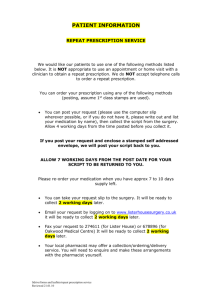

Lecture 1. Part 1. Introduction to pharmaceutical technology. Pharmacy, minimum requirements for it. Responsibilities of pharmacists. First of all, we are going to talk about pharmacy or drugstore. So, what is pharmacy ? Well, we can say that the primary definition is that Pharmacy is a place where drugs are sold. But, contrary to this popular belief, pharmacy is not limited to counting and dispensing pills. Pharmacy is a rewarding profession in the health care system that involves working closely with doctors and patients. Pharmacists educate consumers on medication use, monitor patient's health to ensure that the patient is getting the full benefits of the drug. As a result, patients have come to depend on the pharmacist as a health care information resource of the highest calibre. Pharmacists also advise doctors and other health care professionals on making wise medication decisions. In the interest of protecting the public health and welfare, in order to ensure optimum effect of drug therapy, and to maximize the quality of Pharmaceutical Care, the following rules are essential. A. Minimum Requirements for a Pharmacy 1. Each Pharmacy shall be of sufficient size to allow for the safe and proper storage of Prescription Drugs and for the safe and proper compounding of Prescription Drug Orders. 2. Each Pharmacy shall maintain an area designated for the provision of Patient Counseling services. This area shall be designed to provide a reasonable expectation of privacy. 3. All areas where Drugs and Devices are stored shall be dry, well-lighted, well-ventilated, and maintained in a clean and orderly condition. 4. Each Pharmacy shall maintain on file at least one current reference in each of the following categories: a. State and Federal drug laws relating to the Practice of Pharmacy and the legal distribution of Drugs b. pharmacology c. dosage and toxicology d. general 5. Each Pharmacy shall maintain patient-oriented reference material for guidance in proper drug usage. 6. Each pharmacy shall have access to a sink with cold and hot running water that is convenient to the Compounding area for different purposes. 7. Security. a. Each Pharmacist, while on duty, shall be responsible for the security of the Pharmacy including provisions for effective control against theft or diversion of Drugs and Devices b. Prescription and other patient health care information shall be maintained in a manner that protects the integrity and confidentiality of such information. 8. Equipment/Supplies. The Pharmacy shall carry and utilize the equipment and supplies necessary to conduct a Pharmacy in a manner that is in the best interest of the patients served and to comply with all State and Federal laws. The principal goal of pharmaceutical care is to achieve positive outcomes from the use of medication which improves patients' quality of life. These outcomes include: cure of a disease elimination or reduction of symptoms arresting or slowing a disease process 1 prevention of disease diagnosis of disease desired alterations in physiological processes Pharmacists are specialists in the science and clinical use of medications. They must be knowledgeable about the composition of drugs, their chemical and physical properties, and their manufacture and uses, as well as how products are tested for purity and strength. Additionally, a pharmacist needs to understand the activity of a drug and how it will work within the body. More and more prescribers rely on pharmacists for information about various drugs, their availability, and their activity. The responsibilities of a pharmacist are • • • • • • • Resource to patients, physicians and practitioners about dosing, interactions and general information regarding medications Perform basic staffing responsbilities Answering phones Dispensing prescripitons Entering prescriptions into the pharmacy computer system Oversee technicians and coordinates workflow Maintains relationships with customers and hospital personnel Part 2 Reviewing and Dispensing Prescription and Medication Orders DEFINITIONS Prescriptions are orders for medications, nondrug products, and services that are written by a licensed practitioner or midlevel practitioner who is authorized by state law to prescribe. Although medical doctors, pediatrists, dentists, and veterinarians have traditionally been the practitioners given this authority, some states and countries now allow optometrists, nurse practitioners, physician assistants, and pharmacists to prescribe medications. In the later cases, certain restrictions may apply. For example, such practitioners may be required to pass special certification exams, or they may be restricted to prescribing only under the supervision of a licensed physician, or under a limited, established protocol. Pharmacists are increasingly being given prescribing privileges by enactment of state collaborative drug therapy management (CDTM) legislation. This allows pharmacists to change the dose of existing medications or order new medication under established protocols or guidelines agreed on by the pharmacist and physician. Practitioners may prescribe only medications that are within their scope of practice. For example, veterinarians can only prescribe for animals; dentists are limited to prescribing medications required by their dental patients for their dental problems, and so on. It is the duty of the pharmacist to keep informed about state laws regulating prescribing authority. Prescriptions may be written, presented orally (by telephone), or presented electronically ( i .e., via fax or computer network) to the pharmacist. The requirements of the prescription form include security features and tamper - resistant characteristics and vary with state regulations. The prescription serves as a vehicle for communication from the prescriber to the pharmacist about the needs of the patient. 2 The following information should be included on a prescription: 1. Patient information, including full name and address 2. Date on which the prescription was issued 3. Name and dosage form of the product . The name can be any of the following: a. Proprietary (brand) b. Nonpropr ietary (generic) c. Chemical 4. Product strength. The strength of the product is not required if only one strength is commercially available or if the product contains a combination of active ingredients. It is advisable to include the strength to reduce the chance of misinterpreting the prescription. If the dose is to be calculated by the pharmacist, then the pharmacist can decide the strength of the product dispensed after calculating the patient's dose. 5. Quantity to be dispensed. This should include the amount and the units of measure (e.g., grams, ounces, tablets). If the amount is not specified, the directons should specify the dose to be taken and the duration of therapy so that the pharmacist can calculate the quantity required for the patient . 6. Directions for the pharmacist. Directions may be required for : a. Preparation (e.g., compounding) b. Labeling (i .e., information to be put on the prescription label ) 7. Directions for the patient. These should include explicit instructions on the quantity, schedule, and duration for proper use. “As Directed” should be avoided. 8. Refill information. If refill information is not supplied, it is generally assumed that no refills are authorized. “As needed” (pro re nata [prn] ) refills are usually interpreted as allowing for refills for 1 year unless laws or regulations restrict the amount or time period in which a prescription is valid. 9. Prescriber information. This should include the name, office address, signature of the prescriber, the Drug Enforcement Administrat ion (DEA) number (for controlled substances only) and the National Provider Identifier (NPI ) number. Medication orders are orders for medications by an individual authorized to prescribe and are intended for use by patients while in an institutional setting. They may be written, presented orally (by telephone), or presented electronically ( i .e., via fax or computer network) to the pharmacist. The medication order generally includes 1. Patient informat ion (e.g. , full name, identification number) 2. Date and time the order was written 3 3. Name of the product 4. Product strength, dosage, and route of administration. 5. Prescriber 's signature. If the order was taken verbally, the name of the person transcribing the order should be included. 6. Direct ions for the pharmacist. 7. Instructions for administration, including quantity, route of administration, schedule, and duration of use UNDERSTANDING THE PRESCRIPTION OR MEDICATION ORDER AND EVALUATING ITS APPROPRIATENESS Understanding the order. A complete understanding of all information contained in a prescription or medication order is required. Each piece of information should be appropriate and consistent with the remaining information (i .e., the instructions for use should be appropriate for the medication being ordered). The pharmacist should read the entire prescription or medication order carefully to determine the prescriber 's intent by interpreting the following information: 1. The name and address of both the patient and the prescriber 2. The patient 's disease or condition requiring treatment 3. The reason the order is indicated, relative to the medical need of the patient (e.g., an antibacterial for an infection) 4. The name of the product, the quantity prescribed, and instructions for use 5. All terminology, including units of measure (apothecary, metric, or English) and Latin abbreviations Evaluating the appropriateness. Complete information is required on the prescription or medication order to provide the necessary information to allow the pharmacist to evaluate the appropriateness of the order. When the order is incomplete, the pharmacist must obtain the required information from either the patient or the prescriber. The following should be considered during an evaluation: 1. The patient 's disease or condition requiring treatment 2. The patient 's allergies or hypersensitivities 3. The pharmacological or biological action of the prescribed product 4. The prescribed route of administration 4 5. Whether the prescribed product might result in a drug-drug, drug-disease, or drug-food interaction 6. Whether the dose, dosage form, and dosage regimen are safe and likely to meet the needs of the patient 7. Whether the patient will have any difficulties adhering to the regimen and the potential impact on the therapeutic outcome desired 8. Whether the total quantity of medication prescribed is sufficient to allow proper completion of a course of therapy 9. Whether a physical or chemical incompatibility might result (i.e., if the product requires extemporaneous compounding) 10. Whether a licensed practitioner, acting in the course and scope of practice, issued the prescription in good faith, for a legitimate medical purpose Discovering inappropriate prescriptions or medication orders. Pharmacists are required to review medication profiles to ensure the appropriateness of prescriptions or medication orders. This is commonly called drug utilization review (DUR). Pharmacists should not fill or process prescript ions or medication orders that they have concerns with or that are considered inappropriate but, rather, should contact the prescriber. The process of calling a prescriber to discuss concerns identified during a DUR is commonly called therapeutic intervention. 1. When performing a therapeutic intervention, the following information should be provided: a. A brief description of the problem b. A reference source that documents the problem c. A description of the clinical significance of thde problem d. A suggestion of a solution to the problem 2. The following resolutions are possible to solve the problem or concern: a. The prescription or medication order will be dispensed as written. b. The prescription or medication order will not be dispensed. c. The prescription or medication order will be altered and dispensed. 3. Documentation of the results of a therapeutic intervention are required if the prescription or medication order is changed. The name of the prescriber, date of communication, issues discussed, and resolution should be included in the documentation. This information should be kept for the same time period as the prescription or medication order. 4. I f the pharmacist feels that, in his or her professional judgment, an order is inappropriate and could harm the patient, the pharmacist should not process the order. The pharmacist may also be 5 required to explain the situation to the patient. If, after a therapeutic intervention, the pharmacist believes the order is still inappropriate, the guidelines of the institution and professional judgment should be followed. UNIVERSITY OF WISCONSIN-MADISON 425 N, CHARTER STREET SCHOOL - OF PHARMACY MADISON, WISCONSIN 53706 R# 123456 Name John Doe Address (1) Date 123 North Main Street, City (1) R Amoxil Refill 01/01/00 Age (2) Sex J. Thompson 01/01/00 Amoxicillin Capsules 250 mg (4) #30 (4) Sig: i cap tid for 10 days. (5) 0 1 2 3 4 5 p rn Linus Ashman (3) (6) MD DEA No. ADDRESS 20 S. Park St. (3) Figure 1. UNIVERSITY OF WISCONSIN-MADISON 425 N, CHARTER STREET SCHOOL - OF PHARMACY MADISON, WISCONSIN 53706 R# 123456 Name John Doe Date Address Age R Refill 123 North Main Street, City (4) 01/01/00 Sex Amoxil (5) J. Thompson 01/01/00 (2, 3) Amoxicillin Capsules 250 mg #30 Sig: I cap tid for 10 days. 0 1 2 3 4 5 p rn Linus Ashman MD DEA No. ADDRESS 20 S. Park St. 6 MEDICAL CENTER HOSPITAL Madison, Wisconsin Patient Name: David John (1a) History Number: 120579 (l.b) Weight: 1251b Height: 5'9" Age: 62 y.o. Attending Physician: R. Farrell Date Time 01/01/00 1300 10,000 units Heparin Sodium in 250 mL NS. (4) (3) Infuse IV over 4 hr. (5,6) (3) Orders R. Farrell, MD (7) J. Thompson, 01/01/00 (8,9) 01/01/00 1600 Penicillin G IM Injection. Give 200,000 units stat then 100,000 units q 4 hr. (4,5,6) R. Farrell, MD (7) J. Thompson, 01/01/00 (8,9) 0102/00 1400 Morphine sulfate 10 mg and Atropine sulfate 0.4 mg (4) On call for surgery at 0800 on 01/03/00. (6) Give IM (5) R. Farrell, MD (7) J. Thompson, 01/02/00 (8,9) 7 PROCESSING PRESCRIPTIONS AND MEDICATION ORDERS requires that the pharmacist follow appropriate guidelines. Automation and the use of pharmacy technicians allow the pharmacist to oversee these functions but spend less time performing these activities. The time saved allows the pharmacist greater time for patient- focused activities, such as counseling and patient education. The following information should be recorded on the prescription: 1. The prescription number (for initial filling) 2. The original date of filling 3. The product and quantity dispensed 4. The pharmacist 's initials Product selection. Generic substitution statutes, as well as formulary and therapeutic substitution policies, might provide direction in product selection. Product preparation for use by the patient The following might be necessary for preparation: 1. Obtaining the proper amount of medication to be dispensed 2. Reconstitution 3. Extemporaneous compounding 4. Assembly of the medication delivery unit Selection of the proper package or container is required to ensure product stability, to promote patient compliance, and to comply with legal requirements. Labeling the prescribed product 1. The prescription label typically contains the following information: a. Name and address of the pharmacy b. Patient 's name c. Original date of filling d. Prescription number e. Directions for use f . Product 's brand name or generic name and manufacturer g. Product strength (if available in more than one strength) 8 h. Quantity of medication dispensed i . Prescriber 's name j . Expirat ion date of the medication k. Pharmacist 's initials 2. Unit -dose packages contain one dose or one unit of medication. For a medication order that is dispensed in unit -dose packages, the label should identify the product 's brand or generic name, strength, lot number, and expirat ion date. 3. Auxiliary and cautionary labels. To ensure proper medication use, storage, and compliance with applicable statutes, and to reinforce information provided during counseling, auxiliary and/or cautionary labels should be affixed when appropriate 4. For medicat ion in schedules I I -IV, a federal t ransfer warning is required. Record keeping 1. The patient profile should contain the following patient information: a. Patient 's name b. Patient 's address (or room number in institutional settings) c. Any known allergies, sensitivities, or history of idiosyncratic reactions to previous medications d. Birth date (i.e., to assess the appropriateness of the dose) e. Clinical condition(s) (to help assess the appropriateness of the medication and to prevent drugdisease interactions) f . Weight (to assess the appropriateness of the dose) g. Occupation (to detect conditions associated with a particular occupation and to help determine if the patient will be able to comply with the regimen) h. Nonprescription medication use (to prevent drug-drug and drug-disease interactions, to assess medication effectiveness, and to detect possible adverse effects) 2. In addition, the patient profile should contain the following information from each prescription or medication order : a. Name of the medication b. Medication strength c. Dosage form 9 d. Quantity dispensed e. Directions for use f . Prescription number g. Dispensing date h. Number of refills authorized and remaining i . Prescriber 's name j . Pharmacist 's initials DISPENSING MEDICATION AND COUNSELING. The dispensing of medication requires that the pharmacist verify that patients have the necessary knowledge and ability to adhere to the prescribed treatment. This will increase the likelihood of obtaining the desired outcomes. Counseling patients. The pharmacist should evaluate the patient's understanding of each medication and supply additional information when the patient 's information is incorrect or insufficient. The pharmacist might need to advise patients regarding the proper dosage, appearance, and name of the medication. Information about the route of administration, instructions for use, duration of use, and the reason the product was prescribed may also be needed. In addition, the following topics might also be appropriate during the counseling session: 1. Special procedures. As appropriate, the pharmacist should advise patients on how to take the medication (e.g., on an empty stomach, with plenty of water) and instruct them on foods to avoid while taking the medication (e.g., alcoholic beverages, dairy products) . 2. Potential adverse effects. The pharmacist should ensure that patients are aware of the possible adverse effects associated with the medication. Patients should understand the following: a. The frequency of an adverse effect. This will help patients recognize common adverse effects and not be overly concerned with those that are rare. b. The severity of an adverse effect. This will help patients focus on those adverse effects that are severe and not those that are inconsequential . c. What action should be taken to manage or minimize the adverse effect. This will help patients deal with possible adverse effects in the appropriate manner. 3. Proper storage. The pharmacist should counsel patients on how to store medications properly to ensure stability and potency. 4. Over - the-counter (OTC) products. The pharmacist should instruct patients about the use of OTC products that might or might not be appropriate when taking a prescribed product. 10 Counseling health professionals. Health professionals (i .e., in an institutional setting) may administer medications to patients. In these cases, the pharmacist should ensure that the health professional has sufficient knowledge to administer the product. Information that health professionals would need to administer medications safely and effectively include the following: 1. The choice of a particular product 2. The proper dosage, dosage regimen, and route of administration 3. The cost of the prescribed product and the costs associated with its use ( i .e., administration costs and costs of treat ing possible adverse effects) 4. The availability of commercially made products 5. Potential adverse effects 6. Drug interactions 7. Physical incompatibilities 8. Safe handling and disposal procedures 9. Nutritional interactions or requirements 10. Drug interference with laboratory tests PATIENT MONITORING. Monitoring a patient 's need for medication and the effect of the medication on the patient maximizes the effectiveness of the medications being taken. Undesired outcomes associated with drug therapy are frequently called drug therapy problems. Pharmaceutical care plan To increase the frequency and benefits of desired outcomes, a pharmaceutical care plan should include the following: 1. Assessment . A review of the medical conditions and symptoms to determine the need for medication 2. Plan. A decision of an appropriate drug therapy based on the assessment of the patient 3. Monitoring. A review of the outcomes of drug therapy (i.e., goals and end points) to determine if the patient is obtaining the desired outcomes Drug therapy problems are evidence of less-than-optimal drug therapy. Detection of drug- related problems requires an assessment of the need for a change in drug therapy. Possible problems include 1. Unnecessary drug therapy. The medication cannot be associated with a medical condition or the presence of a condition in which nondrug therapy is more appropriate. 