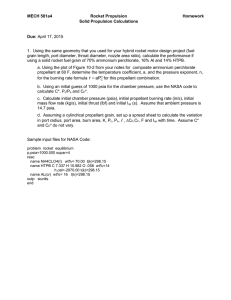

ROCKET PROPULSION By – Bijay Pal (Founder & Tech Head at Space Advancement & Research Cell) Slide 1 Out of 44 The Speech of President Sir John F. Kennedy PRINCIPALS OF ROCKETERY NEWTON'S THIRD LAW OF MOTION PRINCIPLE OF CONSERVATION OF LINEAR MOMENTUM CHEMICAL ENERGY TO KINETIC ENERGY REACTION FORCE FROM EXHAUST. WHAT IS PROPULSION ? Propulsion is the act of changing the motion of a body with respect to an inertial reference frame. Propulsion systems provide forces that either move bodies initially at rest or change their velocity or that overcome retarding forces when bodies are propelled through a viscous medium. Space Propulsion – Rocket launches – Controlling satellite motion – Maneuvering spacecraft Jet Propulsion Using the momentum of ejected mass (propellant) to create a reaction force, inducing motion Hello, I am Nuclea. I am very much excited to know about space , But I have a question from you all ! Could you tell me about the difference between Space and Jet propulsion? DIFFERENCE BETWEEN JET AND SPACE PROPULSION Jet Propulsion Space Propulsion • Air breathing engine (Duct Propulsion) • Non air breathing engine (Rocket Propulsion) • It cannot be operated in vacuum • Space travel possible • Thrust produced depends on altitude and flight velocity. • Trust production does not depends on altitude. • Friction increases with flight speed • Oxygen supply depends on atmospheric conditions. • It carries only fuel • It offers no surface drag. No gravitational effect. Rate of climb increases with altitude. • It carries oxidizer as well as fuel. SPACE PROPULSION APPLICATION • Launch Vehicles • Ballistic Missiles • Earth Orbiting Satellites • Upper Stages • Interplanetary Spacecraft • Manned Spaceflight SPACE PROPULSION TYPES Primary Propulsion – Launch – Maneuvering (Orbit transfer, station keeping, trajectory correction) Auxiliary Propulsion – Attitude control – Reaction control – Momentum management A SHORT HISTORY INTO ROCKETRY Dr.Wernher von Braun Dr. Robert H. Goddard Prof. Konstantin Tsiolkovsky China (300 B.C.) – Earliest recorded use of rockets – Black powder Russia (early 1900’s) – Konstantin Tsiolkovsky – Orbital mechanics, rocket equation United States (1920’s) – Robert Goddard – First liquid fueled rocket (1926) Germany (1940’s) – Wernher von Braun – V-2 – Hermann Oberth PROPULSION SYSTEM CLASSIFICATION • Stored S Gas Chemical Electric • Electrothermal • Electrostatic • Electrodynamic Solid Liquid Gas Pressure Fed Pump Fed Bipropellant Monopropellant Advanced • Nuclear • Solar thermal • Laser • Antimatter Stored Gas Propulsion Propellent Tank GAS Fill Valve P Pressure Gauge High Pressure Installation Valve Filter Pressure Regulator Low Pressure Isolation Valve • Primary or auxiliary propulsion. • High pressure gas (propellant) is fed to low pressure nozzles through pressure regulator. • Release of gas through nozzles (thrusters) generates thrust. • Currently used for momentum management of the Spitzer Space telescope. • Propellants