9.89,

from Eq. (6-37),

log 1 + E MV ( λ − 1) log 1 + 0.064(9.89 − 1)

=

= 0197

.

log λ

log 9.89

Then we need from Eq. (6-21), Na =Nt /Eo = 3/0.197 = 15 trays. Sufficient information is not

given to establish the partial mixing prediction. Therefore, the number of trays required ranges

widely from 15 to 47.

Eo =

Exercise 6.24

Subject: Absorption of SO2 from air into water in an existing packed column.

Given: Feed gas flow rate of 0.062 kmol/s containing 1.6 mol% SO2. Absorbent is 2.2 kmol/s

of pure water. Packed column is 1.5 m2 in cross sectional area and packed with No. 2 plastic

super Intalox saddles to a 3.5-m height. Exit gas contains an SO2 mole fraction of 0.004.

Operating pressure is 1 atm. At operating temperature, equilibrium curve for SO2 is y = Kx =

40x

Assumptions: No stripping of water. No absorption of air.

Find: (a)

(b)

(c)

(d)

L/Lmin

NOG and Nt

HOG and HETP

KGa

Analysis: Compute material balance. SO2-free inlet air rate = 0.062(1-0.016) = 0.061 kmol/s

SO2 inlet rate in feed gas = 0.062(0.016) = 0.001 kmol/s = V'

SO2 outlet rate in gas = 0.061(0.004/0.996) = 0.00025 kmol/s

SO2 rate in outlet water = 0.001 - 0.00025 = 0.00075 kmol/s

Fraction absorbed = 0.00075/0.001 = 0.75 or 75%

(a) From Eq. (6-11), L'min = V'K(fraction absorbed) = 0.061(40)(0.75) = 1.83 kmol/s

Therefore, L/L'min = 2.2/1.83 = 1.20

0.887 N +1 − 0.887

(b) Take A = L/KV = 2.2/[(40)(0.062)] = 0.887, From Eq. (6-13), 0.75 =

0.887 N +1 − 1

Solving, Nt = 4. For NOG, use Eq. (6-89) with yin = 0.016, yout = 0.004, xin =0.0,

ln

N OG =

0.887 − 1 0.016

1

+

0.887

0.004 0.887

= 3.78

(0.887 − 1) / 0.887

(c) Given height of packing = 3.5 m = lT

From Eq. (6-73), HETP = lT /Nt = 3.5/4 = 0.875 m

From Eq. (6-89), HOG = lT /NOG = 3.5/3.78 = 0.926 m

V

K G aPS

3

= 0.045 kmol/s-m -atm

(d) From Table 6.7, HOG =

Therefore, K G a =

V

H OG PS

=

0.062

(0.926)(1)(1.5)

Exercise 6.25

Subject: Operating data for absorption of SO2 from air into water in a packed column.

Given: Column operates at 1 atm (760 torr) and 20oC. Solute-free water enters at 1,000 lb/h.

Mole ratio of water to air is 25. Liquid leaves with 0.6 lb SO2/100 lb of solute-free water.

Partial pressure of SO2 in exit gas is 23 torr (0.0303 atm). Equilibrium data are given as partial

pressures of SO2 in air as a function of lb SO2 dissolved/ 100 lb H2O.

Assumptions: No stripping of water. No absorption of air. Density of liquid taken as water.

Find: (a) % of SO2 absorbed.

(b) Concentration of SO2 in the liquid at the gas-liquid interface in lbmol/ft3 at a point

where the bulk liquid concentration is 0.001 lbmol SO2/lbmol of water and:

kL = 1.3 ft/h

kp = 0.195 lbmol/h-ft2-atm

Analysis: (a) Inlet water rate = 1,000/18.02 = 55.5 lbmol/h

Inlet air rate = water rate/25 = 55.5/25 = 2.22 lbmol/h

Partial pressure of air in exit gas = 760 - 23 = 737 torr

By partial pressure ratio, SO2 flow rate in exit gas = 2.22(23/737) = 0.0693 lbmol/h

Molecular weight of SO2 = 64.06

SO2 flow rate in exit liquid = 0.6(1,000/(100)(64.06) = 0.0937 lbmol/h

By material balance, SO2 flow rate in entering air = 0.0693 + 0.0937 = 0.1630 lbmol/h

