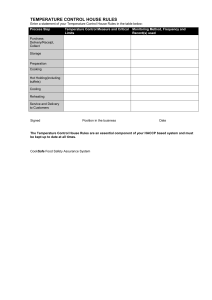

Marriott International Global HACCP Plan Published: June 2010 Questions regarding Marriott’s HACCP Plan can be sent to Global Food Safety at: globalfoodsafety@marriott.com Information contained in this document represent Marriott International’s food safety protocols, global standards and critical limit requirements. Local jurisdiction’s codes that are more stringent must be followed at all times and supersede the requirements contained within. Global HACCP Plan CONTENTS ABSTRACT Objectives and Definition Top Food Borne Illness Risk Factors Food Safety Management System Advantages PREREQUISITE PROGRAMS Standard Operating Procedures Food Contamination Control CRITICAL CONTROL POINTS/CRITICAL LIMITS General Receiving Storage and Preparation Cooking, Cooling, Reheating, Cold and Hot Food Holding, Time in Lieu of Temp. MONITORING/CORRECTIVE ACTIONS Sample Logs PROCESS HACCP PLANS FOR RESTAURANTS Food Preparation Process Explanation Food Preparation Process #1 Food Preparation Process #2 Food Preparation Process #3 Sample HACCP Logs for Process Plans VERIFICATION AND RECORD KEEPING Process GLOBAL FOOD SAFETY BRAND STANDARDS Cleaning and Sanitizing Facility/Controls Food Handling Food Safety Documentation Food Safety Equipment and Utensils Food Storage Personal Hygiene Temperature Control FOOD QUALITY AND SAFETY STANDARDS Fresh Beef Steaks Fresh/Frozen Fish Frozen Chicken Preparing Melons Leafy Greens and Vegetables Frozen Burgers Fresh Burgers Ground Beef Patties Receiving Log Fabricating Ground Beef Patties Citrus Fruits for Food and Drinks Gratis Beverages Fresh Poultry Fresh Shellfish GLOSSARY Terms REFERENCE Web resources Page 3 4 4 5-7 8-10 11 11-13 14 15-21 22 23 24 25 26-28 29 30-31 32 33-34 35-36 37-38 39 40-41 42-43 44 45-46 47 48 49 50 51-53 54 55-58 59 60-61 62 63 64 65 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 2 Global HACCP Plan ABSTRACT The Global HACCP Plan has been created to consolidate and formalize existing food safety brand standards and their extensive related tools. The Plan’s key objectives include: • Ensure Marriott International has a comprehensive food safety management system to control risk factors that may lead to food borne outbreaks. • Protection of guests and associates from public health risks relating to the storage, handling and consumption of potentially hazardous foods. • Provide active managerial controls that include training, vendor specifications, record keeping, employee health policy, quality control, monitoring procedures, establishment of critical limits and control points. HACCP Definition: Hazard Analysis and Critical Control Points (HACCP) is a process control system designed to identify and prevent microbial and other hazards in food production. It includes steps designed to prevent problems before they occur and to correct deviations as soon as they are detected. Such preventive control systems with documentation and verification are widely recognized by scientific authorities and international organizations as the most effective approach available for producing safe food. All HACCP plans must contain seven principles. These principles are included in this plan and are reflected in the Global Brand Standards. https://extranet.marriott.com/marriottstandards/openMultipleDetail.aspx?id=2857,2859,2 852,2853,2856,2858,2854,2855 Principle 1: Conduct a hazard analysis. Determine the food safety hazards and identify preventive measures to control these hazards. Principle 2: Identify critical control points. A critical control point (CCP) is a point, step, or procedure in a food process at which control can be applied and, as a result, a food safety hazard can be prevented, eliminated, or reduced to an acceptable level. Principle 3: Establish critical limits for each critical control point. A critical limit is the maximum or minimum value to which a physical, biological, or chemical hazard must be controlled at a critical control point to prevent, eliminate, or reduce to an acceptable level. Principle 4: Establish critical control point monitoring requirements. Monitoring activities are necessary to ensure that the process is under control at each critical control point. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 3 Global HACCP Plan ABSTRACT Principle 5: Establish corrective actions. These are actions to be taken when monitoring indicates a deviation from an established critical limit. Principle 6: Establish procedures for verifying the HACCP system is working as intended. Validation ensures that hotels are successful in ensuring the production of safe product. Principle 7: Establish record keeping procedures. All hotels must maintain certain documents, including its records documenting the monitoring of critical control points, critical limits, verification activities, and the handling of processing deviations. Top Food Borne Illness Risk Factors These five broad categories of contributing factors directly relate to food safety concerns within food service establishments. Marriott International mandates managerial control of these factors. 1. 2. 3. 4. 5. Food from unsafe sources Inadequate cooking Improper holding temperatures Contaminated equipment Poor personal hygiene Food Safety Management System Advantages Reduction in product losses Increased product quality Better inventory control Consistency of preparation Increased profit Increased associate awareness and participation in food safety practices 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 4 Global HACCP Plan PREREQUISITE PROGRAMS Standard Operating Procedures Approved Vendor Requirement Foods and ingredients must come from inspected commercial suppliers, be wholesome and in good condition. All purchases of foods that will be consumed by guests or associates shall come from suppliers that are audited yearly for sanitation, quality and hygiene standards. Allergen Awareness Training It is recommended that associates whose job it is to provide food and beverage to our valued guests are encouraged to take this course. Food Allergens Course Calibration of Food Thermometers All thermometers used to monitor critical limits must be calibrated at least two times per week and more often if necessary. Conditions when re-calibration must occur: dropping thermometer using a new thermometer for the first time Thermometer Calibration Log ChefTec Recipe Procedure All hotels must utilize Marriott International’s standard recipe database to ensure product integrity. Employee Illness Restriction and Exclusion Policy Associates diagnosed with Salmonella Typhi, Shigella, Shiga Toxin-Producing E-Coli, Hepatitis A or Norovirus must be excluded from work and may not return without medical documentation. Hotels are required to notify the local public health jurisdiction. Associates with the following symptoms must be restricted from the food preparation areas. • Vomiting • Fever • Sore throat with fever • Jaundice • Open sores on their hands or forearms • Diarrhea Associate Illness Policy Exhaust hoods and ductwork system must be professionally cleaned and maintained Professional cleaning must be performed at least every 6 months. An inspection sticker must be affixed to the hood. Floors, walls and ceilings must be free of excessive dust, debris and standing water Structures must be kept sanitary using a cleaning schedule. A cleaning checklist must include the following: Doors and windows Under counters Floor/wall junctions All hand contact areas Floor drains Control of mold 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 5 Global HACCP Plan PREREQUISITE PROGRAMS Standard Operating Procedures (cont) Floors, walls and ceilings must be smooth, easily cleanable, and in good repair Exposed concrete blocks and bricks must be sealed and smooth unless area is used only for dry storage. Carpeting in food production areas is prohibited Floors that are cleaned by water flushing methods must be coved and sealed at the wall juncture Food Manager Certification Requirement A minimum number of food safety managers must be certified in food safety. Positions and number vary by hotel brand and size and the certification is valid for five years. Certification must take place within 60 days of initial employment. Marriott Global Source - Food Safety Certification Food Safety Training Requirement for Non-Management Associates All non-management food handlers must be certified every two years using the Great Food Safe Food training program or the approved management training program. Training must take place within 60 days of initial employment. Marriott Global Source - Great Food Safe Food Food Borne Outbreak Reporting Protocol A current copy of the Food Borne Illness Notification (FBIN) Procedures must be obtained by February 28 of each New Year. The procedures contained in the protocol must be used for the reporting of any suspected food borne outbreak. Marriott Global Source - Food Borne Illness Notification Procedures Monthly Food Safety Self-Inspection Requirement Hotel must minimally conduct a monthly Food Safety self-inspection and document the deficiencies and corrective action. Self Audit Original containers of toxic materials must have a legible manufacturer's label Working containers of cleaners and sanitizers must be labeled with the common name of the product. All chemicals in all containers must be accurately labeled Original containers must have a legible manufacturer's label Working containers such as spray bottles must be labeled with common names such as "Sanitizer" or "Window Cleaner" All unlabeled liquids must be considered a potentially toxic material 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 6 Global HACCP Plan PREREQUISITE PROGRAMS Standard Operating Procedures (cont) Pest Prevention Program Must Be Adopted and Effective Hotels must minimally use a pest sighting log. The following are signs that the prevention program is not effective. Fresh pest droppings Active cockroaches or rodents in food prep and storage areas Trailing ants Birds inside the hotel or nesting on the outside of the building if their droppings create a sanitation issue Pest Sighting Log Refrigerators All refrigerated (but not frozen) storage units are required to have thermometers that accurately reflect the ambient temperature in the warmest part of the unit. If built in devices are absent or not working, hanging thermometers are adequate. One or the other must be present and working in each unit. A3 log Ventilation must be adequate and vents, fan guards and filters clean Dirty fans and ceiling vents can be a source of product contamination. Ceiling air vents and returns must not have dust build-up Exhaust hood ventilation systems must not have grease build-up Air fans must be cleaned regularly Yearly Food Safety Audit Requirement All hotels regardless of brand or location shall be subject to an annual food safety review of all food preparation areas, restaurants, storage areas, back dock areas, banquet facilities or any other food related operations deemed appropriate. Audit forms 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 7 Global HACCP Plan PREREQUISITE PROGRAMS Food Contamination Control Cutting Board System Requirements Minimally hotels must use at least two separate boards for the preparation of food. It is acceptable to use a multiple color cutting board system for non ready-to-eat food items. • White for ready to eat food only • One other color for raw food Wood cutting boards may ONLY be used for: • Butcher blocks • Bakery worktables • Food displays o Chinese kitchens (International), for general use, provided the following are met: Boards are properly maintained and marked for product use Separate boards used for chicken, fish, raw and cooked products All blocks must be scraped, washed and sanitized daily Employee Hygiene Policy Eating, drinking and tobacco use is restricted to nonfood areas. Tasting food is allowed from single serve tasting spoons or at formal documented taste panels. Chewing gum and chewing tobacco are considered eating. There must be no eating and tobacco use in areas with exposed: • Food • Food contact surfaces • Food-contact packaging Drinking is allowed in a food production area if: • Using a cup with lid and straw • If the container is stored so that it will not contaminate food preparation surfaces Food workers must not contact ready-to-eat foods with bare hands All ready-to-eat food (food intended to be eaten without further cooking) must be portioned and served without contacting bare hands. • Utensils, gloves, individual wax papers, etc., are appropriate alternatives if used correctly. Food and food contact surfaces must be protected from potential microbiological, physical and chemical hazards at all times Hazards listed below must be avoided. • Raw animal products stored above or commingled with ready-to-eat products • Physical hazards that would present an imminent health hazard, such as push pins used directly above food prep surfaces. • Chemicals stored above food or food contact surfaces Proper storage examples Where complete vertical separation is not possible, raw poultry must be stored on the bottom and ready-to-eat items must be stored on top. Items with the greatest internal required cooking temperatures must be stored on the lowest shelf. All other products should be stored in between and not commingled. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 8 Global HACCP Plan PREREQUISITE PROGRAMS Food Contamination Control (cont.) Food and food contact packaging must be properly stored The standard gap is 6 inches (15 centimeters) off the floor. This gap facilitates cleaning, protects products from spills and allows monitoring for pest activity. Disposable plastic containers must not be reused for food storage Cottage cheese tubs, mayonnaise/pickle pails and sour cream containers are some examples. Hand Washing Requirement Hands that may have become contaminated must be washed frequently. Food handlers must wash hands frequently using warm water and soap for 20 seconds and dry using disposable towels or a heated- air hand drying device. Mandatory Use of Sanitizer Test Kits Test kits must be readily available for each chemical sanitizer used. • Test kits buried in drawers or in the original aluminum foil wrap are not considered readily available • The calibration of automatic dispensing systems should be tested at least daily • When mixed by hand, each sanitizer batch should be tested prior to use Original containers of toxic materials must have a legible manufacturer's label Working containers of cleaners and sanitizers must be labeled with the common name of the product. All chemicals in all containers must be accurately labeled Original containers must have a legible manufacturer's label Working containers such as spray bottles must be labeled with common names such as "Sanitizer" or "Window Cleaner" All unlabeled liquids must be considered a potentially toxic material Food contact surfaces must be properly cleaned and sanitized Surfaces must be cleaned and sanitized at least every 4 hours during continuous use with a potentially hazardous food at room temperature. • Times vary if the surface or room is refrigerated. If held from: <50°F to 55°F (10°C to 13°C), clean at least every 10 hours <45°F to 50°F (7°C to 10°C), every 16 hours <41°F to 45°F (5°C to 7°C), every 20 hours 41°F (5°C), or below, every 24 hours 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 9 Global HACCP Plan PREREQUISITE PROGRAMS Food Contamination Control (cont.) Foods must be protected from contamination Hotel operators must protect all foods from contamination during preparation and serving including condensation above exposed food or food contact surfaces. • Foods must be protected from receiving through serving to prevent contamination • Foods in freezers and coolers must be covered unless in the process of cooling • Individual food carts may be bagged or each tray may be covered individually • Freezers must not have heavy build-up of frost/ice on the exterior of the boxes 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 10 Global HACCP Plan CRITICAL CONTROL POINTS AND CRITICAL LIMITS General Receiving Minimum Receiving Temperature Requirements Finfish (Fresh): 38° F (3° C) Quality Attributes of Food Groups Firm and elastic flesh. No abnormal odors. Bright red and moist gills, Clear bulging eyes, Vibrant skin color. Beef (Fresh): 41º F (5° C) Firm and elastic flesh. No abnormal odors. Bright cherry red flesh, Bright white fat and marbling. Pork (Fresh): 41º F (5° C) Firm and elastic flesh. No abnormal odors. Bright pink flesh, Bright white fat and marbling. Dairy/Eggs: 45º F (7° C) Is delivered with non-expired “Use-By” date. Yolks do not break easily. Dairy has fresh, sweet aroma. Produce: 41º F (5° C) Delivered free of heavy dirt, and with characteristic color, flavor and aroma of quality ripened products. Frozen Products: 10º F (-12° C) Solid frozen. No signs of freezer burn or ice crystals. IQF products should not be frozen together. Shellfish: 41º F (5° C) Only live products are acceptable. Discard cracked and dead items. Retain tags for 90 days. Shelf life is 7-10 days. Storage and Preparation Beef Upon receipt, immediately refrigerate fresh beef steaks to 34ºF to 38°F (1ºC to 3°C). Hold steaks in their sealed packages in the original cases. Check the invoice for accuracy and record the delivery date on the case if no date is visible. Shelf life for sealed fresh cut steaks is 10 days. Do not accept steaks that have been cut for more than two (2) days prior to receipt. Citrus Fruits Citrus varieties like lemons, limes, grapefruit and oranges require special treatment. Upon receiving citrus fruits, store them in the original cases. The outer rind of these fruits can trap dirt and may contain harmful bacteria from the soil. Fruits must be washed and sanitized before cutting. • Rinse the fruits in cold water • Dip in the approved fruit and vegetable wash for at least 30 seconds When removing the rind or cutting the fruit for use in cocktails, water or iced tea; use a clean and sanitized white cutting board. Use a clean and sanitized knife to prevent cross-contamination when cutting. • Use food handler’s gloves during preparation • When storing prepared fruits, use a clean container and do not mix items • Keep prepared citrus chilled at or below 41°F or 5°C Fish Fresh fish is to be received packed in ice. Store fish immediately immersed in flaked or crushed ice. Internal temperature of fish should be 32º-34ºF (0º-1ºC). Only products from an approved seafood purveyor may be used. No local sport harvested species may be used at any time. At no time may any hotel or restaurant foodservice facility vacuum pack fresh seafood of any kind. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 11 Global HACCP Plan CRITICAL CONTROL POINTS AND CRITICAL LIMITS Storage and Preparation (cont.) Frozen Poultry Purchase chicken from approved vendors only. Frozen chicken must be received with no evidence of previous thawing. Store frozen chicken immediately upon delivery. Place on lowest shelves of freezer or refrigerator to prevent possible cross-contamination. Date product to assure First In, First Out (FIFO) usage. Thaw frozen chicken under refrigeration 36º-38ºF (2º- 3ºC). Pan production needs to allow sufficient time (up to two days) for thawing. Remove frozen chicken from box or plastic container and place on a parchment-lined sheet pan. Keep chicken either covered or placed in food cart with doors. Never refreeze chicken and rinse thawed chicken under potable (drinkable) water. Fresh Poultry Purchase poultry from inspected, (third party or hotel management inspections), facilities or a USDA inspected facility. Whole birds should be well-fleshed with no missing skin, cut marks, blood spots, bruises and other blemishes. Blood spots, bruises and other blemishes shall not exceed normal grade. The tenderloin should be fully intact. Chicken products should be delivered at a temperature of 28º-32ºF (-2º-0ºC). Upon delivery, immediately store on the lowest shelf in the coldest part of the refrigeration unit. Reject delivery of poultry that is slimy, has a pungent odor, grey or green skin color; and is above the minimum required temperature. Poultry storage on property should be maintained at 32º-38ºF (0º-3ºC). The maximum shelf life of all raw poultry products is 12-14 days. Leafy Greens Upon receiving leafy greens, place under refrigeration at or below 41ºF (5ºC) in the original cases. Greens and vegetables can trap dirt and bacteria from the soil. These items have been associated with food borne illness outbreaks and must be washed before preparation. Fill a clean sink with the approved vegetable wash solution • Use cold water • Make sure hands are washed • Submerge the item(s) for at least 30 seconds • Drain If using “Ready to eat (RTE) greens and vegetables that have been previously washed before packing do not need to be re-washed provided: bags are sealed and labeled “triple washed”, “washed” or “ready to eat” and the product comes from an inspected facility. Once prepared and cut, keep out of the danger zone (41-140°F or 5-60°C). Discard all left over leafy greens and vegetables from salad bars and other service areas. Melons Melons, especially the rough-skinned variety require special treatment. Upon receiving melons, place them under refrigeration at or below 41ºF (5ºC) in the original cases. The outside of a melon can trap dirt and bacteria from the soil and melons have been associated with food borne illness outbreaks and need to washed and sanitized before cutting. Scrub the rind with a vegetable brush Rinse melons in cold water Dip in the approved fruit and vegetable wash When removing the rind from a melon, use a clean and sanitized colored cutting board 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 12 Global HACCP Plan CRITICAL CONTROL POINTS AND CRITICAL LIMITS Storage and Preparation (cont.) Fresh or Frozen Raw Hamburgers Hotels must use the approved product or grind beef on premise to make hamburgers using one of the methods below. There are no exceptions. Pre-cooked hamburgers are acceptable. Microbiologically Food Safety Tested (MFST hamburgers) • Fresh or frozen patties must have the MFST sticker affixed to the case • All other ground beef must be cooked to155°F (68° C) • Guidance on MFST program In-house hamburger fabrication must be approved by Global Food Safety Guidance below: • Properties must apply and obtain a current year approval letter from GFS • Fresh beef grinding approval process • Hamburgers must be made using guidelines from HACCP form A12 OR • Hamburgers must made using ChefTec fresh beef grinding guidelines Melons When cutting or slicing melon for service, use a ready to eat or white cutting board. Use a clean and sanitized knife to prevent cross-contamination. When removing seeds from the melon, use a clean and sanitized spoon or scoop. Limit the service time of cut melon to a maximum of 4 hours. Keep melon out of the danger zone (41-140°F or 5-60°C) when serving or displaying. Discard all cut melon left over from salad bars and other service areas and do not mix melon with other fruits until just before serving. Shellfish Fresh clams, mussels, oysters and scallops are to be received at a temperature of no more than 41°F (5°C) and be left in their original containers until ready to prepare. Shellfish must come from approved harvesting areas with affixed tag containing: • catch origination • date of harvest • dealer’s name • identification number. Retain these tags on the original container until empty and thereafter keep on file for 90 days. Shellstock must be reasonably free of mud and dead shellfish or broken shells. All dead, cracked and broken shellstock must be discarded. Shellstock may be removed from original container and displayed for sale providing products are: • washed and cleaned with potable water • maintained on drained ice • kept out of standing water • protected from contamination • identified and not mixed with differing species Warm water oysters (oysters from waters above 72°F-22°C) originating from the Gulf of Mexico or Atlantic Coastal areas in the US, may not be served raw at any time. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 13 Global HACCP Plan CRITICAL CONTROL POINTS AND CRITICAL LIMITS Cooking Minimum Internal Temperature for Cooking Raw Foods unless higher temperatures are required by local regulations. Poultry (Solid & Ground) Pork, Game Roast Beef (hold 2 hrs.) Veal, Lamb Ground Meats (except poultry) Seafood Stuffed Foods (Meats, Pasta) Egg Dishes 165° F (74° C) 145° F (63° C) 130° F (54° C) 145° F (63° C) 155° F (68° C) 145° F (63° C) 165° F (74° C) 145° F (63° C) Cooling Previously cooked food must be cooled to a temperature of 70°F (21°) within 2 hours from the starting time. A critical high limit of 41°F (5°C) must be reached within 6 hours of initial cooling start time. Corrective Actions must only include discarding the out of compliance product or reheating to a temperature of 165°F (74°) unless higher temperatures are required by local regulations, one time only. Reheating Previously cooked foods must be reheated to a minimum temperature of 165°F (74°) within 120 minutes of starting the reheating process unless higher temperatures are required by local regulations. Cold Food Holding Cold potentially hazardous foods must be maintained at 41°F (5°C) or below in all coldholding devices including walk-in coolers, reach-in refrigerated units, cold-top storage devices and ice wells even if higher storage temperatures are allowed by local regulations. Hot Food Holding Hot potentially hazardous foods must be maintained at 140°F (60°C) or above in all hot holding receptacles and devices unless higher temperatures are required by local regulations. Time in Lieu of Temperature No potentially hazardous food can be left in the danger zone, 41°F (5°C) to 140°F (60°C) for more than 30 minutes. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 14 Global HACCP Plan MONITORING AND CORRECTIVE ACTION Sample Logs Review A1 log 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 15 Global HACCP Plan MONITORING AND CORRECTIVE ACTION Sample Logs (cont.) Review form A1 Hot Food 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 16 Global HACCP Plan MONITORING AND CORRECTIVE ACTION Sample Logs (cont.) Review A1 Cold Food Log 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 17 Global HACCP Plan MONITORING AND CORRECTIVE ACTION Sample Logs (cont.) Review A2 Cooling Log 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 18 Global HACCP Plan MONITORING AND CORRECTIVE ACTION Sample Logs (cont.) Review A3 Refrigerator Log 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 19 Global HACCP Plan MONITORING AND CORRECTIVE ACTION P OTENTIALLY H AZARDOUS F OODS R ECEIVING L OG Delivery Date Food Group Item Name (Beef Tenderloin, Cantaloupe, Tuna Loin) Internal Temperature of Product Weight of Product (Except Dairy Items) Accept/Reject Produce Accept Reject Poultry Accept Reject Beef/Pork Accept Reject Produce Accept Reject Dairy Accept Reject Seafood Accept Reject Produce Accept Reject Poultry Accept Reject Beef/Pork Accept Reject Produce Accept Reject Dairy Accept Reject Seafood Accept Reject Produce Accept Reject Poultry Accept Reject Beef/Pork Accept Reject Corrective Action on Rejected Products 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 20 Initials Global HACCP Plan MONITORING AND CORRECTIVE ACTION Sample Logs (cont.) HACCP Form A11 MFST FRESH GROUND BEEF PATTIES RECEIVING LOG (Valid thru 12/31/10) Review one master case of fresh hamburger patties upon delivery checking each sleeve for the temperature sensitive label. Verify that the product has not been temperature abused. Follow guidelines on Form A10 (Section II) Determine that there is a minimum of 4 days usable shelf-life left on the product by noting the day of delivery and subtracting that number from the Use-By date listed on the product Once a week, take the internal temperature of the product following the guidelines found on Form A10 (Section II) If the temperature sensitive label is activated, if there is not at least 4 days or more of usable shelf-life, or if the product is delivered outside of the required temperature parameters; the suspect product should be returned and all other cases of product delivered at that time should be evaluated. Use the Action/Comment column to indicate corrective steps taken if the temperatures are not in the required range. Temperature Sensitive Labels showing product is usable. Yes/No Delivery Date File this document for three (3) months Use-By Amount of Shelf Internal Date as Life Temperature of Labeled Remaining on Product on Product Below 38o F Master Use-By Date minus (3oC) and Case Delivery Date Above 32o F (0oC) Action/Comment If case was returned for credit, date of pick up 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 21 Initials Global HACCP Plan PROCESS HACCP PLANS FOR RESTAURANTS Food Preparation Process Public Health Agencies may require the food service facility or restaurant to develop a HACCP plan for each menu item or groups of potentially hazardous foods. This is called a “Process HACCP Plan”. Most food items produced in restaurants or food service establishments can be categorized into one of three preparation processes based on the number of times the food passes through the temperature danger zone between 41° F (5 °C) to 140 ° (60°C): • • Process 1: Food Preparation with No Cook Step Example flow: Receive⇒ Store⇒ Prepare⇒ Hold⇒ Serve (other food flows are included in this process, but there is no cook step to destroy pathogens) Process 2: Preparation for Same Day Service Example flow: Receive⇒ Store⇒ Prepare⇒ Cook⇒ Hold⇒ Serve (other food flows are included in this process, but there is only one trip through the temperature danger zone) Process 3: Complex Food Preparation Example flow: Receive⇒ Store⇒ Prepare⇒ Cook⇒ Cool⇒ Reheat⇒ Hot Hold⇒ Serve (other food flows are included in this process, but there are always two or more complete trips through the temperature danger zone) 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 22 Global HACCP Plan PROCESS HACCP PLANS FOR RESTAURANTS Food Preparation Process 1 / Food Preparation with No Cook Step Example Flow: RECEIVE⇒ STORE⇒ PREPARE⇒ HOLD⇒ SERVE Several food flows are represented by this particular process. Raw, ready-to-eat food like sashimi, raw oysters, and salads are grouped in this category. Components of these foods are received raw and will not be cooked prior to consumption. All the foods in this category lack a kill (cook) step while at the food service establishment. In other words, there is no complete trip made through the danger zone for the purpose of destroying pathogens. You can ensure that the food received in your establishment is as safe as possible by requiring purchase specifications. Without a kill step to destroy pathogens, your primary responsibility will be to prevent further contamination by ensuring that your employees follow good hygienic practices. Cross-contamination must be prevented by properly storing your products away from raw animal foods and soiled equipment and utensils. Foodborne illness may result from ready-to-eat food being held at unsafe temperatures for long periods of time due to the outgrowth of bacteria. In addition to the facility-wide considerations, a food safety management system involving this food preparation process should focus on ensuring that you have active managerial control over the following: • • • • • • Cold holding to inhibit bacterial growth and toxin production Food source (especially for shellfish) Receiving temperatures Date marking of ready-to-eat PHF held for more than 24 hours to control pathogens Freezing certain species of fish intended for raw consumption due to parasite concerns Cooling from ambient temperature to prevent the outgrowth of spore-forming or toxin-forming bacteria 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 23 Global HACCP Plan PROCESS HACCP PLANS FOR RESTAURANTS Food Preparation Process 2 / Preparation for Same Day Service Example Flow: RECEIVE ⇒ STORE⇒ PREPARE⇒ COOK⇒ HOLD⇒ SERVE In this food preparation process, food passes through the danger zone only once in the food service establishment before it is served or sold to the consumer. Food is usually cooked and held hot until served, i.e. fried chicken, but can also be cooked and served immediately. In addition to the facility-wide considerations, a food safety management system involving this food preparation process should focus on ensuring that you have active managerial control over the following: Cooking to destroy bacteria and parasites Hot holding to prevent the outgrowth of spore-forming bacteria Approved food source, proper receiving temperatures, and proper cold holding before cooking would also be important. (Refer to prerequisite programs starting on page 5) 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 24 Global HACCP Plan PROCESS HACCP PLANS FOR RESTAURANTS Food Preparation Process 3 / Complex Food Preparation Example Flow: RECEIVE⇒ STORE⇒ PREPARE⇒ COOK⇒ COOL⇒ REHEAT⇒ HOT HOLD⇒ SERVE Foods prepared in large volumes or in advance for next day service usually follow an extended process flow. These foods pass through the temperature danger zone more than one time; thus, the potential for the growth of spore-forming or toxigenic bacteria is greater in this process. Failure to adequately control food product temperatures is one of the most frequently encountered risk factors contributing to food borne illness. Food handlers should minimize the time foods are at unsafe temperatures. A food safety management system involving this food preparation process should focus on ensuring active managerial control over the following: Cooking to destroy bacteria and parasites Cooling to prevent the outgrowth of spore-forming or toxin-forming bacteria Hot and cold holding or using time alone to control bacterial growth and toxin formation Date marking of ready-to-eat PHF (TCS food) held for more than 24 hours to control the growth of pathogens Reheating for hot holding, if applicable. Approved food source, proper receiving temperatures, and proper cold holding before cooking would also be important. (Refer to prerequisite programs starting on page 5) 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 25 Global HACCP Plan PROCESS HACCP PLANS FOR RESTAURANTS Sample HACCP Logs for Process Plans #1 - Food Preparation with No Cook Step Food/Menu Items: Leafy greens and lettuces, cut melon, diced tomatoes HAZARD(S) Salmonella, bacillus cereus, listeria monocytoge nes, E coli 0157:H7 PREREQUISITE PROGRAMS Critical Control Points Corrective Action Critical Limits Monitoring Refrigerate upon receiving Hold chilled at or below 41° F (5°C) Monitor refrigerators for proper temperature 2x daily. Log A3 Refrigerate after preparation Hold chilled at or below 41° F (5°C) Monitor products for proper temperature 2x daily. (Log A1) Keep chilled on station Hold chilled at or below 41° F (5°C) Monitor Discard if internal critical limit temperature is not met every two hours (Record on log A1) Verification Report out Hotel engineer of range checks temperatu temperature res in AM and PM immediate ly and record corrective action on form A3 Continue to chill rapidly if limit is not met Records Retain form A3 for 90 days Cooks checks temperatures 2x daily Retain form A1 for 90 days Cooks checks temperatures randomly Retain form A1 for 90 days Purchase produce from approved sources and follow standards A7, A8 and refrigerator temperature requirements 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 26 Global HACCP Plan PROCESS HACCP PLANS FOR RESTAURANTS Sample HACCP Forms for Process Plans #2 - Preparation for same day service Facility: Hotel 324 Preparer: John Smith Date: 1/28/2010 Food Item: Scrambled Eggs Receive ⇒ Store ⇒ CCP 1 Critical Control Points Cook ⇒ CCP 2 Hold ⇒ CCP 3 HACCP CHART Monitoring Procedures ⇓ Serve Corrective Actions (CCPs) 1. Store – eggs are stored under refrigeration at or below 5°C (41°F) Record temperature on form A3 refrigerator log 2X daily Out of range temps must be addressed immediately 2. Cook- eggs are cooked to an internal temp. of 63°C ( 145°F) Cooks record temp. on A1 log for cooking raw foods Continue cooking to correct temp. or discard 3. Hold – hot on steam table at or above 60°C (140°F) Cooks record temp. on A1 log for holding hot foods every two hours Discard product if not at temperature Verification: Monitor temperature logs, and or observe temperature monitoring and calibration. Equipment Utilized at each Critical Control Point (include type and quantity of each unit) CCP 1: Refrigerator, reach-in. (1) CCP 2: Egg pans (4) CCP 3: Chafing dish (1) 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 27 Global HACCP Plan PROCESS HACCP PLANS FOR RESTAURANTS Sample HACCP Forms for Process Plans Process #3 - Complex Food Preparation Food/Menu Items: Soups, Casseroles and Sauces PROCESS STEP HAZARDS Clostridium perfringens, staphyloco ccus areus, Salmonella, bacillus cereus, listeria monocytog enes, E coli 0157:H7 Receive Store Prepare CCP (Y/N) CRITICAL LIMITS Y 41° F (5°C) Y CORRECTIVE ACTIONS VERIFICATION RECORDS Check product temp. use form A13 for receiving attributes If product is temperature abused, refuse delivery Receiving manager observed practices and Retain A13 for 90 days 41° F (5°C) Check refrigerator temps. 2x daily Use form A3 Out of range refrigerators must be corrected at once Hotel engineer checks temps and units 2x daily Retain A3 for 90 days Y 165° F (74°C) Record cooking temps. on form A1 Continue cooking to proper temp. Kitchen manager verifies log entries Retain A1 for 90 days Y Place in shallow pans > 2”. Cool to 70° F (21° C) within 2 hrs. and 41°F (5° C) within 6 hrs. Check internal temperature of food at 1.5 and 6 hours. Use cooling from A2 If product has not reached 70°F 21° C) within 1.5 hrs. separate into smaller containers. If food had not reached 41°F (5° C) within 4 additional hrs., discard Kitchen manager verifies log entries Retain A2 for 90 days Y Reheat all food within 2 hours to 165°F (74°C) Record finish temp. on log A1 reheating Continue cooking until critical limit is achieved Kitchen manager verifies log entries Retain A1 for 90 days Y Hot holding 140°F (60°C) Cooks record temp. on A1 log for holding hot foods every two hours Discard product if not at temperature Kitchen manager verifies log entries Retain A1 for 90 days MONITORING N Cook Cool Reheat Hold N Serve Prerequisite Programs Refrigerated food is to be put away immediately upon delivery. Use of color coded cutting board. Do not reclaim food that has been holding on a buffet. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 28 Global HACCP Plan VERIFICATION AND RECORD KEEPING Process 1) All Marriott International hotels globally regardless of ownership or Management Company must submit to a food safety audit. Audits are done annually and must be preformed by a qualified entity. CCP monitoring records will be examined and validated Food safety training and certification is verified Corrective actions are noted for any critical limit variance Equipment calibration is checked as required by the HACCP plan 2) Temperature logs must be correctly filled in and retained for a period of 3 months. The following procedures apply: • • • • Hot food logs- two entries per meal period Cold food logs- 2 entries per meal period Reheating logs- all reheated foods Refrigerator logs- 2 readings per day 3) All temperature logs must be signed by a management or supervisor and correct action measures verified. 