include nitrogen, helium, nitrous oxide, butane. Thruster • Very simple in concept. CHEMICAL PROPULSION CLASSIFICATION • Liquid Propellant – Pump Fed • Launch vehicles, large upper stages – Pressure Fed • Smaller upper stages, spacecraft – Monopropellant • Fuel only – Bipropellant • Fuel & oxidizer • Solid Propellant – Launch vehicles, Space Shuttle, spacecraft – Fuel/ox in solid binder • Hybrid – Solid fuel/liquid ox – Sounding rockets, X Prize Monopropellant Systems Nitrogen Or Helium Hydrazine Propellent Tank Fuel Fill Valve Pressure Gauge Isolation Valve Filter • Hydrazine fuel is most common monopropellant– N2H4 • Decomposed in thruster using catalyst to produce hot gas for thrust. • Older systems used hydrogen peroxide before the development of hydrazine catalysts. •Aerojet S-405, Granular alumina or Aluminium oxide coated with Iridium Thrusters Bipropellant systems OX Fuel P P Isolation Valve Chamber Engine Nozzle • A fuel and an oxidizer are fed to the engine through an injector and combust in the thrust chamber. • Hypergolic: no igniter needed -propellants react on contact in engine. • Cryogenic propellants include LOX (423 ºF) and LH2 (-297 ºF). – Igniter required • Storable propellants include kerosene (RP-1), hydrazine, nitrogen tetroxide (N2O4), monomethyl hydrazine (MMH) PUMP FED SYSTEMS Propellant delivered to engine using turbopump • Gas turbine drives centrifugal or axial flow pumps – Large, high thrust, long burn systems: launch vehicles, space shuttle – Different cycles developed (Gas Generator, Expander Cycle, Staged Combustion) SOLID PROPELLENT MOTORS • Fuel and oxidizer are in solid binder. • Single use -- no restart capability. • Lower performance than liquid systems, but much simpler. • Applications include launch vehicles, upper stages, and space vehicles. HYBRID PROPELLENT MOTOR • Combination liquid-solid propellant – Solid fuel – Liquid oxidizer • Multi-start capability – Terminate flow of oxidizer • Fuels consist of rubber or plastic base, and are inert. – Just about anything that burns… • Oxidizers include LO2 , hydrogen peroxide (N2O2 ) and nitrous oxide (NO2 ) • Shut-down/restart capability SOLID ROCKET A solid rocket motor is a system that uses solid propellants to produce thrust Advantages Disadvantages – High thrust – Simple – Storability – High density ISP – Low ISP (compared to liquids) – Complex throttling – Difficult to stop and restart – Safety SOLID ROCKET COMPONENTS Thrust Vector control Animation THE NOZZLE • The design of the nozzle follows similar steps as for other thermodynamic rockets – Throat area determined by desired stagnation pressure and thrust level – Expansion ratio determined by ambient pressure or pressure range to allow maximum efficiency • Major difference for solid propellant nozzles is the technique used for cooling – Ablation – Fiber reinforced material used in and near the nozzle throat (carbon, graphite, silica, phenolic IGNITION SYSTEMS • Large solid motors typically use a three-stage ignition system – Initiator: Pyrotechnic