Partial pressure of SO2 in entering gas = 0.1630/(0.1630 + 2.22) = 0.0690 atm

% of SO2 absorbed = 0.0937/0.1630 x 100% = 57.5%

(b)

At the point, the rate of mass transfer for SO2 as a flux across the gas-liquid interface, can

be written by the two-film theory as,

kp(pb - pi) = kL(ci - cb)

(1)

As shown in Fig. 6.31, the equilibrium interface composition can be determined in terms of the

ratio of mass-transfer coefficients. However, here, instead of compositions in mole fractions, the

gas composition is in partial pressure and the liquid is in concentration. From Eq. (1),

kL

1.3

p − pi

=

= 6.67 = b

k p 0.195

ci − cb

(2)

At the point (column height location), bulk liquid concentration = 0.001 lbmol SO2/lbmol H2O

and the flow rate is 0.001(55.5) = 0.0555 lbmol/h for SO2 in the liquid phase. The flow of SO2 in

the gas phase at that location is obtained by a material balance around the top of the column:

SO2 in entering liquid + SO2 in gas at the point = SO2 in liquid at the point + SO2 in exit gas

Therefore, 0 + SO2 flow rate in gas at the point = 0.0693 + 0.0555

Analysis: (b) (continued)

Exercise 6.25 (continued)

SO2 flow rate in gas at the point = 0.1248 lbmol/h. Therefore, the partial pressure of SO2 in the

bulk gas at the point = 0.1248/(0.1248 + 2.22) x 1 atm = 0.0532 atm = pb .

The density of water is 62.4 lb/ft3 or 62.4/18.02 = 3.46 lbmol/ft3. Therefore,

the concentration of SO2 in the bulk liquid at the point = 0.001(3.46) = 0.00346 lbmol/ft3 = cb .

We now need an algebraic equilibrium relationship between pi and ci .

Convert the given equilibrium data to partial pressures and concentrations in the vicinity of the

values at the point:

The SO2 concentration in the liquid is obtained from,

c,

lbmol SO 2

lb SO 2

=

3

100 lb H 2 O

ft

lb SO2 / 100 lb H2O

0.30

0.50

0.70

1.00

ci ,

lbmol SO2 / ft3

0.00292

0.00487

0.00682

0.00974

62.4

64.06

1

100

Partial pressure SO2 ,

torr

14.1

26.0

39.0

59.0

pi of SO2 ,

atm

0.01855

0.03421

0.05132

0.07763

These equilibrium data fit the curve, pi = 5.04536ci + 511.783ci2 - 21714.4ci3

(3)

From Eq. (2),

(4)

Solving Eqs. (3) and (4),

0.0532 - pi = 6.67(ci - 0.00346)

ci = 0.00550 lbmol/ft3 and pi = 0.0396 atm

The same result can be obtained by constructing a plot of SO2 partial pressure versus SO2

concentration in the liquid, similar to Fig. 6.31. First, the operating line is drawn as a straight

line connecting the column end points (0.0303, 0.0) and (0.0690, 0.00584), as (p , c). Then the

equilibrium curve is drawn, using Eq. (3). Then the point (pb , cb) is marked on the operating

line. A straight line is extended from this point, with a slope of (-kL/kp) = -6.67, to the point of

intersection on the equilibrium line, giving the same result as above

Exercise 6.26

Subject: Stripping of benzene from wastewater with air in a packed column.

Given: Column operation at 2 atm (1,520 torr) and 25oC. Wastewater enters at 600 gpm

containing 10 ppm by weight of benzene. Suggested air rate is 1,000 scfm (60oF and 1 atm).

Exit water to contain just 0.005 ppm benzene. Vapor pressure of benzene = 95.2 torr at 25oC.

Solubility of benzene in water = 0.180 g/100 g water at 25oC. Packing is 2-inch polypropylene

Flexirings. Mass transfer coefficients are: kLa = 0.067 s-1 and kGa = 0.80 s-1 (both driving

forces are in concentration units).

Assumptions: No stripping of water. No absorption of air.