4) Food Safety self audits must be completed on a monthly basis and retained for 90 days. 5) Any additional relevant records regarding the flow of the food through the operation must be verified and retained for 90 days. These documents may include, but are not limited to: • • • • • • • • Food invoices Shellfish tags Food allergen documentation Laboratory sampling results of potentially hazardous foods Microbiologically food safety tested ingredients Pest control records Receiving and food attribute logs Thermometer calibration logs 6) Annually, the director of Global Food Safety must conduct a HACCP Plan review to evaluate its effectiveness. A gap analysis must be performed to determine if there are any applicable changes to critical control points, critical limits or other global food safety standards. The revised plan must be issued to the field by the second week of every new year. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 29 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Name: Cleaning and Sanitizing for Food Safety Objective Provide a global standard regarding the proper cleaning and sanitizing of all food service utensils, equipment and food production areas. 1) Chemical sanitizer solutions must be at proper concentration and temperature per label instructions: All sanitizer in buckets, spray bottles, chemical sanitizing dishwashing machines, and dispensing systems in each area must be tested to assure proper levels. Mandatory sanitizer concentrations: • Old Quats 200-300 PPM (e.g. Ecolab Pro 144) • New Quats 150 to 400 PPM (e.g. Ecolab Pro 146) • Chlorine/bleach 50-100 PPM (low temp. machines) • Iodine 12.5-25 PPM 2) All non-chemical sanitizing dishwashing machines must reach the proper water temperature: Dish machines that sanitize with hot water must be maintained to ensure the critical limits below. • Final rinse 180°F (82°C)) • Surface of dishes 160°F (71°C) • Water temperature in a sink compartment 171°F (77°C) 3) Original containers of toxic materials must have a legible manufacturer's label: Working containers of cleaners and sanitizers must be labeled with the common name of the product. • All chemicals in all containers must be accurately labeled • Original containers must have a legible manufacturer's label • Working containers such as spray bottles must be labeled with common names such as "Sanitizer" or "Window Cleaner" • All unlabeled liquids must be considered a potentially toxic material 4) Facilities for manual washing and sanitizing of equipment and utensils must be properly maintained and operated: • Sinks must be cleaned and properly stocked with detergent and sanitizer • Wash, rinse and sanitize is the mandatory process (except Germany) • Sinks must be large enough to accommodate at least half of the largest piece of equipment being cleaned • There must be no damage to sinks such as bent drain boards that do not shed water • Sinks may be used for dishwashing and for food preparation, but never at the same time. o Clean items may not be present on the drain board while food preparation is occurring o Sinks must be washed, rinsed, and sanitized between these two tasks o Pot sink log (PDF) 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 30 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Cleaning and Sanitizing for Food Safety (cont.) 5) Dishwashing machines must be properly maintained and operated: Surfaces must be clean, curtains clean and in place, final rinse pressure adequate and wash temperature meets requirements listed on the machine data plate. • Machines must be in good repair and stocked with detergent • The water pressure in machines that sanitize with hot water must read 15 to 25 psi. • High temp. dish machine log (PDF) • Low temp. dish machine log (PDF) 6) Food contact surfaces must be properly cleaned and sanitized: Surfaces must be sanitized at least every 4 hours during continuous use with potentially hazardous food at room temperature. Times vary if the surface or room is refrigerated, follow the standards below: • <50°F to 55°F (10°C to 13°C), clean at least every 10 hours • <45°F to 50°F (7°C to 10°C), every 16 hours • <41°F to 45°F (5°C to 7°C), every 20 hours • 41°F (5°C), or below, every 24 hours 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 31 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Name: Facility/Controls Food Safety Objective Provide mandatory guidelines regarding physical facilities and the control of food production and restaurant areas to ensure proper sanitation. 1) Exhaust hoods and ductwork system must be professionally cleaned and maintained: Professional cleaning must be performed at least every 6 months. If UV lights/Ozone system is installed, the hotel must provide proof of yearly inspections. (International only) An inspection sticker must be affixed to the hood 2) A pest prevention program must be adopted and effective: Hotels must minimally use a pest sighting log. The following are signs that the prevention program is not effective. Fresh pest droppings Active cockroaches or rodents in food prep and storage areas Trailing ants Birds inside the hotel or nesting on the outside of the building if their droppings create a sanitation issue (The presence of an occasional fly does not mean the pest program is ineffective) 3) Original containers of toxic materials must have a legible manufacturer's label: Working containers of cleaners and sanitizers must be labeled with the common name of the product. All chemicals in all containers must be accurately labeled Original containers must have a legible manufacturer's label Working containers such as spray bottles must be labeled with common names such as "Sanitizer" or "Window Cleaner" All unlabeled liquids must be considered a potentially toxic material. 4) Floors, walls and ceilings must be free of excessive dust, debris and standing water: Structures must be kept sanitary using a cleaning schedule. A cleaning checklist must include the following: Doors and windows Under counters Floor/wall junctions All hand contact areas Floor drains and mold Many floors do not drain properly and repairs may not be economically viable. However, standing water should be mopped up or pushed to a drain with a squeegee immediately. 5) Ventilation must be adequate and vents, fan guards and filters clean: Dirty fans and ceiling vents can be a source of product contamination. Ceiling air vents and returns must not have dust build-up Exhaust hood ventilation systems must not have grease build-up Air fans must be cleaned regularly 6) Floors, walls and ceilings must be smooth, easily cleanable, and in good repair: Exposed concrete blocks and bricks must be sealed and smooth unless area is used only for dry storage. Carpeting in food production areas is prohibited Floors that are cleaned by water flushing methods must be coved and sealed at the wall juncture 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 32 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Name: Food Handling Food Safety Objective Proper food handling is critical to avoid risk factors associated with food borne illness among associates and guests. 1) Fresh or frozen raw hamburgers: Hotels must use the approved product or grind beef on premise to make hamburgers using one of the methods below. There are no exceptions. Pre-cooked hamburgers are acceptable. Microbiologically Food Safety Tested (MFST hamburgers Fresh or frozen patties must have the MFST sticker affixed to the case All other ground beef must be cooked to155°F (68° C) Guidance on MFST program (PDF) In-house hamburger fabrication must be approved by Global Food Safety. Guidance below: Properties must apply and obtain a current year approval letter from GFS Hamburger fabrication approval process Hamburgers must be made using guidelines from HACCP form A12 (PDF) OR Hamburgers must made using ChefTec fresh beef grinding guidelines 2) Foods and ingredients must come from commercial suppliers under regulatory control, be wholesome and in good condition: Hotels must use Marriott International approved suppliers or minimally buy goods from government inspected facilities. Home made products are prohibited Use of non-pasteurized milk products are prohibited 3) Source tags for shellfish must be held at least 90 days after harvest: Hold tags in chronological order. 4) Date marking is applied at time of preparation to ready-to-eat potentially hazardous food: Refrigerated, ready-to-eat, potentially hazardous food intended to be held for more than 24 hours must be dated. This applies to food prepared on site and to commercial containers opened on site. The requirement does not apply to the following: Items intended to be used later the same day Non-potentially hazardous foods, such as cookies or unopened canned products Deli salads & salad dressings manufactured in an inspected processing plant as these products typically contain preservatives Hard and semi-soft cheeses Cultured dairy products such as yogurt, sour cream and buttermilk Fluid milk and cream (based on industry practice) 5) Food products must not be held or sold past expiration date: Items prepared on site are to be given a maximum shelf life of 7 days. "Use by", "Enjoy by" and "Best by" dates are only recommendations based on quality, not safety. 6) All foods must be free of all microbiological, physical and chemical contamination: Foods must be free of Pathogens (bacterial, viral or fungal), and must not contain foreign objects or have the presence of cleaning or sanitizing chemicals. 7) Potentially hazardous foods must be properly thawed: Only the methods described below are allowed and thawing at room temperature is strictly prohibited. Under refrigeration at 41°F (5°C) or below Completely submerged under cool running water that is 70°F (21°C) or below In a microwave oven if it is to be cooked immediately after thawing As part of the cooking process 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 33 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Food Handling Food Safety (cont.) 8) Foods must be protected from contamination: Hotel operators must protect all foods from contamination during preparation and serving including condensation above exposed food or food contact surfaces. Foods must be protected from receiving through serving to prevent contamination Foods in freezers and coolers must be covered unless in the process of cooling Individual food carts may be bagged or each tray may be covered individually Freezers must not have heavy build-up of frost/ice on the exterior 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 34 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Name: Food Safety Documentation Objective Ensure Marriott International hotels world wide have the proper food safety training, conduct self inspections and have the tools needed to investigate potential food borne outbreaks. Documentation 1) Food Borne Illness Notification (FBIN) Procedures: A current copy of the document must be obtained by February 28 of each new year. The procedures must be used for the reporting of any suspected food borne outbreak. Marriott Global Source - Food Borne Illness Notification Procedures 2) Food Safety Certification (hourly staff): All non-management food handlers must be certified every two years using the Great Food Safe Food training program or the approved management training program. Marriott Global Source - Great Food Safe Food 3) Food Safety Certification (management staff): The minimum number of managers must be certified in food safety. Positions and numbers vary by hotel brand and size. NALO: FFI/SHS - 1 manager CY/RI - 250 rooms/suites or less: Chief Engineer (management or salaried), GM, Other manager (or other hourly staff if only 1 management position on property) CY/RI - 251 rooms/suites or more: Chief Engineer (management or salaried), Assistant GM, Other managers (or other hourly staff if only 1 management position on property) MHR/JW/RH/RC/RCC - Assistant Engineer, Banquet Chef, Chief/Executive Steward, Culinary managers, Director of Engineering, Executive Chef, Restaurant Managers, Sous Chefs International CY - 250 rooms/suites or less: Chief Engineer (management or salaried), GM, Other manager (or other hourly staff if only 1 management position on property) CY - 251 rooms/suites or more: Chief Engineer (management or salaried), Assistant GM, Other managers (or other hourly staff if only 1 management position on property) JW/MH/RHR- Assistant Engineer, Banquet Chef, Culinary Mangers, Director of Engineering, Executive/Head Chef, Restaurant Managers, Sous Chefs,Executive Steward/Chief Steward, Event Operations Manager/Maitre’d. 4) Certifications are valid for 5 years and must be from one of the approved accredited providers. CIEH (Charter Institute of Environmental Health) NRFSP (National Registry of Food Safety Professionals) Prometric (formerly Experior Assessments) ServSafe (National Restaurant Association/Educational Foundation) CRFA-NFSTP (Canadian hotels only) 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 35 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Food Safety Documentation (cont.) 5) Monthly Food Safety self-inspection: Hotel must minimally conduct a monthly Food Safety self-inspection and document the deficiencies and corrective action. Documentation must only be in one of the specific forms listed below: Data Entry Form – QA site Food Safety Review form - Answer Summary – QA site Marriott Global Source - Forms (Food Quality and Safety Standards/Monthly Essentials checklist) It is acceptable if the checklist format is adapted for multiple kitchens Marriott Global Source - Forms It is acceptable if the checklist format is adapted for multiple kitchens QA On-Line Review Form (ORF) for Food Safety QSSA - Quality Safety Standards Audit (FFI/SHS only) Self Review (brand specific) - Executive Summary It is acceptable if multiple form types are use 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 36 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Name: Food Safety Equipment and Utensils Objective Sanitary control and detailed maintenance of food production equipment and utensils is essential to prevent cross-contamination in the food production environment. 