e-HIRARC User Manual: Occupational Safety Risk Assessment

advertisement

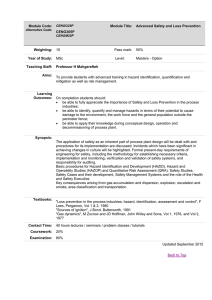

E-HIRARC Useful Information and User Manual A step-by-step guideline to operate an assessment of occupational safety risk at workplace via user-friendly of e-HIRARC format. CONTENT Chapter Page 1.0 Introduction 1 2.0 What is HIRARC 2 3.0 Workplace Assessment through HAZID Table 3 4.0 Custom-made of e-HIRARC 5 5.0 How to run e-HIRARC 5 6.0 Completing the e-HIRARC output 9 6.1 Additional information in e-HIRARC format 9 6.2 Prioritization based from risk rating 9 7.0 Saving / Printing 13 8.0 Correction 13 9.0 Benefits and advantages of using e-HIRARC 13 10.0 User-friendliness of the e-HIRARC 13 11.0 Frequent Answer - Question (FAQ) 14 Summary 16 1.0 Introduction HIRARC or Hazard Identification, Risk Assessment and Risk Control are the fundamental concept that person shall be mastered if they interest to learn on risk management in OSH. This method has been recognized internationally as one of the tool widely used by industries in identifying the hazard and how to manage it effectively. Therefore, the intent of this eBook being created is to cater the needs of safety practitioner in meeting their daily working task. But, important to be informed, the content of this eBook does not explaining the reader on basic measurement in risk assessment (e.g. how to identify risk, the step taken for risk evaluation etc.), but it will focus for guiding the user (and potential user) on step-by-step process to assess the risk at workplace by using a tool that we called e-HIRARC. The features of e-HIRARC can be explained in section 4.0 Custommade of e-HIRARC. E-HIRARC provides template in Microsoft Excel format. There is also FREE version may available and it can be downloaded from this link (click button OK to open the file). The format has been fully equipped with the features for user to generate HIRARC format more easier, faster and efficient in time (displayed in section 10.0 User-friendliness of the eHIRARC) Then, it will tell the user on how to operate e-HIRARC as specified in chapter 5.0 How to run e-HIRARC. The comprehensiveness of e-HIRARC can be demonstrated by section 6.0 Completing the e-HIRARC output. Up to this level, every single activity has been jotted down the risk result. Prioritization of significant risk should be systematically defined * Only applicable for complete version 1|Page by thoroughly assessment but with simple step. At this point, we hope that user will realized on efficiency of time management compared with common methodology applied. Most important aspects, that format and criteria of e-HIRARC has been adopted from guideline of HIRARC 2008 by DOSH Malaysia as a reference. It is nothing to worry on compliance with standard practice demanded by authority. 2.0 What is HIRARC HIRARC is an integration tool to identify, assess/measure and to control hazard and risk of any workplace and its activities. By strictly implementing it, it will eliminate, reduce/control the possibility for any accidents to occur. The acronym of HIRARC uses the Hazard Identification, Risk Assessment and Risk Control. A universal method widely used by Occupational Health and safety practitioner in any field of industries. According clause 4.3.1 of OHSAS 18001:2007, an establishment of procedure is a MUST to ensure the identification of risk, risk assessment, and its determination can be implemented and maintained. The aspects of hazard should take into account for; 1. routine and non-routine activities 2. activities of all persons having access to the workplace (including contractors and visitors); 3. human behaviour, capabilities and other human factors 4. identified hazards originating outside the workplace capable of adversely affecting the health and safety of persons under the control of the organization within the workplace 5. hazards created in the vicinity of the workplace by work-related activities under the control of the organization 6. infrastructure, equipment and materials at the workplace, whether provided by the organization or others 7. changes or proposed changes in the organization, its activities, or materials 8. modifications to the OH&S management system, including temporary changes, and their impacts on operations, processes, and activities 9. any applicable legal obligations relating to risk assessment and implementation of necessary controls 10. the design of work areas, processes, installations, machinery/equipment, operating procedures and work organization, including their adaptation to human capabilities Significantly, e-HIRARC process has determined to include ALL of the following elements; - Identification/classification of all health hazards (e.g. acceptable – significant or insignificant, uncertain health hazards Quantitative assessment of risk for all