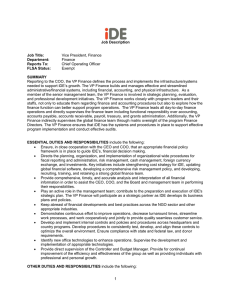

IDE - APPROVED 11/11/20 Formosa Injection Quills Project no. 00503 EP-17742 Rev. 00 Revision Notes Revision History Rev. Date Name Description P0 14.4.20 O. Yamin First Revision 00 3.11.20 O. Yamin For procurement Revision Approval IDE - APPROVED 11/11/20 Name Signature Date Prepared O. Yamin 04.11.2019 Checked R. Luzia 04.11.2019 QA Approved T. Kinar 04.11.2019 Approved L. Baum 04.11.2019 Table of Contents Revision Notes 2 1. General 4 1.1. Description 4 1.2. Scope of supply 4 Quality Control Requirements 7 2.1. Documentation to Be Submitted 7 .2.2 Quality Control Inspection by the Vendor 7 2.3. Delivery approval 7 2.4. Quality Control Inspection by IDE at Warehouse on site 7 IDE - APPROVED 11/11/20 2. 1. General 1.1. Description Chemical Injection Quills are used to introduce medium to highly corrosive chemicals into a process pipeline without damage to the side port or pipe wall at the point of injection. Chemical injection quills ensure that chemicals are evenly dispersed into the center of the pipeline, which prevents channeling of the chemical down the pipe wall Quills are designed to withstand the reaction between the chemical and process fluid and are constructed with chemical resistant material. 1.2. Scope of supply Supply of injection quills as per MTO-00403. PT NUMBER Description MOC PT-00090235 PT-00090236 PT-00091575 PT-00118278 PT-00119040 PT-00119041 PT-00119042 INJECTION QUILL 2" FL. ANSI 150 1" L=400 FOR 20" PROCESS PIPE INJECTION QUILL 2" FL. ANSI 150 1" L=235 FOR 6" PROCESS PIPE INJECTION QUILL 2" FL. ANSI 150 1" L=290 FOR 10" PROCESS PIPE HAST. INJECTION QUILL 2" FL. ANSI 300 1/2" L=240 FOR 6" PROCESS PIPE INJECTION QUILL 2" FL. ANSI 150 1" L=680 FOR 48" PROCESS PIPE INJECTION QUILL 2" FL. ANSI 150 1" L=550 FOR 32" PROCESS PIPE INJECTION QUILL 2" FL. ANSI 150 1" L=760 FOR 56" PROCESS PIPE CS + PTFE lining CS + PTFE lining CS + PTFE lining Hastelloy CS + PTFE lining CS + PTFE lining CS + PTFE lining IDE - APPROVED 11/11/20 All the injection quills shall be supplied with 2" flanged end connection as per injection points nozzles (refer Fig.1 & Fig.2). All injection quills shall be supplied with proper length mentioned in MTO-00403 with respect to the process pipe diameter. All injection quills shall be designed and constructed with respect to the dosing chemicals. The design pressure of the CS + PTFE Lined quills shall be 10 bar unless specified otherwise. The design pressure of the HASTELLOY quills shall be 35 bar unless specified otherwise. The design temperature shall be from 7-48 deg Celsius. The supply should be as per the MTO-00403. Fig. 1 DOSING LINE FLANGE 2" INJECTION QUILL INJECTION NOZZLE IDE - APPROVED 11/11/20 PROCESS PIPE IDE - APPROVED 11/11/20 FORMOSA BOP NON METALLIC QUILLS EP-17742 REV.P0 2. Quality Control Requirements 2.1. Documentation to Be Submitted Table 1 list the documents, certificates and test reports to be submitted by the vendor, and the milestones for submission. Submission of these certificates and test reports is mandatory, unless stated otherwise in IDE’s purchase order. The documents will be in the English language. Table 1 – Documents to be submitted to IDE and their milestones Document Description Document Type Due Date from PO (Weeks) Comments include main dimensions and essential interface dimensions Certified Drawings DWG-Drawing 2 Datasheet DTS-Data Sheet 2 EN- 10204/2.1 material certificates CRT-Certificate 2 before delivery Comply with dosing chemicals COC - Certificate of Compliance stating full compliance with the order CRT-Certificate 2 before delivery in accordance with EN 10204/2.1 2.2. Quality Control Inspection by the Vendor The equipment/items shall be manufactured and inspected in accordance with this technical specification and any other technical codes as specified, to ensure compliance to the technical specification requirements. Test equipment used by the vendor will be calibrated by a certified laboratory. 2.3. Delivery approval The equipment will be released for delivery only after IDE approval of the test reports/quality certificates that must be submitted by the vendor. IDE might reject equipment or items that do not comply strictly with all the technical requirements of IDE’s technical specification and any other technical codes as defined and agreed upon. IDE - APPROVED 11/11/20 2.4. Quality Control Inspection by IDE at Warehouse on site If the equipment is IDE responsibility, IDE will perform an incoming inspection of its purchased equipment. The inspection is performed in accordance with IDE internal procedures. FORMOSA BOP NON METALLIC QUILLS IDE PROPRIETARY AND CONFIDENTIAL 7 IDE - APPROVED 11/11/20 FORMOSA BOP NON METALLIC QUILLS EP-17742 REV.P0 Supplier * Tel: * Fax: * Web * Email * Agent * FORMOSA BOP NON METALLIC QUILLS IDE PROPRIETARY AND CONFIDENTIAL 8