Find: (a)

rate.

(b)

(c)

(d)

(e)

Minimum air stripping rate. Is it less than suggested? If not, use 1.4 times minimum

Stripping factor

NOG

KGa in units of s-1 and mol/m3-s-kPa, and which phase controls mass transfer

Volume of packing in m3

Analysis: Water flow rate = 600(8.33)(60)/18.02 = 16,640 lbmol/h

For benzene, xin = (10/1,000,000)(18.02/78) = 2.31 x 10-6

xout = (0.005/1,000,000)(18.02/78) = 1.16 x 10-9

Fraction of benzene stripped = 1 - (2.31 x 10-6/1.16 x 10-9) = 0.9995

(a) System is very dilute with respect to benzene, therefore use Kremser equation to determine

the minimum gas rate. From Eq. (6-12),

Vmin = L (fraction stripped)/ K

(1)

For the K-value, use Eq. (4) in Table 2.3, a modified Raoult's law, K = γLPs/P

(2)

To obtain the liquid-phase activity coefficient, use the given benzene solubility data. For liquidliquid equilibrium with respect to benzene, which is distributed between a water-rich phase (2)

and a benzene-rich phase (1), using Eq. (2-30), γ ( 2 ) = x (1) / x ( 2 ) γ (1) . But if the benzene-rich

phase is nearly pure benzene, γ(1) = 1 and x(1) = 1. Therefore, γ(2) = 1/x(2)

018

. (18.02)

From the given benzene solubility in water, x =

= 4.2 × 10 −4

100(78)

1

Therefore from Eq. (3), γ L =

= 2,380

4.2 × 10 − 4

(3)

From Eq. (2), K = (2,380)(95.2)/1,520 = 149

From Eq. (1), Vmin = 16,640(0.9995)/150 = 111.6 lbmol/h

At 60oF and 1 atm, there are 379 scf/lbmol. Therefore, Vmin = 111(379)/60 = 705 scfm.

This is less than the 1,000 scfm suggested by the expert. Therefore, use the value suggested by

the expert, rather than revise it.

Exercise 6.26 (continued)

Analysis: (continued)

(b) Operating V = 111.6(1,000/705) = 158.3 lbmol/h

From Eq. (5-51), S = KV/L = 149(158.3)/16,640 = 1.417 (a good value)

(c) For NOG, use Eq. (6-93), with A = 1/S = 1/1.417 = 0.7057

Benzene stripped = Linxin(fraction stripped) = 16,640(2.31 x 10-6)(0.9995) = 0.0384 lbmol/h

Therefore, yout = 0.0384/158.3 = 0.0002427. Also, xin = 2.31 x 10-6 and yin = 0.0. Therefore,

ln

N OG =

0.7057 − 1

0.7057

0.0 − 149(2.31× 10−6 )

1

+

−6

0.0002427 − 149(2.31× 10 )

0.7057

= 14.2

(0.7057 − 1) / 0.7057

(d) Note that both kL and kG are given for concentration driving forces. Therefore, we write the

rate of mass transfer of benzene as:

r = kG acG ( yb − yi ) = k L acL ( xi − xb ) = K G acG ( yb − y* )

(4)

where cG and cL are total gas and liquid concentrations, respectively, and y* is the vapor mole

fraction in equilibrium with the bulk liquid mole fraction, as given by y* = Kxb .

Solving Eq. (4) for the driving vapor and liquid phase driving forces,

Adding Eqs. (5) and (6) to eliminate yi and solving for r and equating to the last term in Eq. (4),

r=

yb − y*

=

1

K

+

kG acG k L acL

Solving Eq. (7) for KGa,

KG a =

yb − y *

1

K G acG

1

KcG

1

+

kG a k L acL

The total gas concentration is obtained from the ideal gas law,

(7)

(8)

Analysis: (d) continued)

xercise 6.26 (continued)

cG =

P

2(101.3)

=

= 81.8 mol/m3

−3

RT 8.314 × 10 (298)

ρ L 106 g / m3

=

= 55,500 mol/m3

ML

18.02

1

1

KG a =

=

= 0.22 s-1

1

150(81.8)

1.25

+

3.29

+

0.80 0.067(55,500)

This is with a concentration driving force.

cL =

The liquid phase controls with a relative resistance of 3.29 compared to 1.25 for the gas phase.

