Tunnel Construction Methods: Geotechnical Analysis & Design

advertisement

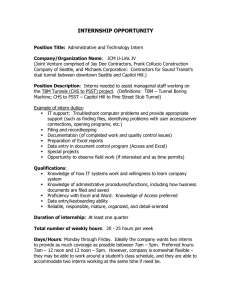

MKAJ 1023 ANDVANCED GEOTECHNIICAL ANALYSIS AND DESIGN ASSIGNMENT : TUNNEL CONSTRUCTION METHOD NAME : MUHAMMAD AMEER ZAHID BIN MOHD ZAFRULLAH MATRIC NO. : MKA191024 LECTURER : DR.NORAFIDA REVISION What is difference between hard and soft ground tunneling? Soft Ground Tunneling Hard Ground Tunneling Shallow tunnel (cover less or equal to 2 times diameter of tunnel) Deeper depth of tunnel Complex due to ground water level Complex due to rock conditions Soil-structure interaction Rock-structure interaction More settlement especially for shallow depth More stable, long stand up time Excavation stages must be sufficiently short, both in terms of dimensions and duration. Deeper depth of tunnel Erection of the ‘full ring’ of initial ground support must be completed immediately after excavation. Do you know shallow tunneling? Yes. Shallow tunnel has a cover less or equal two times the diameter of the tunnel. What suitable tunnel for clay/saturated/high water condition? Earth Pressure Balance Machine TUNNEL BORING MACHINE: A GENERAL REVIEW ON SOFT GROUND TUNNELING Muhammad Ameer Zahid Bin Mohd Zafrullah Introduction Mechanized tunneling is an alternative to method to the classic drill and blast, New Austrian Tunneling Method (NATM) and New Italian Tunneling Method. Tunnel Boring Machine (TBM) is a well-known tunneling machine that bore through variety of soft and hard ground with circular-cross section in shape. The TBM are divided into two group which is shielded TBM and non-shielded TBM. The shield resist surrounding pressure and hold back ground water from the excavated cavity priorly before the temporary support and final lining installed as the tunnel continues to advance. Three most common shield TBM in soft ground tunneling is Slurry Shield TBM, Earth Pressure Balance (EPB) Machine, and Variable Density Machine. Slurry Shield TBM Slurry Shield TBM is one of the common closed shield TBM that uses slurry face support method. Depending on the soil condition the slurry which is a fluid support medium can be a suspension of water and bentonite or clay (sometimes with additives). The functional of the slurry is to form a “filter cake” which can be describe as an almost impermeable layer of bentonite or clay particle that formed as the suspension is filtered under flow gradient at the surface face. The filter cake enables the pressurized suspension in the excavation chamber to equilibrium against ground and water pressure. In order to from the filter cake, the slurry is pumped into the closed excavation chamber against the face, where it penetrates under pressure into the soil, seals it and form the filter cake. The slurry purpose as a support medium also undertakes the role as a transport medium by mixing with the excavated material before being pumped out back to a slurry separation plant, usually outside of the tunnel. Slurry separation plants are multi-stage filtration systems, which remove the soil from the slurry so that it may be reused if required and pump back down to the face. The removal of the excavated soil as a suspension in a fluid pumped by a centrifugal pump can be characterize as hydraulic mucking. The method of soil excavation is full-face machine with cutting wheel. The cutting wheel of a slurry shield is flat and almost closed, which provide a certain degree of mechanical support in addition to the action of the pressurized slurry. The excavation tools, in general scrapers or teeth, are fitted in two rows radially so that the machine can excavate while rotating in either direction. The soil can pass through slots in the cutting wheel parallel to the excavation tools; the width of the slots has to be suitable for the expected maximum grain size The main disadvantage of slurry shield TBM are the space and energy required by the slurry separation plant. However, the most crucial part is the difficulties with encountering fine grained material. Separated fine grained material are difficult to disposed and any bentonite suspension loaded with fine material cannot be separated. The cost-effectiveness of a slurry shield in comparison with other processes is essentially determined by the cost and difficulty of separating the transport suspension. The technical limits to its application are set by the permeability of the soil encountered. For this reason, slurry shield TBMs are not suitable for silts and clays as the particle sizes of the spoil are less than that of the bentonite clay from which the slurry is made (Maidl et al., 2013). Earth Pressure Balance (EPB) Machine Earth Pressure Balance (EPB) Machine is one of the common closed shield TBM that distinct from other closed shield TBM that does not mainly rely on additive for the support medium as the role was taken by the excavated soil by the cutting wheel. However, it depends on soil condition to increase the stability of the ground. Unlike slurry shield the soil cut from the face by the tools on the cutting wheel squeeze through the opening in the cutting wheel into the excavation chamber mixes with the already remoulded earth mud. To reach the state of equilibrium between the support pressure of the earth mud and the face pressure, the earth mud in the excavation chamber is compacted by the thrust cylinder. Thrust cylinder provide thrust to the earth slurry through the pressure bulkhead and