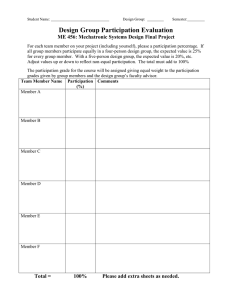

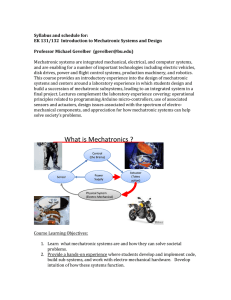

Al-Azhar University Faculty of Engineering & Information Technology Mechatronic Design (ITME4333) Chapter 1 : Introduction in Mechatronic Design Prepared by Dr. Alaa AbuZaiter First Semester, 2020/2021 What is Mechatronic ? ■ Mechatronics is a multidisciplinary field of engineering that includes a combination of mechanical engineering, robotics, electronics, computer engineering, telecommunications engineering, systems engineering and control engineering. ■ As technology advances, the subfields of engineering multiply and adapt. Mechatronics' aim is a design process that combines these subfields. ■ Originally, mechatronics just included the combination of mechanics and electronics, therefore the word is a combination of mechanics and electronics; however, as technical systems have become more and more complex the definition has been broadened to include more technical areas. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 2 Mechatronics Systems Computers Cars Tools Consumer Electronics Stealth Bomber High Speed Trains MEMS 3 What is Mechatronic design ? ■ Mechatronic design is the integrated design of a mechanical system and its embedded control system. In order to make proper choices early in the design stage, tools are required that support modelling and simulation of physical systems together with the controllers with parameters that are directly related to the real-world system. ■ Such software tools are becoming available now. Components in various physical domains (e.g. mechanical or electrical) can easily be selected from a library and combined into a ‘process’ that can be controlled by block-diagram-based (digital) controllers. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 4 Components of a Mechatronic System There are basically four main components of any mechatronic system. Some mechatronic systems might contain some other components, but these four are essential for the successful operation of a mechatronic system: 1. The physical system being controlled (mechanical, fluidic, chemical, thermal, and electrical). 2. Actuator: The actuator provides the force or torque (or other relevant physical input) to the physical system to be controlled. In mechanical systems, the actuator could be either translational (usually referred to as linear) or rotational. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 5 Components of a Mechatronic System 3. Sensors. Sensors are the eyes and ears of the controller. Sensors are also referred to as transducers (although strictly speaking there are subtle differences between sensors and transducers). 4. Controller: The controller is the brain of the mechatronic system. It reads the input signals representing the state of the system; compares them to the required states; and outputs signals to the actuators to control the physical system. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 6 Al-Azhar University – Dr. Eng. Alaa AbuZaiter 7 The following are examples of mechatronic systems: ■ Home applications (e.g., washing machines). Many of the home applications that are in use today are mechatronic systems. They are manufactured in large numbers of masse and typically require small controllers to be “embedded” within them. ■ ABS (anti-lock braking system) and many areas in automotive engineering. An anti-lock braking system on a vehicle is a system that prevents the wheels from ceasing up or stopping to rotate when the brakes are suddenly pressed. ■ Sorting and packaging systems in production lines. Mechatronic systems are effectively the basis for modern factory automation. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 8 ■ Mobile robots and manipulator arms. Robots are widely used today in all spheres of life. Robots are generally used for applications that are inaccessible (difficult locations to get to due to height or space), dull (repetitive and tedious tasks) or dangerous (hazardous environments). ■ Computer Numerically Control production machines (CNC). CNC machines are critical in modern manufacturing systems. They allow the user to produce a product directly from a computer model of the piece. ■ Aeroplanes and helicopters: These are complex examples of mechatronic systems that incorporate hundreds or even thousands of smaller sub-mechatronic systems. ■ Tank fluid level and temperature control systems, an example of which is the process used to produce bio-fuels from vegetable oil. ■ Temperature control system in an industrial oven. ■ Using robots for painting windows and doors Al-Azhar University – Dr. Eng. Alaa AbuZaiter 9 The Four Questions that Should be Asked when Designing a Mechatronic System 1- Is system dynamics important? If the speed of response of a system is critical to its stability and time response specification (e.g. overshoot, rise time, settling time …), then system dynamics is important and has to be considered in the design. In this case, a dynamic model has to be developed for the whole system (including the plant, controller, actuator and sensor). The model is then used to design a suitable controller. System dynamic is usually important if one or both of the following two conditions is true: - The system must respond quickly to change in the reference value to overcome the effect of disturbances - when achieving an accurate and exact value of the controlled variable(s) is important. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 10 The following list includes examples of systems for which system dynamics is critical: - Quad-rotor - Vehicle active suspension system - Space vehicle On other hand, for the following systems, system dynamics is not critical: - eyes scanning system for identification purposes - Artificial nose - A solar tracking photo-voltaic system Al-Azhar University – Dr. Eng. Alaa AbuZaiter 11 The Four Questions that Should be Asked when Designing a Mechatronic System 2. What type of components to select for each of the four main components for the mechatronic system? The designer of the system will have to make a decision regarding the components of the mechatronic system, as follows: a- Control algorithm: example: PI,PD,PID, lead-lag compensator, Fuzzy controller, neural… genetic, digital PID … b- Physical controller: This is the physical controller within which the control algorithm will be implemented. Examples: PLC, PC/laptop, and microcontrollers, as well as relays and the older type of analogue computers and logic gates. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 12 c- Actuator System: The actuator executes the instructions of the controller to realize changes in the plant. The actuator systems comprises the following three sub-components: variable speed drive (optional); actuator (mandatory); mechanical drive (optional). d- Sensor/Transducer/feedback Drivers): The sensor or feedback devices are the eyes and ears of the mechatronic system. They can be thermal, mechanic (translational or rotational) … etc. Where system dynamics is important, it is necessary to find transfer function of the sensor as well, as it forms the H(s) transfer function shown in the figure below. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 13 Al-Azhar University – Dr. Eng. Alaa AbuZaiter 14 The Four Questions that Should be Asked when Designing a Mechatronic System 3- The size of each component: Once the design has selected the components to be used he/she has to size them. Calculations have to be carried out to find the necessary size. This is especially true of the actuator system (e.g. motor, variable frequency drive, gearbox). 4- Resolution, accuracy and precision: Once the sensor/feedback has been selected, it is necessary to ensure that it can achieve the required accuracy, resolution and precision. The user requirements specify the required accuracy, resolution and precision. In some cases, the controller selection and the actuator selection have to be revised or changed in order to achieve these requirements Al-Azhar University – Dr. Eng. Alaa AbuZaiter 15 Examples of User Requirements Specifications for a Mechatronic System ■ The following categories include the types of users requirements for mechatronic systems: 1. Size/Capacity/Force/Torque/Stroke: This is the most obvious user requirement. It is related to the size of the system, in relationship to what is can do. For example, a bottle filling system will be able to fill 1000 bottles per hour; or on elevator can carry eight persons; or a printer can print 12 pages per minute. 2. Safety/Reliability/Maintainability/Availability. 3. System dynamics (e.g. rise time; overshoot; settling time). 4. Resolution/Accuracy/Precision: These characteristics are related to both actuator(s) and transducer(s). Resolution is the smallest change in input that would cause a change in output. Accuracy is freedom from systematic errors. Precision Is freedom from random errors. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 16 Examples of User Requirements Specifications for a Mechatronic System 5. User Friendliness: The system user interface should be user friendly. It should allow different levels if access. It should also be “fool proof”. 6. Energy Consumption: In some application, reducing the amount of energy consumed must be restricted/reduced. 7. Cost (Capital cost/Running cost): It is important to consider all costs associated with the system, throughout the lifetime of the system. This includes capital costs (initial cost of the system) as well as running costs (energy costs, maintenance cost). 8. Space/Size/Weight: In certain cases, there may be constraint on the size of the system and its weight. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 17 Examples of User Requirements Specifications for a Mechatronic System 9. Environment: It is important to consider the environment in which the system will be operated. For example, ambient temperature, humidity, dust, and foreign particle and fluid ingress. 10. Versatility : A versatile system is one that can be used in different ways. Al-Azhar University – Dr. Eng. Alaa AbuZaiter 18