11 2. Wrong drug. The drug is not indicated for the condition or is not delivering the desired outcomes, or a more effective drug is available. 3. Dose too low. Incorrect dose, frequency, administration, or duration of therapy results in an insufficient dose of drug to the patient. 4. Adverse drug reaction. An allergic reaction, drug interaction, or an undesirable effect occurs from a medication. 5. Dose too high. Incorrect dose, frequency, or duration, results in more medication than is required. 6. Inappropriate adherence. The patient is not taking the optimal amount of medication owing to cost, administration difficulties, or a lack of understanding of the need for the medication. 7. Need additional drug therapy. Owing to an undertreated condition, synergism with concurrent drug therapy or prophylactic therapy is required. 12 Medical abbreviations and symbols Dangerous or Confusing Abbreviations Numerous common abbreviations and symbols have been associated with errors. Detailed lists of these can be found at the websites of the Institute for Safe Medication Practices (ISMP) and Joint Commission for the Accreditation of Healthcare Organizations (JCAHO) at : http://www. ismp.org/Tools/abbreviationslist.pdf ht tp://www.jcaho.org/accredited + organizations/patient + safety/06_dnu_ list.pdf The JCAHO has created a “Do Not Use” list of abbreviations that its accredited organizations should not allow to be used. “U” or “IU” for units: the “U” has been misinterpreted as various numbers such as zero, four ; serious harm has occur red wit h insulin and heparin as a result of confusion. For example, a patient received 66 units of insulin instead of 6 units. The order was written for “6u” of regular insulin but was misinterpreted. The word “units” should be written out in full. “QD, Q.D, qd, q.d.”: common abbreviations for daily have been misinterpreted as “QID” or “qid” and overdoses have occurred. “Daily” should be written out in full. “Q.O.D, QOD, qod”: common abbreviations for every other day have been misinterpreted as QID ( four times daily) . This should be written out completely as “every other day”. Trailing zero: when a dose is ordered and followed with a decimal point and a zero, such as 2.0 mg or 25.0 mg, errors can occur. The decimal point may be missed and an overdose can occur . For example, Warfarin 2.0 mg may be misinterpreted as 20 mg. Trailing zeros should be avoided and the dose written without the additional zero, for example Warfarin 2 mg rather than 2.0 mg. Lack of leading zero: a drug's dose may be less than 1 mg, such as Digoxin. Often the dose may be written without a leading zero, such as Digoxin .25 mg, rather than as Digoxin 0.25 mg. Errors have occurred because the decimal point is missed. For example, Warfarin .5 mg may be interpreted as Warfarin 5 mg. Leading zeroes should be included, so the dose is written as “Digoxin 0.25 mg or Warfarin 0.5 mg.” MS, MSO4, MgSO4: Abbreviations for morphine sulfate (MS, MSO4) have been confused with Magnesium sulfate (MgSO4 ). It is recommend to write out each name in full rather than using abbreviations: morphine sulfate or magnesium sulfate. In addition to the above abbreviations, there are numerous other hazardous symbols and abbreviations which should be reviewed with caution when used on prescriptions. Examples include: “cc”: Often used instead of “mL.” This has been misinterpreted as a “0” (zero). Use “mL ” “μg”: Used for “micrograms,” for example, Levothyroxine 250 μg. daily. The symbol has been mistaken for “mg” and overdoses have occurred. Best to use “mcg.” Or write out “micrograms.” “<” or “ >”: Symbols for “ less than” (<) or “greater than” (>) have been mistaken for each other or misinterpreted as numbers. Best to write out as “ less than” or “greater than. ” 13 “HCT”: An abbreviat ion for “hydrocortisone” has been misinterpreted as “hydrochlorothiazide” Best to write name out completely. “HCl” An abbreviation for “hydrochloric acid” has been misinterpreted as “KCl” (potassium chloride). Best to write out name completely. Common Abbreviations Considerable variation occurs in the use of capitalization, italicization, and punctuation in abbreviations. The following list shows the abbreviations that are most often encountered by pharmacists. A, aa., or aa .......... of each a.c.............. before meals ad ...............to, up to a.d...............right ear ad lib..........at pleasure, freely a.m. ............morning amp.............ampule ante.............before aq................water a.s................left ear asa...............aspirin a.u...............each ear, both ears b.i.d.............twice a day BSA............body surface area c. or cum ...with cap. or caps...capsule cp.................chest pain D.A.W..........dispense as written cc or cc..........cubic centimeter comp...............compound, compounded 14 dil...................dilute D.C., dc, or disc...discontinue disp....................dispense div.....................divide, to be divided dl or dL.............deciliter d.t.d..................give of such doses DW..................distilled water D5W..............dextrose 5% in water elix...................elixir e.m.p................as directed et ....................and ex aq................in water fl or fld...........fluid fl oz................fluid ounce ft....................make g or Gm.........gram GI..................gastrointestinal gr or gr. ........grain gtt or gtt.......drop, drops h. or hr.........hour h.s................at bedtime IM................intramuscular inj.................injection IV.................intravenous lb..................Pound M..................Mix 15 N&V...............nausea and vomiting noct.................night, in the night non rep...........do not repeat NPO...............nothing by mouth N.S., NS, or N/S.......normal saline 1/2 NS.......................half -strength normal saline o.d....................right eye o.l. or o.s..........left eye OTC.................over the counter o.u....................each eye, both eyes p.c...................after meals PDR.................Physici ans' Desk Reference p.m...................afternoon, evening p.o....................by mouth Ppt...................precipitated Pr....................for the rectum prn or p.r.n.......as needed pulv................powder pv.....................for vaginal use q.......................every q.i.d..................four times a day q.s.....................a sufficient quantity q.s. ad................a sufficient quantity to make R.......................rectal R.L. or R/L.......Ringer's lactate s. .......................without 16 Sig....................write on label sol.....................solut ion S.O.B................shortness of breath s.o.s...................if there is need (once only) ss. or ss..............one-half stat.....................immediately subc, subq, or s. c......subcutaneously sup. or supp...........suppository susp.......................suspension syr.........................syrup tab.........................tablet tal..........................such, such a one tal. dos..........such doses tbsp. or T......tablespoonful t.i.d...............three times a day tr. or tinct......tincture tsp. or t.........teaspoonful u.d. or ut dict......as directed ung............ointment U.S.P. or USP......United States Pharmacopoeia w/ v...........weight /volume 17 Compounding and manufacturing “Compounding” – the combining, mixing, packaging or labeling of a drug as a result of a Practitioner’s Prescription Order or initiative based on the practitioner/patient/pharmacist relationship in the course of professional practice, or for the purpose of research, teaching, or chemical analysis and not for sale or dispensing. “Manufacturing”- the production, or processing of a drug or device by extraction from substances of natural origin or by means of chemical or biological synthesis, and includes any packaging of the substances or labeling of its containers, and the promotion and marketing of drugs and devices. Although compounding drug dosage forms has been an integral part of the profession of pharmacy since antiquity, the last 70 or 80 years, with the birth and growth of the pharmaceutical industry, has been a significant decline in compounding by pharmacists, and, even more, a 1994 survey of US pharmacies showed that less than 1% of prescriptions dispensed by pharmacies required compounding. More recently, primarily over the last 15 years, interest in compounding customized drug preparations by pharmacists has increased. 1. This increase has been due partly to a shift of interest on the part of the profession from merely “dispensing” drugs to an intensified concern for patients and their individual drug therapy needs- the pharmaceutical care movement. The commonly used definition of pharmaceutical care promulgated by Hepler and Strand, “the responsible provision of drug therapy for the purpose of achieving definite outcomes that improve a patient’s quality of life”, carries with it the tacit requirement for considering individualized dosage and drug delivery systems. 2. There is a renewed awareness that individual patient therapy needs cannot always be met by drug products from the pharmaceutical industry, which has constraints imposed upon it by mass production and market-share requirements. 2a Medications that are not commercially availableManufacturers must be assured that there will be a return on their investment when entering the market place with a drug product. Therefore, there are limited chemical forms, dosage forms, strengths, flavors and packaging that are available for the physician to prescribe and the pharmacist to dispense. Compounding allows the physician to prescribe a custom-tailored medication that is not available commercially. 2b Medications that are not stablePharmacists prepare small quantities of a prescription more frequently to ensure stability of the product for its intended use. 18 2c Altered commercially available medicationsPhysicians prescribe a commercially available medication in a different dosage form to meet a specific patient need and ensure patient compliance. 3. A contributing factor has been the trend toward home health care. For various reasons, including cost containment and patient comfort, patients who previously would have been concentrated for treatment in hospitals and medical centers are being treated at home. These patients often require individualized infusion therapy and other treatment modalities. This has created the need for a whole new type of pharmacy practice in which pharmacists in retail settings are required to prepare custom sterile and no sterile dosage forms. 4. The expansion of custom-compounded drug preparations has been made possible in recent years partly because of the availability of new and useful items of equipment, packaging and labeling materials, drugs and chemicals. New companies have been established and older existing companies have expanded which specialize in marketing these needed supplies 5. Needed information on compatibility and stability of compounded drug preparations has become available and more widely disseminated. New books, journals, and technical support have played an important role in enabling compounding to come of age in this scientific era. For example, USP which traditionally has provided standards and support for quality drug products, has taken the initiative to develop and publish monographs for compounded drug preparations with tested formulations and stability information. No other health care professional has studied chemical compatibilities and can prepare dosage forms. Even when modern scientific technologies have produced new chemical entities, the ability of the pharmacist to combine one or more chemicals into a new preparation or process the existing dosage form into one that is better suited to the patient's needs, has remained the domain of the pharmacist. Compounding of medications by pharmacists is a long-standing and traditional part of pharmacy. 19 Basic steps to follow in compounding drug products In compounding any drug preparation, follow the steps given below: A. Carefully read and interpret the prescription or medication order. It may be necessary or helpful to consult with the prescriber and the patient about the intent of drug preparation and preferences or limitations of the patient. B. Note any missing or confusing information; clarify, gather and add this information to the drug order. C. Check the dose, dosage regimen, dosage form, and route of administration for appropriateness. D. Determine a preliminary compounding procedure. E. Perform necessary calculations. If possible, have a colleague check the calculations for appropriateness and accuracy. F. Select required ingredients. G. Choose appropriate compounding equipment H. Using recommended techniques, prepare the product. I. Perform quality control procedures J. Choose an appropriate container and package the preparation. K. Determine an appropriate beyond-use date. L. Label the container, including recommended auxiliary labels. M. Recheck all work. N. Document the compounding process. This includes adding additional information to the prescription document or making a quality control record. This is a sample compounding formula sheet. O. Deliver the product to the patient or caregiver with appropriate consultation and check for understanding of use of the product. As we can see, the quality of a finished compounded drug product can be affected by numerous factors including the quality of the active pharmaceutical ingredient used and the compounding practices of the pharmacy in which the product is created. 20 Labeling Prescriptions and Medications Labels For Outpatient Prescriptions 123 Main Street Anytown, USA 00000 Phone: (123) 456-789 Dr. Ashman R 123456 Joe Doe 010/01/00 JET Take one capsule three times daily for ten days. Amoxicillin 250 mg. Beecham Labs Some countries have additional requirements for the label. It is the duty of each pharmacist to be informed about the specific legal requirements for labeling for the state in which he or she is practicing. 1. Quantity dispensed; 2. Expiration or beyond-use labeling; 3. Number of refills. Two of the labeling requirements merit additional discussion: 1) directions for use, and 2) name and strength of product/active ingredients. Directions for Use The directions for use should be written in clear, concise English using terminology that the general public (including patients with minimal education) can understand. Avoid abbreviations and medical terms that the patient may not understand. For patients who do not speak English, be certain that they understand how to use their medication. Remember that verbal instruction to the patient in techniques of administration is an excellent opportunity for the pharmacist to provide professional service to the patient. For difficult to use dosage forms, such as inhalers, written labels and product instructions are rarely sufficient: demonstrate the appropriate technique to the patient, and then have the patient show you how he or she will use it. Directions for use should be in complete sentences including a verb: "Take one tablet three times daily," as opposed to "One tablet three times daily." Use easily understood verbs such as take, give, apply, insert, place, use, and put. Avoid outdated terms such as' 'instill'' unless you are certain the patient understands. For topical administration, the adverbs "topically" or "locally" are sometimes used, but are optional. The route of administration should be specified in most cases, including eye, ear, nose, rectum, vagina, and urethra. For medications given by mouth, the route is usually understood from the directions and is not required unless the prescriber has specifically written this in the directions for use, or if there is a possibility of confusion. Some countries require the route of administration to be specified in all cases, including oral products. 21 Numbers, when part of the directions for use, should be spelled out whenever possible. This is a safety feature. Because the numbers are next to each other on the keyboard, it would be easy to type a "2" when a "3" is desired. A typing error made in spelling the number, such as tjree for three, would be detected easily, and the patient would not confuse the misspelling with another number. Volume doses such as teaspoons should be written with the suffix "ful," for example, teaspoonful. If the prescription is for a bulk powder, specify "level," for example, level teaspoonful. While the directions for use should be as close as possible to those on the prescription order, the pharmacist may clarify the instructions as long as the intent of the prescriber is not changed. Vague instructions, such as "Take as directed" or "Take as needed," are not sufficient, and the prescriber should be consulted for more specific instructions. Name and quantity of active ingredients Prescriptions may be labeled either with the generic name or the brand name of the product dispensed. Some countries require that drug products be labeled with both the brand and the generic name of the drug product; others specify that prescription products that are labeled generically must have the name of the manufacturer or distributor of the product. For topical products, strength usually is expressed as a percent concentration, although topical antibiotics are sometimes labeled in units or milligrams per gram of ointment or milliliter of liquid. Some drug products that are used in very dilute concentrations have traditionally been labeled in ratio strength. This is acceptable. For individual dosage forms (e.g., capsules, divided powders, lozenges, suppositories), the strength is expressed as a metric weight of each active ingredient per dosage unit. The dosage system is understood and need not be identified, for example, Codeine 15 mg, as opposed to Codeine 15 mg/capsule. For prescription labeling, when the salt form is identified, chemical symbols for the common inorganic salts are permitted, for example, HCl for Hydrochloride and Na for Sodium. For oral liquids and oral bulk powders, label either: 1) the quantity of active ingredient per standard volume, for example, Amoxicillin 250 mg/5mL or Digoxin 50 mcg/mL; or 2) the quantity of active ingredient(s) per dosage volume specified in the directions for use on the label. For example, with directions for use of ''Take one tablespoonful one hour after each meal,'' the label may specify the quantity of active ingredient as, for example, either Calcium Carbonate 20 mg/mL, Calcium Carbonate 100 mg/5 mL, or Calcium Carbonate 300 mg/tablespoonful. The content of alcohol in a liquid dosage form should be stated as a percentage v/v of C2H5OH. Labels For Inpatient Drug Orders 22 Although many states have no legal requirements for labeling inpatient drug products, The NABP Model Rules for Pharmaceutical Care does address this issue. The following are recommendations for drug products which are not in the possession of the ultimate user: a. The label for single unit packages should include: Name (proprietary or generic) of the drug product Route of administration, unless oral Strength and, if applicable, volume of the product, expressed when possible in the metric system Control number and expiration date If repackaged, identification of the repackager Special storage conditions, if needed If a multiple-dose distribution system is used, the container should be labeled with: Identification of the dispensing pharmacy Patient's name Date of dispensing Name (proprietary or generic) of the drug product b. Strength, expressed when possible in the metric system If a drug product for an inpatient is to be self-administered, the label should conform to the standards of outpatient prescriptions. Control # 000101-2 Prep d: 01/01/00 1700 JET Penicilin G 200,000 units/mL For IM use Do not use after 01/02/00 1700 This syringe contains 0.1 mL excess for priming Refrigerate, Do not freeze Auxiliary Labels Auxiliary labels are placed on drug product containers to give the patient, caregiver, or healthcare provider important information needed for storing or using the product. Auxiliary labels may be used to clarify directions, provide additional instructions, or reinforce directions given on the regular label. They are not intended to be used in place of patient consultation. Common auxiliary labels and some recommended uses are given below. Although some labels are absolutely required (e.g., Shake Well labels for disperse systems), in most cases the pharmacist must exercise professional judgement in deciding what, if any, auxiliary labels to use. Shake Well Required on all liquid disperse systems such as suspensions and emulsions. 