218

IEEE TRANSACTIONS ON SYSTEMS, MAN, AND CYBERNETICS—PART C: APPLICATIONS AND REVIEWS, VOL. 38, NO. 2, MARCH 2008

A Genetic-Algorithm-Based Optimization Model

for Solving the Flexible Assembly Line

Balancing Problem With Work Sharing

and Workstation Revisiting

Z. X. Guo, W. K. Wong, S. Y. S. Leung, J. T. Fan, and S. F. Chan

Abstract—This paper investigates a flexible assembly line balancing (FALB) problem with work sharing and workstation revisiting. The mathematical model of the problem is presented, and

its objective is to meet the desired cycle time of each order and

minimize the total idle time of the assembly line. An optimization

model is developed to tackle the addressed problem, which involves

two parts. A bilevel genetic algorithm with multiparent crossover

is proposed to determine the operation assignment to workstations

and the task proportion of each shared operation being processed

on different workstations. A heuristic operation routing rule is then

presented to route the shared operation of each product to an appropriate workstation when it should be processed. Experiments

based on industrial data are conducted to validate the proposed

optimization model. The experimental results demonstrate the effectiveness of the proposed model to solve the FALB problem.

Index Terms—Assembly line balancing (ALB), genetic algorithms (GAs), optimization, work sharing, workstation revisiting.

I. INTRODUCTION

ACING ever-increasing global competition and unpredictable demand fluctuations, more and more manufacturing enterprises are seeking benefits from manufacturing flexibility and effective assembly line management. This paper will

investigate the balancing problem of the assembly line with features of flexible manufacturing so as to implement the effective

assembly line control.

F

A. Manufacturing Flexibility and Assembly Lines

Beach et al. [1] have provided a comprehensive review on

manufacturing flexibility. Manufacturing flexibility is of various types, such as machine flexibility, routing flexibility, etc.

Machine flexibility is measured by the number of operations

that a workstation processes and the time needed to switch from

one operation to another. If a workstation can process multiple

Manuscript received October 9, 2006. This work was supported by the Innovation and Technology Commission of the Government of the Hong Kong

SAR and Genexy Company, Ltd., under Project UIT/62. This paper was recommended by Associate Editor R. Subbu.

Z. X. Guo is with the Institute of Textiles and Clothing, The Hong Kong

Polytechnic University, Kowloon, Hong Kong and also with the College of

Information Science and Technology, Donghua University, 200051 Shanghai,

China (e-mail: zx.guo@polyu.edu.hk).

W. K. Wong, S. Y. S. Leung, J. T. Fan, and S. F. Chan are with the Institute

of Textiles and Clothing, The Hong Kong Polytechnic University, Kowloon,

Hong Kong (e-mail: tcwongca@inet.polyu.edu.hk; tcleungs@inet.polyu.edu.

hk; tcfanjt@inet.polyu.edu.hk; tcchansf@inet.polyu.edu.hk).

Digital Object Identifier 10.1109/TSMCC.2007.913912

operations, the machine flexibility is high. Routing flexibility

is the ability of a production system to manufacture a product

using several alternative routes in the system, and it is usually

determined by the number of such potential routes.

Assembly lines are flow-oriented production systems that are

still attractive means of large-scale series production, and even

gain importance in low-volume production of customized products [2]. In the traditional assembly line, work sharing and

workstation revisiting are not permitted. Work sharing means

that one operation (task) is assigned to multiple workstations

for processing. Workstation revisiting occurs when the semifinished product (uncompleted product) revisits the workstation

for another operation to be processed after the product has been

processed by other workstations. In other words, the workstation performs two or more operations that are not proximate in

the predetermined processing sequence.

Undoubtedly, allowing work sharing and workstation revisiting is helpful to improve both the machine and the routing

flexibility of the assembly line. Actually, the flexible assembly

line (FAL) with these two features is widely adopted in some

manufacturing industries, and a typical example is the apparel

assembly line in the apparel industry.

B. Assembly Line Balancing Problem

The first published analytical statement of the assembly line

balancing (ALB) problem can be traced back to the middle of

the twentieth century [3], [4]. Since then, the topic of line balancing has been of great interest to researchers and practitioners,

and their research has been expanded greatly. With the growth of

knowledge on this subject, many studies have also been reported

to review the published literature comprehensively [2], [5]–[7].

Most of the existing ALB literature focuses on modeling and

solving the simple ALB problem that has some restricting assumptions with respect to real-life assembly lines [5], [7]. In recent years, a lot of research work has been done in order to solve

more realistic ALB problems—generalized ALB problem [2],

which considers some realistic features of assembly lines, such

as parallel workstations, U-shaped line layout, mixed-model or

multimodel assembly environment, etc.

Mcclain et al. [8] have pointed out that work sharing can

improve the efficiency of the assembly line. Some ways of sharing work in the assembly line have been presented, such as

bucket brigade [9], D-skill chaining [10], craft [11], etc. However, work sharing has received little attention in the existing

1094-6977/$25.00 © 2008 IEEE

GUO et al.: GENETIC-ALGORITHM-BASED OPTIMIZATION MODEL FOR SOLVING THE FALB PROBLEM

ALB literature. Furthermore, the ALB problem with workstation revisiting has also not been reported so far.

In the FAL with work sharing and workstation revisiting, the

line balancing activity mainly relies on managers/supervisors’

experience, and subjective and ad hoc assessment. However,

the human decision tends to be late, inconsistent, and nonoptimal owing to the complexity of the ALB problem. Thus, a

methodology to make the ALB decision better in the FAL is

needed.