uncertain hazards Control of unacceptable health risks via appropriate counter measures (e.g. personal protective equipment, engineering controls, product, substitution etc.) Annual reviews of effectiveness of the process * Only applicable for complete version 2|Page 3.0 Workplace Assessment through HAZID Table* HAZID Table is only provided to compliment with the package offered for full version of eHIRARC. It is a practical approach for assessor to examine the hazard that may available at workplace. The HAZID table has elaborated the extent information on main hazard. It will help the assessor to conform to the suitable hazard factor without thinking further on what subject that supposed to feed in the e-HIRARC later. It would be more reliable for assessor to perform on-site verification through HAZID Table to observe the actual situation before document it in e-HIRARC. Once completed, assessor can start to perform assessment as determined in chapter 5.0 How to run e-HIRARC Hazard identification stage through the use of HAZID table is the most important part whether all aspect of activities or processes are covered or not. Consideration shall be made by assessor on what type of activity regardless the frequency of job to be done is extremely low or high which definitely shall be spotted as main task. There is common mistake done by assessor during identification of hazard at workplace. 1. Ignore the task relatively to be observed as low risk (e.g. office work, tea/coffee making, toilet cleaning, general waste disposal etc.) 2. Lack of consideration for non-customary event within the organization. (e.g. annual housekeeping day, activity runs at neighbour-factory, plant tour by visitor, factory inspection by authority officer etc.) 3. Not anticipating the major activity such as construction work, re-wiring, facility inspection (LEV, chimney, dust collector etc.) etc. 4. Less concern on geographical or workplace location. 5. Skip the common flow process sequence or activity performed by worker. 6. Executing the assessment through work instruction document without observing the actual situation done by process owner Following page is a sample of HAZID Table for reference * Only applicable for complete version 3|Page HAZARD IDENTIFICATION TABLE Department: Process Name: HAZARD IDENTIFICATION NAME OF ACTIVITY IN SEQUENCE: Activity Hazard No Sub-hazard No Consequence 1). 2). 3). 4). 5). 1 W ork Envi r o nment 2 3 4 Ener g y M echani cal M achi ner y 5 Po w er ed Hand t o o l a. Elect ricusion a. Inadequat e access a. Elect rical a. Vehicle a. Backhoe b. Air-condit ioning b. Gravit y b. Excavat or c. Conf ined space c. Kinet ic (mot ion) b. M obile and f ixed equipment c. M oving part s b. eject ions c. drawning in d. Ergonomics e. Temperat ure ext remes d. Thermal (f rom heat or cold) c. Powered t ools (rot at ion, pulleys, belt s et c. ) d. Rot at ion part s e. Piling d. ent anglement e. cut t ing f . Grinding g. Elect ricit y f . shearing g. f lying object f . Heat (inc. f ire, f lames) e. Pneumat ic and Hydraulic g. Cold g. Flammable d. Non-powered t ools (hammer, knives, pliers et c.) h. Light ing h. M agnet ic f ields e. Compressed air i. M ent al st ress i. Dehydrat ion f . Welding equipment g. Lif t ing equipment j. j. h. Ot hers l. k. Falls, t rips, slips et c. f . Chemical / gases Ot hers h. Ot hers h. st ubbing and punction uring and i. Frict abrasion impact k. noise f alling object 6 Er g o no mi c i n manual hand l i ng 7 8 C hemi cal B i o l o g i cal 9 Envi r o nment al / N at ur al event / 10 11 12 13 Pr o p er t y R ad i at i o n M aj o r event A ni mal / i nsect s a. Part of body bend a. Direct cont act a. Inf ect ion a. Flood a. Fire b. Part of body t wist b. Ent ry int o human body b. Weat her b. Eart hquake b. Explosion c. Facilit y design c. Landslides c. Falling c. Inhalat ion d. Individual healt h d. Weat her d. skin absorpt ion e. Social e d. Building collapse e Leaking e f . Food c. St ret ch / f orcing part of t he body d. Over-reach e. work or reach above shoulder height f . Awkward posit ion g. Long t ime period of t ask h. Handle heavy object s i. Repet it ion / Rapid t ask Ingest ion f . f lammable g. Parasit e(s) g. vapour h. Ot hers h. Virus(es) i. Fungi j. Bact eria k. insect s l. blood-borne pat hogens Table 1: HAZID Table Ot hers f Ot hers 14 Psycho so ci al / Psycho l o g i cal a. Direct ionizing bet a a. Bomb t hreat a. Inf ect ion f rom animal a. St ress b. Terrorist b. Indirect ionizing gamma c. Criminal b. diseases of pest s c. Discriminat ion d. Riot d. Harassment c. Indirect ionizing Charged nuclei e c. Animals and allergies d. Bit e, at t acked or ot her injuries f rom animals f . overwork/ burnout d. Indirect ionizing Neut rons e. Ot her ionizing radiat ion hazard f . Ot her t ype of radiat ion Ot hers e. Ot hers b. Violence e Bully g. Undet ermined