23 Keep in the Refrigerator, Do Not Freeze Required on products that are chemically unstable at room temperature (e.g., many antibiotics) and on products that are physically unstable at room temperature (e.g., cocoa butter suppositories). It is recommended for parenteral products that have been manipulated and which are not being used immediately, especially those which do not contain a preservative. Do Not Use After Required on all manipulated parenteral products, antibiotics and liquids, and other products known to be unstable. Recommended on all other dispensed products, especially compounded products. Refrigerate, Shake Well, Discard After Used to avoid multiple auxiliary labels when all three messages, 1, 2, and 3 above, are required, such as on most reconstituted antibiotic suspensions. External Use Only Recommended on external use products, especially those that would potentially be dangerous if ingested. May Cause Drowsiness; Alcohol and Operating Car or Machine Warning Used for adult ambulatory patients. Required for all Schedule II narcotics and other medications, such as some muscle relaxants, that cause significant drowsiness. Recommended on other narcotics, antianxiety agents, tranquilizers, long-acting barbiturates, sedating agents, antihistamines and antidepressants, and any other medication that may cause drowsiness. The use of this label on products prescribed as sleeping aids is a matter of professional judgement. Do Not Drink Alcohol Required for medications that give a disulfiram reaction, such as disulfiram, metronidazole, and chlorpropamide. Recommended with hypnotic drags or others in which the additive CNS effect may be hazardous. Oral explanation should also be given. Avoid Sun Exposure Required on drugs that cause photosensitivity reactions, such as tetracyclines, sulfonamides, nalidixic acid, thiazides, and phenothiazines. Take with Food Recommended for drugs that cause stomach upset when this effect may be decreased by taking the medication with food. Examples of medications in this group include valproic acid, erythromycin, aspirin. Take on an Empty Stomach Recommended for drugs that have decreased absorption or increased destruction in the stomach when taken with food, such as tetracycline and ampicillin. Take with Plenty of Water Recommended for sulfonamides to decrease the likelihood of crystalluria, for expectorants to enhance viscosity reduction of bronchial secretions, for bulk laxatives to increase stool bulk and decrease the likelihood of compaction, and for irritating drugs, such as potassium supplements, chloral hydrate, certain antibiotics, and theophyllme products. Do not Take with Dairy Products, Antacids Required for tetracycline products to prevent inactivation of the drug by polyvalent ions. Recommended for entericcoated products because milk products and antacids create a basic pH in the stomach which could cause premature dissolution of the enteric coating. 24 May Cause Discoloration of Urine or Feces Recommended for drugs that discolor urine or feces, such as methylene blue, nitrofurantoin, and phenazopyridine. Do not Take Aspirin Required on warfarin-type anticoagulants. Caution: Federal Law Prohibits Transfer of this Drug to Another Person Required by law on all outpatient drug containers for controlled substances in Schedules II-IV. This Prescription May be Refilled ___ Times An optional label informing the patient of the number of refills. This information is now often printed directly on the prescription label. Keep out of the Reach of Children May be used for any drug product container, but required for drug containers without safety closures. Protect from Light Required for parenteral products that are photosensitive, such as Na Nitroprusside, furosemide, and phenothiazines. This label is especially important when the immediate container for these products is not amber or opaque. It is appropriate labeling for all photosensitive drugs. Cancer Chemotherapy, Dispose of Properly Required for containers of cytotoxic drug products. CONTROLLED SUBSTANCES DEA REGISTRATION 1. To aid government officials in administering and enforcing the controlled substance regulations, all importers and exporters, manufacturers, distributors, researchers, prescribers, and dispensers of controlled substances must register with the Drug Enforcement Administration (DEA). 2. Upon registration, these parties are issued DEA registration numbers. Registrants must record their DEA numbers on all documents that they use for the transfer or distribution of controlled substances up to the ultimate consumer. 3. Prescribers of Controlled Substances Traditionally, practitioners who were registered with the DEA to prescribe controlled substances included physicians, veterinarians, dentists, and podiatrists. In 1993, the DEA established a new category of registrant called "mid-level practitioner" (MLP). An MLP is anyone other than a physician, veterinarian, dentist, or pediatrist who is authorized to prescribe controlled substances in the state in which he or she practices. Depending on the country, this category may include advanced-practice nurses, physician assistants, and/or optometrists. Specific privileges and restrictions on prescribers of controlled substances are defined by each state. The DEA registration number of the prescriber must appear on any outpatient prescription order for a controlled substance. 4. Dispensers of Controlled Substances 25 Although prescribers register as individuals, dispensers, such as pharmacists, do not. A pharmacist who is dispensing controlled substances is considered an agent of a registered pharmacy. Pharmacies that order, receive, handle, and dispense controlled substances must be registered with the DEA and must have a DEA registration number. The pharmacy's DEA number is required when the pharmacy orders controlled substances from manufacturers or distributors. 5. DEA numbers are unique, nine-character numbers which are computer generated to contain check digits that help pharmacists identify invalid registration numbers and fraudulent prescription orders for controlled substances. Many dispensing software packages automatically check for invalid numbers when new prescription orders for controlled substances are entered into the computer. DEA numbers can be manually checked by following these steps: 6. DEA # AD5426817 The first digit should be a letter: A for prescribers and dispensers, M for midlevel practitioners, and P for distributors. The second digit is usually a letter, specifically, the first letter of the registrant's last name. In the above case, if the prescriber's last name is Jones, the second letter of a valid DEA number would be J, so the above example DEA number would be invalid. If the registrant is a business with a name that starts with a number, such as "5th Avenue Pharmacy," the second digit should be the number "9." The third through the eighth positions of the DEA number should contain numbers that are used to calculate the number in the ninth position, the check digit. a. Add the 1st, 3rd and 5th digits: 5 + 2 + 8 = 15 b. Add the 2nd, 4th, and 6th digits and multiply the sum by 2: 4 + 6+1 = 11 x 2 = 22 Add the two results: 15 + 22 = 37 d. The far right-hand digit of this check number should be the same as the ninth digit of the DEA number. In this example, both numbers are "7," so the DEA number is a valid number. GENERAL PRINCIPLES To prepare accurate dosage forms, the pharmacist must use weighing and measuring apparatus with care and understanding and must be conscious of the following general principles: A. Select weighing equipment and measuring devices appropriate for the intended purpose. B. Use the devices and operate the equipment with recommended techniques that ensure accuracy of measurement. C. Maintain the equipment so that it is clean and free of chemical contamination. WEIGHING 26 In selecting a balance for purchase or for use in compounding, the pharmacist needs to be familiar with the following terms: 1. Capacity: The maximum weight, including containers, that can be placed on a balance pan. 2. Sensitivity: The smallest weight that gives a perceptible change in the indicating element (e.g., one subdivision deflection of the indicator pointer on the index plate of double-pan balance; one number change on the digital display of an electronic single-pan balance). 3. Readability: The smallest weight increment that can be read on the dial or digital display of a balance. The term is used mostly in specification descriptions for electronic balances. For these, it is the smallest increment on the digital display; for example, 0.001 g. The readability on double-pan balances is determined by the value of the hash-mark increments on the graduated dial; for example, each mark stands for 0.01 g. 4. Precision: This term is used primarily in specifications on electronic balances and it means the reproducibility of the weighing measurement. 5. Accuracy: The closeness of the displayed weight, as measured by the balance, to the true weight, as known by the use of a calibration weight or weights. This value is given in some electronic balance descriptions in lieu of a precision specification. Prescription Balances A prescription balance is a scale or balance adapted to weighing medicinal and other substances required in prescriptions or in other pharmaceutical compounding. 1. Double-pan Torsion Balance (Class A prescription balance). The National Bureau of Standards Handbook gives the assumed capacity of this balance to be 15.5 g unless a larger capacity is stated in the manufacturer's specifications for that particular balance. While many balance brands have capacities exceeding 15.5 g, such as 60 or 120 g, it is usually impractical to weigh amounts greater than 15-30 g on a double-pan balance because heavier weights cause excessive wear on the balance internal parts, and because the volume occupied by larger weights of most powders and dry ingredients is difficult to contain on weighing papers without spilling. 2. Electronic single-pan balances: Although the USP 23 specifies that a Class A Prescription Balance be used for all weighing operations required in prescription compounding, a note states that other balances may be used provided they give equivalent or better accuracy. Electronic, single-pan balances with internal weights, digital display features, and readability and precision of 1 mg are available at relatively reasonable costs. Most pharmacists who have used these balances find them easier to use and more accurate than a traditional double-pan Torsion balance. Although appropriately selected electronic balances meet or exceed the requirements for prescription balances, the pharmacist should consult with his or her state board of pharmacy to determine if a given balance meets the applicable state statutes or codes for pharmacy equipment before purchasing an electronic balance. 3. Minimum Weighable Quantity (MWQ): The minimum weighable quantity must be determined for any balance being used for compounding. To avoid errors of 5% or more on a Class A balance with a measured sensitivity requirement of 6 mg, do 27 not weigh less than 120 mg of any drug or chemical; for example, 5% x 120 mg = 6 mg. The 5% rule is a general standard for weighing operations used in compounding. This means that a smaller minimum weighable quantity may be used on a more sensitive balance. For example, a balance with a sensitivity requirement of 5 mg would have a MWQ of 100 mg because 5% x 100 mg = 5 mg. 4. Balance testing: All balances should be tested and calibrated at regular intervals (at least yearly) using appropriate test weights and procedures specified by the USP or the balance manufacturer. A balance-testing record should be maintained by the pharmacy; the record should include the date, the type of testing and calibration procedures performed, the results, and the name or initials of the person who performed the procedures. The USP 23 specifies the following tests to be performed on Class A prescription balances. Sensitivity Requirement Level the balance, determine the rest point, and place a 6-mg weight on one of the empty pans. The rest point is shifted not less than one division on the index plate each time the 6-mg weight is added. Weights 1. Weights are to be stored in a rigid, compartmentalized box and should be handled with special tweezers to prevent contamination. 2. All weights must have cylindric construction, and coin-type weights should not be used. Weight sets that contain both metric and apothecary weights should be used with extreme caution because it is easy to select a weight from the wrong system. This is especially true when people who are not familiar with both systems use these weights. 3. When purchasing a weight set for use in compounding, the pharmacist should require information from the vendor on the class of the weight set because catalog descriptions such as "precision metric weight set" and "accurate weights" do not give sufficient information. Recommended Weighing Procedures The following instructions were written specifically for double-pan Torsion prescription balances. Many of the same principles apply to electronic balances. When using an electronic balance, refer to the operator's manual for weighing instructions specific to balance. 1. Position the balance on a flat, level surface and check to be sure that the weighbeam rider is at the zero position. 2. Using the leveling feet at the front of the balance, bring the balance into equilibrium. Equilibrium is reached when the index pointer either comes to rest at the center on the index plate, or when it travels an equal number of divisions to the right and left of the center. 3. Place a weighing paper on each balance pan. Never put weights, drugs, or chemicals directly onto a balance pan. This includes the balance pan of an electronic balance. 28 Glassine papers are preferred for weighing. They have a smooth, shiny surface that does not absorb materials placed on them, and drugs and chemicals easily slipped off for complete transfers. Glassine papers come in various sizes including 3X 3, 4X4, and 6X6. Weighing papers should be creased to create a depression or ''boat,'' which helps to contain the substance being weighed and prevents spilling on the balance pans or balance platform. This depression can be formed in many ways: for example, pinching each of the four corners of the paper; folding the paper in quarters and then opening the sheet. Weighing papers should be positioned on balance pans so that they do not interfere with the free movement of the pans or the accurate weighing of the material. 4. With the weighing papers in place, repeat the process of bringing the balance pans into equilibrium. This is necessary because there may be minor differences in the weights of weighing papers, even with the same type and size of paper. 5. During the entire weighing procedure, keep the balance pans arrested when adding papers, weights, or substances to be weighed. Some of the newer Torsion balances allow for the dial weights to be adjusted without arresting the balance pans. The arresting procedure is not necessary with electronic balances. This is one of the reasons weighing can be accomplished more efficiently with electronic balances. With an electronic balance, material is added until the display indicates that the target weight has been reached. 6. Add the appropriate dial weights to the balance. Handle external weights with forceps, never with your fingers. External weights are added to the left-hand balance pan. 7. Using a spatula, add material to be weighed to the paper on the right-hand balance pan. When using a spatula for this purpose, you may find it helpful to hold the spatula between your thumb and middle finger so that the index finger is free to tap the blade of the spatula. This is a good way to tap off small, controlled amounts of drug from the spatula blade. 8. Release the arresting mechanism and observe the balance pointer to determine if you have transferred the desired amount of material, or if too much or too little material was added. 9. If the pans are not in balance, arrest the pans before adding or removing material. Repeat steps 6 and 7 until the index pointer indicates that equilibrium has been reached. As you approach the required weight of material, you may release the balance arrest as you slowly and carefully add very small amounts of material until the exact weight is reached. 10. Arrest the balance pans and remove the weights. As you do this, recheck the weights to be sure you have selected the desired weights. Return the external weights to their appropriate compartments in the weight box. 29 11. Clean the balance. VOLUMETRIC MEASURING Definitions Capacity: The designated volume, at the maximum graduation, which the vessel will contain (labeled as "TC," meaning "to contain") or deliver (labeled as "TD," meaning "to deliver") at the temperature indicated on the vessel. Generally, graduates, pipettes, and burettes are calibrated TD, whereas volumetric flasks are calibrated TC. Cylindrical graduate: A measuring vessel that is a right circular cylinder, that is, with sides which are parallel to each other and perpendicular to the base. Conical graduate: A measuring vessel whose cross-section is circular, but whose sides flare outward from its base. The circumference of the vessel is larger at the top graduation than at the lowest graduation marking. Volumetric apparatus: The USP 23 lists pipets, burets, graduates, and medicine droppers as pharmaceutical devices used for measuring volumes of liquids. Burettes are not commonly used in general compounding. Medicine droppers have limited usefulness. Graduates are the devices most commonly used and are available in two shapes, cylindrical or conical as described above. The following devices are not listed in the USP as volumetric devices, but they are routinely used by pharmacists for measuring volumes when compounding prescriptions. Each has limitations which should be considered. Syringes: Small syringes of 1 and 3 mL capacities are useful for accurately measuring volumes less than the 2 mL minimum recommended for a 10 mL graduated cylinder (20% X 10 mL = 2 mL). Syringes of the appropriate size are also preferred over graduated cylinders for measuring viscous liquids such as glycerin or mineral oil, since these liquids drain slowly and incompletely from graduated cylinders. Oral syringes are available and are recommended for giving more accurate measurement of doses than is possible with household measuring spoons. If syringes are used for oral dosing, the tip cap, if present, should be removed before dispensing. Fatalities have been reported which were caused by tip caps being inadvertently squirted in the throat of a patient when an oral liquid was administered. Graduated beakers: Beakers are used in the pharmacy as vessels for compounding solutions and for many other purposes. Newer beakers have painted graduation marks. These marks are not precise and not meant to be used for accurate measuring. They should not be used when "qs'ing" a product to a desired volume. Graduated prescription bottles: Like graduated beakers, graduated prescription bottles have approximate volume markings. The capacity markings are sufficiently accurate for measuring and dispensing a manufactured liquid product where the strength of the product is not dependent on the accuracy of the capacity markings, but graduated prescription bottles are not meant for the 30 accurate measuring needed in compounding. Pharmacists often "qs" in prescription bottles when compounding thick liquid products because there is no loss of product in transferring from a measuring cylinder. When this is done, the final desired volume should first be determined and marked on the prescription bottle. This is done by accurately measuring a compatible mobile liquid, water if possible, in a graduated cylinder, pouring the liquid into the prescription bottle, marking the volume on the bottle with a marking pen, then pouring out the calibration liquid before using the bottle in the compounding process. Selection and Use of Volumetric Apparatus Cylindrical graduates are usually preferred for measurement over conical graduates. Because of the constant diameter of a cylindrical graduate, a given deviation in reading (e.g., ± 1 mm) gives a constant error in a measured volume throughout the entire length of the graduate. This is not true for conical graduates, where the diameter continually increases from the base to the top graduation. According to the USP, conical graduates having a capacity of less than 25 mL should not be used in prescription compounding. For maximum accuracy in measuring, select a graduate with a capacity equal to or slightly larger than the volume to be measured. The smaller the volume to be measured as a percentage of the graduate capacity, the larger the potential percentage error from a given deviation in reading the meniscus. The general rule is to measure volumes no less than 20% of the capacity of the graduate. When reading the volume of liquid in a graduate, the graduation mark, the meniscus of the liquid, and the line of sight should all be in alignment. This minimizes errors caused by the parallax effect. Patient Consultation PROFESSIONAL STANDARDS OF PRACTICE Although it may seem to you that talking with patients about their prescriptions is a normal function of pharmacists, this has not always been true. In the past pharmacists were prohibited by ethical codes from discussing medications with their patients. There was concern that pharmacists could disrupt the patient-physician relationship if they discussed with patients topics like therapeutic indications, side effects, precautions, and so on. The opposite expectation now exists. The current codes of ethics and standards of practice promulgated by the American Pharmaceutical Association and other pharmacy associations promote patient education as a primary professional responsibility of pharmacists. Here you have statements from Code of Ethics that address the issue of patient consultation and pharmacist-patient communication: 31 a. "Pharmacists are health professionals who assist individuals in making the best use of medications." b. “A Pharmacist promotes the right of self-determination and recognizes individual self-worth by encouraging patients to participate in decisions about their health. A pharmacist communicates with patients in terms that are understandable. In all cases, a pharmacist respects personal and cultural differences among patients." c. "... a pharmacist promises to help individuals achieve optimum their medications, to be committed to their welfare, and to maintain their trust" benefit form GENERAL GUIDELINES FOR PATIENT COUNSELING Before you prepare the prescription: The consultation process begins not when you transfer the prescription to the patient, but as you receive the prescription order from the patient or the agent of the patient. 