In this paper, the balancing problem of an FAL with work sharing and workstation revisiting, i.e., the FAL balancing (FALB)

problem, will be investigated, which considers two objectives

including meeting the desired cycle time of each production

order and minimizing the total idle time of the assembly line.

C. Techniques for Assembly Line Balancing

A large variety of techniques have been developed to solve

the ALB problem [2], [5], [7]. Some classical optimization

techniques can provide optimal or near-optimal solutions, for

example, shortest-path technique [12], branch and bound algorithm [13], linear programming method [14], dynamic programming method [15], and integer programming method [16].

It is well known that the ALB problem belongs to NP-hard

class of combinatorial optimization problems [17]. In recent

years, various intelligent algorithms have been studied and applied extensively, such as tabu search method [18], simulated

annealing method [19], immune algorithm [20], ant colony algorithm [21], [22], and genetic algorithm (GA) [23]–[25] in

which GA is the most commonly used, and has been proven to

be very powerful in finding heuristic solutions from a wide variety of applications [26]–[28]. Furthermore, some researchers

have concluded that using multiparent crossover does increase

the performance of GA with binary or real-coded representation [29], [30]. However, the GA with multiparent crossover has

not been developed to solve the ALB problem.

In the FALB problem with work sharing and workstation

revisiting, it is significant to determine the flexible operation

assignment, find the shared work (operation), and assign the

shared operation to different workstations. In this paper, a

GA-based optimization model will be presented to solve them.

First, a bilevel GA with multiparent crossover [bilevel multiparent GA (BiMGA)] will be proposed to determine the operation

assignment to workstations and the task proportion of the shared

operation to be processed at different workstations. Second, an

operation routing rule will be presented to route each shared

operation of each product to an appropriate workstation.

The rest of this paper is organized as follows. In Section II,

the FALB problem is formulated. The GA-based optimization

model is described in detail to solve the addressed problem in

Section III. Experiments and detailed discussions are presented

to validate the effectiveness of the proposed optimization model

in Section IV. Finally, the paper is summarized and further

research is suggested in Section V.

II. PROBLEM FORMULATION

In this section, the ALB problem in an FAL is formulated.

The FAL is composed of a number of workstations including

219

several different machine types. Each workstation is a physical location that accommodates an operator, a machine, and a

buffer. Several production orders with given quantities representing different product types will be produced in the FAL.

Each order comprises a series of manual operations. According

to a predetermined processing sequence, operations involved in

each order must be processed on corresponding workstations. In

the FAL, work sharing and workstation revisiting are allowed,

that is, one operation can be assigned to multiple workstations and one workstation can also process multiple operations

simultaneously.

In this paper, we let Pi represent the ith prodution order

(1 ≤ i ≤ p). In each order, a certain quantity of identical type

of product will be produced. Oil denotes the lth operation of

order Pi , Mk j denotes the jth machine (workstation) of the kth

machine type, and STil represents the standard time of operation

Oil , i.e., the time to complete operation Oil of one product

with 100% operative efficiency. We use the symbol ηilk j (0 ≤

ηilk j ≤ 1) to denote the task proportion (weight) of operation

Oil being performed on machine Mk j , i.e., the ηilk j time of the

total tasks of operation Oil is processed on machine Mk j . On

average, for operation Oil of each product, the task of ηilk j STil

should be processed on machine Mk j . If operation Oil is only

processed on machine Mk j , ηilk j = 1; and if operation Oil is

not processed

on machine Mk j , ηilk j = 0. For each operation

Oil , k j ηilk j = 1. The average assembly time MATk j of each

product on machine Mk j can be expressed as

ηilk j STil

MATk j =

(1)

EMilk j

il,O i l ∈SO k j

where SOk j denotes the set of operations that can be processed

on machine Mk j and EMilk j denotes the operative efficiency

of operation Oil on machine Mk j .

A. Objective Function

The aim of ALB is to generate the optimal operation assignment and routing Xilk j of each operation Oil . Xilk j indicates

that if operation Oil is assigned to machine Mk j , Xilk j is equal

to 1, otherwise it is equal to 0. In this paper, the objective of the

FALB problem includes two folds. The first one is to satisfy the

desired cycle time of each order, whereas the second one aims

at minimizing the total idle time in each cycle. The objective of

satisfying the desired cycle time can be described as

min Z(Xilk j )

{X i l k j }

with

Z(Xilk j ) =

p

[αi λi (DCTi − ACTi )

i=1

+ βi (1 − λi )(ACTi − DCTi )]

(2)

where DCTi represents the desired cycle time of order Pi that

is the desired time interval of consecutive jobs entering the

assembly line, ACTi represents the actual cycle time of order

Pi , αi denotes the penalty weight for order Pi when its actual

cycle time is less than its desired cycle time, βi denotes the

220

IEEE TRANSACTIONS ON SYSTEMS, MAN, AND CYBERNETICS—PART C: APPLICATIONS AND REVIEWS, VOL. 38, NO. 2, MARCH 2008

penalty weight for order Pi when its actual cycle time is greater

than its desired cycle time, and λi indicates that if the actual

cycle time ACTi is less than the desired cycle time DCTi , λi

is equal to 1; otherwise it is equal to 0. Z is used to measure

the degree how the actual cycle time is close to desired cycle

time. The smaller the value of Z, the better the actual cycle

time satisfies the desired cycle time. The delivery dates will

be delayed and tardiness penalties generate if the actual cycle

time is greater than the desired cycle time, whereas the storage

cost arise and earliness penalties generate if the actual cycle

time is less than the desired cycle time.