To obtain KGa with a partial pressure driving force, we write the rate of mass transfer as,

r = K G acG ( yb − y* ) = ( K G ) p aP ( yb − y* )

(9)

where KGa is with the concentration driving force = 0.22 s-1 and (KG)pa is with the partial

pressure driving force. Solving Eq. (9), and applying the ideal gas law in the form, cG=P/RT,

(K G ) p a = K G a

cG K G a

0.22

=

=

= 0.089 mol/kPa-m3-s

P

RT (8.314 × 10−3 )(298)

(e) From Table 6.7, with a partial pressure driving force,

H OG =

G

(K G ) p aPS

However, the cross sectional area of the tower, S, is not known. Therefore, can not compute HOG

From Eq. (6-89), lT = HOGNOG . Therefore, can not compute the height because HOG is

unknown. However, we can compute the packed volume.

Packed volume = lTS = NOGHOGS = N OG

G

(149)(454)

= (14.2)

= 14.8 m3

(K G ) p aP

0.089(3, 600)(2)(101.3)

Exercise 6.27

Subject: Absorption of GeCl4 from air into dilute caustic solution in an existing packed column.

Given: Column operates at 25oC (77oF) and 1 atm. Gas enters at 23,850 kg/day containing 288

kg/day of GeCl4 and 540 kg/day of Cl2. Dissolved GeCl4 and Cl2 react with the caustic so that

neither has a vapor pressure. Packed tower is 2-ft diameter with 10 ft of 1/2-inch ceramic

Raschig ring packing of given characteristics. Liquid rate is to give 75% of flooding. Equation

is given for estimating Kya.

Assumptions: No stripping of water. No absorption of air.

Find: (a) Entering dilute caustic flow rate.

(b) Required packed height. Which controls, GeCl4 or Cl2? Is 10-ft height adequate?

(c) % absorption of GeCl4 and of Cl2 for 10 ft of packing. If necessary, select an

alternative packing.

Analysis: (a) Determine entering dilute caustic flow rate from the 75% of flooding

specification, using the flooding curve of Fig. 6.36(a), with the correction factors of Figs.

6.36(b,c). The air rate in the entering gas = 23,850 - 288 - 540 = 23,022 kg/day.

MW of Cl2 = 71. MW of GeCl4 = 214.6. MW of air = 29.

23,022 288 540

Molar gas rate = V =

+

+

= 803 kmol/day or 73.7 lbmol/h or 2189 lb/h

29

214.6 71

Average molecular weight of gas = 23,850/803 = 29.7

Tower cross sectional area for 2-ft diameter = 3.14(2)2/4 = 3.14 ft2

The continuity equation for flow through the tower based on the gas superficial velocity is,

m = uoSρ. Therefore, the superficial velocity is, uo = m/Sρ

(1)

3

From the ideal gas law, ρ = PM/RT = (1)(29.7)/(0.7302)(460+77) = 0.076 lb/ft

Therefore, from Eq. (1), uo = (2189)/(3.14)(0.076) = 9,170 ft/h or 2.55 ft/s.

From Eq. (6-102), noting that for the dilute caustic solution at 25oF, f{ρL} = 1 and f{µL} = 0.98

for a liquid viscosity of 0.95 cP at 25oC,

Y=

uo2 FP ρV

g ρH 2O

f {ρ L }f {µ L }=

(2.55) 2 (580) 0.076

(1.0)(0.98)=0.14

32.2

62.4

(uo)flood = uo/0.75 =2.55/0.75 = 3.40 ft/s.

Therefore, Yflood = 0.14/(0.75)2 = 0.25

LM L

From Fig. 6.36,

VM V

ρ

LM L = X (GM G ) L

ρG

1/ 2

62.4

= 0.009(2,191)

0.076

ρV

ρL

1/ 2

= 0.009

1/ 2

= 565 lb/h or 0.071 kg/s of entering liquid

Exercise 6.27 (continued)

Analysis:

(b) Assume that GeCl4 is the controlling species, with mass transfer controlled in the gas phase.