1. Input from the patient: a. Ask the patient or caregiver if there is any information you should have before filling the prescription. For example, has the doctor given the patient any special instructions? Can the patient open safety closures? b. If the prescription order is for a branded product, check if a generic equivalent can legally be dispensed. If so, does the patient want a generic product? 2. Review of the patient's medication record: Look not only for problems with the new prescription, but also review the patient's total drug therapy. Does this patient need a talk or advice on strategies concerning compliance issues? Are there possible helpful hints you may give the patient? For example, if the patient is taking other medications, he or she would probably like to know about taking more than one drug product at the same time. When delivering the prescription to the patient: Imagine yourself as the patient, and then practice "The Golden Rule." 1. It is helpful to give the patient an estimate of the length of time the consultation requires. Recognize the patient's right to refuse counseling. You want to make your services available, but you cannot force the patient to listen to what you have to say. Most patients are appreciative of your professional advice and counsel; however, circumstances may exist that interfere with a complete counseling encounter. For example, a patient may be very ill and just want or need to get home to bed. Perhaps the patient is a sick child, and the parent or caregiver is not, at this moment, in a position to be attentive to your counseling. Be sensitive of these types of needs. In cases like this, you may want to give only the essential information and offer to call the patient or caregiver later, or ask the patient or caregiver to call you at a mutually convenient time for a more complete consultation. Patients who are in pain or other distress probably are not able to concentrate on what you are saying. When they have returned to the familiar surroundings of their home and have experienced some relief, they probably are better able to understand you and remember what you have told them. Questions about the use of their medication may 32 also have come to mind. 2. Maintain a professional, sincere attitude. Use a professional, but friendly, relaxed, and sincere behavior. This attitude should help put the patient at ease and foster an atmosphere that encourages the patient to ask questions. 3. Use language appropriate to the needs and level of the patient. Avoid technical medical terms and jargon unless you are talking with a fellow medical practitioner, such as a nurse or physician. At the same time, do not "talk down" to the patient. Many patients are very knowledgeable. Discussing the medication with the patient rather than lecturing about it helps you to assess the patient's level of knowledge and understanding. 4. Do not frighten the patient. Disclose necessary precautions in a tactful way. Think about how you would feel about taking a medication if you were warned by your pharmacist that you may cough up blood, stop breathing, or go into convulsions. How would you feel? 5. Notice the patient's body language. Watch the patient's face for feedback. Do the eyes indicate that you are being understood? Does the patient appear to be interested in what you are saying, or have you obviously lost contact? 6. Be aware of cultural differences in patients. If you deal with patients who have different cultural backgrounds from your own, make it a point to learn about cultural issues that will help you in communicating most effectively with these patients. TOPICS FOR PATIENT COUNSELING Guidelines that give recommended patient counseling topics have been published by professional pharmacy associations and government agencies. I. Introduction: 1. Establish relationship with patient: Introduce yourself to the patient if he or she is not known to you. Find out whether you are talking directly with the patient, a family member, or some other agent of the patient. You might want to find out how the patient wishes to be addressed. Some patients prefer to be called by their first names, whereas others, especially elderly patients, may be offended by such familiarity. This also is your opportunity to get an initial sense of the level of understanding of the patient. 2. Patient assessment: a. Find out the patient's understanding of the prescribed medication. What did the prescriber tell the patient? Does he or she know what the medication is and why it was prescribed? Did the prescriber tell the patient how to take or use the medication? What is the patient to expect from this therapy? b. Ask the patient if he or she has ever taken medication like this before. If so, what was the result? Has the patient ever had either an unusual or allergic reaction to a medication of this type? 33 c. Is the patient taking any other medications including nonprescription drags like aspirin or cough-andcold medications? d. If the prescription is a refill, ask questions to determine the effectiveness of the therapy. Do not just ask, "Do you have any questions?" Find out if the patient thinks that the medication is "working." Is he or she experiencing any side effects? What time(s) of day are the doses being taken? How is the patient feeling? What kind of medication or health-related problems, if any, is he or she experiencing? 3. Name of medication and therapeutic indication: a. From the patient assessment, you know the patient's current understanding of the medication. Therefore, you need not repeat any information that the patient already knows. b. It is absolutely essential to establish with the patient the name and therapeutic indication of the medication being dispensed. This is an important safe-guard in preventing dispensing errors. Many drug names look or sound alike. You can provide some protection against dispensing errors if you cover this quick and easy point of information. 4. Intent and duration of consult: a. Offer to spend a few minutes with the patient to give advice on the effective use of the prescribed medication and to answer any questions. b. If the use and monitoring of the medication is complicated and needs an ex tended consult, be honest with the patient about this. He or she may want to be told the essentials with an agreed time for a more complete conversation. c. Be sensitive to patients who are obviously ill. They may need a brief consult with a follow-up phone call. II. Administration: 1. Label directions: a. Repeat the directions for use on the label, including information on auxiliary labels. b. Check the label one last time as you do this. 2. Special instructions: a. Give any special instructions, such as take on an empty stomach or swallow tablets whole. b. If you have a special dosage form, such as an inhaler, ophthalmic drops, or suppositories, make sure that the patient knows how to use the product. 3. What to do about a missed dose: Help the patient to establish clear, specific guidelines for deciding when, and if, to skip or double forgotten doses. 4. How long to continue taking: 34 Patients need to know if medications should be taken only when needed, on schedule until the prescription is all gone, for the rest of their life, or until told to discontinue by their doctor. 5. Status of refills: a. Are refills authorized? If so, how many? How does the patient order needed refills? b. Are there any special circumstances? For example, if the patient is seriously ill and is taking Schedule II pain medication, be sure you give information on how he or she can get more needed medication. Do not just say that there are no refills with this medication. III. Precautions/side effects/monitoring therapy: 1. Precautions and untoward effects: Communicating about precautions and untoward effects is probably the area of greatest difficulty for pharmacists: How much should 1 say? What are the most important issues? Will I scare the patient if I talk about possible serious side effects? Current philosophy concerning drug therapy holds that patients have the right to self-determination, that they should be given full information about proposed therapy so that they can make informed decisions. a. Some drugs have many potential side effects; emphasize those side effects or precautions that are of major or moderate clinical significance. b. Distinguish between those side effects that may be annoying, but of no clinical harm, and those that require a physician's attention. c. If a side effect can be minimized by timing of administration, such as by taking the medication with food or by taking on an empty stomach, communicate this information to the patient. 2. Monitoring of therapy: Monitoring of therapy can be anything from encouraging the patient to see the physician for follow-up checks, to giving instructions on how to watch for signs of improvement or sharing warning signals of potential drug toxicity. To give you some sense for what and how to cover this information, here is the information which one veteran clinical pharmacist typically relates to her patients about side effects and precautions for the use of controlled-release theophylline products with initial prescription orders for these products. a. This is a potent medication that should be used with caution. Take it as directed; do not switch brands without first checking with your doctor; let your doctor know if you start any new medications or if you stop taking any medications that you are currently taking. b. The most common side effects are those usually associated with drinking too much coffee or caffeinated soda — jittery, can't sleep, headaches. These usually go away as your body adjusts to the medicine and are minimized if you avoid or limit extra stimulants, such as caffeinated beverages. c. Some people experience stomach upset (nausea, vomiting, heartburn). This is minimized by taking your medication with food. 35 d. If any side effect continues or if you notice anything more serious, such as diarrhea, consult your doctor immediately. IV. Storage instructions: The usual instructions are to keep out of the reach of children, in a place with moderate temperature, and away from high humidity. You may have to balance proper storage recommendations against compliance issues. If the patient explains that he or she can only remember to take medication by keeping it in plain view in the kitchen, your professional judgment may say that compliance is more important than providing perfect protection from relatively high humidity found in many kitchens. V. Check for patient understanding of information: Ask questions to be sure that the patient understands all necessary information, but do this in a pleasant way. You do not want to sound like a teacher giving a quiz. Perhaps you can determine patient understanding in a way that puts the responsibility on you rather than on the patient. You may say, ' 'I know I covered a lot of information, So that I am sure I didn't forget any important points, why don't you tell me about your understanding of what I've said?" Ethical principles and moral rules Autonomy (right of determination) The principle of autonomy states that an individual’s liberty of choice, action, and thought is not to be interfered with. In health care, we think of autonomy as the right of individuals to make decisions about what will happen to their bodies, what choices will be made about competing options, and what medications they choose to take, or not to take. Confidentialty This principles serves to assure the patient that information about their health, medical condition, treatment will not be given to anybody without their permission. Beneficence (doing good) The health care professional should act in the best interests of a patient. Decisions are made with perceptions based on needs of a patient. Non-maleficence (prevent harm) requests that we refrain from acting in ways that will harm or injure others. For example, pharmacist will refuse to fill a prescription order because of concern for patient safety. Veracity is the ethical principle that instructs pharmacists to be honest in their dealings with patients. Calculations for pharmaceutical practice. Expressions of quantity of drug Pharmaceutically useful dimensions of quantity: 1. weight of drug (milligram- mg, gram- g, grain- gr); for example, diazepam 5 mg 2. volume of drug (milliliter- mL, liter- L, drop- gtt); for example, Glacial Acetic Acid 2 drops 36 3. units (used for insulin, some antibiotics, and certain other natural products); for example, Insulin 25 units Measurement of temperature In pharmacy practice, there are two common systems for measuring temperature – degrees Celsius and degrees Fahrenheit. The conversion equations between these are (every 5 degrees measured in the Celsius scale is equal to 9 degrees as measured by the Fahrenheit scale) ºF = (9/5 x ºC)+ 32 ºC = 5/9 x (ºF – 32) Example: A patient reports that she has a temperature of 101ºF on her home thermometer. What is her temperature in degrees Celsius? Temperature in degrees Celsius = (101 – 32) x 5/9 = 38.3 ºC Expressions of concentration Concentration gives quantity of drug or active ingredient per amount (volume or weight) of product. For individual dosage units such as capsules, tablets, and suppositories, the dose is expressed as a quantity of drug rather than as a concentration. However, because pure drug is almost never dispensed, these quantities are technically concentrations. For example, when the label on the bottle of aspirin states Aspirin 325 mg, what is really meant is Aspirin 325 mg per tablet. Because the tablet contains other ingredients (excipients such as disintegrants, lubricants) besides the aspirin, the tablet weighs more than 325 mg and the content could be given as concentration, for example aspirin 325 mg per 450 mg of tablet material. Pharmaceutically useful expressions of concentration 1. Weight per weight; for example, Gentamycin Ophthalmic ointment 3 mg/g is 3 mg of gentamycin in each 1 g of ointment. 2. Weight per volume; for example, Tobramycin Ophthalmic Solution 3 mg/mL is 3 mg of Tobramycin in each 1 mL of solution; 3. Percent: for mixtures of solids – percent weight in weight. A percentage weight in weight is the number of grams of an active ingredient in 100 grams of a mixture. For example, Hydrocortisone 1% ointment is 1 gram hydrocortisone powder in 100 grams of ointment mixture. Example: How many grams of a drug should be used to prepare 240 g of a 5% w/w solution? x __ = 5__ 240 100 x = 5 x 240 = 12 g 100 for solutions of solids in liquids – percent weight in volume. A percentage weight in volume is the number of grams of an active ingredient in 100 mL of liquid. For example, Dextrose 5% in Water is 5 grams of dextrose powder in 100 mL of solution. Example: 37 If 3 g of iodine is in 150 mL of iodine tincture, calculate the percentage of iodine in the mixture. _x_ = _3_ 100 150 x = 2% w/v for solutions of liquids in liquids – percent volume in volume. A percentage volume in volume indicates the volume of active ingredient in 100 mL of a liquid. Isopropyl Alcohol 70% is 70 mL of isopropyl alcohol in 100 mL of solution. Example: If 20 ml of ethanol is mixed with water to make 40 mL of solution, what is the percentage of ethanol in the solution. _x_ = _20_ 100 40 x = 50% v/v 4. Ratio strength Concentrations of very dilute solutions or solid mixtures are sometimes expressed as ratio strengths rather than as percents. A ratio is the relative magnitude of two like quantities. Thus: 1:10 = 1 part in 10 parts, which might be 1 g in 10 g or 1 mL in 10 mL. Therefore, if 1 g of sucrose is in 10 g of solution, the ratio strength is 1:10. Equally, if we have 10 g of sucrose in 100 g of solution the ratio remains 1:10. For example, Potassium Permanganate Solution 1:5000 means that there is 1 g of potassium permanganate crystals in 5000 mL of solution. Example: Express 1: 2500 as a percentage strength 1 part = x% 2500 parts 100% x = 0.04 % Example: Express 0.1% as a ratio strength x = 1 part 100 0.1 x = 1000 Therefore, the ratio strength is 1:1000. 38 Not all prescribers are knowledgeable about the above conventions. You may get prescription orders that use ratio strength notation, and the prescriber intends the colon to be interpreted as a plus rather than the conventional q.s. ad. Example: Gentamycin ointment White Petrolatum Mix 1:2 Dispense 30 g. Two interpretations are possible: 1. If interpreted by official convention, this would be made by weighing one part of Gentamycin Oinment, the the q.s. ad to two parts with White Petrolatum. In other words, there would be one part of Gentamycin Oinment and one part of White Petrolatum for a total of two parts. 2. The alternative plus interpretation would mean to mix one part of gentamycin ointment with two parts of White Petrolatum for a total of three parts. In cases like this, consult the prescriber for clarification. 5. Pediatric doses Calculation of children's doses is commonly performed by the pharmacist. Fried's rule for infants (1 month to 1 year of age) Clark's rule Child's dosage based on body sur face area (BSA) Young's rule for children ≥ 2 years old 39 Most important conversions 1 kg = 1000 g 1 g = 1000 mg 1 mg = 1000 mcg 1 grain (gr) = 65 mg 1 kg= 2.2 lb 1 lb = 454 g 1 ounce (fl. oz.) = 30 mL 1 pint = 480 mL 1 gallon = 4 quarts = 8 pints 1 teaspoonful = 5 mL 1 tablespoonful = 15 mL SOLUTIONS Definition "Solutions are liquid preparations that contain one or more chemical substances dissolved, i.e., molecularly dispersed, in a suitable solvent or mixture of mutually miscible solvents" —USP Solutions are used pharmaceutically in a wide variety of ways. Specific desired or required properties depend on the intended route of administration and/or the solvent or solvent system. Below are descriptions of various classes of pharmaceutical solutions. Solutions by Route of Administration 1. Oral solutions These are liquid preparations intended for oral administration. They contain one or more therapeutically active ingredients dissolved in water or a watercosolvent system. Oral solutions may contain inactive ingredients to improve their taste, stability, and/or aesthetic appeal, such as flavors, sweetening or coloring agents, buffers, antioxidants, and preservatives. 2. Topical solutions These are solutions intended for topical application to the skin or mucous membranes. They are usually aqueous but may also contain other solvents, such as alcohols. 40 They may also contain additives, such as preservatives, antioxidants, buffers, humectants, viscosity inducing agents, colors, or scents. 3. Otic solutions These are intended for instillation in the outer ear. The vehicle may be water or glycerin, or a cosolvent system containing water and alcohol. They may also contain additives such as preservatives, antioxidants, buffers, viscosity inducing agents, or surfactants. 4. Nasal solutions These solutions are sprayed or instilled into the nose. The vehicle is usually water, but it may be a cosolvent system. They may also contain preservatives, buffers, antioxidants, or surfactants. 5. Ophthalmic solutions These are sterile, particle-free solutions formulated for instillation in the eye. The vehicle for ophthalmic solutions is water. In addition to the active ingredients and water, ophthalmic solutions may also contain buffers, preservatives, antioxidants, tonicity adjustors, and viscosity inducing agents. Because of the delicate nature of the eye and surrounding membranes, special consideration must be given to isotonicity, buffering, and preservation. 6. Irrigating solutions These are sterile solutions used to soak, flush, or irrigate wounds or body cavities, such as the bladder. They are not for parenteral use and should be labeled "Not for injection" and "For irrigation only." The usual vehicle for irrigating solutions is water. Because irrigating solutions come in contact with open wounds and delicate body tissues and membranes, special consideration must be given to isotonicity and pH of the solution. Additives may be necessary to achieve these objectives. 7. Parenteral solutions These are solutions injected through the skin or directly into a blood vessel, muscle, organ, or other tissue. Because these solutions are injected into delicate body tissues, special consideration must be given to osmolarity and pH of the solution. 