The second objective of the FALB problem is to minimize

the total idle time IT in each cycle, which can be expressed as

follows:

min IT(Xilk j )

i.e.,

with

In order to solve the addressed FALB problem, a GA-based

optimization model is presented in this section. In this model, the

BiMGA will be used firstly to deal with the operation assignment

of the FAL, i.e., assign operations to workstations and determine

the task proportions of the shared operation to be processed

on different workstations. Then, a heuristic operation routing

process (operation routing rule) will be used to route the shared

operation of each product to an appropriate workstation. The

two processes are described in detail as follows.

{X i l k j }

IT(Xilk j ) =

p

(ACTi Ni −

MATk j )

(3)

k j,M k j ∈A M i

i=1

where AMi denotes the set of workstations processing order Pi ,

and Ni denotes the number of workstations processing order Pi .

B. Assumptions and Constraints

In this research, the addressed problem satisfies the following

assumptions.

1) Each operator’s efficiency is constant during production.

2) Once an operation of the product is started, it cannot be

interrupted.

3) There is no shortage of materials, workstation breakdown,

and operator absenteeism in the FAL.

4) The FAL discussed is empty initially, in other words, there

is no work-in-progress (WIP) in each workstation.

Furthermore, the real-life manufacturing environment has

many peculiar characteristics and is subject to some constraints.

A feasible solution of the FALB problem must satisfy the following three basic types of constraints.

1) Allocation Constraint: Operation Oil can only be operated

on workstations that can handle it, i.e.,

Xilk j = 0

(4)

k j,M k j ∈

/ SM i l

where SMil denotes the set of machines that can handle operation Oil .

Each workstation must process at least one operation, i.e.,

Xilk j ≥ 1.

(5)

il

Each operation of a particular production order must be processed, i.e.,

Xilk j ≥ 1.

(6)

kj

2) Operation Precedence Constraint: For each product, an operation cannot be started before the completion of its preceding

operation plus an elapsed time-out between the two operations,

Cil + ETil + 1 ≤ Si l , Oil ∈ PR(Oi l )

(7)

where Cil is the completion time of operation Oil , ETil is

elapsed time between operation Oil and its latter operation including the transportation time and the setup time, Si l is the

starting time of operation Oi l , and PR(Oi l ) is the set of the

preceding operations of operation Oi l .

3) Processing Time Requirements: Operation Oil must be

assigned with processing time, i.e.,

Cil = Sil + Til − 1

(8)

where Til is the time for processing operation Oil .

III. GA-BASED OPTIMIZATION MODEL FOR FALB

A. Bilevel Multiparent Genetic Algorithm

The operation assignment of the addressed FALB problem

can be considered as a two-stage optimization problem where

the first stage is to assign operations to workstations, while

the second one is to determine the task proportions of each

operation assigned to different workstations. Since the solution

for the second-stage subproblem has to depend on the solution

for the first-stage subproblem, the complexity of the addressed

problem is increased greatly. The BiMGA is proposed to solve

the two-stage FAL optimization problem.

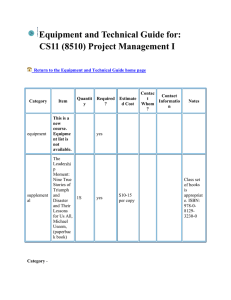

Fig. 1 illustrates the steps involved in the BiMGA. The algorithm comprises two genetic optimization processes where the

second-level GA (GA-2) is nested in the first-level GA (GA-1).

The GA-1 generates the optimal operation assignment to workstations using the order-based representation. The chromosome

in the GA-1 represents the operation assignment of the FALB

problem. Based on each chromosome of GA-1, GA-2 will determine the task proportion (weight) of the operation that is

assigned to different workstations. If an operation is assigned

to multiple workstations, the weights on these workstations will

be optimized. Seeking the optimal weights is a first-order multivariate function optimization problem, which can be optimized

by a real-coded GA.

The following sections describe the detailed mechanism of

GA-1 and GA-2 of the BiMGA.

1) Representation: The first step of the GA is to define an

appropriate genetic representation. A representation that can

well describe problem-specific characteristics is crucial since it

significantly affects all the subsequent steps of the GA.

In GA-1, each chromosome represents a feasible solution

of assigning each operation to different workstations. Various

GUO et al.: GENETIC-ALGORITHM-BASED OPTIMIZATION MODEL FOR SOLVING THE FALB PROBLEM

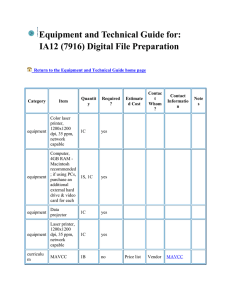

Fig. 2.

Fig. 1.

BiMGA.

order-based representations tackling operation assignment have

been introduced, e.g., workstation-oriented representation [31],

operation-oriented representation [32], sequence-oriented representation [33], etc. In the chromosome of these representations, the gene represents one operation or one workstation.

Work sharing implies that one operation will be assigned to

multiple workstations, and workstation revisiting implies that

one workstation will process multiple operations. Obviously,

these existing representations cannot deal with the operation

assignment considering both work sharing and workstation

revisiting.

In GA-1, each chromosome is composed of a sequence of

genes whose length is equal to the number of workstations to

which operations can be assigned. In a chromosome, each gene

represents a workstation, and the value of each gene represents

the operation number(s) of one or more operations that the corresponding workstation processes. If the number of the machine

type is t(t ≥ 1), the genes in each chromosome will be divided

into t parts in turn. Each part represents one type of machines.