From Table 6.7, column height = lT = HGNG where, HG = V/kyaS

(1)

(1 − y ) LM dy

(1 − y )( y − yI )

and, N G =

(2)

At the interface, yI = 0 because it is given that dissolved GeCl4 has no vapor pressure

In entering gas, y = (288/214.6)/803 = 0.00162. Therefore (1 - y)bottom = (1 - 0.00162) = 0.9984

In exiting gas, y = 0.01 of y in entering gas = 0.0000162. Therefore (1 - y)top = 1.0000

Therefore, (1 - y)LM = 0.9992. Also, on the average, (1 - y) is approximately 0.9992.

Therefore, Eq. (2) for NG simplifies to,

NG =

0.00162

dy

0.00162

= ln

= 4.61

y

0.0000162

0.0000162

V

DPV ′

Equation given for ky is, k y =

1.195

S

µ (1 − ε o )

−0.36

( NSc )

−2 / 3

(3)

V = 803/24(3,600) = 0.0093 kmol/s

S = 3.14 ft2 or 0.292 m2

V' = (V/S)MG = (0.0093/0.292)(29.7) = 0.944 kg/s-m2

DP = 0.01774 m

At 25oC, from Perry's Handbook, for air, µ = 0.018 cP or 1.8 x 10-5 kg/m-s

εο = ε - hL

ε = 0.63

hL = 0.03591(L')0.331

(4)

L' =(LML) /S= 0.071/0.292 = 0.243 kg/s-m2 From Eq. (4), hL = 0.0359(0.243)0.331 = 0.0225

Therefore, εo = 0.63 - 0.0225 = 0.608 NSc = µ/ρDGeCl4

(5)

3

3

From above, ρ of the gas = 0.076 lb/ft = 1.21 kg/m

DGeCl4 = 6 x 10-6 m2/s

From Eq. (5), NSc = (1.8 x 10-5)/(1.21)(6 x 10-6) = 2.48

0.0093

(0.01774)(0.944)

From Eq. (3), k y =

1195

.

0.292

(18

. × 10 −5 ) 1 − 0.608

Equation given for interfacial area is,

Equation given for exponent,

Therefore, from Eq. (6), a =

−0.36

2.48

−2 / 3

14.69(808 V ′ / ρ1/ 2 ) n

a=

0.111

( L′ )

= 126

. × 10 −3 kmol/s-m2

(6)

n = 0.01114 L' + 0.148 = 0.01114(0.243) + 0.148 = 0.151

(808)(0.944)

14.69

(121

. )1/ 2

0.243

0.111

0.151

= 46.2 m2/m3

Exercise 6.27 (continued)

Analysis: (b) (continued)

Kya = kya = (1.26 x 10-3)(46.2) = 0.058 kmol/s-m3

From Eq. (1), HG = HOG = (V/S)/kya = (0.0093/0.292)/0.058 = 0.55 m or 1.8 ft

Packed height = HGNG = 0.55(4.61) = 2.53 m or 8.3 ft.

Therefore, a 10 foot height is sufficient.

Now check the assumption that GeCl4 controls. Because gas is dilute in Cl2 and 99% of it is

absorbed, NG is the same as for GeCl4. Note that in Eq. (3),

k y is proportional to ( N Sc ) −2 / 3 or Di2 / 3 . Since the given gas diffusivity of Cl2 is about twice that

of GeCl4, the mass transfer coefficient for Cl2 is higher and the corresponding HG is lower.

Therefore, the assumption that GeCl4 controls is correct.

(c) If a packed height of 10 ft rather than the computed 8.3 ft is used, then for GeCl4 ,

NG = lT /HG = 10/1.8 = 5.55 rather than 4.61.

y

From above, N G = ln in = 5.55

yout

y

Solving, in = 258

Therefore, yout = 0.00162/258 = 0.0000063

yout

% absorption of GeCl4 = (1 - 0.0000063/0.00162) = 0.996 or 99.6% compared to 99% specified

For Cl2, from above, HG = HG of GeCl4 (DGeCl4/DCl2)2/3 = 1.8(0.000006/0.000013)2/3 = 1.08

Therefore, NG = 10/1.08 = 9.26 = = ln

yin

yout

Solving,

yin

= 10,500

yout

% absorption of Cl2 = (1 - 1/10,500) = 0.9999 or 99.99% compared to 99% specified

Exercise 6.28

Subject: Packed tower diameter and pressure drop for conditions of Exercise 6.26.