f act or 4.0 Custom-made of e-HIRARC This e-HIRARC format has been designed to cater the needs of Occupational Health & Safety Practitioner in meeting their task for risk management. The tool has been incorporated with OHSAS 18001 standard compliance by readily built-in the risk factor and extinguishment of hazard-risk aspects. The hazard has been break through from the numbers of source, namely as; - Work environment Energy Mechanical Machinery Powered hand tool Ergonomic in manual handling Chemical Biological Environment / Natural event Property Radiation Animal / insects Major disaster, and Psychosocial / Psychological There is also assistance for users to get them comfortable to choose the risk control at their workplace through drop-down button needs to be selected via E-S-I-E-A-P. The E-S-I-E-A-P approach carried the means of prioritization of action sequence by Elimination (E), Substitution (S), Isolation (I), Engineering control (E), Administration (A) and P for PPE. It was however, Elimination control measure does not apply in the format at the moment. 5.0 How to run e-HIRARC 1. A simple step for user to operate this e-HIRARC template 2. Once received a valid file of e-HIRARC, save it into your PC. FREE sample is available by browsing to this link. 3. Name of company is protected and same as the time it was registered. 4. Go to worksheet 'JOBLIST' and start to insert the data of department and person-incharge. 5. Use the input identified in HAZID table which has been described in chapter 3.0 Workplace Assessment through HAZID Table, raw data can be transferred to Joblist in e-HIRARC template format. 6. HAZID Table will later can be retained as safety record or disposed depending on company’s OSH management system procedure. 7. To log the activity and its sub-process. It is important for user to define ALL activity including non-routine process and emergency event. It may possible for the assessment will incomplete if the user did not addressed the process comprehensively. 8. Choose the process that going to be assessed in Task Name select button. 9. Including of it nature of task routine, non-routine or emergency event. 10. Identify the hazard that may possible to be available. User can specify into detail description in the column (if any). 11. Determine the potential risk that would be occurred as a result the existence of hazard. 12. Analyse the risk based from existing control implemented in workplace 13. Specify the control where it was needed 14. Take into consideration on applicable legal * Only applicable for complete version 6|Page 15. Assess the risk through combination of Probability vs Severity. Worksheet 'matrix' has addressed the assessment scale (min: 1 & max: 5) for likelihood and severity and result of risk evaluation as well. Risk evaluation can refer to Table 2 below for details Table 2: Risk Matrix Evaluation 16. Once completed, press button 'update e-HIRARC' and see the output is automatically generated. Complete HIRARC document will displayed similarly as Table 3: HIRARC Format Overall interfaces of HIRARC Joblist can be displayed as follows; * Only applicable for complete version 7|Page Diagram 1: Joblist * Only applicable for complete version 8|Page Diagram 2: Hazard Identification & Risk Analysis 17. User may create another file for assessing the risk of other process. Where necessary, additional file can be created if a lot of process sequence being observed. Currently, e-HIRARC provides total of 10 process sequences and 18 space of work ready for assessment. 6.0 Completing the e-HIRARC output E-HIRARC, at current stage was defined the hazard identification and risk analysis. Next step for user to update the necessary risk control to be recommended for minimizing the risk 6.1 Additional information in e-HIRARC format E-HIRARC format is a protected view for editing. However, user is still allowed to modify or add information at the editable area. Those areas are limited to; 1. 2. 3. 4. 5. 6. 6.2 Approver column, including position and date Position / designation of the process owner. Effective date (until the date of e-HIRARC need to be reviewed) Priority number for the selection of safety program purpose Risk Control including recommended action, person in charge and dateline Revision history (Rev. 00 to Rev. 06) Prioritization based from risk rating Mark the Priority Number (1 to 5) to assist you on which activity that needs to be taken action first. Once complete, summarization can be sighted in the worksheet 'RISK REG LIST'* for user to make overview and plan for improvement activity * Only applicable for complete version 9|Page 6.3 Significant Risk Register* List of significant activity with risk will reflect automatically as a result of priority remark being numbered as described in section 6.2 or marking with number in ‘Priority No.’ column as