Each operation can only be assigned to the workstations that

can handle it. Fig. 2 shows an example of this representation

that considers a problem with 11 operations to be assigned to

11 workstations. These workstations are divided into two types,

type 1 including machines 1 through 8, and type 2 including

machines 9 through 11. Operations 1, 2, 3, 5, 6, 7, 9, and 11

must be processed on the machines of type 1, while operations

4, 8, and 10 must be operated on the machines of type 2. A

feasible solution, represented as an array of length 11, could be

[5 (1,6) 9 3 11 7 6 2 (4,10) 4 (8,10)]. In this solution, workstation

revisiting occurred in workstations 2, 9, and 11. For each product, workstation 2 firstly processed operation 1, and then, the

semifinished product was transported to the other workstations

for further processing of operations 3–5. After operation 5 was

completed, the semifinished product revisited workstation 2 for

the processing of operation 6. Moreover, some shared operations

221

Example of the chromosome representation.

existed in this solution. For example, the processing of operation 6 was shared on workstations 2 and 7, and the processing

of operation 4 was shared on workstations 9 and 10.

In GA-2, the real-coded representation is adopted. Each gene

represents the task proportion of an operation assigned to the

corresponding workstation. Considering the assignment of nQ

operations, let nmil denote the number of machines that are allocated to process operation Oil and PSil denote the summation

of nmil −1 weights of Oil . The number of genes in each chromosome of GA-2 is the summation of nmil minus nQ since the

nmil th weight is equal to 1−PSil .

2) Initialization: The GA operates on a population of chromosomes. Either heuristic or random procedures can be used to

generate the initial population comprising a specified number

of chromosomes. Anderson and Ferris [32] have mentioned that

the performance of the GA is not so good from the preselected

initial population as it is from a random start.

In GA-1, each chromosome is randomly initialized by assigning each operation, from operations 1 to nOp, to the workstations that can handle it. The initialization process can, thus, be

described as procedure 1.

Procedure 1:

Step 1. Initialize parameters: index i = 1, a population size

P size, population POP = {φ}, and a maximum quantity mxQ of machines that an operation can be assigned to.

Step 2. In light of procedure 2, randomly generate a string

chromosome CHRi , POP = POP ∪ CHRi .

Step 3. Set i = i + 1. Stop if i > P size, else go to Step 2.

Procedure 2:

Step 1. Set index j = 1. For each operation, let PRO = 1,

where PRO represents the probability that an operation is selected to be processed.

Step 2. Generate randomly an integer k between 1 and the

number of operations that can be processed on machine j.

Step 3. Randomly select k operation(s) that can be processed

on this machine. The operation with greater PRO will

be selected with a greater probability. If PRO = 0, the

operation cannot be selected.

Step 4. Assign the selected operation(s) to machine j. For

each selected operation, let PRO = PRO − 1/mxQ.

Step 5. Set j = j + 1. If j > nOp, go to Step 6, else go to

Step 2.

Step 6. Stop if all operations are assigned, else go to Step 1.

In GA-2, the initial population is generated by initializing

randomly each task proportion (weight) in the chromosome

between 0 and 1 based on the condition of PSil ≤ 1.

3) Fitness: The fitness of a particular chromosome represents its probability to survive. The greater the fitness of a

222

Fig. 3.

IEEE TRANSACTIONS ON SYSTEMS, MAN, AND CYBERNETICS—PART C: APPLICATIONS AND REVIEWS, VOL. 38, NO. 2, MARCH 2008

Example of the modified-fitness-based scanning crossover operator.

chromosome is, the greater the probability to survive. The value

of the fitness is relevant to the objective function to be optimized. The fitness of GA-1 is the same with that of GA-2,

which is described as follows.

In this research, two objective functions described in

Section II are optimized, which can be combined as the equation

OBJ(Xilk j ) = wZ Z(Xilk j ) + wIT IT (Xilk j )

(9)

where wZ and wI T are the relative weights placed upon the

objectives Z(Xilk j ) and IT(Xilk j ), respectively.

The less the weighted summation of the two objectives is, the

greater the fitness. Thus, the fitness function f t can be defined

as

ft =

100

.

OBJ(Xilk j ) + 1

(10)

4) Selection: The selection in GA, based on the natural law

of survival of the fittest, is the process to determine which chromosomes are selected for the next generation in terms of their

fitness. Many selection schemes have been presented [34]. The

tournament selection [35] is commonly utilized because it is

simple to implement and provides good solutions. In this study,

this scheme is applied in GA-1 and GA-2, and its procedure can

be described as follows.

Procedure 3:

Step 1. Set a tournament size δ ≥ 2.

Step 2. Generate a random permutation of the chromosomes

in the current population, which is a feasible solution

of operation assignment or task proportions.

Step 3. Compare the fitness value of the first δ chromosomes listed in the permutation, and copy the best one

into the next generation. Discard the chromosomes

compared.

Step 4. If the permutation is exhausted, generate another

permutation.

Step 5. Repeat steps 3 and 4 until no more selections are

required for the next generation.

The scheme can control the population diversity and selective

pressure by adjusting the tournament size δ. A larger value of δ

will increase the selective pressure but decrease the population

diversity.

5) Genetic Operators: To improve the adaptability of the

population, two basic operators, crossover and mutation, are

used to modify the chromosome. The detailed descriptions of

the two genetic operators are as follows.

a) Crossover: Crossovers are deterministic operators that

capture the features of the parents and pass it to a new offspring.