element that converts electrical impulse into a chemical reaction (primer) – Booster charge – Main charge: A charge (usually a small solid motor) that ignites the propellant grain. Burns for tenths of a second with a mass flow about 1/10 of the initial propellant grain mass flow. PROPELLENT TYPES Double Base Composite A homogeneous propellant grain, usually nitrocellulose dissolved in nitroglycerin. Both ingredients are explosive and act as a combined fuel, oxidizer and binder. A heterogeneous propellant grain with oxidizer crystals and powdered fuel held together in a matrix of synthetic rubber binder. CONVENTIONAL PROPELLENT Fuel (5-22% Powdered Aluminium) Oxidizer (65-70% Ammonium Perchlorate (NH4ClO4 or AP) Binder (8-14% Hydroxyl-Terminated Polybutadiene (HTPB)) FUELS WE COMMONLY USE Aluminium (Al) Magnesium (Mg) Beryllium (Be) – Molecular Weight: 26.98 kg/kmol – Density: 2700 kg/m3 – Most commonly used – Molecular Weight: 24.32 kg/kmol – Density: 1750 kg/m3 – Clean burning (green) – Molecular Weight: 9.01 kg/kmol – Density: 2300 kg/m3 – Most energetic, but extremely toxic exhaust products BINDERS To form a powdered propellant into a sturdy and durable propellant grain, you have to convert it into a solid stick, and you do this with a material called a binder. A binder can be anything that, when added to the propellant. fills in the spaces between the particles, and glues the whole mass together. Ideally, a binder should take part in the combustion reaction, so rocket makers normally choose a binder that doubles as a fuel. Hydroxyl Terminated Polybutadiene (HTPB) – Most commonly used – Consistency of tire rubber Nitrocellulose (PNC) Polybutadiene Acrylonitrile(PBAN) – Double base agent HOW MUCH ENERGY DO WE NEED TO PUT 1KG OF PAYLOAD INTO ORBIT AT 400 KM? Soln:- There are two types of Energy related to it . • Potential Energy • Kinetic Energy So, Total energy = P.E + K.E (Potential energy + Kinetic Energy ) CALCULATION Potential Energy Calculation Kinetic Energy Calculation Potential Energy = m×g×h Kinetic Energy = × 𝑚𝑣 2 P.E = 1Kg × 9.8m/s× 400,000m P.E = 3.92 × 106 Joules 1 2 K.E = 0.5× 1𝑘𝑔 × (8 × 103 𝑚Τ 𝑠 )2 K.E = 3.2× 107 𝐽𝑜𝑢𝑙𝑒𝑠 Total Energy = K.E + P.E =) 3.6× 107 𝐽𝑜𝑢𝑙𝑒𝑠 Where, 1 Joule = 1 watt-sec So, 36 Megajoule = 3.6 × 107 𝑤𝑎𝑡𝑡 − 𝑠𝑒𝑐 It is as similar as 10Kilowatts of energy (When Converted) , And cost of 1Kwh Of energy <$1 SO, WHY DO WE SPEND LAKHS OF DOLLARS TO DO SO ? Answer :) Because, we have to carry the payload in rockets and for the last bit we need to carry all the propellent with us to reach the orbital velocity or, we will fall off from space due to drag. To carry the payload of 1 Kilogram we need propellent and to carry that propellent we need more propellent and doing that add’s tons of Kilograms to the rocket . And, the cost to put 1 kilogram of Payload to orbit becomes $10,000-$20,000 Hence, making it very very Expensive DERIVING THE IDEAL ROCKET EQUATION Payload 𝑀𝑃𝑎𝑦 Payloa 𝑇𝑜𝑡𝑎𝑙 𝑀𝑎𝑠𝑠 = 𝑀𝑃𝐴𝑌 + 𝑀𝑃𝑅𝑂𝑃 + 𝑀𝑆𝑇𝑅𝑈𝐶 (During the initial stage) Mass of rocket Fuel Propellent 