in HIRARC (Table 3: HIRARC Format). * Only applicable for complete version 10 | P a g e *** THIS FORMAT IS FOR SAMPLE ONLY *** HAZARD IDENTIFICATION, RISK ASSESSMENT AND RISK CONTROL REGISTER Department : 0 Process handler / ow ner : Position Process/location : Approved by : Position : Date : Priority No No **Main Activity Effective from Changes history HAZARD IDENTIFICATION Hazard #N/A 1 #N/A 5 #N/A 6 #N/A 7 #N/A Rev. 4 Rev. 5 Rev. 6 RISK ASSESSMENT LEGAL Risk REQ. Like. Sev. 0 0 #N/A 0 0 #N/A 0 0 #N/A 0 0 #N/A 0 0 #N/A 0 0 #N/A 0 0 #N/A #N/A #N/A #N/A Rev. 2 Rev. 3 #N/A #N/A #N/A Rev. 1 #N/A #N/A #N/A : #N/A #N/A #N/A Likelihood: 1 - Inconceivable 2 - Remote 3 - Conceivable 4 - Possible 5 - Most likely : #N/A #N/A #N/A #N/A 4 CURRENT RISK CONTROL #N/A #N/A #N/A 3 EFFECTS : OTHER REQ. #N/A #N/A Table 3: HIRARC Format Severity: 1 - Negligible 2 - Minor 3 - Serious 4 - Fatal 5 - Catastrophic RISK CONTROL Recommended control #N/A #N/A 2 : to SEQUENCE OF BASIC JOB 0 Risk evaluation (Probability x severity): 1 - 4: Low - no a cti on required 5 - 12: Medi um - Acti on if necessary 15 - 25 : High - Acti on needed to reduce risk rtdredrt Action by Dateline Normal Page Abnormal Form No SIGNIFICANT RISK REGISTER Emergency Rev. No Indirect Date APPROVED BY CHECKED BY PREPARED BY SIGNATURE NAME SIGNATURE DATE SIGNATURE NO 1 2 3 4 5 6 ACTIVITIES / PROCESS #N/A #N/A #N/A #N/A #N/A #N/A POTENTIAL HAZARD RISK RANKING SCORE LEVEL #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A *** RISK RANKING * PROBABILITY (PROB) / LIKELIHOOD X COMPLETION DATE #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A ** SEVERITY Level 5: MOST LIKELY - Non-stop / continuously happen 5: CATASTHROPHIC - Numerous fatalities, irrecoverable property damage and productivity HIGH - High 4: FATAL - Approximately one single fatality OR/AND major property damage 3: SERIOUS - Non fatal injury, major amputations e.g lost finger, multi fructure, mc > 30 days, permanent loss, cancer, permanent disability 2: MINOR -hearing Lacerations, 1st finger burn, electrical shock, minor fractures, unconsciousness 5 - 12 MED. - Medium 4: POSSIBLE - Repeated or happens every day 3: CONCEIVABLE - Once in a w eek or happens but only occasionnaly 2: REMOTE - Once in a month or happens but only unusually 1-4 LOW - Low 1: INCONCEIVABLE - Once in a year or happens but very rarely 15 - 25 #N/A #N/A #N/A #N/A #N/A #N/A ACTION BY Severity Index - Description Probability Index - Description Score ADDITIONAL CONTROL MEASURE dermatitis, w ith mc till 29 days, hearing tresshold shift, slight property damage. 1: NEGLIGIBLE - Small cuts, minor bruishes w hich require first aid, minor skin or eye irritation, headache or dizziness w ithout require medical attention. Minor injury, mild electrical shock Table 4: Significant Risk Register * Only applicable for complete version 12 | P a g e 7.0 Saving / Printing It is highly recommended that the completed e-HIRARC needs to be saved in protected file such as PDF. This is to ensure that the data inserted in the e-HIRARC is remained secured and to prevent unintendedly change cause to record will be lost. For those PC did not provide with PDF software, they may download it from http://www.dopdf.com/ , a free file converter that you can find it from internet. This free software is reliable to protect your record from missing The other option of record protection is printing process. 8.0 Correction* Data in the Hazard Identification & Risk Analysis are remained empty until insertion of input from the user. However, once the form has been updated, it would not be possible the form to be re-empty again via undo process Nevertheless, if user wants to correct the Hazard Identification & Risk Analysis content and makes data to blank again, click 'Clear Data' button and delete the reference number in the respective activity. Then, user may resume the data input by clicking the 'Back to Joblist' button 9.0 Benefits and advantages of using e-HIRARC 1. Ready-fixed input of hazard to help user in identification of hazard. 2. Analysis data for trend of hazard available at workplace (environment, health, mechanical etc.) 3. Save time in e-HIRARC generation 4. Improve record keeping. 5. Emphasize participation from all parties (process owner). Prevent centralizing the eHIRARC preparation 6. Straight forward oriented. 7. Educate user the concept & structure of basic e-HIRARC such as identification of hazard source, risk control via ESIEAP and risk evaluation conceptual. 10.0 User-friendliness of the e-HIRARC 1. 2. 3. 