The population is recombined according to a probability of

crossover that ranges typically between 0.6 and 1.0.

In GA-2, the center of mass crossover operator [29] is used.

In GA-1, the fitness-based scanning crossover [30] is modified

to suit the proposed representation, which is described as next.

Procedure 4:

Step 1. Let sp1 , sp2 , . . .,spr be the selected parents with L

genes.

Step 2. Initialize parameters: position markers i1 = · · · =

ir = 1, i.e., the position markers are all initialized

to the first position in each of the parents; the gene

position in the child chromosome k = 1.

Step 3. Choose a gene from the r genes in the marked positions of the parents, which is based on the rule that

the probability of the gene of the parent being chosen

is proportional to the fitness values of the parent. For

example, for a maximization problem where parent

spi has a fitness of f t(i), the probability PR(i) of

choosing the gene from parent spi can be

f t(i)

.

PR(i) = f t(i)

(11)

Step 4. Put the chosen gene in the kth position of the child

chromosome.

Step 5. Update position markers i1 , . . . , ir . For each parent,

if the gene in the current position is the same with

the chosen gene, increase its marker until it denotes a

value that has not already been added to the child or

equals L.

Update k = k + 1.

Step 6. Repeat steps 3, 4, and 5 until the gene position k is

greater than L.

Step 7. Stop if each operation in the parent is assigned to

machines, else go to Step 2.

Fig. 3 shows an example of how the proposed crossover mechanism works, in which the fitness of parents 1–3 are 0.90, 0.45,

and 0.45, respectively. The marked positions in parents are indicated by shaded grids.

b) Mutation: After crossover, the offspring undergoes

mutation according to the probability of mutation (the typical

value is between 0.0015 and 0.03). The mutation operation is

important to the success of the GA since it diversifies the search

GUO et al.: GENETIC-ALGORITHM-BASED OPTIMIZATION MODEL FOR SOLVING THE FALB PROBLEM

223

TABLE I

EXAMPLE OF OPERATION ROUTING TO PROCESS

OPERATION O 1 1 OF TEN PRODUCTS

Fig. 4.

Example of the modified inversion mutation operator.

direction and prevents a population prematurely converging at

local minima.

In GA-2, the nonuniform mutation operator [36] is adopted.

In GA-1, a modified mutation operation being similar to inversion mutation operator [35] is developed, which is described

detailedly as procedure 5.

Procedure 5:

Step 1. Inverse the genes between two randomly selected

genes of a chromosome.

Step 2. The gene with two or more operations is separated

according to a suitable probability (between 0.6 and

1).

Step 3. The separated operation is recombined randomly with

its proximate genes.

In this procedure, steps 2 and 3 are helpful to increase the population diversity of GA and avoid the premature convergence.

Fig. 4 shows an example of this mutation operator.

In GA-1, the crossover and mutation operations can only

be performed among genes with the same machine type since

each operation must be processed on machines of a certain

type. Therefore, for the genes of each machine type, the genetic

operations should be performed separately. In GA-2, after the

genetic operations are performed, its nmil weights should be

changed to the corresponding values between 0 and 1 if P Sil of

the operation Oil is greater than 1. Firstly, randomly generate

a real number between 0 and 1 as the nmil th weight. Then,

normalize the nmil weights, and the normalized weights are the

final weights.

6) Termination Criterion: The GA in this study is controlled

by a specified number of generations and by using a diversity

measure to stop the algorithm. The diversity of the algorithm

is defined by the standard deviation of the fitness values of all

chromosomes of a population in a certain generation. If either

of these two termination criteria is satisfied, the cycled process

of GA-1 or GA-2 is terminated.

ment, ηilk

j denotes the optimized task proportion that operation

Oil should be processed on machine Mk j (ηilk

j > 0), ηilk j denotes the task proportion that operation Oil has been processed

on machine Mk j , and Qilk j denotes the number of operation

Oil that has been assigned to machine Mk j .

For shared operation Oil of a product, the heuristic operation

routing rule is described as the following procedure.

Procedure 6:

n

Step 1. Calculate ηilk

j = Qilk j /(

l=1 Qilk j ) for each ma

chine Mk j (for the first product, set ηij

k l = 0).

Step 2. Calculate ηilk j /ηilk j for each machine Mk j .

Step 3. Assign operation Oil of the current product to the ma

chine Mk j with the minimum ηilk

j /ηilk j . If multiple

machines have the same minimum value, one of these

machines will be chosen randomly.

Table I shows an example of the operation routing to process

operation O11 of 10 units of identical product. The operation

O11 is assigned to machines M11 , M12 , and M13 . The task

proportions of operation O11 to be processed on these three

machines are 0.4, 0.4, and 0.2, respectively, generated by the

proposed BiMGA. The row of ηilk

j /ηilk j describes the current

value ηilk j /ηilk j of operation O11 of each product in the relevant

machine, and the shaded grid represents that the corresponding

machine is selected to process the operation of the corresponding

product. According to the result of operation routing shown in

Table I, operation O11 of the first unit of product is assigned

to M11 , that of the second unit of product is assigned to M13 ,

etc. After the 10 units of product are completed, the actual task

proportion processed on each machine is equal to the optimized

task proportion.

IV. EXPERIMENTAL RESULTS AND DISCUSSIONS

This section will present the validation of the effectiveness

of the proposed optimization model; performance comparison

between the proposed model and the industrial practice; analysis of the effects of task proportion, operation routing, and

violation of assumption (presented in Section II-B) on the FALB

performance.