41 Parenteral solutions must meet the standards given in section of Injections of the USP, including requirements for sterility, pyrogens, particulates, and contaminants. Vehicles and extra ingredients, such as preservatives, for these solutions must be approved for parenteral use. Advantages of solutions Because solutions are molecularly dispersed systems, they offer these advantages: Completely homogenous doses. Immediate availability for absorption and distribution. B. Solutions provide a flexible dosage form: They may be used by any route of administration. They can be taken or administered to patients who cannot swallow tablets or capsules. Doses are easily adjusted. Disadvantages of solutions Drugs and chemicals are less stable when in solution than when in dry form. Some drugs are not soluble in solvents that are acceptable for pharmaceutical use. Drugs with objectionable taste require special additives or techniques to mask the taste when in solution. Because solutions are more bulky and heavy than dry solid dosage forms, they are more difficult to handle, package, transport, and store. Oral solutions in bulk containers require measurement by the patient or caregiver. This is often less accurate than individual solid dosage forms, such as tablets and capsules Pharmaceutical solvents Water is the most commonly used and most desirable solvent for liquid products for all uses. Others common solvents include ethyl alcohol, isopropyl alcohol, glycerin, propylene glycol, polyethylene glycol 400 and various oils. Some solvents, such as isopropyl alcohol, are approved for topical solutions but may not be used internally because of their systemic toxicity. Some other solvents are used pharmaceutically in processing drug products, for assays and tests. Examples include acetone, ether, and chloroform. Types of water When water is used in making official USP preparations, it must meet the criteria specified in the USP for the type of preparation being made. For example, the water used for making parenteral products must meet the requirements for injections. The basic starting ingredient for all USP water items is potable (drinking) water. Water for making dosage forms must be one of the following USP water preparations: 42 a. Purified water is water obtained by distillation, ion exchange, reverse osmosis, or other suitable treatment. It cannot contain more than 10 parts per million (ppm) of total solid and should have a pH between 5 and 7. Purified water is used in prescriptions and finished manufactured products except parenteral and ophthalmic products. b. Water for injection is water obtained by distillation or by reverse osmosis. It conforms to the standards of purified water but is also free of pyrogen. Water for injection is used as a solvent for the preparation of parenteral solutions. c. Sterile water for injection is water for injection that is sterilized and packaged in single-dose containers. These containers do not exceed a capacity of 1 L. d. Bacteriostatic water for injection is sterile water for injection that contains one or more suitable antimicrobial agents. It is also packaged in single- or multiple-dose containers. These containers do not exceed the capacity of 30 mL. e. Sterile water for inhalation is water that is purified by distillation or by reverse osmosis (i .e. , water for injection) and rendered sterile. It contains no antimicrobial agents, except when used in humidifiers or similar devices. This type of water should not be used for parenteral administration or for other sterile dosage forms. f . Sterile water for irrigation is water for injection that is sterilized and suitably packaged. It contains no antimicrobial agents or other added substance and is used for irrigation only. g. Sterile purified water is purified water sterilized and suitably packaged. It is not intended for use in parenterals. Alcohols In organic chemistry, alcohols have the general formula R-OH. In pharmacy, when the term “alcohol” is used, it refers to ethyl alcohol (C2H5OH), unless a different alcohol name is specified, for example isopropyl alcohol. Alcohol USP Content: Not less than 92.3% and not more than 93.8%, by weight (w/w), corresponding to not less than 94.9% and not more than 96.0%, by volume (v/v), of C2H5OH. Specific gravity: between 0.812 and 0.816 Description: clear, colorless, mobile, volatile liquid, flammable, boils at 78º. Labeling: “The content of alcohol in a liquid preparation shall be stated on the label as a percentage (v/v) of C2H5OH. Solubility: Miscible with water, isopropyl alcohol, glycerin, acetone, propylene glycol, ether and chloroform. Will mix with castor oil, but not other fixed oils and not with mineral oil. Glycerin (Glycerol) Content: Not less than 95.0% of C3H8O3 Description: Clear, colorless, syrupy liquid. Practically odorless, hygroscopic. Specific gravity: not less than 1.249 Solubility: Miscible with water, ethyl alcohol, isopropyl alcohol, propylene glycol, polyethylene glycol 400, insoluble in ether and chloroform, fixed oils,mineral oil, and volatile oils. 43 It is used as as a solvent for the preparation of pharmaceutical dosage forms for internal and external use. It is also useful as a humectant and preservative. Polyethylene Glycol Polyethylene Glycol, also known as PEG, is an addition polymer of ethylene oxide and water. It has the formula H( OCH2CH2)n OH where n represents the number of oxyethylene groups. PEG is labeled with a number indicating the average nominal molecular weight of Polyethylene Glycol. The numbers range from 200 to 8000; polyethylene glycols 200, 300, 400 and 600 are liquids at room temperature and the higher molecular polymers are waxy solids. Principles of compounding solutions When making a solution of a drug or chemical, consider the following: 1. Will the drug or chemical dissolve in the desired solvent? 2. How long will it take to dissolve the drug or chemical? 3. Will the drug or chemical be stable in solution? For how long? 4. Is a preservative needed to prevent the growth of microorganisms inadvertently introduced at the time of preparation or during use by the patient? To make a solution of a solid in a solvent, the concentration of the solid in the solvent must be at or below the solubility of the solid in that solvent. Obviously, a solid will not dissolve above its solubility. When predicting solubility very generally, the old saying "Like dissolves like" is a useful guide, where like refers to similarity of functional group or molecular structure. Usually more precise information on solubility is required, so the first step in making a drug solution is to check the solubility of the drug. Example: Boric Acid 10 % Sterile Water q s ad 60 mL On checking the solubility of Boric Acid, the pharmacist finds it to be 1 g/18 mL water, or approximately 5%. The above preparation cannot be made because the prescribed concentration, 10%, is above the solubility of the Boric Acid in water. Remember that solubilities are given in grams of solute per milliliter of solvent, not per milliliter of solution, so unless you know the density of the saturated solution, you cannot know the precise amount of solution that will result. Therefore, the 5% given above is a rough estimate. Many times solubility is given in descriptive terms, such as soluble, slightly soluble, and sparingly soluble. The numerical equivalents of these terms can be found in the USP and other references. If possible, always dissolve the drug in pure solvent. For example, although Syrup USP contains a lot of water, these solvent molecules are tied up through hydrogen bonding with sucrose and are unavailable for the purposes of interacting with and dissolving additional solute. Desciption Solubility range 44 Very soluble less than 1 in 1 Freely soluble Soluble Sparingly soluble Slightly soluble Very slightly soluble Practically insoluble 1 in 1 to 1 in 10 1 in 10 to 1 in 30 1 in 30 to 1 in 100 1 in 100 to 1 in 1000 1 in 1000 to 1 in 10 000 1 in greater than 10 000 Beware of dissolving drugs or chemicals in boiling water (a useful technique to speed up dissolution) because the drug may precipitate when the preparation cools to room temperature if its concentration is above its solubility at room temperature. In the example with Boric Acid, the solubility of Boric Acid is 1g/4 mL of boiling water, or approximately 25%. The 10% solution could easily be made using hot or boiling water, but the Boric Acid will precipitate out on cooling to room temperature. If the solution is to be stored or used at a temperature other than room temperature, the solubility of the drug at that temperature must be considered. Miscibility of liquids You know that oil and water don't mix, but consider the miscibility of the following examples: Alcohol and Water? Yes Glycerin and Water? Yes Glycerin and Alcohol? Yes Glycerin and Mineral Oil? No Alcohol and Mineral Oil? No (Mineral Oil is miscible with chloroform, ether, benzene, and many other oils, but not with Alcohol and not with Glycerin) Alcohol and Cottonseed Oil? No Alcohol and Castor Oil? Yes (Castor Oil is the only fixed oil which is miscible with Alcohol) (in equal parts) Cottonseed Oil and Mineral Oil? Yes Castor Oil and Mineral Oil? No (Castor Oil is the only fixed oil not miscible with Mineral Oil) Compounding strategies when it is necessary to combine immiscible liquids: Make an emulsion by adding an emulsifying agent. Be sure to use a "Shake Well" label. Use a different solvent or an appropriate cosolvent system. In all cases in which changes are required, consult with the prescriber. 45 How long will it take to dissolve the drug or chemical? In other words, what is the rate of dissolution? In practical terms, what we often want to know is, how can we speed up the rate of dissolution? This can be analyzed in terms of the Noyes-Whitney equation. 1. The dissolution rate constant, K, is equal to D/hV, where D is the diffusion coefficient, h is the thickness of the unstirred layer around the particle, and V is the volume of the solvent into which the drug is dissolved. 2. The diffusion coefficient D is actually composed of several factors expressed in the Stokes-Einstein equation given below. A knowledge of these factors will help the pharmacist to understand conditions that can be changed or controlled to increase rate of dissolution. D= kT 6ηπr where: k is the Boltzmann constant T is absolute temperature, η is viscosity of the medium r is the radius of the drug molecule From the Noyes-Whitney and Stokes-Einstein equations, it can be seen that some factors can be controlled or modified to increase the rate of dissolution and some cannot. dC/dt, the rate of dissolution, is dependent on: a. T: Temperature is an important factor which can be altered by the pharmacist. As temperature increases, D increases, so diffusion and the rate of dissolution increase. In practical terms, we can use warm solvents or can heat solutions to increase the rate of dissolution. Care must be exercised when using heat because increasing the temperature also increases the rate of degradation of drug molecules. b. η: Changing the viscosity of the medium has the opposite effect on diffusion and dissolution rate. Increasing viscosity decreases rate of dissolution. For this reason, drugs dissolve more slowly in viscous vehicles like syrups. This is one reason why it is best to dissolve drugs in pure solvents, like water or alcohol, which have low viscosity, then add the more viscous necessary liquids, such as glycerin, syrups. c. r: Even though we cannot control the radius of the drug molecule, it is important and helpful to understand how it affects diffusion and the rate of dissolution. The larger the radius (r), the smaller D becomes and the slower the rate of dissolution. This means that, all other things being equal, large drug molecules dissolve more slowly than do smaller molecules. This is especially important when working with macromolecules, such as Erythromycin Lactobionate and Amphotericin B. When making solutions of these drugs, it is necessary to give them sufficient time to dissolve. This factor will have increasing importance as pharmacists handle 46 more peptide and protein drugs because these are very large molecules. d. The factor h, which is the thickness of the unstirred layer around the particle, can be affected by stirring. The dissolution rate is faster if the drug-solvent-solution system is agitated or stirred. By stirring, the dissolved drug molecules are moved away from the surface of the solid to the bulk of the solution. This has the effect of decreasing h, which increases K and therefore increases the rate of dissolution. e. The surface area of the solid, S: As was stated in the discussion on powders, because, for a given weight of solid, the surface area of a solid increases as the particle size is decreased, the smaller the particle size, the larger the surface area and the faster the rate of dissolution. Although important, this principle has limited practical application in compounding solutions. Most drugs and chemicals are purchased in a fine state of subdivision. Unless a solid ingredient is in large pieces, any mechanical manipulation, such as trituration, by the pharmacist has only a minor effect on the rate of dissolution. f. The solubility of the solid, Cs; Although the solubility of the solid is a given property of the drug, it is important to know that poorly soluble drugs may dissolve slowly. g. C, the concentration ovff the drug or chemical in solution at time = t. As the solution approaches saturation, the quantity (Cs—C) gets smaller and smaller until Cs = C. At this point, (Cs—C) = 0, saturation is reached, and dissolution stops. As saturation is approached, the rate of dissolution may become very slow. This is one reason for making saturated solutions ahead of time because getting that last little amount to dissolve may take a long time. Some pharmacists maintain stock bottles of saturated solutions with excess drug or chemical on the bottom of the vessel and then decant the saturated solution when it is needed. A differentiation is sometimes made between solutions on the basis of solute molecular size. Micromolecular solutions consist of dispersed molecules or ions in the 1-10 A size (MW < 10,000). In macromolecular solutions (MW > 10,0000), the solutes are in true solutions, but the solute size of macromolecular solutions lends special properties to them. Because the particles are so large, most cannot be sterilized by filtration. The solutions are also quite viscous, and may be used as thickening agent for other dispersed dosage forms. Macromolecular solutions include those containing acacia, methylcellulose and other cellulose derivatives, and proteins such as albumin. SYRUPS 47 A syrup is a concentrated or nearly saturated solution of sucrose in water. A simple syrup contains only sucrose and purified water (e.g. Syrup USP). Syrups containing pleasantly flavored substances are known as flavoring syrups, e.g. Cherry Syrup. Medicinal syrups are those to which therapeutic compounds have been added (e.g. Guaifenesin Syrup). Syrup USP contains 850 gm sucrose and 450 ml of water in each liter of syrup. Although very concentrated, the solution is not saturated. Since 1 gm sucrose dissolves in 0.5 ml water, only 425 ml of water would be required to dissolve 850 gm sucrose. This slight excess of water enhances the syrup's stability over a range of temperatures, permitting cold storage without crystallization. The high solubility of sucrose indicates a high degree of hydration or hydrogen bonding between sucrose and water. This association limits the further association between water and additional solutes. Hence, Syrups have a low solvent capacity for water -soluble drugs. For this reason, it can be dif ficult or impossible to dissolve a drug in a syrup. Often, the drug is best dissolved in a small quantity of water, and the flavoring syrup is added. The sucrose concentration of syrup plays a crucial role in the control of microbial growth. Dilute sucrose solutions are excellent media for microorganisms. As the concentration of sucrose approaches saturation, the syrup becomes self -preserving ( i .e. , requires no additional preservative). However, a saturated solution is undesirable because temperature fluctuations may cause crystallization. Simple sirup is a selfpreserved solution with a minimal tendency to undergo crystallization. ELIXIRS Elixirs are traditionally peroral solutions that contain alcohol as a cosolvent. Many peroral solutions are not described as elixirs but contain alcohol. (1) To be considered an elixir , the solution must contain alcohol . Traditionally, the alcohol content of elixirs has varied from 5% to 40%. Most elixirs become turbid when moderately diluted by aqueous liquids. Elixirs are not the preferred vehicle for salts because alcohol accentuates saline taste. Salts also have limited solubility in alcohol. Therefore, the alcoholic content of salt -containing elixirs must be low. AROMATIC WATERS Aromatic waters are clear, saturated aqueous solutions of volatile oils or other aromatic or volatile substances. Aromatic waters may be used as pleasantly flavored vehicles for a water soluble drug or as an aqueous phase in an emulsion or suspension. If a large amount of water soluble drug is added to an aromatic water, then an insoluble layer may form at the top. This “salting out” is a competitive process. The molecules of water –soluble drugs have more attraction for the solvent molecules of water than the “oil ” molecules. The associated water molecules are pulled away from the oil molecules, which are no longer held in solution. Aromatic waters should be stored in tight, light - resistant bottles to reduce volatilization and 48 degradation from sunlight . Aromatic waters are usually prepared by one of the following methods: a. Distillation is a universal method but is not practical or economical for most products. It is the only method, however, for preparing strong rose water and orange flower water. b. With the solution method, the volatile, or aromatic, substance is admixed with water , with the use of a dispersant (e.g., talc). SPIRITS Spirits, or essences, are alcoholic or hydroalcoholic solutions of volatile substances, that contain 50%-90% alcohol . This high alcoholic content maintains the water -insoluble volatile oils in solution. If water is added to a spirit , the oils separate. Some spirits are medicinal (e.g., aromatic ammonia spirit). Many spirits (e.g., compound orange spirit, compound cardamom spirit ) are used as flavoring agents. Spirits should be stored in tight containers to reduce loss by evaporation. TINCTURES Tinctures are alcoholic or hydroalcoholic solutions of chemicals or soluble constituents of vegetable drugs. Although tinctures vary in drug concentration (≤ 50%), those prepared from potent drugs are usually 10% in strength ( i.e., 100 mL of the tincture has the activity of 10 g of the drug). Tinctures are usually considered stable. Most tinctures are prepared by an extraction process of maceration or percolation. The selection of a solvent, or menstruum, is based on the solubility of the active and inert constituents of the crude drugs. Aging can cause precipitation of the inactive constituents of tinctures. Glycerin may be added to the hydroalcoholic solvent to increase the solubility of the active constituent and reduce precipitation on storage. Tinctures must be tightly stoppered and kept from excessive temperatures. Because many of their constituents undergo a photochemical change when exposed to light, tinctures must be stored in light -resistant containers. FLUIDEXTRACTS Fluidextracts are liquid extracts of vegetable drugs that contain alcohol as a solvent, preservative, or both. Fluidextracts are prepared by percolation so that each milliliter contains the therapeutic constituents of 1g of the standard drug. Because of their high drug content, fluidextracts are sometimes refer red to as “100% tinctures.” Fluidextracts of potent drugs are usually 10 times as concentrated, or potent, as the corresponding tincture. For example, the usual dose of tincture belladonna is 0.6 mL; the equivalent dose of the more potent fluidextract is 0.06 mL. Many fluidextracts are considered too potent for self administration by patients, so they are almost never prescribed. In addition, many fluidextracts are simply too bitter . Today, most fluidextracts are modified by either flavoring or sweetening agents. 49 ASTRINGENTS Astringents are locally applied solutions that precipitate protein. They reduce cell permeability without causing injury. Astringents cause constriction, with wrinkling of the skin. Because astringents reduce secretions, they can be used as antiperspirants. Aluminum acetate and aluminum subacetate solutions are used as wet dressings in contact dermatitis. Calcium hydroxide solution is a mild stringent that is used in lotions as a reactant and an alkalizer. HOW TO USE NOSE DROPS 1. 2. 3. 4. Blow your nose gently. Wash your hands with soap and warm water. Draw up a small amount of medication into the medicine dropper. Lie down on your back and place a pillow under your shoulders. Tilt your head back so that it is hanging lower than your shoulders. Note: If putting drops into the nose of a child, lie the child on his or her back over your lap. The head should be tilted back. 5. Breathe through your mouth. 6. Place the tip of the medicine dropper just inside your nostril. Avoid touching the dropper against the nostril or anything else. 7. Squeeze the directed number of drops into your nostril. 8. Repeat steps 3-7 for the other nostril. 9. Remain lying down for about 5 minutes, so that the medication has a chance to spread throughout your nasal passages. 10. Replace the cap tightly on the bottle. NOTE: • Some of the solution may drain down into your mouth. If the taste is unpleasant, you may cough the excess solution into a handkerchief or tissue. • It may be much easier to have someone help you instill your nose drops. HOW TO USE EAR DROPS 1. 2. 3. 