5-SAFETY ANALYSIS ROCK BREAKING CONFINED EXCAVATION FOR PUMP HOUSE 30-07-2019

advertisement

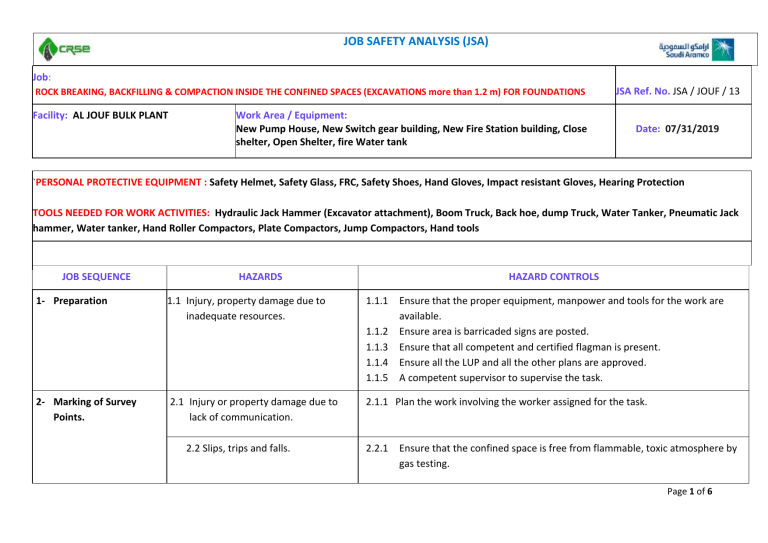

JOB SAFETY ANALYSIS (JSA) Job: ROCK BREAKING, BACKFILLING & COMPACTION INSIDE THE CONFINED SPACES (EXCAVATIONS more than 1.2 m) FOR FOUNDATIONS Facility: AL JOUF BULK PLANT Work Area / Equipment: New Pump House, New Switch gear building, New Fire Station building, Close shelter, Open Shelter, fire Water tank JSA Ref. No. JSA / JOUF / 13 Date: 07/31/2019 `PERSONAL PROTECTIVE EQUIPMENT : Safety Helmet, Safety Glass, FRC, Safety Shoes, Hand Gloves, Impact resistant Gloves, Hearing Protection Fire at, Safety Shoes, Safety Goggles, Hand Gloves, TOOLS NEEDED FOR WORK ACTIVITIES: Hydraulic Jack Hammer (Excavator attachment), Boom Truck, Back hoe, dump Truck, Water Tanker, Pneumatic Jack hammer, Water tanker, Hand Roller Compactors, Plate Compactors, Jump Compactors, Hand tools JOB SEQUENCE 1- Preparation HAZARDS 1.1 Injury, property damage due to inadequate resources. HAZARD CONTROLS 1.1.1 1.1.2 1.1.3 1.1.4 1.1.5 2- Marking of Survey Points. 2.1 Injury or property damage due to lack of communication. 2.2 Slips, trips and falls. Ensure that the proper equipment, manpower and tools for the work are available. Ensure area is barricaded signs are posted. Ensure that all competent and certified flagman is present. Ensure all the LUP and all the other plans are approved. A competent supervisor to supervise the task. 2.1.1 Plan the work involving the worker assigned for the task. 2.2.1 Ensure that the confined space is free from flammable, toxic atmosphere by gas testing. Page 1 of 6 JOB SAFETY ANALYSIS (JSA) Job: ROCK BREAKING, BACKFILLING & COMPACTION INSIDE THE CONFINED SPACES (EXCAVATIONS more than 1.2 m) FOR FOUNDATIONS Facility: AL JOUF BULK PLANT Work Area / Equipment: New Pump House, New Switch gear building, New Fire Station building, Close shelter, Open Shelter, fire Water tank Date: 07/31/2019 2.2.2 Ensure that the confined space is water wetted. 2.3.1 2.3.2 2.3.3 Wear safety shoes, full body coverall. Watch your steps while walking. Be careful from reptiles. 2.1 Fire, electrocution or explosion due to unauthorized commencement of work 2.1.1 Saudi Aramco certified WPR shall obtain and maintain valid CONFINED SPACE ENTRY as per Saudi Aramco G.I 2.100. A SA hot work permit shall be obtained per GI 2.100 for use of mechanical or heavy equipment with internal combustion engines. 2.2 Injury or fatality to the persons in the excavation. 2.2.1 A confined space entry permit shall be obtained to enter any excavation equal to or more than 1.2 m. 2.2.2 Ensure that the gas testing to be conducted prior to entry into the excavation and the work is only allowed if the reading are in the permissible limit as per CSM. 2.2.3 Ensure that any energized power line to be logged out and tagged out. 2.2.4 Ensure that the excavation is free from flooding hazard. 2.3 Environment hazards. 3- Obtaining Work Permit JSA Ref. No. JSA / JOUF / 13 2.1.2 Page 2 of 6 JOB SAFETY ANALYSIS (JSA) Job: ROCK BREAKING, BACKFILLING & COMPACTION INSIDE THE CONFINED SPACES (EXCAVATIONS more than 1.2 m) FOR FOUNDATIONS Facility: AL JOUF BULK PLANT 4- Excavations JSA Ref. No. JSA / JOUF / 13 Work Area / Equipment: New Pump House, New Switch gear building, New Fire Station building, Close shelter, Open Shelter, fire Water tank 3.1 Asphyxiation due to deficiency of oxygen in the confined space. 3.1.1 3.1.2 3.1.3 3.2 Injury or damage due to sliding of excavated material into the confined space. 3.2.1 3.3 Injury due to slip, trip and falls 3.3.1 3.2.2 3.3.2 3.3.3 3.4 Fatality due to exposed or underground high voltage power cables. 3.4.1 3.4.2 Date: 07/31/2019 Ensure that the gas testing is being done after every 30 minute and logged in the Gas Testing Log. Ensure that the Air compressor and other equipment are not parked close to the excavation to prevent the exhaust fumes to accumulate in the excavation. Ensure that the standby man is appointed to monitor the behavior of person working in the confined space. Ensure that the material is set back kept at least 0.6 m from the edge of excavation. Where ever required (as per CSM, SEC. Ensure that the proper mean of access or egress is provided with the maximum lateral travel distance of 7.5 m. Ensure that the excavation free from tripping hazards. Ensure that the access ladders are extended 1 m from the edge of the excavation. Mark, barricade and protect all the existing cables. Use UG