A. Validation of GA-Based Optimization Model

B. Operation Routing

The proposed BiMGA can only obtain the optimized operation assignment and task proportion of the shared operation

on different workstations. After the previous operations of the

shared operation of each product are completed, the operation

should be then routed to an appropriate workstation so as to satisfy the optimized task proportion in each assigned workstation

during production.

Assume that operation Oil is assigned to n machines (Mk 1 ,

Mk 2 , . . ., Mk n ) according to the optimized operation assign-

To evaluate the performance of the GA-based optimization

model, real industrial data were collected from an FAL of a

Hong Kong-owned manufacturing company, and a series of experiments were conducted. This section highlights four out of

these experiments in detail. The FAL consists of 11 workstations with two types of machines. The workstations of type 1

machines include eight workstations numbered as 1 to 8 and

those of type 2 machines include three workstations numbered

as 9 to 11. In these experiments, the transportation time of

semifinished products and the setup time of each operation are

224

IEEE TRANSACTIONS ON SYSTEMS, MAN, AND CYBERNETICS—PART C: APPLICATIONS AND REVIEWS, VOL. 38, NO. 2, MARCH 2008

TABLE II

OPERATIVE EFFICIENCIES IN WORKSTATIONS OF EXPERIMENT 1

TABLE III

OPERATIVE EFFICIENCIES IN WORKSTATIONS OF EXPERIMENT 2

known in advanced and included in the processing time. Moreover, each production order is available for processing starting

from time zero.

In each experiment, two different production orders are

scheduled. Some basic data of these experiments are as

follows.

Experiment 1: The desired cycle times of orders 1 and 2 are

both 400 s. The product’s assembly process of order 1 is from

operations 1 to 7, and order 2 is from operations 8 to 12.

Experiment 2: The desired cycle times of orders 1 and 2 are

55 and 130 s, respectively. The product’s assembly process of

order 1 is from operations 1 to 6, and order 2 is from operations

7 to 11.

Experiment 3: The desired cycle times of two orders are both

50 s. The assembly processes of two orders are the same with

those in experiment 2.

Experiment 4: The desired cycle times of orders 1 and 2 are

70 and 225 s, respectively. The product’s assembly process of

order 1 is from operations 1 to 5, and order 2 is from operations

6 to 10.

The standard time of each operation in these experiments is

shown in the last row of Tables II–V. The operative efficiency

of each workstation depends on the type of the machine and

the skill level as well as recent performance of the operator,

as shown in Tables II–V. The operative efficiency is set as 0 if

the operator cannot process the corresponding operation. The

processing time of operation Oil on workstation Mk j is equal

to the standard time of this operation divided by its operative

efficiency on workstation Mk j .

In experiments 2–4, the number of workstations is equal to

or greater than the number of operations. In order to evaluate

the effect of work sharing and workstation revisiting on the

FALB performance, different assignment strategies are implemented. In case 1, both work sharing and workstation revisiting

are allowed whereas both are not allowed in case 2 of experiments 2 and 3. In case 2 of experiment 4, only work sharing is

implemented.

The optimized operation assignments and line balancing results of the four experiments generated by the proposed BiMGA

are shown in Tables VI and VII. In Table VI, the first column (Machine type) represents the machine type, the second

(Workstation No.) shows the workstation number, and other

columns show the optimized operation assignment of different experiments to the workstation, in which the first value of

each cell represents the operation number and the value in the

bracket represents the task proportion ηilk j of the operation being processed in the corresponding workstation. For example,

the value 12(1) in the column of “Experiment 1” describes that

workstation 1 processes all (100%) operation 12, and the value

[7(0.67), 9(0.15)] in the column of “Experiment 2” shows that

workstation 2 processes 67% tasks of operation 2 and 15% tasks

of operation 9. In Table VII, the rows of “Actual cycle time”

show the optimized actual cycle time (seconds) of orders 1 and

2 in four experiments whereas the rows of “Idle time” and “Line

efficiency” show the optimized average idle time (seconds) in

each cycle and the optimized line efficiencies of orders 1 and

2 in four experiments, respectively. The line efficiency of order

Pi is defined as the average processing time of workstations

GUO et al.: GENETIC-ALGORITHM-BASED OPTIMIZATION MODEL FOR SOLVING THE FALB PROBLEM

TABLE IV

OPERATIVE EFFICIENCIES IN WORKSTATIONS OF EXPERIMENT 3

TABLE V

OPERATIVE EFFICIENCIES IN WORKSTATIONS OF EXPERIMENT 4

TABLE VI

OPTIMIZED OPERATION ASSIGNMENT OF FOUR EXPERIMENTS

TABLE VII

OPTIMIZED RESULTS OF LINE BALANCING OF FOUR EXPERIMENTS

225

226

IEEE TRANSACTIONS ON SYSTEMS, MAN, AND CYBERNETICS—PART C: APPLICATIONS AND REVIEWS, VOL. 38, NO. 2, MARCH 2008

processing this order in each cycle divided by the actual cycle

time of this order.

As shown in Table VI, the proposed genetic optimization

algorithm can implement flexible operation assignments considering both work sharing and workstation revisiting. For example, in case 1 of experiment 2, the processing of operation

9 was shared on workstations 2, 3, and 4 while workstation revisiting occurred on workstation 2. Moreover, in the optimized

operation assignment of case 1 of experiment 4, some parallel

workstations existed, which processed the same operation set,

such as workstations 1 and 3, workstations 2 and 6, workstations

4 and 8, etc. It indicates that the proposed algorithm can also

handle the ALB problem with parallel workstations.