4. Hyperlink format to Joblist Button selection: direct link icon for 18 hazards identification from defined activities* To clear out data input of respective activity for correction* Buttons selection 11.0 Frequent Answer - Question (FAQ) What is e-HIRARC? Answer: e-HIRARC is a tool developed to assist safety practitioner in assessing the hazard at their workplace through combination of severity and likelihood to determine the risk level. Furthermore, prioritization of risk is then to be placed in order to minimize the potential unneeded incident that may occur. It is really a powerful medium for identification, determination and makes a decision for continuous improvement in OSH within minimum time to be spent but proven to be efficient and effective. Details of this e-HIRARC had been explained in chapter 4.0, 5.0 and 6.0. Who is target user of e-HIRARC? Answer: Anyone can use the e-HIRARC, but it is very useful for Safety Manager, Safety and Health Officer, Safety Supervisor, HSE Admin and other equivalent position. * Only applicable for complete version 14 | P a g e What platform is the e-HIRARC program available on? Answer: This e-HIRARC format is only compatible to run with Microsoft Excel. What is the minimum capability of the system processing requirement? Answer: The PC shall have at least Microsoft Excel version 2010 or latest. Do I need special software to use e-HIRARC? Answer: No. e-HIRARC format may be served by Microsoft Excel only. User is only required to add information through built-in button information, and then the result will automatically reflect. How do I download e-HIRARC? How do I install it? Answer: User will receive template either trial version or complete program from administrator (mail us at admin@osh-isis.com). Then, user should save into their PC and they can start to use it. Direct downloading is also available by browsing to this link. How can get start with e-HIRARC? Answer: This program is very simple and user friendly. However, for new user, they can explore it with guidelines as addressed in chapter 5.0 How to run e-HIRARC. What does the system features? Answer: Basic of the e-HIRARC system is consists 1. 2. 3. 4. Job definition and its associated activities (Refer to here & here for sample) Hazard Identification*, (Sample) Assessing the risk, (Sample) and Prioritizing the significant risk* (Sample) Detail of the program can refer to this User Manual What does the package offers? Answer: This e-HIRARC format is inclusively covers (1) e-HIRARC Template in Microsoft Excel format (Sample), (2) HAZID Table* (Sample) and (3) Significant Risk Register* (Sample). It was however, FREE version is available & it can be downloaded from this link. FREE version only consist e-HIRARC Template. How to get system support in troubleshooting or when the program facing a problem? Answer: Maintenance of this program is low unless system configuration or system format has been modified by user. However, user can get service assistance by writing email to us at admin@osh-isis.com Which industry can use and apply e-HIRARC? Answer: This format has been designed to cater all type of industries including construction, factory, plantation, office etc. * Only applicable for complete version 15 | P a g e How to know whether e-HIRARC is recognized to be applied for industries? Answer: The approaches used in this program has been followed according to DOSH Guidelines of Hazard Identification, Risk Assessment and Risk Control (e-HIRARC) 2008 and aligned with clause 4.3.1 of OHSAS 18001:2007 Standard Requirement. (Refer to chapter 2.0 What is HIRARC) Is e-HIRARC transferrable to others? Answer: This e-HIRARC format is registered based from single user. As long as the file is circulating within the company where it has been formatted to, it is allowable. Therefore, it is not possible for the file to be transferred to third party without permission from system administrator Is there validity for e-HIRARC? Answer: Yes. Trial version is valid for one month but subject to be extent where there is requested by user. Complete version may valid up to 18 months and renewable is available by contacting to administrator. Does customization is available for e-HIRARC? Answer: Yes. Customer can ask for customization to meet their needs but it subject to additional cost to be incurred. Also, the change is only limited to minor modification such as wording, criteria, risk rating etc. No major modification of system structure to be offered. Summary This eBook is a guidebook to the Safety Practitioner written from the viewpoint of a person who developed a tool called e-HIRARC. Side notes are included to give a background perspective to the decisions made in risk assessment and why the methods were made in that template along the way. The eBook briefly explains the e-HIRARC objectives that directed both the use of HIRARC template and apply it at their workplace. Appreciate for any comment, feedback or suggestion (mail us at admin@osh-isis.com) to allow us to know on how e-HIRARC can help user and make sense to attain a good result in their work performance. * Only applicable for complete version 16 | P a g e