Given: Suggested tower diameter of 0.80 m and pressure drop of 500 N/m2-m of packed height

(0.612 in. H2O/ft).

Find: (a)

(b)

(c)

(d)

Fraction of flooding if FP = 24 ft2/ft3.

Pressure drop at flooding.

Pressure drop at operating conditions using GPDC chart.

Pressure drop at operating conditions using Billet-Schultes correlation.

Analysis: (a) Using data from Exercise 6.26 and Fig. 6.36,

LML = 600(8.33) = 5,000 lb/min

VMV = (1,000/379)(29) = 76.5 lb/min

From ideal gas law, ρV = PM/RT = (2)(29)/(0.7302)(460+77) = 0.148 lb/ft3

ρL =62.3 lb/ft3

1/ 2

1/ 2

LM L ρV

5, 000 0.148

From Fig. 6.36, X =

=

= 3.19

VM V ρ L

76.5

62.3

From Fig. 6.36, at flooding, Y = 0.0053

For the actual operation, by the continuity equation, m = uoSρ

Area for flow = S = πD2/4 = (3.14)(0.8/0.3048)2/4 = 5.41 ft2

Superficial velocity = uo = m/Sρ = (76.5/60)/(5.41)(0.148) = 1.59 ft/s

From Eq. (6-102), noting that for the dilute aqueous solution at 25oF, f{ρL} = 1 and f{µL} = 0.98

for a liquid viscosity of 0.95 cP at 25oC,

uo2 FP ρV

Y=

g ρH 2O

(1.59) 2 (24) 0.148

(1.0)(0.98)=0.0044

f {ρ L }f {µ L }=

32.2

62.3

1/ 2

u

Y

0.0044

Fraction of flooding = o =

=

uflood

Yflood

0.0053

This is too high. Should increase tower diameter.

1/ 2

= 0.91 or 91%

(b) From Eq. (6-104), ∆Pflood = 0.115 FP0.7 = 0.115(24)0.7 = 1.06 in. H2O/ft of packed height

(c) From Fig. 6.36, ∆P at design = 1.50 in. H2O/ ft of packed height (seems high)

(d) From Table 6.8, for 2-inch (50-mm) plastic Pall rings, the packing characteristics are:

a = 111.1 m2/m3 or 33.9 ft2/ft3 , ε = 0.919 m3/m3 , Ch = 0.593 , Cp = 0.698, Cs = 2.816

The pressure drop per unit height of packed bed is given by Eq. (6-115),

∆P

ε

=

∆Po

ε − hL

3/ 2

exp

1/ 2

13300

N

3/ 2 ( FrL )

a

(1)

Exercise 6.28 (continued)

Analysis: (d) (continued)

where, hL is given by (6-97) and is in m2/m3 and N FrL is given by (6-99).

From Eq. (6-110),

∆Po

a u2ρ 1

= Ψo 3 V V

lT

ε 2 KW

(2)

1− ε

1 − 0.919

=6

= 0.0143 ft

a

33.9

1

2 1 DP

2

1

0.0143

From Eq. (6-111),

= 1+

= 1+

= 1045

.

KW

3 1 − ε DT

3 1 − 0.919 2.62

Therefore, KW = 0.957 .

From Eq. (6-112), DP = 6

From Perry's Handbook, µ for air at 25oC = 0.018 cP, and uo = uV = 1.59 ft/s

From Eq. (6-114), N ReV =

uV DP ρV

(1.59)(0.0143)(0.148)(0.957)

KW =

= 3, 287

(1 − ε ) µV

(1 − 0.919 ) [(0.018)(0.000672)]

From Eq. (6-113), Ψ o = C p

64

1.8

64

1.8

+ 0.08 = 0.698

+

= 0.671

3, 287 3, 287 0.08

N ReV N ReV