As shown in Table VII, since the desired cycle times of orders

1 and 2 were achieved in experiment 1 and case 1 of experiment

3, and the actual cycle times of two orders were very close to

the desired cycle time in case 1 of experiments 2 and 4, the

proposed BiMGA can solve the FALB problem effectively.

Moreover, in case 2 of experiments 2, 3, and 4, the actual

cycle times went beyond the desired cycle times; the other two

performances were also inferior to the corresponding performances in case 1. Obviously, the work sharing can improve the

performance of the assembly line.

In the optimization processes of these experiments, the evolutionary trajectories of the maximum value of the fitness over

generations are shown in Fig. 5. The optimal results in this paper are obtained based on the settings: the population sizes of

GA-1 and GA-2 are 200 and 100, respectively; the maximum

numbers of generations of GA-1 and GA-2 are 100 and 50,

respectively; the penalty weights αi and βi of each order are

10 and 100; and the relative weights wZ and wI T are both set

as 1. Moreover, in order to reduce the computation time of the

optimization process, we adjust probabilities of crossover and

mutation according to the fitness values of the population based

on the method developed by Syswerda [37].

Fig. 5. Trends of the chromosome fitness. (a) Experiment 1 and case 1 of

experiments 2–4. (b) Case 2 of experiments 2–4.

TABLE VIII

RESULTS OF LINE BALANCING IN SECTIONS IV-B–D

B. Comparison Between GA-Based Optimization Model

and Industrial Practice

In industrial practice, the manager of shop floor usually balances the assembly line using precedence diagrams and trialand-error methods [38]. Considering case 1 of 4 experiments in

last section, their line balancing results based on industrial practice are shown in the rows of “Industrial results” of Table VIII.

The due dates of most orders could not be satisfied, and a large

number of earliness and tardiness penalties occurred that are

inferior to the optimized results shown in Section IV-A.

C. Effect of Task Proportion on FALB Performance

In the previous studies, it was assumed that the task proportions of the shared operation were the same on the workstations processing the operation. For example, if one operation

is assigned to four workstations, the task proportion on each

workstation should be 0.25. In light of this assumption, the

optimized balancing results of case 1 of the aforementioned

four experiments are shown in the rows of “Same task proportion” of Table VIII. These results are also inferior to those of

Section IV-A. That is because this assumption restricts the flexibility of the operation assignment and shrinks the search space

of the possible ALB solutions.

D. Effect of Operation Routing on FALB Performance

The previous studies on ALB only focused on the operation

assignment and did not pay attention on the operation routing

based on the optimized operation assignment. However, different operation routing rules can generate different balancing

performances. Here, we balance case 1 of the aforementioned

GUO et al.: GENETIC-ALGORITHM-BASED OPTIMIZATION MODEL FOR SOLVING THE FALB PROBLEM

four experiments based on the same operation assignment described in Section IV-A and the following routing rule (ORR2).

ORR2: Let OSize denote the order size. Operation Oil of

ηilk

j OSize products should be processed on machine Mk j . We

assign the first ηilk

j OSize operation Oil to machine Mk 1 , then

ηilk 2 OSize ones to machine Mk 2 , . . ., and the last ηilk

n OSize

ones to machine Mk n .

Assuming that OSize is equal to 3000, the final balancing results are shown in the rows of “ORR2” of Table VIII. The actual

cycle times are much greater than the desired cycle times and

the line efficiencies are comparatively low. The results indicate

that the effectiveness of an operation routing rule is important

for the performance of the FALB.

E. Discussion on Assumption Relaxation

In the real-life manufacturing environment, the assumptions

described in Section II-B are often violated.

The operative efficiency is often variable. Thus, the factors

affecting operative efficiencies should be considered, such as

effects of learning and forgetting, and physiological and psychological effects. The variable operative efficiency will lead

to the fluctuation of the actual cycle time and increases the

complexity of the FALB.

Once one operation is preempted and another operation is

processed, more additional time should be spent on adjusting

the machine setup. If the processing time of an operation is not

very long and the time precision of the ALB is not too high, the

operation preemption has little influence on the performance of

the ALB. Contrariwise, operation preemption can lead to the

decrease of the ALB performance owing to the additional setup

time of machine.

The shortage of materials, workstation breakdown, and operator absenteeism will increase the uncertainty of the ALB and

the processing time of the production order undoubtedly. In general, the ALB solution can be obtained if the occurrence of these

uncertain factors is assumed with certain probabilities.

V. CONCLUSION

In this paper, we investigated an FALB problem with work

sharing and workstation revisiting. The mathematical model

for the problem has been proposed. Besides the objective of

meeting the desired cycle time of each order, the model also

minimizes the total idle time of the FAL. These objectives are

particularly useful to help manufacturing enterprises to meet the

due dates, and also to improve the efficiency of the assembly

line by optimizing the use of limited resources.

A GA-based optimization model was developed to deal with

the proposed FALB problem, in which a BiMGA and a heuristic

operation routing rule were presented. The BiMGA generates

the optimal operation assignment to workstations and the task

proportion of each shared operation being processed on different workstations. In the BiMGA, the fitness-based scanning

crossover and the inversion mutation are modified to suit the

representation of the flexible operation assignment. The shared

operation of each product is routed to an appropriate workstation by the proposed operation routing rule when it need be

processed.

227

The production data from the real-life FAL have been collected to validate the proposed optimization model. The experimental results have demonstrated that the optimization model

can solve the FALB problem effectively. Moreover, since the

FAL investigated contains the features of multimodel and the

mixed-model assembly line, the proposed optimization model

can be extended to solve the balancing problem of the multimodel assembly line or the mixed-model assembly line.