avoid uncontrolled penetration. The quantity of soil taken from excavation chamber is regulated by the screw conveyor rotational speed which is match to the advance speed. The aim is to maintain the state of equilibrium between the quantity of soil removed by the screw conveyor and the quantity of soil accumulated from the shield tunneling process. The requirement for the excavated material to be used as support medium: Good plastic deformability Plastic consistency Low internal friction Low water permeability Good elasticity by being compressible Good plastic deformation properties and a pasty consistency ensure that the support pressure is as evenly distributed across the face as possible, a continuous flow of material to the screw conveyor inlet and that blockages are avoided in areas with little pressure gradient. The internal friction of the soil should be as low as possible to minimize wear and energy consumption. A low permeability is necessary to transfer the material to the transport conveyor at the outlet of the screw conveyor without an air lock. Good compressibility simplifies the control of support pressure by regulating the screw conveyor. Soil conditioning is needed when natural excavated soil does not meet the required properties. Therefore, selection of conditioning process must compliment the type of soil encountered and depended on the parameter grading curve, water content 𝑤(%), liquid limit 𝑤𝐿 (%), plasticity index (𝐼p) and liquidity index(𝐼c). These parameters can be influenced by the addition of: Water Bentonite, clay or polymer suspensions Tenside or polymer foams Several main disadvantage EPB is the increasing of sand content from initial condition of the soil in which addition of water no longer effective. The increased water permeability also makes sealing of the screw conveyor difficult. The absence of fines content has to be supplemented with the addition of clay or bentonite suspension (Maidl et al., 2013) Variable Density TBM Classic shield TBM have certain limits encountering variable geologies in term of technical and economics. A new generation of multi-mode TBM, the Variable Density TBM have been introduced to the industry. The technology combines the slurry-supported mode (Mixshield method) and earth pressure balance mode (EPB method) thus combining their advantages in a single machine without any major mechanical changes. Operational of the machine is control by mode it is use in. In earth pressure balance mode, the face support pressure is control through the screw conveyor speed and the advance rate of the TBM. Meanwhile, in slurry mode the face support pressure is automatically controlled by an air cushion. (Release, 2015) Varied from Mixshield TBM the submerged wall opening is replaced by communicating pipes. Excavated material from both modes will be removed from the pressurized excavation chamber through the screw conveyor. In EPB mode, the screw conveyor drops the excavated material onto a belt conveyor. An additional slurryfier box at the end of the screw conveyor makes it possible to drive the TBM with a hydraulic slurry circuit in slurry mode. This makes the range of application of the Variable Density TBM even larger and makes the machine the all-rounder for loose soils of all kinds (Gripper TBM – Herrenknecht AG, n.d.). From your point of view, why advancement of tunnel different from one country /case study to the other The term advancement in tunnel is quite broad. In terms of advancement of a country in developing experts in tunnel engineering really depends on how that country had been involve in tunneling projects in which shaping and developing engineer and workers involve in it. Malaysia’s SMART tunnel can be considered the pioneer of the country’s involvement in tunneling project. Compared to other countries like China and Germany that have large number of tunneling project have produce large number of experts and specialize workers related to tunnel engineering. In terms of how the advancement of a country embracing the development of tunnel. Every country has different geological profile even from one city to another. Government funds are often required for the creation of tunnels. When a tunnel is being planned or constructed, economics and politics play a large factor in the decision-making process. Civil engineers usually use project management techniques for developing a major structure. Understanding the amount of time, the project requires, and the amount of labor and materials needed is a crucial part of project planning. The project duration must be identified using a work breakdown structure (WBS) and critical path method (CPM). Also, the land needed for excavation and construction staging, and the proper machinery must be selected. Large infrastructure projects require millions or even billions of dollars, involving long-term financing, usually through issuance of bonds. Reference Gripper TBM – Herrenknecht AG. (n.d.). Retrieved May 16, 2020, from https://www.herrenknecht.com/en/products/productdetail/multi-mode-tbm/ Maidl, B., Thewes, M., & Maidl, U. (2013). Handbook of Tunnel Engineering. In Handbook of Tunnel Engineering (Vol. 1). Wiley Blackwell. https://doi.org/10.1002/9783433603499 Release, P. (2015). HERRENKNECHT Variable Density Technology : Game Changer for Kuala Lumpur. 1–8. https://www.herrenknecht.com/en/newsroom/pressreleasedetail/variable-densitytechnology-game-changer-for-kuala-lumpur/