cable detector prior to excavate the area. Page 3 of 6 JOB SAFETY ANALYSIS (JSA) Job: ROCK BREAKING, BACKFILLING & COMPACTION INSIDE THE CONFINED SPACES (EXCAVATIONS more than 1.2 m) FOR FOUNDATIONS Facility: AL JOUF BULK PLANT Work Area / Equipment: New Pump House, New Switch gear building, New Fire Station building, Close shelter, Open Shelter, fire Water tank JSA Ref. No. JSA / JOUF / 13 Date: 07/31/2019 5- Shoveling of excavated 4.1 Injury or fatality due to sliding of the 4.1.1 Ensure the heavy equipment (e.g excavator, dump truck etc.) is parked at material (by Excavator & heavy equipment into the excavation. the safe distance from the excavation (at least 3 m ). JCB) 4.1.2 Hard barricading by plastic jersey barriers shall be at 1 m from the edge to keep the heavy equipment at as safe distance from excavation. 6- . Backfilling & compaction 4.2 Injury due to striking 4.2.1 4.2.2 4.2.3 No one will be permitted to stand next to the heavy equipment. The area shall be barricaded around the excavator swing radius. Ensure that the competent and certified Heavy equipment operator performing the task. 4.3 Head Injury or fatality due to falling excavated rock debris. 4.3.1 4.3.2 4.3.3 The area shall be barricaded during the removal and loading of debris. All the workers in the area will wear all the PPE. The workers working inside the excavation (confined space) shall not be permitted to work while the excavated material is being loaded. 5.1 Fall / Trip / Slip 5.1.1 5.1.2 Maintain barricade while back filling and compaction. Only worker performing the backfilling and compaction will be allowed inside the excavation. Keep away unauthorized personnel. 5.1.3 Page 4 of 6 JOB SAFETY ANALYSIS (JSA) Job: ROCK BREAKING, BACKFILLING & COMPACTION INSIDE THE CONFINED SPACES (EXCAVATIONS more than 1.2 m) FOR FOUNDATIONS Facility: AL JOUF BULK PLANT Work Area / Equipment: New Pump House, New Switch gear building, New Fire Station building, Close shelter, Open Shelter, fire Water tank JSA Ref. No. JSA / JOUF / 13 Date: 07/31/2019 5.2 Injury due to machine 5.2.1 5.2.2 5.2.3 Only Inspected and Aramco approved equipment shall be used. Only trained and competent operator will operate the equipment. Daily maintenance log of the equipment shall be maintained. 5.3 Injury or illness due to exposure to dust, noise and vibration. 5.3.1 5.3.2 5.3.3 5.3.4 Continues water spray to control the dust. Use suitable dust masks. Hearing protection shall be used during the compaction. Impact resistant gloves shall be used 5.4 Accumulation of hazardous/toxic gases in the excavation because of working with equipment (i.e Hand Roller, Plate compactor etc.) 5.4.1 Regular monitoring by gas tester and maintain gas monitoring log. Emergency response: In case of emergency immediately report it on the following numbers, From Saudi Aramco Phone 911 From mobile phone 0138770911 Project Manager CRSE 0596562640 In case of minor Injury contact the first aiders at site. In case of medical a CRSE Ambulance is available is available at site Page 5 of 6 JOB SAFETY ANALYSIS (JSA) Job: ROCK BREAKING, BACKFILLING & COMPACTION INSIDE THE CONFINED SPACES (EXCAVATIONS more than 1.2 m) FOR FOUNDATIONS Facility: AL JOUF BULK PLANT JSA Originated by: Work Area / Equipment: New Pump House, New Switch gear building, New Fire Station building, Close shelter, Open Shelter, fire Water tank JSA Reviewed by: Project Name: Date: SAPMT Site Superintendent Approval: Name. __________________________ ID # . ___________________________ Signature: __________________________ SAMPT field safety compliance approval: Name. __________________________ ID # . ___________________________ Signature: __________________________ 6600043480 Upgrade Fire Water Protection and Industrial Drainage System-Al Jouf Asif Imran (Safety Supervisor) SAPMT approval: Date: 07/31/2019 Company Name: CRSE Contract No.: Joseph Palad (Civil Superintendent) JSA Ref. No. JSA / JOUF / 13 07/31/2019 JFBP OME review & approval Maintenance Foreman: Name. __________________________ ID # . ___________________________ Signature: __________________________ Operation Engr. Name. ___________________________ ID # . ____________________________ Signature: ___________________________ Maintenance Engineer: Name. __________________________ ID # . ___________________________ Signature: __________________________ Operation Foreman Name. __________________________ ID # . ___________________________ Signature: __________________________ Page 6 of 6