1) A cutting board system must be in place: Minimally hotels must use at least two separate boards for the preparation of food. It is acceptable to use a multiple color cutting board system for non ready-to-eat food items. • White for ready to eat food only • One other color for raw food Wood cutting boards may ONLY be used for: • Butcher blocks • Bakery worktables • Food displays o Chinese kitchens (International), for general use, provided the following are met: • Boards are properly maintained and marked for product use • Separate boards used for chicken, fish, raw and cooked products • All blocks must be scraped, washed and sanitized daily 2) Food contact surfaces of equipment and utensils must be durable, non-toxic, easily cleanable and in good condition: All food contact surfaces in the food preparation area must be made of materials that are safe, corrosion resistant, nonabsorbent, smooth and easily cleanable. • Food contact surfaces must be made of food-grade plastic or non-reactive metals such as stainless steel • Surfaces must also be in good condition to facilitate cleaning and to prevent physical contamination of the food. 3) In-use utensils must be properly handled and stored in a sanitary manner: Handles of utensils stored in the product must not touch the product and extend out of the container for moist foods. • For dry ingredients only, scoops may be stored inside the product container; the handle must extend out of the product • For moist products, the scoop must extend completely out of the container • Glasses, cups and bowls with no handle may not be used as a scoop • Ice scoops, shovels, paddles, etc., stored at the ice machine are considered to be in use at all times and must be kept sanitary • Utensils may not be stored in containers of sanitizer Alternative methods of storing utensils include: 1. Holding on a clean, sanitary surface and wash-rinse-sanitize at least every 4 hours 2. Holding in hot water 140°F (60°C) or above NOTE: Ice water is not an alternative allowed by the Food Code 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 37 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Food Safety Equipment and Utensils 4) Non-food contact surfaces of equipment and utensils must be properly cleaned daily: See examples below: • Sides of sinks • Gaskets on coolers • Freezer doors tracks • Sliding doors of ice machines • Exterior of ice machines • Exterior/sides of food containers • On/off switches of food processing equipment • Handles to cooler doors • Shelves and racks for food 5) Non-food contact surfaces of equipment and utensils must be maintained in good condition: Equipment and utensils must be durable, non-toxic, and easily cleanable and in good condition. See examples of acceptable food contact surfaces: • Corrosion resistant • Nonabsorbent • Smooth • Easily cleanable 6) Hotels must use sanitizer test kits: Test kits must be readily available for each chemical sanitizer used. • Test kits buried in drawers or in the original aluminum foil wrap are not considered readily available • The calibration of automatic dispensing systems should be tested at least daily • When mixed by hand, each sanitizer batch should be tested 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 38 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Name: Food Storage Food Safety Objective To protect food from microbiological cross-contamination, physical and chemical hazards during storage. 1) Food and food contact surfaces must be protected from potential microbiological, physical and chemical hazards at all times: Hazards listed below must be avoided. • Raw animal products stored above or commingled with ready-to-eat products • Physical hazards that would present an imminent health hazard, such as push pins used directly above food prep surfaces or • Chemicals stored above food or food contact surfaces Proper storage examples • Where complete vertical separation is not possible, raw poultry must be stored on the bottom and ready-to-eat items must be stored on top. Items with the greatest internal cooking temperatures must be stored on the lowest shelf. • All other products should be stored in between and not commingled • If various items are stored in a cold drawer, raw chicken should be at the front and ready-to-eat items at the rear so that raw animal juices do not drip onto ready-to-eat products as they are removed from the drawer 2) Food and food contact packaging must be properly stored: The standard gap is 6 inches (15 centimeters) off the floor. This gap facilitates cleaning, protects products from spills and allows monitoring of pest activity. 3) Disposable plastic containers must not be reused for food storage: Cottage cheese tubs, mayonnaise/pickle pails and sour cream containers are some examples. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 39 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Name: Personal Hygiene - Food Safety Objective Associate hygiene practices are an integral component to any HACCP plan. Pathogens spread by food workers is the leading cause of food borne outbreaks worldwide. Hygiene standards must be mandated and managed by stakeholders in all hotels to mitigate risks. 1) Hands that may have become contaminated must be washed frequently: Food handlers must wash hands frequently using hot water and soap for 20 seconds and dried using disposable towels or a heated- air hand drying device. See Hand Washing brand standard (B-FBC-008) 2) Food workers must not contact ready-to-eat foods with bare hands: All ready-to-eat food (food intended to be eaten without further cooking) must be portioned and served without contacting bare hands. Utensils, gloves, individual wax papers, etc., are appropriate alternatives if used correctly. 3) Food workers displaying symptoms of illness are restricted from working around exposed food: Persons displaying symptoms such as vomiting, diarrhea, jaundice, sore throat with fever or exposed pustular lesions are restricted from working around exposed food, utensils or equipment. Employees with the following symptoms should be restricted from food handling duties: Diarrhea Vomiting Fever Sore throat with fever Jaundice Open sores on their hands or forearms Employees diagnosed with illnesses due to the following organisms should be excluded from the food establishment: Norovirus Salmonella Typhi Shigella Hepatitis A Shiga toxin-producing E. coli (STEC) Review Associate exclusion guidelines (PDF) 4) Eating, drinking and tobacco use is restricted to nonfood areas: Tasting food is allowed from single serve tasting spoons or at formal documented taste panels. Chewing gum and chewing tobacco are considered eating. There must be no eating and tobacco use in areas with exposed: Food Food contact surfaces Food-contact packaging Drinking is allowed in a food production area if: Using a cup with lid and straw If the container is stored so that it will not contaminate food preparation surfaces 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 40 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Personal Hygiene (cont.) - Food Safety 5) Hand washing facilities in food handling areas are used only for that purpose: Hand sinks must be maintained clean and accessible at all times; supplied with readily available hot water, soap, disposable towels or heated-air hand drying device. Hand sanitizer may be available in addition to, but not in place of soap. In addition, hand sinks must: Have 100°F (38°C) water at the faucet in at least 60 seconds Be designated with a sign reminding associates to wash their hands Have a trash can in the general area 6) Food handler gloves must be changed whenever damaged or torn: In addition, gloves must be worn over bandages, fingernail polish or artificial nails. Wearing gloves on only one hand can be done safely and effectively. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 41 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS Name: Temperature Control for Food Safety Objectives 1. Use temperature logs to ensure the monitoring of critical control points for potentially hazardous foods. 2. Maintain holding equipment to ensure hazardous foods are not temperature abused. 3. To prevent food borne outbreaks by cooking and reheating foods to proper internal temperatures. 4. To ensure proper handling of hazardous foods during display and when left out of temperature controlled environments. 1) Temperature logs: Hotels must minimally use the following documents to ensure food is kept safe. Electronic or paper forms of the documents are acceptable. All forms must be retained for 3 months. • Cooking & Holding temperature logs - (HACCP Form A-1) Form A1 (PDF), International A1 Cold, A1 Hot • Log must minimally record: • Date, Food Item, Time, Temperature (cooking and/or holding), Meal Period and Location (Outlet Name), Corrective Action (if temperature out of range) • 2 hot and 2 cold temperatures are required per meal period • Both cooking and holding temperatures are required • Holding temperatures above 41°F (5°C) and below 140°F (60°C) are out of range. • Re-Heating temperature logs – (HACCP Form A-1) • Log must minimally record: • Date, Food Item, Location, Time, Temperature, Corrective Action (if temperature out of range) • All foods reheated must be recorded • All fields must be correctly completed • Temperatures below 165°F (74° C) are out of range • Refrigerator and Freezer temperature logs (HACCP Form A-3) Sample form A3 Refrigerator-Freezer log (PDF) • Log must minimally record: • Date, AM internal temp, PM internal temp, Corrective Action (if temperature is out of range) • Refrigerator temperatures above 41°F (5°C) are out of range • Freezer temperatures above 5°F (-15°C)are out of range • Cooling temperature logs (HACCP Form A-2) Form A2 (PDF) • Log must minimally record • Date, Food Item, Temp at Start, Temp #1 (after 1 hour), Temp #2 (after 2 hours), Temp #3 (after 4 hours), Temp #4 (after 6 hours), Corrective Action (if temperature out of range) • Temp #2 (after 2 hours) above 70°F (21°C) are out of range • Temp #4 (after 6 hours) above 41°F (5°C) are out of 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 42 Global HACCP Plan GLOBAL FOOD SAFETY BRAND STANDARDS range Temperature Control for Food Safety (cont.) • All reheated foods must be recorded 2) Equipment: Hotels must maintain hot and cold holding equipment to ensure hazardous foods are not temperature abused. • Cold food stored under refrigeration: • Cold potentially hazardous foods must be maintained at 41°F (5°C) or below in all cold-holding devices including walk-in coolers, reach-in refrigerated units, cold-top storage devices and ice wells. • All refrigerated (but not frozen) storage units are required to have thermometers that accurately reflect the ambient temperature in the warmest part of the unit. If built in devices are absent or not working, hanging thermometers are adequate. One or the other must be present and working in each unit. • Food stored in hot holding equipment • Hot potentially hazardous foods must be maintained at 140°F (60°C) or above in all hot holding receptacles and devices. • All hot holding equipment must be maintained at all times at a temperature sufficient to keep hot food at the required temperature. 3) Cooking, holding, and reheating temperatures: Hotels must cook, hold and reheat food to the proper internal temperatures to prevent food borne outbreaks. • Minimum internal temperatures: Form A1 (PDF) o Seafood and pork 145°F (63° C) o Ground beef 155°F (68° C) ** o Poultry 165°F. (74° C) o Veal and lamb 145° F (63° C) o Egg dishes 145°F (63° C) *** o Previously cooked food must be reheated to 165°F (74° C) within 2 hours. ** Hamburgers can be cooked to customer preference in some jurisdictions • See form A8 (PDF) *** Fresh shell eggs can be cooked to customer preference in some jurisdictions 4) Foods must not be left out at ambient temperature: No potentially hazardous food can be left in the danger zone, 41°F (5°C) to 140°F (60°C) for more than 30 minutes. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 43 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A4 STORAGE AND HANDLING OF FRESH BEEF STEAKS (Valid thru 12/31/10) Food Quality and Safety Standards PROCEDURE: 1) Upon receipt, immediately refrigerate fresh beef steaks to 34ºF to 38°F (1ºC to 3°C). Hold steaks in their sealed packages in the original cases. Check the invoice for accuracy and record the delivery date on the case if no date is visible. Shelf life for sealed fresh cut steaks is 10 days. Do not accept steaks that have been cut for more than two (2) days prior to receipt. 2) Check steaks for broken vacuum-seal packages. Any “leakers” should be returned to the vendor for credit. Rotate cases of steaks, first in first out. (FIFO) 3) Preparing for service: o Remove steaks (a one day supply only) from the packaging. o Discard any juices present. o Blot dry with a single-use paper towel. o Allow steaks to “breathe” for 30 to 45 minutes on pans, under refrigeration. o Lightly brush each steak with a tasteless vegetable oil. 4) Store oiled steaks fat side up, with the cut side of each steak in contact with the next. Use clean, shallow steam-table pan(s) of one layer. 5) To simplify inventory, it is preferable to store a standard number of each size and variety of steak per pan. Cover pan(s) with plastic film with 6-8 slit holes, made by the point of a knife, to prevent smothering and to inhibit spoilage. Label and date each pan. 6) Store pans of oiled steaks at 34ºF to 38°F (1ºC - 3°C). 7) Use oiled steaks within 72 hours. Steaks that are not used after 72 hours should be used for other purposes and fully cooked to at least 140°F (60°C). NOTES: • Do not reuse vegetable oil; discard after coating procedure. • Do not add seasonings to oil. • Do not store steaks flat (cut side down) on pan after coating procedure. • Excessive oil can cause flare-up during cooking. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 44 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A5 RECEIVING, STORING AND HANDLING OF FRESH OR FROZEN FISH (Valid thru 12/31/10) Food Quality and Safety Standards PROCEDURE: 1) Fresh fish is to be received packed in ice. Store fish immediately immersed in flaked or crushed ice. Internal temperature of fish should be 32º-34ºF (0º-1ºC). Only products from an approved seafood purveyor may be used. No local sport harvested species may be used at any time. 2) At no time may any hotel or restaurant foodservice facility vacuum pack fresh seafood of any kind. 3) No raw fresh fish is to be accepted in vacuum packaging or modified atmosphere packaging (MAP) under any circumstances. Fresh fish packed in oxygen-permeable bags can be accepted provided the bag is clearly marked “High OTR or 10K OTR”. This distinction indicates a high oxygen exchange inside the packaging. 4) Frozen fish can be accepted in reduced oxygen packaging providing the seal is broken during thawing and the product is stored under refrigeration at 36 -38 °F (2-3°C). This includes smoked fish, smoked shellfish or mollusks and sushi-grade frozen fish. 5) Fresh fish is to be received and stored quickly in the coldest part of the refrigerator or in a fish file. 6) Fish is to be stored: o In a perforated pan nested in a solid pan with a space between each pan to hold crushed or flaked melting ice water. o In a fish file with crushed or flaked ice. 7) Fish is never to come in contact with the sides or bottom of the perforated container or fish file. 8) Fish fillets are to be placed: o Skin to skin. o Wrapped loosely in clean plastic film or butcher’s paper. o On a layer of flaked or crushed ice, with a thin additional layer of flaked or crushed ice on top so as not to crush the fillets. 9) Whole fish, skin on, can be immersed in flaked or crushed ice without plastic packaging with belly facing down. 10) Drain melted ice daily and replenish with fresh flaked or crushed ice. Never allow fish to soak in water and become waterlogged. It extracts the flavor and makes the flesh flabby. 11) Store each fish variety in separate pan(s) or fish file drawer. Label and date. 12) Never mix a fresh shipment of fish with older fish. 13) Ensure proper rotation of fish following the FIFO procedures. Hold fish for no more than 3 days from receipt. 14) Thaw frozen fin-fish and/or shellfish (scallops, shrimp, etc): o If vacuum packed, take out of original packaging. o Allow 24 hours thaw time at refrigerated temperatures of 34º-38ºF (1º-3ºC). 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 45 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE 15) Do not defrost fish in stagnant water or at room temperature. Defrosting under cold running water is acceptable, but not recommended. 16) Once defrosted, cook and serve immediately. Defrosted fish held for more than 24 hours can become mushy, dry, and fibrous and should be discarded. 17) Clean utensils and surfaces after handling fish, rinse in cold water, wash with hot soapy water, rinse, and sanitize. NOTES: • Fresh fish, properly handled and stored, has a shelf life of three days from time of receipt. • Flesh should be firm, elastic & spring back quickly (leaving no indentation) when pressed with a finger. • Fresh fish will have no fishy odor. • Fresh whole fish will have clear eyes and bright red gills. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 46 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A6 STORING, HANDLING AND PREPARATION OF FROZEN CHICKEN (Valid thru 12/31/10) Food Quality and Safety Standards PROCEDURE: 1. Purchase chicken from approved vendors only. 2. Frozen chicken must be received with no evidence of previous thawing. 3. Store frozen chicken immediately upon delivery. o Place on lowest shelves of freezer or refrigerator to prevent possible crosscontamination. o Date product to assure First In, First Out (FIFO) usage. 4. Thaw frozen chicken under refrigeration 36º-38ºF (2º- 3ºC). o Plan production needs to allow sufficient time (up to two days) for thawing. o Remove frozen chicken from box or plastic container and place on a parchment-lined sheet pan. o Keep chicken either covered or placed in food cart with doors. o Never refreeze chicken. 5. Rinse thawed chicken under potable (drinkable) water: o Be careful that draining water does not drip or splash on surrounding foods or surfaces. o Drain chicken thoroughly before preparing. o Thoroughly wash, rinse, and sanitize all surfaces, equipment, and utensils that came in contact with the chicken or the rinsing water. 6. Any marinade used for chicken must be discarded after use. Under no circumstances should marinades be re-used for fresh products or added to the product later in the cooking process (e.g. for basting). 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 47 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A7 STORING, HANDLING AND PREPARING MELONS (Valid thru 12/31/10) Food Quality and Safety Standards Procedure: 1. Melons, especially the rough-skinned variety require special treatment. o Upon receiving melons, place them under refrigeration at or below 41ºF (5ºC) in the original cases. 2. The outside of a melon can trap dirt and bacteria from the soil. Melons have been associated with food borne illness outbreaks and need to be washed and sanitized before cutting. o Scrub the rind with a vegetable brush. o Rinse melons in cold water. o Dip in the approved fruit and vegetable wash. o Rinse again. 3. When removing the rind from a melon, use a clean and sanitized colored cutting board. o Use a clean and sanitized knife to prevent cross-contamination when cutting melon. 4. When cutting or slicing peeled melon for service, use a ready to eat or white cutting board. o Use a clean and sanitized knife to prevent cross-contamination. o When removing seeds from the melon, use a clean and sanitized spoon or scoop. 5. Limit the service time of cut melon to a maximum of 4 hours. o Keep melon out of the danger zone (41-140°F or 5-60°C) when serving or displaying. 6. Discard all cut melon left over from salad bars and other service areas. 7. Do not mix melon with other fruits until just before serving. Notes: ● “Victory Wash” (Ecolab) and “Fit” Fruit and Vegetable Wash” are approved washes for produce. Follow the user instructions. Test Victory Wash once a month to make sure the correct strength has been calibrated. Contact Ecolab for testing or to purchase test strips. Strength recommendation is 60-80 parts per million. ● Fit Fruit and Vegetable Wash is available from US Foodservice. Read the label for mixing the correct strength directions. ● Ozonated water as a vegetable rinse is an approved method as of 2010 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 48 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A8 STORING AND HANDLING LEAFY GREENS AND VEGETABLES (Valid thru 12/31/10) Food Quality and Safety Standards Procedure: 1. Leafy greens and vegetables require special treatment. o Upon receiving these items, place under refrigeration at or below 41ºF (5ºC) in the original cases. 2. Greens and vegetables can trap dirt and bacteria from the soil. These items have been associated with food borne illness outbreaks and must be washed before preparation. o Fill a clean sink with the approved vegetable wash solution o Use cold water o Make sure hands are washed o Submerge the item(s) for at least 30 seconds o Drain 3. If using “Ready to eat (RTE) greens and vegetables that have been previously washed before packing do not need to be re-washed provided: 1. Bags are sealed and labeled “triple washed”, “washed” or “ready to eat” 2. The product comes from an inspected facility 4. Once prepared and cut, produce is potentially hazardous and must be kept out of the danger zone (41-140°F or 5-60°C) 5. Discard all left over leafy greens and vegetables from salad bars and other service areas. Notes: ● “Victory Wash” (Ecolab) and “Fit” Fruit and Vegetable Wash” are approved washes for produce. Follow the user instructions. Test Victory Wash once a month to make sure the correct strength has been calibrated. Contact Ecolab for testing or to purchase test strips. Strength recommendation is 60-80 parts per million. ● Fit Fruit and Vegetable Wash is available from US Foodservice. Read the label to ensure the correct strength. Purchase test strips. ● Ozonated water as a leafy greens and vegetable rinse is an approved method as of 2010. (7-204.12) 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 49 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A9 STORAGE AND HANDLING OF MFST FROZEN GROUND BEEF PATTIES (Valid thru 12/31/10) Food Quality and Safety Standards PROCEDURE: 1. Upon receiving, each case of frozen (Microbiologically Food Safety Tested) patties should be clearly marked with the MFST sticker. Check that hamburgers: o Are hard frozen. o Show no signs of freezer burn, or ice crystal formation. 2. Place burgers into the freezer immediately upon arrival. 3. Remove for thawing4 a one-day supply of frozen hamburgers from freezer: o Place one-high on a parchment-lined sheet pan. o Typically, 24 patties can be shingled on one sheet pan. 4. Cover the sheet pan with plastic wrap, label, and date. Use the date the product was removed from the freezer. Let the hamburgers defrost under refrigeration. It takes approximately 24 hours for hamburgers to defrost using this procedure. 5. Do not force thaw hamburgers under running water or at room temperature. 6. When hamburgers are completely defrosted, they are ready to be cooked within the next 24 hours. 7. Any patties remaining after the 24 hour defrost limit, should be utilized in completely cooked ground beef recipes such as meat loaf, chili, meat sauce, etc. NOTES: • Current Marriott International Standard requires that all ground beef products be cooked to a minimum internal temperature of 155°F (68°C) • Follow all local, county, state and federal food code requirements regarding the minimum cooking temperatures for ground beef and menu verbiage alerts regarding the consumption of undercooked protein products. • Guests may request that their ground beef patties be cooked below the 155°F (68°C) and do so at their own risk. • Service associates/employees should not at any time solicit guests for “doneness” on ground beef patties. • If a guest does not request a specific doneness during the order taking process, then the ground beef patty should be cooked to a minimum of 155°F (68°C), per Marriott International standard. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 50 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A10 PURCHASING, RECEIVING, STORAGE & HANDLING MFST F R E S H G R O U N D B E E F P A T T I E S Food Quality and Safety Standards (Valid thru 12/31/10) I. Purchasing and Packaging: Purchase only MFST (Microbiologically Food Safety Tested) product (Note illustration) Each master case must be coded with a “PACKED ON” date and “USE BY” date on the exterior of the packaging (e.g. PKD month/date/year/time EXP month/date/year/time). The USE BY date must be listed on each cryovac sleeve of ground beef patties contained in each master case. Each individual sleeve of ground beef patties must be fitted with a temperaturemanagement device to ensure adequate cold chain management from the processor to the end user. (See illustration) II. Receiving: (Use Form A-11 for HACCP documentation purposes and initial) The person receiving a delivery of MFST fresh hamburgers must: 1. Review each master case of fresh hamburgers delivered, by opening it and viewing the individual cryovac sleeves of ground beef patties and their temperature sensitive labels to verify that the product temperature has been maintained throughout the distribution process and delivered at or below 41°F (5°C). 