4. Wash your hands with soap and warm water. Draw up a small amount of medication into the medicine dropper. Lie on your side so that the affected ear points toward the ceiling. Position the tip of the medicine dropper just inside the affected ear canal. Avoid touching the dropper against the ear or anything else. For adults, hold the earlobe up and back; for children, hold the earlobe down and back. 5. Squeeze the directed number of drops into your ear canal and allow the drops to run in. 50 6. Remain lying down for 3 to 5 minutes so that the medication has a chance to spread throughout the ear canal; you may gently massage the area around your ear to aid the spreading and distribution of the ear drops in the canal. 7. Place a clean cotton pledget just inside your ear to prevent leakage of the solution when your head is held in an upright position. 8. Replace the cap tightly on the bottle. IMPORTANT: Never use ear drops if your eardrum has been damaged. Avoid using very hot or very cold ear drops. The medication should be at room temperature or slightly warmer. If necessary, warm the drops by holding the bottle in your hand for a few minutes. NOTE: It may be much easier to have someone else instill your ear drops. Pharmaceutical additives Pharmaceutical additives are defined as non-drug adjuncts in a formulation to aid stability, strength and protectivity to final dosage forms. Surface active agents (surfactants) The pharmaceutical additives that reduce interfacial tension between the dispersed phase and dispersion medium are defined as surface-acting agents. They are normally classified into 4 different categories: 1. Anionic agents 2. Cationic agents 3. Nonionic agents 4. Amphoteric agents 1. Anionic agents are groups of surfactants which ionize in an aqueous media and whose surfactant activity is related to anionic parts. They can be subdivided into: a. soap b. sulfated compounds 51 c. sulfonated compounds Soaps are normally prepared by the saponification of natural fatty acid triglycerides in an alkaline solution. The most common cations associated with soaps are sodium, potassium, ammonium and triethanolamine. The degree of water solubility is greatly influenced by the length of the alkyl chain and the presence of double bonds. Multivalent cations such as calcium and magnesium produce marked water insolubility, and therefore soaps are not useful in hard water which is high in content of these ions. Sulfated compounds are derivatives of sulfuric acid in which one of the hydrogen atoms is replaced by the R group. For example, sodium lauryl sulfate, sodium cetyl sulfate. Sulfonated compounds are derivatives of sulfurous acid in which one of the hydrogen atoms is replaced by the R group. For example, dioctyl sodium sulfosuccinate. 2. Cationic agents are derivatives of quaternary ammonium compounds in which all of the four hydrogen atoms have been replaced by alkyl groups. Their use in pharmaceurical preparation as surfactants is limited, they are used rather as antimicrobial preservatives. For example, benzalkonium chloride, cetyltrimethyl ammonium bromide. 3. Nonionic surfactants are most widely used surfactants in pharmaceutical industry since thay are highly stable and compatible in a wide range of pH. For example, spans (sorbitan esters, hydrophobic) and tweens (hydrophilic). 4.Amphoteric agents can be generated by reacting carboxylate or phosphate groups with amino or quaternary ammonium groups. The former group is represented by various polypeptides and proteins while the latter group consists of natural phospholipids such as lecithin and cephalins. For example, dodecyl alanine. 52 Antioxidants Antioxidants are additives that protect the formulation from oxidative degradation. The additives that enhance the effect of antioxidants by only their presence are defined as synergist. Water soluble antioxidants Sodium bisulfite Sodium metabisulfite Sodium thiosulfate Thiourea Synergists Citric acid Lecithin Glycerine Phosphoric acid PEG Propylene glycol Oil soluble antioxidants Tocopherol Ascorbyl palmitate Butylated hydroxyanisole (BHA) Butylated hydroxytoluene (BHT) Preservatives are additives that prevent microbial growth and prohibit large scale chemical changes in formulation. Phenol 53 Benzoic acid Boric acid Formic acid Benzalkonium chloride Salicylic acid Phenylmercuric nitrate COLLOIDAL DISPERSIONS When two different substances are mixed together, a two component system is produced. When one component is distributed uniformly throughout the second, the first component is called the dispersed phase and the second, the dispersion medium. Either phase may be solid, liquid, or gas. Frequently in pharmaceutical practice a solid substance is dispersed in a liquid, usually water, and the resulting product may have the characteristics of either a molecular dispersion (true solution), a colloidal dispersion, or a coarse dispersion depending on the particle size of the dispersed solid. In true solutions the dispersed particles are ions or small molecules having particle size less than 1 nanometer (nm). In colloidal dispersions the particles are either single, large molecules of high molecular weight (macromolecules) or aggregates of smaller molecules with diameters between 1 nm and 500 nm in size (0.001 - 0.5µ). In coarse dispersions the particles are greater than 500 nm in diameter. The dispersed phase of a colloidal dispersion may be classified as being either lyophilic (solventloving) or lyophobic (solvent-hating). If the solvent is water these classifications are termed by hydrophilic and hydrophobic, respectively. Neutralization of the particle charge may occur by addition of ions of opposite charge. The neutralized particles, which possess high surface free energy, cling together resulting in a precipitate. PROPERTIES OF COLLOIDS Colloid dispersions exhibit several properties. Among these are the scattering of a light beam directed through a colloidal dispersion. This is known as the Tyndall effect and its magnitude is due to the size and number of particles present. When observed under ambient light, colloidal 54 dispersions may appear translucent, opalescent or cloudy depending on the type of colloid and the degree of particle concentration and dispersion. Under a microscope colloidal particles may be seen to "dance" or move at random. This is known as Brownian movement and is due to bombardment of the colloidal particles by molecules of the dispersion medium. Brownian movement is usually observed when particles are below 5µ in size. Colloids do not pass through a semi-permeable membrane. Thus, when a protein solution such as albumin is placed into a cellophane sac and submerged into water, water molecules will enter the sac to dilute the albumin molecules which cannot diffuse out. The principle is also operational in the kidney where ions and small molecules are filtered out of the blood across the glomerular membrane but the macromolecular serum proteins are retained. Sterilization of injections is sometimes performed by filtration through a synthetic membrane having a mean pore size of 0.22µ (220 nm). It is important to realize that colloidal injections may not be sterilized by this method unless the particles are smaller than the mean pore size of the membrane. STABILITY OF COLLOIDS Since a uniform dispersion of particles is important for the diagnostic and therapeutic effectiveness as well as the safety of administration of pharmaceutical colloids, stability against settling or coprecipitation is an important consideration. The addition of a hydrophilic colloid to a hydrophobic one causes the hydrophilic colloid to adsorb onto and completely surround the hydrophobic particles which then take on some of the properties of the hydrophilic colloid. The hydrophilic colloid shields the hydrophobic system from the destabilizing effects of electrolytes; thus the hydrophilic substance is called a "protective colloid". Stability of such a system is enhanced, because in order to precipitate the hydrophobic colloid, both the protective solvent sheath surrounding it and the electric charge must be removed. Gelatin and methylcellulose derivatives are commonly used as protective colloids. Sometimes in pharmaceutical formulations buffer salts are added to maintain a pH required for product stability. Occasionally such buffers may contribute to potential instability by forming insoluble salts with metallic ions. This problem may occur especially with phosphate buffers since most heavy metal phosphates are insoluble. If an insoluble phosphate salt precipitates from a colloidal dispersion, it may co-precipitate the colloidal particles along with it. To prevent this phenomenon from occurring, chelating agents may be used that will preferentially complex the 55 metal ions, and thus prevent them from reacting with the phosphate. Alternatively, nonphosphate buffers may be substituted for phosphate buffers, when feasible, to prevent the instability. Suspensions Definitions Suspensions: “Suspensions (coarse dispersion) are liquid preparations that consist of solid particles dispersed throughout a liquid phase in which the particles are not soluble”. — USP23 The internal phase consisting of insoluble solid particles having a specific range of size which is maintained uniformly throughout the suspending vehicle with aid of single or combination of suspending agent. The external phase (suspending medium) is generally aqueous in some instance, may be an organic or oily liquid for non oral use. So, the term "suspension" refers to a two-phase system consisting of a finely divided solid dispersed (suspended) in a liquid (the dispersing medium). Surfactants: Surfactants are molecules that are adsorbed at interfaces. Their molecular structures contain both a hydrophilic and hydrophobic portion. They orient themselves at interfaces so as to reduce the interfacial free energy. Wetting agents: Wetting agents are surfactants that, when dissolved in water, lower the contact angle between a surface and the liquid and aid in displacing the air phase at the surface and replacing it with liquid phase. Classification Based On General Classes Oral suspension Externally applied suspension Parenteral suspension Based On Proportion Of Solid Particles Dilute suspension (2 to10%w/v solid) Concentrated suspension (50%w/v solid) The reasons for the formulation of a pharmaceutical suspension: When the drug is insoluble in the delivery vehicle To mask the bitter taste of the drug To increase drug stability To achieve controlled/sustained drug release 56 Uses of suspensions Oral products Suspensions possess certain advantages over other dosage forms. Some drugs are insoluble in all acceptable media and must, therefore, be administered as a tablet, capsule, or as a suspension. Because of their liquid character, suspensions represent an ideal dosage form for patients who have difficulty swallowing tablets or capsules. These patients include adults who cannot swallow solid dosage forms, infants or children who have not yet learned how to swallow whole tablets or capsules, patients with nasogastric tubes, and geriatric patients who no longer have the ability to swallow solid oral dosage units. In the case when needed solids aren’t soluble in the solvent we prepare suspensions. Also, drugs in suspension are chemically more stable than in solution. This is particularly important with certain antibiotics and the pharmacist is often called on to prepare such a suspension just prior to the dispensing of the preparation. A manufactured liquid product should be used if available because the manufacturer has conducted stability and bioavailability testing on the product. Fortunately, in recent years, a larger number of oral liquid products are being marketed by pharmaceutical companies. Topical Products As with oral liquids, a manufactured liquid product should be used if available. Often, topical liquid preparations require compounding by the pharmacist because dermatologists and other prescribers like to create their own unique formulas customized for a specific patient with a particular skin condition. Suspensions also possess some disadvantages relative to other dosage forms. The primary disadvantage is their physical instability; i.e., that they tend to settle over time leading to a lack of uniformity of dose. This can, however, be minimized by careful formulation and by shaking the suspension before each dose is delivered. An additional disadvantage is that the texture of suspensions may be unpleasant to patients and should be carefully considered during formulation. Desired properties of a suspension A. Fine, Uniform-sized Particles 1. Very fine particles are desirable for both topical and oral suspensions. Particles in suspensions usually range from 0.5-3 microns (micrometers) in diameter. 57 a. Uniform, finely-divided particles give optimal dissolution and absorption. This is particularly important for suspensions that are intended for systemic use. b. A smooth, nongritty product is essential for patient acceptance. This is true for both topical and internal-use preparations. c. As discussed below, small, uniform-sized particles are needed to give suspensions with acceptable sedimentation rates. 2. Solid powders used for making suspensions should be in the finest state of subdivision possible. This is achieved through choice of drug form, through proper selection of equipment, and through use of good compounding technique. a. Choice of drug form. 1. If a prescription order specifies a certain form of a drug, that form must be used unless the prescriber is consulted. For example, if the prescription lists Precipitated Sulfur as an ingredient, that form should be used in the formulation. 2. If a drug or chemical is available in more than one form and no form is specified on the prescription order, choose the form that has the finest particle size (e.g., Boric Acid powder rather than Boric Acid crystals, Colloidal Sulfur rather than Precipitated Sulfur). The form used should be specified on the face of the prescription document. This ensures product uniformity with each prescription refill. b. Compounding equipment and technique 1. Suspensions are made in the pharmacy using mortars and pestles. Choice of mortar type depends both on the characteristics of the ingredients and the volume of the preparation. 2. Some pharmacists have found that they can ensure more uniform particles of the desired size for dispersions by passing the prepared powder through a sieve. A mesh size of the range 35-45 is considered adequate for suspensions. B Uniform Dispersion of the Particles in the Liquid Vehicle 1. Because, in a suspension, the solid does not dissolve, the solid should be well dispersed in the liquid vehicle. This ensures a uniform mixture and a uniform dose. To accomplish this, the insoluble powder must be properly "wet." That is, the air on the surface of the powder particles must be displaced by liquid. a. If the liquid vehicle is one with a low surface tension, this is not a problem; the liquid will easily wet the solid. b. In most situations, however, water constitutes all or part of the dispersing liquid; water has a high surface tension and does not easily wet many solids, especially hydrophobic drugs or chemicals. c. When the liquid vehicle contains water, special additives, techniques, or order of mixing must be used to create a uniform suspension. The ingredients and procedure depend on the nature of the solid phase, the other ingredients in the formulation, and the intended route of administration. 58 If the insoluble powders are hydrophilic, they will be wet easily by water or any other liquid used for pharmaceutical preparations. In this case, no special additives or procedures are necessary. Examples of powders in this class are Zinc oxide, Calcium and Magnesium carbonates, Caolin (white clay), Talc, Aluminium hydroxide, Calamin. Many water-insoluble drugs are hydrophobic; these powders are not easily wet by water. For example, Camphor, Menthol, Thymol, Sulfur, Streptocid, Norsulfasol. To wet such a solid, either a water-miscible liquid with a low surface tension must be used, or a wetting agent must be added to the water to reduce its surface tension. In both cases, remember to consider the route of administration when selecting an additive to improve wetting; additives to oral suspensions must be approved for internal use. Use of water-miscible liquids with low surface tension for wetting solids: Although water has a surface tension of 72.8 dynes/cm at 20° C, glycerin has a surface tension of 63.4 dynes/cm; therefore, glycerin is a better wetting medium for hydrophobic drugs than is water. Examples of liquids used for wetting hydrophobic solids include glycerin, alcohol, propylene glycol, polyethylene glycol. Use of wetting agents: A wetting agent is a surfactant that, when added to water, improves its ability to wet hydrophobic powders. Examples include soaps such as sodium stearate, detergents such as sodium lauryl sulfate and nonionic surfactants such as Polysorbate 80. 2. If possible, an ingredient that is already in the prescription order should be used for wetting the insoluble solid. If there are no suitable liquids or surfactants in the formulation, use professional judgment to decide what, if anything, should be added. A small amount of glycerin, alcohol, or propylene glycol is often helpful. A convenient source of surfactant in a pharmacy is the stool softener Docusate Sodium. Docusate Sodium is available formulated both in a liquid or in soft-gelatin capsules. To use a capsule, cut through the soft-gelatin with a razor blade and express the contents into a small amount of water. C. Slow Settling of the Particles, That Is, Slow Rate of Sedimentation Although it is impossible to completely prevent settling of solid particles in a suspension, the rate of sedimentation can be controlled. Stoke's Law provides useful information in determining what parameters of a suspension should be controlled to retard the sedimentation rate of particles in a suspension. V= 2 r2 (ρs – ρl) g 9η where: v - velocity of sedimentation g = gravitational acceleration 59 ρs = density of the solid ρl = density of the liquid r = radius of the particles η = viscosity of the liquid Although gravitational acceleration (g) is a constant and the density of the solid (ρs) cannot be changed, the other factors in Stoke's Law can be manipulated to minimize sedimentation rate (v): 1. The particle size should be as small as possible. As discussed previously, this is controlled through choice of drug form and through proper use of compounding equipment and technique. 2. The density of the liquid may be increased. If the density of the liquid could be made equal to the density of the solid, the term (ρs - ρl) becomes zero, the sedimentation rate becomes zero, and the suspended particles do not settle. Although this is rarely achieved, the density of the medium can be manipulated to improve the sedimentation rate. a. For oral suspensions, the density of the liquid can be increased by adding sucrose, glycerin, sorbitol, or other soluble or miscible, orally acceptable additives. Glycerin has a density of 1.25, Syrup USP has a density of 1.3, and Sorbitol 70% has a density of 1.285. b. For topical suspensions, any nontoxic soluble or miscible ingredient which is approved for topical use and which would increase density is acceptable. 