𝑀𝑃𝑟𝑜𝑝 𝑀𝑖 = 𝑀𝑃𝑎𝑦 + 𝑀𝑃𝑟𝑜𝑝 + 𝑀𝑠𝑡𝑟𝑢𝑐 𝑀𝑓𝑖𝑛𝑎𝑙 = 𝑀𝑃𝑎𝑦 +𝑀𝑆𝑡𝑟𝑢𝑐 , 𝑂𝑟 Oxidizer Structure 𝑀𝑆𝑡𝑟𝑢𝑐 𝑀𝑓𝑖𝑛𝑎𝑙 = 𝑀𝑖 − 𝑀𝑝𝑟𝑜𝑝 ROCKET THRUST EQUATION Nozzle 𝑚ሶ Fuel Oxidizer Thrust = (𝑚ሶ × 𝑣𝑒 ) + (𝑝𝑒 − 𝑝0 ) × 𝑎𝑒 𝑣𝑒 𝑝𝑒 𝑎𝑒 𝑚ሶ = 𝑚𝑎𝑠𝑠 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒 𝑝𝑒 = 𝑃𝑟𝑒𝑠𝑠𝑢𝑟𝑒 𝑣𝑒 = 𝐸𝑥ℎ𝑎𝑢𝑠𝑡 𝑣𝑒𝑙𝑜𝑐𝑖𝑡𝑦 Exhaust Basically , Assure we have crossed the atmosphere and we are in free space (Ignore the pressure . So we get Forward Thrust = 𝑚ሶ × 𝑣𝑒 𝑇ℎ𝑖𝑠 𝑖𝑠 𝑡ℎ𝑒 𝑐𝑜𝑛𝑠𝑒𝑟𝑣𝑎𝑡𝑖𝑜𝑛 𝑜𝑓 𝑙𝑖𝑛𝑒𝑎𝑟 𝑚𝑜𝑚𝑒𝑛𝑡𝑢𝑚 . ROCKET EQUATION (IN FREE SPACE) 𝐹 = 𝑚ሶ × 𝑣𝑒 We can write it as, 𝐹 = −𝑉𝑒𝑥ℎ𝑎𝑢𝑠𝑡 × 𝑑𝑚ൗ𝑑𝑡 − eqn 1 According, to Newtonian physics (F = ma) F = m× 𝑑𝑣Τ 𝑑𝑡 , −𝑒𝑞𝑛 2 On Comparing equation(1) , equation(2) F =−𝑉𝑒𝑥ℎ𝑎𝑢𝑠𝑡 × 𝐹 = −𝑉𝑒𝑥ℎ𝑎𝑢𝑠𝑡 𝑑𝑚Τ 𝑑𝑡 𝑑𝑚Τ 𝑚 =𝑚× 𝑑𝑣Τ 𝑑𝑡 , = 𝑑𝑣, 𝑑𝑣 = −𝑉𝑒𝑥ℎ𝑎𝑢𝑠𝑡 𝑑𝑚ൗ𝑚 , Now, Lets initialize from initial stage to final stage. CONTINUED.. 𝑑𝑣 = −𝑉𝑒𝑥 𝑑𝑚ൗ𝑚 , Integrating the equation 𝑣𝑡 𝑚𝑓 න 𝑑𝑣 = −𝑉𝑒𝑥 න 𝑑𝑚ൗ𝑚 , 𝑣𝑖 𝑚𝑖 𝑉𝑓 − 𝑉𝑖 = −𝑉𝑒𝑥 ln(𝑚𝑓ൗ𝑚𝑖) , 𝑉𝑓 − 𝑉𝑖 = 𝑉𝑒𝑥 ln 𝑚𝑖ൗ𝑚𝑓 , ∆𝑉 = 𝑉𝑒𝑥 ln(𝑚𝑖ൗ𝑚𝑓 ) Hence, we derived the famous Rocket Equation at this point. ROCKET EQUATION ∆𝒗 = 𝒗𝒆𝒙 𝒍𝒏 ( 𝒎𝒇ൗ 𝒎𝒊) “The amount of change in velocity that we can get by burning a certain amount of propellent is equal to exhaust velocity coming out of the rocket times the natural logarithm of the ratio of the initial mass to the final mass of rocket.” This equation tells you how much you can increase the velocity of the rocket in a certain amount of propellent or slow down if you want to do so. This Propellent fraction tells us how much propellent we require to achieve certain amount of velocity to cross the earth. PERFORMANCE FACTORS Thrust Specific impulse Effective exhaust velocity Total impulse Thrust coefficient Characteristic velocity THRUST CALCULATION 𝑭𝑻 = 𝒎ሶ × 𝑽𝒆 + 𝑷𝒆 − 𝑷𝟎 × 𝑨𝒆 , Where , 𝒎ሶ = 𝑅𝑎𝑡𝑒 𝑜𝑓 𝑚𝑎𝑠𝑠 𝑓𝑙𝑜𝑤𝑖𝑛𝑔 𝑜𝑢𝑡 𝑜𝑓 𝑟𝑜𝑐𝑘𝑒𝑡 𝑉𝑒 = 𝐸𝑥ℎ𝑎𝑢𝑠𝑡 𝑉𝑒𝑙𝑜𝑐𝑖𝑡𝑦 𝑜𝑓 𝑡ℎ𝑒 𝑟𝑜𝑐𝑘𝑒𝑡 , 𝑃𝑒 = 𝐸𝑥𝑖𝑡 𝑃𝑟𝑒𝑠𝑠𝑢𝑟𝑒 , 𝑃0 = 𝐴𝑚𝑏𝑖𝑒𝑛𝑡 𝑃𝑟𝑒𝑠𝑠𝑢𝑟𝑒, 𝐴𝑒 = 𝐸𝑥𝑖𝑡 𝐴𝑟𝑒𝑎 𝑁𝑜𝑧𝑧𝑙𝑒 , 𝐹𝑇 = 𝐹𝑜𝑟𝑤𝑎𝑟𝑑 𝑇ℎ𝑟𝑢𝑠𝑡. SPECIFIC IMPULSE CALCULATION (I OR 𝑰𝒔𝒑 ) “The ratio of thrust / ejects mass flow rate is used to define a rocket’s specific impulse-best measure of overall performance of rocket motor.” 𝐼𝑆𝑝 𝐹𝑇 = 𝑚ሶ Where, 𝐼𝑠𝑝 = 𝑆𝑝𝑒𝑐𝑖𝑓𝑖𝑐 𝐼𝑚𝑝𝑢𝑙𝑠𝑒 𝐹𝑇 = 𝐹𝑜𝑟𝑤𝑎𝑟𝑑 𝑇ℎ𝑟𝑢𝑠𝑡, 𝑚ሶ = 𝑚𝑎𝑠𝑠 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒 . TOTAL IMPULSE 𝑡𝑏 𝐼𝑇𝑜𝑡𝑎𝑙 = න 𝐹𝑇 𝑑𝑡 0 Where, 𝑡𝑏 = 𝑡𝑖𝑚𝑒 𝑜𝑓 𝑏𝑢𝑟𝑛𝑖𝑛𝑔 . 𝐴𝑛𝑑, 𝐼𝑓 𝐹𝑇 𝑖𝑠 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡 𝑑𝑢𝑟𝑖𝑛𝑔 𝑏𝑢𝑟𝑛 𝑡ℎ𝑒𝑛 𝐼𝑇𝑜𝑡𝑎𝑙 = 𝐹𝑇 × 𝑡𝑏 • Thus the same total impulse may be obtained by either : • high FT, short tb (usually preferable), or • low FT, long tb • Also, for constant propellant consumption (ejects) rate : 𝑰𝑻𝒐𝒕𝒂𝒍 = 𝑭𝑻 × 𝒎 ×ሶ 𝒕𝒃 𝒎ሶ THRUST COEFFICIENT (𝑪𝒇 ) 𝐹𝑇 𝐶𝑓 = 𝑃𝑐 × 𝐴 𝑇 Where, 𝑃𝑐 = Combustion Chamber Pressure, 𝐴 𝑇 = 𝑁𝑜𝑧𝑧𝑙𝑒 𝑇ℎ𝑟𝑜𝑎𝑡 𝑎𝑟𝑒𝑎, CHARACTERISTIC VELOCITY (C*) C* 𝑃𝑐 ×𝐴𝑇 = ሶ 𝑚 • Calculated from standard test data. • It is independent of nozzle performance and is therefore used as a measure of combustion efficiency dominated by Tc (combustion chamber temperature). BOOKS, I RECOMMEND THANK-YOU (SPACE ADVANCEMENT AND RESEARCH CELL)