2. Make sure all temperature-sensitive labels are showing either a “Fresh” or “Still Fresh – Use Now”. Place the product into refrigeration between 3638oF (2-3oC) within 15 minutes of receipt. 3. If any of the temperature sensitive labels are indicating “Freshness NOT Guaranteed” the entire case must be returned to the vendor immediately and replaced with product that meets the listed specifications. 4. Once a month, the internal product temperature should be randomly checked during the receiving process by placing a calibrated stem 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 51 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE 5. 6. 7. 8. thermometer, accurate to +/- 2°F (1°C) between two of the internal cryovac packages of ground beef patties for a minimum of one minute so that an accurate temperature reading can be taken. The internal product temperatures must be at or below 41°F (5°C) and above 32°F (0°C) (Do not pierce beef patty packaging) If the internal temperature is not at or below 41°F (5°C) and above 32°F (0°C), the product must be returned immediately to the vendor. Any other cases of fresh hamburger patties delivered along with the inferior case of product should also be evaluated for temperature abuse and accepted or rejected as necessary. The person receiving the product must also verify that there is a minimum of 4 days usable shelf life still remaining on the product contained in each master case. This can be calculated by reviewing the USE BY date and determining if that date is a minimum of 4 days from the date the product was delivered. All products determined to have less that 4 days of usable shelf life remaining, must be immediately returned to the vendor for credit. III. Storage: 1. Place the master cases of ground beef patties into refrigerated storage at or below 38°F (3°C) and above 32°F (0°C) within 15 minutes of receipt at the hotel 2. Do not allow product to sit at room temperature for any given period of time 3. Ground beef patties must be maintained in storage at or below 38°F (3°C) and above 32°F (0°C) continually until the product is cooked 4. At no time should the fresh patties be allowed to be frozen or stored below 32°F (0°C) 5. Do not remove any cryovac packages of ground beef patties from the master cases until they are taken into production for use. IV. Handling/Preparation: 1. Cut open enough cryovac packages of ground beef patties for one shift use by using kitchen shears or pair of scissors. Wearing latex or vinyl gloves, remove the patties from the cryovac packaging. For ease of use, the individual patties can be separated and shingled onto a sheet pan or into a 2” (5.1 cm) hotel pan. 2. When the ground beef patties are removed from the cryovac packaging, they must be prepared, cooked and served within the next 48 hours (2 days). Never use ground beef patties for any purpose if they are older than the USE BY DATE listed on the individual cryovac packages. 3. Any patties that have been opened and remain after the 48 hour time period has elapsed, they must be utilized in completely cooked ground beef recipes such as meat loaf, chili, meat sauce, etc. that are cooked to or above 155°F (68°C) NOTES: • Current FDA food code requires that all ground beef products be cooked to a minimum internal temperature of 155°F (68°C) 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 52 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE • Follow all local, county, state and federal food code requirements regarding the minimum cooking temperatures for ground beef and menu verbiage alerts regarding the consumption of raw protein products, i.e. ground beef, seafood, and shell eggs. • Guests may request that their ground beef patties be cooked below the 155°F (68°C) and do so at their own risk. • Service associates/employees should not at any time solicit guests for “doneness” on ground beef patties. • If a guest does not request a specific doneness during the order taking process, then the ground beef patty should be cooked to a minimum of 155°F (68°C), per Marriott International standard. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 53 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE HACCP Form A11 MFST FRESH GROUND BEEF PATTIES RECEIVING LOG (Valid thru 12/31/10) Review one master case of fresh hamburger patties upon delivery checking each sleeve for the temperature sensitive label. Verify that the product has not been temperature abused. Follow guidelines on Form A10 Determine that there is a minimum of 4 days usable shelf-life left on the product by noting the day of delivery and subtracting that number from the Use-By date listed on the product Once a week, take the internal temperature of the product following the guidelines found on Form A10 If the temperature sensitive label is activated, if there is not at least 4 days or more of usable shelf-life, or if the product is delivered outside of the required temperature parameters; the suspect product should be returned and all other cases of product delivered at that time should be evaluated. Use the Action/Comment column to indicate corrective steps taken if the temperatures are not in the required range. File this document for three (3) months Temperature Sensitive Labels showing product is usable. Yes/No Delivery Date Use-By Date as Labeled on Master Case Amount of Shelf Life Remaining on Product Use-By Date minus Delivery Date Internal Temperature of Product Below 38o F (3oC) and Above 32o F (0oC) Action/Comment If case was returned for credit, date of pick up 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 54 Initials Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A12 PURCHASING, STORING & FABRICATING FRESH GROUND BEEF PATTIES CLEANING, SANITIZING & MAINTENANCE OF THE GRINDING MACHINE AND PARTS. Food Quality and Safety Standards (Valid thru 12/31/10) OBJECTIVE: The grinding of fresh ground beef and its use for hamburger patties has inherent risks. Due to the nature of the product, certain procedures must be followed by all properties handling raw ground beef products, fresh or frozen. If the following procedures are followed, the risks are low and manageable. Good raw product sourcing is paramount to avoid the potential of a food borne illness outbreak due to pathogens such as E. Coli 0157: H7, Salmonella and Listeria. Failure to adhere to these policies may cause monetary and reputation damages to your hotel, Marriott International and its partners. The maintenance of refrigeration, equipment and product temperatures throughout the preparation process, along with the cleanliness and condition of the grinding machine and equipment will ensure that the end product served to a guest is of the highest quality and a wholesome product. You can follow areas of these procedures for the production of other products, including pork, veal, lamb, or other related meats. The grinding of beef trimmings is strictly prohibited for use in the production of ground beef patties. Ground beef produced from beef trimmings is to be used only in products that are to be cooked to a minimum of 165° F (74°C). International hotels should utilize these procedures as a guidance document and should make every attempt to come into complete compliance. PURCHASING SPECIFICATIONS: ¾ When purchasing beef for use in the production of ground beef, you must specify: o Fresh boneless whole steer chucks (NAMPS # 115, North America only) o Weight from 70 – 80 lbs (31.75 – 36.29 kg) o Maximum fat of 20–22 % o Packed in sealed cryovac packaging according to standard boxed beef cardboard packaging requirements (USDA) o International hotels should make every attempt to purchase product meeting the stated specifications o Frozen beef, meeting the NAMPS #115 specifications, should only be used if fresh is not available DELIVERY ¾ AND STORAGE: Beef should be delivered under refrigeration at between 36°- 38°F (2-3°C) with the cryovac packaging showing no signs of leakage o Frozen, where used, should be delivered and received at 10ºF (-12ºC) or below. o Note that beef that has been placed in cryovac packaging tends to have a purple color while under vacuum and when initially opened, emits a slightly sour aroma. This is due to the wet aging process. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 55 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE o o o o MAINTENANCE o o o o o Store the meat on property in the original packaging for a maximum of 10 days. When the cryovac seal is broken, a maximum holding time of 3 days should be used. At international hotels, if non-cryovac (naked) boneless chucks from a local processor are purchased, they must be fresh on the day of arrival with no stickiness, odor or uncharacteristic attributes. Upon delivery, the beef should be placed in an NSF plastic container, labeled and dated and stored at 36°- 38°F (2-3°C) and have a maximum holding time on property of 3 days. AND HYGIENE: Grinders should be located in a refrigerator or cooled room at or below 36°- 38°F (2-3°C). The grinder head, worm, knife, plates, patty molds, storage tubs and all other related equipment must be kept refrigerated between uses and optimally stored wrapped in plastic and within a plastic tub in the coldest part of the refrigerator until needed for immediate use. Culinary associates/employees must wash their hands with an approved anti-microbial soap before working with the meat and again after leaving the area to prevent any possible contamination or cross-contamination of the product. Limit the number of employees who are authorized to fabricate the product. This will minimize training needs and chances of product contamination. Food grade quality vinyl gloves are to be worn throughout the fabrication and processing steps, including the molding (pattying) of the ground beef. FABRICATION: o Remove all meat from the cryovac packaging as necessary making sure to keep the residual liquid remaining inside the packaging and not on work surfaces. The product should be between 36°- 38°F (2-3°C). Remove any excess liquid from the meat with a clean paper towel. o Using a cutting board designated for raw products, and a clean sharp boning knife, proceed to remove any gristle, ligament, or unusable material from the chuck primal. o Disassemble and cut enough meat into workable pieces that are small enough to be gravity-fed into the mouth of the grinder and that will pass quickly through the knives and machine. o Large portions that pass through the machine with difficulty will increase the chances of emulsification and creaming of the fat. o Prepare only enough portioned raw beef product needed to process enough ground beef for a maximum of 24 hour usage. 12 hour usage is optimal if possible. o If less than a full chuck is to be used, the pieces should be cut from the chuck under refrigeration to assure keeping all the meat at a constant cold temperature between 36°- 38°F (2-3°C). o Store the cut meat in a chilled, NSF approved container. o It is strongly recommended to re-chill the meat again before grinding until the internal temperature of the meat is below 38°F (3°C). The colder the meat during the grinding process, the better final product will result. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 56 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE GRINDING: ¾ It is important to remember that when grinding any meat product, especially beef that contains both lean and fat, that heat is the enemy. Heat is generated by the simple process of running the grinder, dull grinding machine knives, and the handling of the product. Even low amounts of heat will melt the fat within the ground product, causing emulsification and creaming, both which greatly reduce the quality of the end product. o Remove grinder head, worm, knife, and plate from the refrigerated storage and assemble the grinder immediately before starting the grinding process. o Feed the well-chilled meat from the hopper into the grinder, catching the ground product in a clean, chilled and sanitized NSF approved container. o If a second grind is required, grind the product again into a suitable chilled and sanitized NSF container. o Continuous grinding once started, is essential to produce maximum efficiency of (chilled) machine and reduce the possibility of contamination. o Immediately following the grinding process, the ground beef should be stored refrigerated at or below 36°- 38°F (2-3°C) in a covered, NSF approved container for later molding, or used immediately. PORTIONING OF RAW GROUND BEEF: o All production of ground beef patties should be done under refrigeration at or below 36°- 38°F (2-3°C). o Preparation should be done using gloved hands at all times. o All molds should also be chilled. o Cover the mold with plastic wrap. o Place portioned ground beef into the mold and using the heel of the hand, press firmly to form the meat into the mold being sure edges are well formed and smooth. o Do not over-press the ground beef, avoiding over manipulation of the product. o Once the patties are formed, remove them individually onto suitable sized pieces of parchment paper and stack 4 – 6 deep in an appropriate NSF approved, clean and sanitized stainless steel or plastic storage pan. o Never mix older product with new and always use a clean and sanitized storage container. o Date, label, and cover immediately. o Refrigerate and use all patties within a 24 hour period. o Any patties or bulk ground beef not used within 24 hours must be utilized in products heated to a minimum of 155° F (68°C). CLEANING AND MAINTENANCE OF THE GRINDER AND ITS PARTS: ¾ An important factor in keeping ground beef wholesome and of the highest quality is the cleaning and maintenance of the grinder itself. o Keep grinder and its parts, washed, rinsed, sanitized, air dried and chilled between uses. o Break down the grinder after each use and limit its use to as few production episodes daily as possible. One to two times per day is best. o When cleaning the machine, make sure to unplug it prior to washing, or if hard-wired, make sure to shut off the power to the connection prior washing. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 57 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE o o o o o o o o Remove all attachments and parts from the machine and wash, rinse and sanitize them in a three compartment sink, (two compartment sink and pot washer for international hotels). Avoid washing the parts in a dish machine because the high heat and washing process can bake the meat onto the plates, worm, and other attachments. Using a compartment sink to wash the equipment will allow the associate/employee to get the meat residue off of the equipment much more thoroughly. The use of a synthetic scrub brush on the grinding blades versus a synthetic pad will best maintain their sharpness. Since many of the parts are small, it is a good idea to have them washed, rinsed, sanitized, and returned to the person responsible for the grinding immediately. Air drying can occur in the area where the grinding takes place. Knives and plates should be sharpened or replaced with a second sharp set periodically, (once a month is recommended). Dull knives and plates significantly reduce the quality of the final product. NOTES: • Ground beef trimmings should be used within 24 hours from time of grinding and may not be utilized for hamburgers. Adulterating, (adding of fresh or dried seasonings, herbs, or spices), can significantly increase the chances of cross-contamination by bacteria and their growth within the product. Keep all work surfaces, equipment, and product at the highest possible levels of sanitation and at the required temperatures throughout production. Keep limited quantities of ground beef in production at any given time. Do not freeze product at any time for later use. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 58 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A14 STORING, HANDLING AND PREPARING CITRUS FRUITS FOR FOOD AND DRINKS (Valid thru 12/31/10) Food Quality and Safety Standards Procedure: 1. Citrus varieties like lemons, limes, grapefruit and oranges require special treatment. o Upon receiving citrus fruits, store them in the original cases 2. The outer rind of these fruits can trap dirt and may contain harmful bacteria from the soil. Fruits must be washed and sanitized before cutting. o Rinse the fruits in cold water o Dip in the approved fruit and vegetable wash for at least 30 seconds 3. When removing the rind or cutting the fruit for use in cocktails, water or iced tea; use a clean and sanitized white cutting board. o Use a clean and sanitized knife to prevent cross-contamination when cutting o Use food handler’s gloves during preparation 4. When storing prepared fruits, use a clean container and do not mix items. o Keep prepared citrus chilled at or below 41°F or 5°C o Do not mix old with new o View the recommended container for bar use at: Mini Dome Garnish Center (PDF) Notes: ● “Victory Wash” (Ecolab) and “Fit” Fruit and Vegetable Wash are the approved washes for produce. Follow the user instructions. Test Victory Wash once a month to make sure the correct strength has been calibrated. Contact Ecolab for testing or to purchase test strips. Strength recommendation is 60-80 parts per million. ● Fit Fruit and Vegetable Wash is available from US Foodservice. Read the label for mixing the correct strength directions. ● Mini Dome Garnish Center can be purchased from Wasserstrom (item #801643) ● If using an ozone wash, test the solution once a month with test strips provided with the unit. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 59 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A15 PREPARATION OF LOBBY AND SPA GRATIS BEVERAGES (Valid thru 12/31/10) Food Quality and Safety Standards 1) Lemons, limes, oranges, cucumbers, herbs and other citrus fruits must be stored under refrigeration when received. 2) Rinse and sanitize all ingredients prior to preparing or cutting. 3) Use a clean knife and prepare ingredients on a white cutting board. 4) Food grade gloves must be worn while cutting fruit, vegetables or preparing herbs and placing them in the beverage dispenser. 5) Use clean ice that has not been cross-contaminated. 6) All beverages not refrigerated must be discarded after 4 hours. 7) Wash and sanitize drink dispensers between uses. 8) Disposable containers and napkins are to be used with a trash receptacle within ten feet. PREPARATION NOTES: • • • • FOR GUEST CHECK-IN AND SPA AREAS Citrus-infused water or cucumber water is recommended Do not combine citrus with cucumber Citrus water may include lemon, lime, or orange One citrus ingredient or a combination may be used Standard recipe Crushed Ice ………………………………….…..7 quarts Filtered Cold Water ………….…………………1 gallon Sliced Citrus or Peeled Cucumber.…………..24 each Procedure #1: 1) In a clean container, mix 5 quarts of ice with cold water, fruit or cucumber. 2) Mix ingredients lightly to blend and pour in dispenser. 3) Top with remaining 2 quarts of ice and cover. 4) Taste the beverage and serve. Procedure #2: 1) Shingle fruit or cucumber slices around the inside of a clean dispenser. 2) Add 5 quarts of ice to the center of the container. 3) Slowly pour cold water onto the ice making sure slices are left intact. 4) Top with remaining ice and cover. 5) Taste the beverage and serve. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 60 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE • Certain fruits do not work well as their flavor will not infuse without heat. Do not use strawberries, raspberries, grapes, apples, kiwi, stone fruit or similar fruits. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 61 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A16 PURCHASING, RECEIVING, STORAGE AND HANDLING OF FRESH POULTRY (Valid thru 12/31/10) Food Quality and Safety Standards Procedure: 1. Purchase poultry from inspected, (third party or hotel management inspections), facilities or a USDA inspected facility. o Whole birds should be well-fleshed with no missing skin, cut marks, blood spots, bruises and other blemishes. o Boneless single and double breast portions should be free of excess fat, bone, cartilage, foreign material, and have the rib meat removed. Blood spots, bruises and other blemishes shall not exceed normal grade. The tenderloin should be fully intact. o Bone-in single and double-breast lobe breast portions should be free of excess fat, cartilage, any foreign material and have the rib meat removed. Blood spots, bruises, and other blemishes shall be minimal. The tenderloin should be fully intact. 2. Chicken products should be delivered at a temperature of 28º-32ºF (-2º-0ºC). The product, though not frozen, will be firm to the touch. o No ice should be used as a refrigerant during distribution or storage. o Upon delivery, immediately store on the lowest shelf in the coldest part of the refrigeration unit. o Reject delivery of poultry that is slimy, has a pungent odor, grey or green skin color; and is above the minimum required temperature. 3. Poultry storage on property should be maintained at 32º-38ºF (0º-3ºC). o The maximum shelf life of all raw poultry products is 12-14 days from kill date. o Maximum storage time on property is 3 days from date of delivery. Notes: ● Handle all raw poultry with care, utilizing gloves for personal protection and to prevent cross-contamination. ● Cook raw poultry products to a temperature of 165°F (74°C). 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 62 Global HACCP Plan FOOD QUALITY AND SAFETY GUIDANCE Form A17 RECEIVING, STORING and HANDLING OF FRESH SHELLFISH (Valid thru 12/31/10) Food Quality and Safety Standards PROCEDURE: 1) Shellfish (in the shell) including clams, mussels, oysters and scallops are to be received: at a temperature of no more than 41°F (5°C) in their original containers until ready to prepare 2) Shellfish must come from approved harvesting areas with an affixed tag containing: catch origination date of harvest dealer’s name and identification number. Retain these tags on the original container until empty and thereafter keep on file for 90 days. Warm water oysters (oysters from waters above 72°F-22°C) such as those originating from the Gulf of Mexico or Atlantic Coastal areas in the US, may not be served raw at any time. 3) Shellfish must be reasonably free of mud, dead shellfish or broken shells. All dead, cracked and broken shellstock must be discarded. Only tightly-closed shellfish can be used. 4) Shellfish may be removed from original container and displayed for sale providing products are: washed and cleaned with potable water maintained on drained ice kept out of standing water protected from contamination identified and not mixed with differing species Best practice for International Hotels: Retain a frozen sample from each batch of shellfish for future testing if necessary. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 63 Global HACCP Plan GLOSSARY Terms CCP Decision Tree: A sequence of questions to assist in determining whether a control point is a CCP. Control: (a) To manage the conditions of an operation to maintain compliance with established criteria. (b) The state in which correct procedures are being followed and criteria are being met. Control Point: Any step at which biological, chemical, or physical factors can be controlled. Corrective Action: Procedures followed when a deviation occurs. Criterion: A requirement on which a judgment or decision can be based. Critical Control Point: A step at which control can be applied and is essential to prevent or eliminate a food safety hazard or to reduce it to an acceptable level. Critical Limit: A maximum and/or minimum value to which a biological, chemical, or physical parameter must be controlled at a CCP to prevent, eliminate, or reduce to an acceptable level the occurrence of a food safety hazard. Deviation: Failure to meet a critical limit. HACCP: A systematic approach to the identification, evaluation, and control of a food safety hazard. HACCP Plan: A preventive approach to food safety that addresses physical, chemical, and biological hazards as a means of prevention rather than finished product inspection. HACCP System: The result of the implementation of the HACCP plan. HACCP Team: The group of people who are responsible for developing, implementing, and maintaining the HACCP system. Hazard: A biological, chemical, or physical agent that is reasonably likely to cause illness or injury in the absence of its control. Hazard Analysis: The process of collecting and evaluating information on hazards associated with the food under consideration to decide which are significant and must be addressed in the HACCP plan. Monitor: To conduct a planned sequence of observations or measurements to assess whether a CCP is under control and to produce an accurate record for future use in verification. Prerequisite Programs: Procedures, including Good Manufacturing Practices that address operational conditions providing the foundation for the HACCP system. Severity: The seriousness of the effect(s) of a hazard. Step: A point, procedure, operation, or stage in the food system from primary production to final consumption. Validation: That element of verification focused on collecting and evaluating scientific and technical information to determine whether the HACCP plan, when properly implemented, will effectively control the hazards. Verification: Those activities, other than monitoring, that determine the validity of the HACCP plan and that the system is operating according to the plan. 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 64 Global HACCP Plan REFERENCE Web Resources Global Food Safety forms on Marriott Global Source Food Safety Review by Brand on Marriott Lodging Quality Assurance Hazard Analysis and Critical Control Point Principles and Application Guidelines Food and Agriculture Organization HACCP Guidance FDA Food Code 2009 2010 Marriott International, Inc. All rights reserved. All contents are confidential and proprietary and may not be reproduced, disclosed or distributed, in whole or in part, without permission. 65