3. The viscosity of the liquid medium may be increased by adding a viscosity inducing agent, such as Methylcellulose, Sodium Carboxymethylcellulose, Acacia, Tragacanth. So the rate of sedimentation is independent of the lipophilic nature of particles. D. Ease of Redispersion When the Product Is Shaken Solids should not form a hard "cake" on the bottom of the bottle when the product is allowed to stand. The product should not be so viscous that redispersion is difficult. One special formulation technique, flocculation, is useful in producing suspensions that readily redisperse. Flocculation gives a controlled lacework-like structure of particles held together by weak bonds. These weak bonds hold the particles in the structure when the suspension is at rest, but break apart easily when the suspension is shaken. This technique is often used in the pharmaceutical industry but is somewhat difficult to achieve in extemporaneous compounding. Some viscosity inducing agents, such as Bentonite, form flocculated systems and are useful as suspending agents in compounding. Various manufactured suspending vehicles, such as Ora Plus®, Vehicle S®, and Suspendol®, are flocculated systems and are helpful in making suspensions that settle slowly, but that are easily redispersed on shaking. Labeling All suspensions are disperse systems and require a SHAKE WELL auxiliary label. External use suspensions should be labeled for EXTERNAL USE ONLY. 60 Suspending agents A suspending agent helps reduce the sedimentation rate of particles in suspension. These are insoluble particles that are dispersed in a liquid vehicle. The suspending agent works by increasing the viscosity of the liquid vehicle, and thereby slowing down settling in accordance with Stokes Law. Suspending agents include hydrophilic colloids, clays, and a few other agents. Some are also used as emulsifying agents. a. Hydrophilic colloids ( i .e., hydrocolloids) increase the viscosity of water by binding water molecules, thus limiting their mobility. Viscosity is proportional to the concentration of the hydrocolloid. These agents support the growth of microorganisms and require a preservative. They are mostly anionic, with the exception of methyl cellulose (neutral ) and chitosan (cationic) . Thus the anionic hydrocolloids are incompatible with quaternary antibacterial agents and other positively charged drugs. Chitosan is incompatible with negatively charged drugs and excipients. Most hydrocolloids are insoluble in alcoholic solutions. (1) Acacia is usually used as a 35% dispersion in water (mucilage). Its viscosity is greatest between pH 5 and pH 9. Acacia is susceptible to microbial decomposition. (2) Tragacanth is usually used as a 6% dispersion in water (mucilage). One advantage of tragacanth over acacia is that less is needed. Also, tragacanth does not contain the oxidase that is present in acacia. This oxidase catalyzes the decomposition of organic chemicals. The viscosity of tragacanth is greatest at pH 5. (3) Methylcellulose is a polymer that is nonionic and stable to heat and light . It is available in several viscosity grades. Because it is soluble in cold water, but not in hot water, dispersions are prepared by adding methyl cellulose to boiling water and then cooling the preparation until the material dissolves. (4) Carboxymethylcellulose is an anionic material that is soluble in water. Prolonged exposure to heat causes loss of viscosity. b. Clays (e.g. , bentonite, Veegum) are silicates that are anionic in aqueous dispersions. They are strongly hydrated and exhibit thixotropy ( the property of forming a gel- like structure on standing and becoming fluid on agitation). Veegum is hydrated to a greater degree than bentonite. Thus it is more viscous at the same concentration. c. Other agents include agar, BHT(butylated hydroxytoluene ), chondrus (carrageenan), gelatin, carbomer, pectin, and gelatinized starch. Their use is limited by their susceptibility to bacterial attack, their incompatibilities, and their cost. Xanthan gum is used in many modern suspension 61 formulations because of its cosolvent compatibility, its stability, and its solution's high viscosity relative to concentration. Preparation of a suspension The following are the procedure for preparing a suspension. The steps are: 1. Wetting and dispersion of active ingredient 2. Stabilization of dispersed solid 3. Preparation of the vehicle 4. Addition and dispersion of active ingredient in vehicle 5. Addition of remaining ingredients and final mixing Step 1. Wetting and dispersion of active ingredient Mill to achieve target particle size. Drug powder may be treated with a water miscible material such as glycerin to aid in wetting. Large quantities of drug may make this impractical. Powder should be added to a low viscosity portion of the product, preferably plain water. This allows for most efficient mixing and homogenization. A surfactant is frequently added to the water to aid in wetting and displacement of air. Step 2. Stabilization of the dispersed solid 1. Electrical (Controlled flocculation). Addition of electrolytes to produce charges around each particle and allow for electrical repulsion to prohibit particle interactions. From a practical aspect, this is not effective except where particles are in the colloidal size range. 2. Adsorption of a hydrophilic colloid: Such a material forms a layer around the particle. It is highly hydrated and the attractive forces between the hydrophilic colloid and water molecules are greater than the attractive forces between the solid particles, thus overcoming those forces and stabilizing the dispersion. Step 3. Preparation of the vehicle Structured vehicles called also thickening or suspending agents. They are aqueous solutions of natural and synthetic gums. These are used to increase the viscosity of the suspension. E.g. Methyl cellulose, sodium carboxymethyl cellulose, acacia, gelatin and tragacanth. These are non-toxic, pharmacologically inert, and compatible with a wide range of active and inactive ingredients. These structured vehicles entrapped the particle and reduces the sedimentation of particles. Note that too high viscosity isn’t desirable: a-it causes difficulty in pouring and administration. b-it may affect drug absorption since they adsorb on the surface of particle and suppress the dissolution rate. Step 4,5 Addition and dispersion of active ingredient in vehicle. Addition of remaining ingredients and final mixing 62 Sensitive ingredients such as flavours are added after the high energy stages. Water is added to bring the suspension to its target volume. Diffusible and indiffusible suspensions Diffusible suspensions These are suspensions containing light powders which are insoluble, or only very slightly soluble in the vehicle, but which on shaking disperse evenly throughout the vehicle for long enough to allow an accurate dose to be poured. Indiffusible suspensions These are suspensions containing heavy powders which are insoluble in the vehicle and which on shaking do not disperse evenly throughout the vehicle long enough to allow an accurate dose to be poured. In the preparation of indiffusible suspensions, the main difference when compared to diffusible suspensions is that the vehicle must be thickened to slow down the rate at which the powder settles. This is achieved by the addition of a suspending agent. Choice of suspending agent The amount of suspending agent used in any given formulation depends on the volume of vehicle being thickened. It does not vary with the amount of powder in the preparation. A suspending agent is intended to increase the viscosity of the vehicle and therefore slow down sedimentation rates. This outcome could also be achieved by decreasing the particle size of the powder in suspension. The most common suspending agents used in extemporaneous dispensing are Tragacanth BP (internal or external suspensions), Compound Tragacanth Powder BP (containing: 15% Tragacanth BP, 20% Acacia BP, 20% Starch BP and 45% Sucrose BP) (internal suspensions) and Bentonite BP (external suspensions). General method for the preparation of a suspension containing a diffusible solid 1. Check the solubility in the vehicle of all solids in the mixture. 2. Calculate the quantities of vehicle required to dissolve any soluble solids. 3. Prepare any Double Strength Chloroform Water BP required. 4. Weigh all solids on a Class II or electronic balance. 5. Dissolve all soluble solids in the vehicle in a small glass beaker. 6. Mix any insoluble diffusible powders in a porcelain mortar using the ‘doubling-up’ technique to ensure complete mixing. 7. Add a small quantity of the vehicle (which may or may not be a solution of the soluble ingredients) to the solids in the mortar and mix using a pestle to form a smooth paste. 8. Add further vehicle in small quantities, and continue mixing until the mixture in the mortar is of a pourable consistency. 9. Transfer the contents of the mortar to a conical measure of suitable size. 63 10. Rinse out the mortar with more vehicle and add any rinsings to the conical measure. 11. Add remaining liquid ingredients to the mixture in the conical measure. (These are added now, as some may be volatile and therefore exposure whilst mixing needs to be reduced to prevent loss of the ingredient by evaporation.) 12. Make up to final volume with vehicle. 13. Stir gently, transfer to a suitable container, ensuring that all the solid is transferred from the conical measure to the bottle, and label ready to be dispensed to the patient. The ‘doubling-up’ technique 1. Weigh the powder present in the smallest volume (powder A) and place in the mortar. 2. Weigh the powder present in the next largest volume (powder B) and place on labeled weighing paper. 3. Add approximately the same amount of powder B as powder A in the mortar. 4. Mix well with pestle. 5. Continue adding an amount of powder B that is approximately the same as that in the mortar and mix with the pestle, i.e. doubling the amount of powder in the mortar at each addition. 6. If further powders are to be added, add these in increasing order of volume as in parts 3, 4 and 5 above. General method for the preparation of a suspension containing an indiffusible solid Oral indiffusible suspensions are prepared using the same basic principles as for oral diffusible suspensions. The main difference is that the preparation will require the addition of a suspending agent. The suspending agent of choice will normally be combined with the indiffusible solid using the ‘doublingup’ technique before incorporation into the product. 1. Check the solubility in the vehicle of all solids in the mixture. 2. Calculate the quantities of vehicle required to dissolve any soluble solids. 3. Prepare any Double Strength Chloroform Water BP required. 4. Weigh all solids on a Class II or electronic balance. 5. Dissolve all soluble solids in the vehicle in a small glass beaker. 6. Mix any insoluble indiffusible powders and the suspending agent in a porcelain mortar using the ‘doubling-up’ technique to ensure complete mixing. 7. Add a small quantity of the vehicle (which may or may not be a solution of the soluble ingredients) to the solids in the mortar and mix using a pestle to form a smooth paste. 8. Add further vehicle in small quantities, and continue mixing until the mixture in the mortar is a pourable consistency. 9. Transfer the contents of the mortar to a conical measure of suitable size. 10. Rinse out the mortar with more vehicle and add any rinsings to the conical measure. 11. Add remaining liquid ingredients to the mixture in the conical measure. (These are added now, as some may be volatile and therefore exposure whilst mixing needs to be reduced to prevent loss of the ingredient by evaporation.) 12. Make up to fi nal volume with vehicle. 64 13. Stir gently, transfer to a suitable container, ensuring that all the solid is transferred from the conical measure to the bottle, and label ready to be dispensed to the patient. The preparation of Paediatric Chalk Mixture BP You receive a prescription in your pharmacy with the following details: Patient: Miss Jane Peacock, 12a The Ridings, Astonbury Age: 7 Prescription: Chalk Mixture Paed Directions: 10 ml qds Mitte: 100 ml 1. Use of the product Used to treat diarrhoea (Martindale 26th edn, p 131). 2. Is it safe and suitable for the intended purpose? This is an official preparation, therefore the formula is safe and suitable for purpose. The dose of 10 ml four times a day is consistent with the reco mmended dosage of 10 ml three to four times a day by convention. 3. Calculation of formula for preparation Prepare 100 ml of Paediatric Chalk Mixture BP. Product formula (from the British Pharmacopoeia 1988, p 724) Master 100 ml Chalk BP 20 g 2g Tragacanth BP 2g 200 mg Concentrated Cinnamon Water BP 4 ml 0.4 ml Syrup BP 100 ml 10 ml Double Strength Chloroform Water BP 500 ml 50 ml Potable water to 1000 ml to 100 ml Interim formula for Double Strength Chloroform Water Concentrated Chloroform Water BPC 1959 2.5 ml Potable water to 50 ml 4. Method of preparation a. Solubility where applicable Not applicable as there are no soluble solids in the preparation. b. Vehicle/diluent 65 Double Strength Chloroform Water BP and potable water would be used as the vehicle as per the product formula. c. Preservative Double Strength Chloroform Water BP is included in this product as the preservative as per the product formula. d. Flavouring when appropriate Concentrated Cinnamon Water BP is included in this product as the flavouring as per the product formula. The following method would be used to prepare 100 ml of Paediatric Chalk Mixture BP from the formula above: 1. Calculate the composition of a convenient quantity of Double Strength Chloroform Water BP, sufficient to satisfy the formula requirements but also enabling simple, accurate measurement of the concentrated component. Method of compounding for Double Strength Chloroform Water BP a. In this case, 50 ml of Double Strength Chloroform Water BP is required and so it would be sensible to prepare 50 ml. To prepare 50 ml Double Strength Chloroform Water BP, measure 2.5 ml of Concentrated Chloroform water BPC 1959 accurately using a 5 ml and a 1 ml syringe. b. Add approximately 45 ml of potable water to a 50 ml conical measure (i.e. suffi cient water to enable dissolution of the concentrated chloroform component without reaching the fi nal volume of the product). c. Add the measured Concentrated Chloroform Water BPC 1959 to the water in the conical measure. d. Stir gently and then accurately make up to volume with potable water. e. Visually check that no undissolved chloroform remains at the bottom of the measure. 2. Weigh 200 mg Tragacanth BP accurately on a Class II or electronic balance. 3. Weigh 2 g Chalk BP accurately on a Class II or electronic balance. 4. Measure 10 ml Syrup BP in a 10 ml conical measure. 5. Measure 0.4 ml Concentrated Cinnamon Water BP using a 1 ml syringe. 6. Measure 50 ml of Double Strength Chloroform Water BP in a 50 ml conical measure. 7. Transfer the Tragacanth BP to a porcelain mortar. 8. Add the Chalk BP to the mortar using the ‘doubling-up’ technique to mix the two powders. 9. Add the Syrup BP to the mortar and mix to form a smooth paste. 10. Add some of the Double Strength Chloroform Water BP to the paste and mix until pourable. 11. Transfer the contents to a 100 ml conical measure. 12. Rinse out the mortar with more Double Strength Chloroform Water BP or potable water and add the rinsings to the conical measure. 13. Add the Concentrated Cinnamon Water BP to the mixture in the conical measure. 66 14. Make up to volume with any remaining Double Strength Chloroform Water BP and potable water. 15. Transfer to an amber flat medical bottle label and dispense. 5. Choice of container A plain amber bottle with a childresistant closure would be most suitable as the preparation is a suspension for internal use. 6. Labelling considerations a. Title The product is official, therefore the following title would be suitable: ‘Paediatric Chalk Mixture BP’ b. Quantitative particulars Quantitative particulars are not required as the product is official. c. Product-specifi c cautions (or additional labelling requirements) ‘Shake the bottle’ will need to be added to the label as the product is a suspension and will need shaking before use to ensure an accurate dose is measured. d. Directions to patient – interpretation of Latin abbreviations where necessary ‘Give TWO 5ml spoonfuls FOUR times a day’. The word ‘give’ is used here as the preparation is for a child and so will be administered by a parent or guardian. e. Recommended British National Formulary cautions when suitable f. Discard date The British Pharmacopoeia states that this product should be recently prepared, therefore it will attract a 4-week discard date (British Pharmacopoeia 1988, p 724). g. Sample label (you can assume that the name and address of the pharmacy and the words ‘Keep out of the reach of children’ are pre-printed on the label): Paediatric Chalk Mixture BP 100 ml Give TWO 5 ml spoonfuls FOUR times a day. Shake the bottle Do not use after (4 weeks) Miss Jane Peacock Date of dispensing 7. Advice to patient The parent or guardian would be advised to give two 5 ml spoonfuls four times a day. In addition, the discard date and the need to shake the bottle before a dose is measured would be highlighted. Emulsions Definitions Emulsions: Emulsions are two-phase systems in which one liquid is dispersed throughout another liquid in the form of small droplets. 67 Emulsification: Emulsification of two immiscible phases can be accomplished when energy is applied to the system (e.g., trituration or homogenization) to create small droplets and cause a physical and/or electrostatic barrier to form around the droplets to prevent them from coalescing. This is accomplished by the use of emulsifying agents. Emulsifying Agents: These are surfactants which concentrate at the interface of the two immiscible phases, reduce the interfacial tension between the immiscible phases, provide a barrier around the droplets and prevent coalescence of the droplets. Some emulsifying agents also increase the viscosity of the system, slowing aggregation of the droplets and decreasing the rate of creaming. So, an emulsion is a thermodynamically unstable two-phase system consisting of at least two immiscible liquids, one of which is dispersed in the form of small droplets throughout the other, and an emulsifying agent. The dispersed liquid is known as the internal or discontinuous phase, whereas the dispersion medium is known as the external or continuous phase. Creaming: This is the migration of the droplets of the internal phase to the top or bottom of the emulsion. The migration is caused by the difference in density between the two phases, and the direction of the movement depends on whether the internal phase is more or less dense than the external phase. In this case, the emulsion can be easily redispersed by shaking. Coalescence: This is the merging of small droplets into larger droplets with eventual complete separation of phases so that the droplets cannot be re-emulsified by simple shaking of the product. With coalescence, the barrier formed by the emulsifying agent(s) is broken or destroyed. This irreversible coalescence of the droplets is also called “cracking”. Uses of emulsions a. Increased drug solubility. Many drugs have limited aqueous solubility but have maximum solubility in the oil phase of an emulsion. b. Increased drug stability. Many drugs are more stable when incorporated into an emulsion rather than an aqueous solution. c. Prolonged drug action. Incorporation of a drug into an emulsion can prolong bioavailability, as with certain intramuscular injection preparations. d. Improved taste. Drugs with an unpleasant taste are more palatable and thus more conveniently administered in emulsion form. e. Improved appearance. Oily materials intended for topical application are more appealing in an emulsified form. Oral Products: Oral liquid emulsions are less acceptable to patients than solutions or suspensions because of the objectional oily feel of emulsions in the mouth. Therefore, an oral emulsion is formulated only when it is necessary to make a liquid product of an oil or when the solubility or 68 bioavailability characteristics of a drug make this drug dosage form clearly superior. For example, emulsions are the formulation of choice to mask the taste of a very bitter drug. Topical Products: Topical emulsions are more common. Topical emulsions are creams which have emollient properties. They can be either o/w or w/o and are generally opaque, thick liquids or soft solids. When the oils are emulsified, they feel less greasy and are more aesthetically appealing to patients. Emulsion type Oil-in-Water (o/w): In this type, the oil is dispersed as droplets in an aqueous solution. This is the most common emulsion type. It is always preferred for oral products where an oily feel in the mouth is objectional. It is also used for external products when ease of removal and/or a non-greasy feeling preparation is desired. An o/w emulsion is generally formed if the aqueous phase constitutes > 45% of the total weight, and a hydrophilic emulsifier is used. Water-in-Oil (w/o): In this type, the water is dispersed as droplets in an oil or oleaginous material. This type is used for external products when emollient, lubricating, or protective properties are desired. Many ointments which are emulsion systems are w/o emulsions. W/O emulsions are generally formed if the aqueous phase constitutes < 45% of the total weight and a lipophilic emulsifier is used. W/O emulsions tend to be immiscible in water, not water washable, will not absorb water and may be greasy. This is primarily because oil is the external phase, and oil will repel any of the actions of water. The occlusiveness is because the oil will not allow water to evaporate from the surface of the skin. Conversely, o/w emulsions are miscible with water, are water washable, will absorb water, are nonocclusive, and are nongreasy. Here water is the external phase and will readily associate with any of the actions of water. Factors That Determine Emulsion Type 1. Dilution test: based on the solubility of external phase of emulsion. O/w emulsions may be diluted with water (as this is the composition of the external phase) whereas w/o emulsions cannot be diluted with water. 2. Conductivity Test: Water is good conductor of electricity whereas oil is non-conductor. Therefore, continuous phase of water runs electricity more than continuous phase of oil. 3. Dye-Solubility Test. When an emulsion is mixed with a water soluble dye such as amaranth and observed under the microscope. If the continuous phase appears red, then it means that the emulsion is o/w type as water is the external phase if the scattered globules appear red and continuous phase colorless, then it is w/o type. Desired properties of emulsions A. Fine Droplets Emulsions with fine droplet size are desired. Many factors can contribute to small droplets. One factor is the mechanical method used for mixing and shearing the two immiscible liquids. The pharmaceutical industry has specialized equipment for this task. For extemporaneous 69 compounding, a rough-sided Wedgewood mortar is usually used for the emulsification process. Simple, relatively inexpensive hand-homogenizers and high-speed blenders are available, which may give finer, and more uniform, droplets. Besides, some emulsifying agents give finer emulsions. For example, amino-soaps are better balanced emulsifiers than are the alkali soaps and give more stable emulsions of finer droplet size. B. Slow Aggregation of the Droplets and Creaming of the Product Although almost all emulsions eventually cream, the rate of creaming should be slow enough to insure accurate measurement of a dose or application of a uniform product. Aggregation and creaming can be slowed through proper emulsification and through the use of various additives, such as viscosity-inducing agents. To control the rate of creaming, you can adjust some of the parameters found in Stake's Law. Although this equation was developed for particles settling in a suspension, many of the same factors affect the rate of creaming for droplets in an emulsion. These include droplet size, viscosity of the continuous phase, and relative density difference of the droplets and the continuous phase. C. Ease of Redispersion When Shaken Although aggregation and creaming are usually unavoidable, the product should be formulated so that the internal phase readily redisperses to give a uniform emulsion when the product is shaken. Furthermore, coalescence should not occur. Emulsifying agents Emulsions are stabilized by adding an emulsifier or emulsifying agents. These agents have both a hydrophilic and a lipophilic part in their chemical structure. All emulsifying agents concentrate at and are adsorbed onto the oil/water interface to provide a protective barrier around the dispersed droplets. In addition to this protective barrier, emulsifiers stabilize the emulsion by reducing the interfacial tension of the system. Some agents enhance stability by imparting a charge on the droplet surface thus reducing the physical contact between the droplets and decreasing the potential for coalescence. Some commonly used emulsifying agents include tragacanth, sodium lauryl sulfate, sodium dioctyl sulfosuccinate, and polymers known as the Spans and Tweens. Emulsifying agents can be classified according to: 1) chemical structure; or 2) mechanism of action. Classes according to chemical structure are synthetic, natural, finely dispersed solids, and auxiliary agents. Classes according to mechanism of action are monomolecular, multimolecular, and solid particle films. Regardless of their classification, all emulsifying agents must be chemically stable in the system, inert and chemically non-reactive with other emulsion components, and nontoxic and nonirritant. They should also be reasonably odorless and not cost prohibitive. Synthetic Emulsifying Agents Cationic, e.g., benzalkonium chloride 70 Anionic, e.g., alkali soaps (sodium or potassium oleate); amine soaps (triethanolamine stearate); detergents (sodium lauryl sulfate, sodium dioctyl sulfosuccinate, sodium docusate). Nonionic, e.g., sorbitan esters (Spans), polyoxyethylene derivatives of sorbitan esters (Tweens). Cationic and anionic surfactants are generally limited to use in topical, o/w emulsions. Cationic agents (quarternary ammonium salts) are incompatible with organic anions and are infrequently used as emulsifiers. Soaps are subject to hydrolysis and may be less desirable than the more stable detergents. Natural Emulsifying Agents A variety of emulsifiers are natural products derived from plant or animal tissue. Most of the emulsifiers form hydrated lyophilic colloids (called hydrocolloids) that form multimolecular layers around emulsion droplets. Hydrocolloid type emulsifiers have little or no effect on interfacial tension, but exert a protective colloid effect, reducing the potential for coalescence, by: providing a protective sheath around the droplets imparting a charge to the dispersed droplets (so that they repel each other) swelling to increase the viscosity of the system (so that droplets are less likely to merge) Hydrocolloid emulsifiers may be classified as: vegetable derivatives, e.g., acacia, tragacanth, agar, pectin animal derivatives, e.g., gelatin, lanolin, cholesterol, lecithin semi-synthetic agents, e.g., methylcellulose, carboxymethylcellulose synthetic agents, e.g., carbomers (PEG and acrylic acid) Naturally occurring plant hydrocolloids have the advantages of being inexpensive, easy to handle, and nontoxic. Their disadvantages are that they require relatively large quantities to be effective as emulsifiers, and they are subject to microbial growth and thus their formulations require a preservative. Vegetable derivatives are generally limited to use as o/w emulsifiers. The animal derivatives general form w/o emulsions. Lecithin and cholesterol form a monomolecular layer around the emulsion droplet instead of the typically multimolecular layers. Cholesterol is a major constituent of wool alcohols and it gives lanolin the capacity to absorb water and form a w/o emulsion. Lecithin (a phospholipid derived from egg yolk) produces o/w emulsions because of its strong hydrophilic character. Animal derivatives are more likely to cause allergic reactions and are subject to microbial growth and rancidity. Finely Divided or Finely Dispersed Solid Particle Emulsifiers These agents form a particulate layer around dispersed particles. Most will swell in the dispersion medium to increase viscosity and reduce the interaction between dispersed droplets. Most commonly they support the formation of o/w emulsions, but some may support w/o emulsions. These agents include bentonite, magnesium hydroxide, aluminum hydroxide and magnesium trisilicate. Auxiliary Emulsifying Agents A variety of fatty acids (e.g., stearic acid), fatty alcohols (e.g., stearyl or cetyl alcohol), and fatty esters (e.g., glyceryl monostearate) serve to stabilize emulsions through their ability to thicken 71 the emulsion. Because these agents have only weak emulsifying properties, they are always use in combination with other emulsifiers. HLB System A system was developed by Griffin to assist in making systemic decisions about the amounts and types of surfactants needed in stable products. The system is called the HLB (hydrophilelipophile balance) system and has an arbitrary scale of 1 – 18 (tab. 1) HLB numbers are experimentally determined for the different emulsifiers. If an emulsifier has a low HLB number, there is a low number of hydrophilic groups on the molecule and it will have more of a lipophilic character. For example, the Spans generally have low HLB numbers and they are also oil soluble. Because of their oil soluble character, Spans will cause the oil phase to predominate and form an w/o emulsion. The higher HLB number would indicate that the emulsifier has a large number of hydrophilic groups on the molecule and therefore should be more hydrophilic in character. The Tweens have higher HLB numbers and they are also water soluble. Because of their water soluble character, Tweens will cause the water phase to predominate and form an o/w emulsion. Table 1. Commonly Used Emulsifiers And Their HLB Values Commercial Name Chemical Name HLB Value Glyceryl monostearate Glyceryl monostearate 3.8 PEG 400 Monoleate Polyoxyethylene monooleate 11.4 PEG 400 Monostearate Polyoxyethylene monostearate 11.6 PEG 400 Monolaurate Polyoxyethylene monolaurate 13.1 Potassium oleate Potassium oleate 20.0 Sodium lauryl sulfate Sodium lauryl sulfate 40 Sodium oleate Sodium oleate 18 Span® 20 Sorbitan monolaurate 8.6 Span® 40 Sorbitan monopalmitate 6.7 Span® 60 Sorbitan monostearate 4.7 Span® 65 Sorbitan tristearate 2.1 Span® 80 Sorbitan monooleate 4.3 Span® 85 Sorbitan trioleate 13.2 Triethanolamine oleate Triethanolamine oleate 12 Tween® 20 Polyoxyethylene sorbitan monolaurate 16.7 Tween® 21 Polyoxyethylene sorbitan monolaurate 13.3 Tween® 40 Polyoxyethylene sorbitan monopalmitate 15.6 Tween® 60 Polyoxyethylene sorbitan monostearate 14.9 Tween® 61 Polyoxyethylene sorbitan monostearate 9.6 Tween® 65 Polyoxyethylene sorbitan tristearate 10.5 Tween® 80 Polyoxyethylene sorbitan monooleate 15.0 72 Tween® 81 Polyoxyethylene sorbitan monooleate 10.0 Tween® 85 Polyoxyethylene sorbitan trioleate 11.0 Combinations of emulsifiers can produce more stable emulsions than using a single emulsifier with the same HLB number. The HLB value of a combination of emulsifiers can be calculated as follows: e.g. What is the HLB value of a surfactant system composed of 20 g Span 20 (HLB = 8.6) and 5 g Tween 21 (HLB = 13.3)? Compounding basic emulsion types Commercially, emulsions are prepared in large volume mixing tanks and refined and stabilized by passage through a colloid mill or homogenizer. Extemporaneous production is more concerned with small scale methods. Several methods are generally available to the pharmacist. Each method requires that energy be put into the system in some form. The energy is supplied in a variety of ways: trituration, homogenization, agitation, and heat. Acacia emulsions: Acacia is unique among the polymer emulsifiers in its ability to form emulsions using only a Wedgewood mortar and pestle. It is therefore a useful ingredient for extemporaneous compounding of emulsions. The term “primary emulsion” is used to describe the initial emulsion formed with a prescribed ratio of ingredients. This prescribed set of ingredients gives a system of optimal viscosity and consistency so that the shearing force exerted in the mortar is maximized to allow the formation of an emulsion. 1. Ingredient ratio for primary acacia emulsions a. For fixed oils, such as vegetable oils, and mineral oil, the oil to water to acacia ratio (o : w : a) is 4 : 2 : 1. b. The ratio for volatile and essential oils is 3 : 2 : 1 or 2 : 2 : 1. Because Acacia forms oil-in-water emulsions, the oil is the internal phase. Therefore, all of the oil must be emulsified when making the primary emulsion. After the primary emulsion is formed, the emulsion may be diluted with any extra water or water-miscible phase, as required. 2. Methods of forming the primary emulsion a. Dry gum method (or Continental Method). This usually is the preferred method. Its steps are as follows: 73 The calculated amount of acacia and all the oil contained in the formulation are put in a Wedgewood mortar and triturated until a smooth slurry results and all the acacia is properly "wet" by the oil. The amount of the aqueous phase, which is calculated from the ratio given above, is measured in a clean, dry graduated cylinder and is added, all at once, with hard and fast trituration. Trituration is continued until the primary emulsion is formed (usually 3-4 minutes) You know this has occurred when the system changes from a translucent, oilyappearing liquid into a thick, white liquid. The sound of trituration also changes to give a "crackling" sound. b. Wet gum method (or English Method). With this method, the order of mixing is as follows: The appropriate amount of acacia is put in a Wedgewood mortar, and a small amount of water-miscible wetting agent, such as glycerin, is added to "wet" the acacia. This is necessary because powdered acacia gets "lumpy" when water is added directly to it. The calculated amount of water is then gradually added in portions with trituration. The oil is then gradually added with trituration until all the oil has been added and the primary emulsion is formed. As with the dry gum method, once the primary emulsion is formed, water or other ingredients may be added. Generally speaking, the English method is more difficult to perform successfully, especially with more viscous oils, but may result in a more stable emulsion. 3. Order of mixing for acacia emulsions 1. Make the primary emulsion first using all the oil(s), the acacia, and Purified Water, in the appropriate ratio. 2. Additional water, water-miscible liquids, including flavored syrups, and watersoluble drugs or chemicals may then be added directly to the primary emulsion. Soluble ingredients that are in solid form may be dissolved first in water or another appropriate solvent before being added to the emulsion. 3. Insoluble ingredients, such as zinc oxide and calamine, should be put in a separate mortar, and the primary emulsion should be added to the powders in portions with trituration. This is done to "wet" the powders and reduce their particle size so that a smooth preparation results. 4. In some cases, oil-soluble ingredients may be dissolved in the oil phase before the formation of the primary emulsion Any substance which might reduce the physical stability of the emulsion, such as alcohol (which may precipitate the gum) should be added as near to the end of the process as possible to avoid breaking the emulsion. When all agents have been incorporated, the emulsion should be transferred to a calibrated vessel, brought to final volume with water, then homogenized or blended to ensure uniform distribution of ingredients. 4. Preservation: Preservatives are required for acacia emulsions because of their susceptibility to microbial growth. Unless the formulation contains an additive that would 74 alter the pH, acacia emulsions have a pH in the range of 4.5-5.0. Therefore, preservatives that require a slightly acid pH, such as benzoic acid or sorbic acid, are effective preservatives for acacia emulsions. An official acacia emulsion, Mineral Oil Emulsion USP recommends the use of either benzoic acid 0.2% or Alcohol 4-6%. The benzoic acid can be added as its sodium salt. The quaternary ammonium preservatives, such as benzalkonium chloride and benzethonium chloride may not be used because they are inactivated through binding with acacia. 5. Storage: Internal preparations should be stored in a refrigerator, but external preparations should be stored at room temperature. The preparation beyond-use date depends on the stability of the ingredients. If all ingredients are chemically stable, a 14-day dating is acceptable for internal use preparations. The usual maximum dating for chemically stable external preparations is 1 month. This, of course, assumes that an appropriate preservative has been added. When ingredients of unknown stability are present, more conservative datings should be used. Nascent Soap Emulsions The term "nascent" means beginning to exist or to develop. As the name implies, the emulsifier is formed as these emulsions are made. These emulsifiers are the hard and soft soaps. We’ll concentrate on a specific emulsion type, so-called Lime Water emulsions, in which the emulsifier, calcium oleate, is formed when Calcium Hydroxide Topical Solution (Lime Water) is added to a vegetable oil. Oil: Olive oil was the original oil used in these emulsions because, of the vegetable oils, it has the largest amount of free fatty acid necessary for forming the soap emulsifying agent. Olive oil may be replaced by other vegetable oils; however, extra free fatty acid in the form of oleic acid must be added. Depending on its source, olive oil may also need fortification with extra oleic acid. It may be advisable to add 3-5 drops of oleic acid/30 mL of olive oil and 1-1.5 mL oleic acid/30 mLof any other vegetable oil before the emulsification process is begun. Extra oleic acid can be added dropwise during emulsification if necessary. Lime Water should be freshly prepared. The formula can be found in the USP 23 under Calcium Hydroxide Topical Solution. It is reproduced below: Calcium Hydroxide 3 g Purified Water 1000 mL Add the Calcium Hydroxide to 1000 mL of cool Purified Water, and agitate the mixture vigorously and repeatedly during 1 hour. Allow the excess calcium hydroxide to settle. Dispense only the clear, supernatant liquid. 1. Methods of preparation a. Bottle (Forbes) method: With this method, equal amounts of oil (containing adequate oleic acid) and Lime Water are placed in a bottle. The bottle is shaken vigorously to form the emulsion. The emulsion can then be used as a wetting agent for any solid insoluble ingredients. b. Mortar method: This method is often preferred when the formulation contains solid insoluble ingredients, such as zinc oxide or calamine. The solids are placed in a mortar. The oil (containing oleic acid) is added in portions with trituration until all the oil has been added and a 75 smooth slurry of oil-powders is obtained. The Lime Water is then added in portions with trituration to form the emulsion. 2. Order of mixing: This depends somewhat on the method of emulsification as previously described. a. With either method, water-miscible liquids and water-soluble drugs or chemicals should be added to the Lime Water before it is added to the bottle or mortar for emulsification. This is because water is the internal phase. b. Because oil is the external phase, oil-soluble and oil-miscible ingredients can be added to the oil before emulsification or to the emulsion after the water phase is emulsified. c. Any insoluble ingredients should be placed in a mortar. If the bottle method is used, the formed emulsion can serve as a wetting agent in triturating and incorporating these solids. Insoluble solids should never be merely added to the bottle with shaking. As described previously, when the mortar method is used, insoluble ingredients may be placed in the mortar at the beginning of the compounding process. In all cases, the wetting liquid should be added in portions with trituration to ensure the formation of a smooth preparation. 3. Preservation: Preservatives are not usually required for these emulsions. The Lime Water has a high pH, which is not favorable toward microbial or mold growth. Furthermore, these are external use emulsions that often contain antiseptic ingredients. If a preservative is necessary, alcohol is suitable. Benzoic acid/sodium benzoate is not effective because of the alkaline pH of these emulsions. 4. Storage: Store at room temperature. The preparation beyond-use date depends on the stability of the ingredients. If all ingredients are chemically stable, a 1-month dating is acceptable for these external use preparations. When ingredients of unknown stability are present, more conservative datings should be used. All emulsions are disperse systems and need a SHAKE WELL auxiliary label. 76 1. Medication orders differ from prescriptions in which of the following ways? They a) are intended for ambulatory use b) contain only generic name of the medication c) are intended for institutional use d) contain the quantity of medication to be dispensed 2) If a therapeutic intervention is necessary, all of the following information should be communicated to the prescriber except a) a declaration that “a mistake was made” b) a brief description of the problem c) a reference source that documents the problem d) an alternative or suggestion to resolve the problem 3) The following information should be recorded on a prescription except the a) prescription number b) date of filling c) expiration date d) product and quantity dispensed 4) Auxiliary and cautionary labels should be utilized for all of the following purposes except to a) substitute for verbal consultation b) ensure proper usage c) inform of storage requirments d) comply with regulatory requirements 5) Which of the following DEA registration numbers is a valid one, taking into account that registrant’s last name is Ashman and he is a physician assistant? 1. MA1286549 2. MA1390981 3. MA4545325 4. AM4545325 a) 3,4 b) 2,3 c) 3,4 d) 1,2 6) What are the causes of increasing interest to compounding 1. need for individualized drug therapy 2. pharmaceutical care movement 3. some medications are not commercially available 4. some medications are not stable enough to be manufactured a) 1,2 b) 1,2,3,4 c) 3,4 d) 1,2,3 7) A patient reports that she has a temperature of 39C on her home thermometer. What is her temperature in degrees Fahrenheit? a. 100 b. 101.6 77 c. 102.2 d. 98.6 8) What is the HLB value of a surfactant system composed of 20 g Span 20 (HLB = 8.6) and 5 g Tween 21 (HLB = 13.3)? a. 51.6 b. 30.0 c. 9.54 d. 8.66 9) Advantages of suspensions over solutions include a. chemical stability of drugs b. physical stability of drugs c. higher bioavailability d. all above mentioned 10) Calcium Hydroxide Solution (Lime Water) and olive oil are used because an emulsifying agent is formed when these two solutions are agitated together. What is the emulsifying agent that is formed? a. calcium succinate b. calcium oleate c. succinic hydroxide d. palmitic hydroxide 11) Which is the most frequently used PEG ? a. 200 b. 800 c. 400 d. 600 12) Which equation corresponds to Stokes-Einstein equation a. D = k T ηπr b. K=D/hV c. dC = k S ( CS – C) dt d. D = k T 6ηπr 13) Types of water include all of the following except a. water for injection b. sterile water for irrigation c. sterile water for nasal solutions d. bacteriostatic water for injection 14) How much Alcohol USP (95% v/v) is needed to prepare 50 mL of 60% ethanol? a. 79.2 78 b. 31.6 c. 12.0 d. 24.8 15) How can we achieve the finest state of subdivision of drug in suspensions? a. by using the drug form that has the finest particle size b. by choosing proper equipment c. by using good compounding technique d. all above-mentioned is correct 16) Which agent forms a flocculated system a. methylcellulose b. bentonite c. glycerin d. docusate sodium 17) Which preservative do we use when compounding Nascent soap emulsion? a. benzalkonium chloride b. alcohol c. benzoic acid d. no preservative 18) The usual maximum dating for chemically stable emulsion for external use is a. 14 days b. 1 month c. 6 months d. 20 days 19) Which statement about surfactants is false? a. they help in displacing the air phase at the surface of the solid by liquid phase b. their molecules contain a hydrophilic and hydrophobic portion c. they are absorbed at interfaces d. they cause an increase of interfacial free energy 20) Which statement about synthetic emulsifyers is false? a. they are the strongest emulsifiers b. they do not support microbial growth c. are generally limited to use as o/w emulsifiers d. are generally limited to use as w/o emulsifiers 79