This paper also showed that the GA with multiparent

crossover can be used in tackling the operation assignment of

the ALB problem. However, the performance of the multiparent

GA has not been compared with that of two-parent GA on solving this problem. Further research will focus on it and the effects

of various uncertainties on the FALB, including machine breakdown, operator absenteeism, shortage of materials, and learning

effects on operative efficiency, etc.

REFERENCES

[1] R. Beach, A. P. Muhlemann, D. H. R. Price, A. Paterson, and J. A. Sharp,

“A review of manufacturing flexibility,” Eur. J. Oper. Res., vol. 122, no. 1,

pp. 41–57, Apr. 2000.

[2] C. Becker and A. Scholl, “A survey on problems and methods in generalized assembly line balancing,” Eur. J. Oper. Res., vol. 168, no. 3,

pp. 694–715, Feb. 2006.

[3] M. E. Salveson, “The assembly line balancing problem,” J. Ind. Eng.,

vol. 6, no. 3, pp. 18–25, 1955.

[4] J. R. Jackson, “A computing procedure for a line balancing problem,”

Manage. Sci., vol. 2, no. 3, pp. 261–271, 1956.

[5] I. Baybars, “A survey of exact algorithms for the simple assembly line

balancing problem,” Manage. Sci., vol. 32, no. 8, pp. 909–932, Aug.

1986.

[6] E. Erel and S. C. Sarin, “A survey of the assembly line balancing procedures,” Prod. Plan. Control, vol. 9, no. 5, pp. 414–434, Jul./Aug. 1998.

[7] A. Scholl and C. Becker, “State-of-the-art exact and heuristic solution procedures for simple assembly line balancing,” Eur. J. Oper. Res., vol. 168,

no. 3, pp. 666–693, Feb. 2006.

[8] J. Mcclain, L. Thomas, and C. Sox, “On-the-fly line balancing with very

little WIP,” Int. J. Prod. Econ., vol. 27, no. 3, pp. 283–289, Oct. 1992.

[9] J. Bartholdi and D. Eisenstein, “A production line that balances itself,”

Oper. Res., vol. 44, no. 1, pp. 21–34.

[10] W. Hopp, E. Tekin, and M. Van Oyen, “Benefits of skill chaining in serial

production lines with cross-trained workers,” Manage. Sci., vol. 50, no. 1,

pp. 83–98, Jan. 2004.

[11] W. Hopp and M. Van Oyen, “Agile workforce evaluation: A framework for

cross-training and coordination,” IIE Trans., vol. 36, no. 10, pp. 919–940,

Oct. 2004.

[12] B. H. Faaland, T. D. Klastorin, T. G. Schmitt, and A. Shtub, “Assembly

line balancing with resource dependent task times,” Decis. Sci., vol. 23,

no. 2, pp. 343–364, Mar./Apr. 1992.

[13] A. Tozkapan, O. Kirca, and C. S. Chung, “A branch and bound algorithm to minimize the total weighted flowtime for the two-stage assembly

scheduling problem,” Comput. Oper. Res., vol. 30, no. 2, pp. 309–320,

Feb. 2003.

[14] M. Peeters and Z. Degraeve, “An linear programming based lower bound

for the simple assembly line balancing problem,” Eur. J. Oper. Res.,

vol. 168, no. 3, pp. 716–731, Feb. 2006.

[15] R. L. Carraway, “A dynamic programming approach to stochastic assembly line balancing,” Manage. Sci., vol. 35, pp. 459–471, 1989.

[16] H. Gokcen and E. Erel, “Binary integer formulation for mixed-model

assembly line balancing problem,” Comput. Ind. Eng., vol. 34, no. 2,

pp. 451–461, Apr. 1998.

[17] A. L. Gutjahr and G. L. Nemhauser, “An algorithm for the line balancing

problem,” Manage. Sci., vol. 11, no. 2, pp. 308–315, 1964.

[18] S. Lapierre, A. Ruiz, and P. Soriano, “Balancing assembly lines with tabu

search,” Eur. J. Oper. Res., vol. 168, no. 3, pp. 826–837, Feb. 2006.

[19] A. Baykasoglu, “Multi-rule multi-objective simulated annealing algorithm

for straight and U type assembly line balancing problems,” J. Intell.

Manuf., vol. 17, no. 2, pp. 217–232, Apr. 2006.

228

IEEE TRANSACTIONS ON SYSTEMS, MAN, AND CYBERNETICS—PART C: APPLICATIONS AND REVIEWS, VOL. 38, NO. 2, MARCH 2008

[20] L. P. Khoo and D. Alisantoso, “Line balancing of PCB assembly line using

immune algorithms,” Eng. Comput., vol. 19, no. 2/3, pp. 92–100, 2003.

[21] P. McMullen and P. Tarasewich, “Multi-objective assembly line balancing

via a modified ant colony optimization technique,” Int. J. Prod. Res.,

vol. 44, no. 1, pp. 27–42, Jan. 2006.

[22] P. Vilarinho and A. Simaria, “ANTBAL: An ant colony optimization

algorithm for balancing mixed-model assembly lines with parallel workstations,” Int. J. Prod. Res., vol. 44, no. 2, pp. 291–303, Jan. 2006.

[23] A. Haq, K. Rengarajan, and J. Jayaprakash, “A hybrid genetic algorithm

approach to mixed-model assembly line balancing,” Int. J. Adv. Manuf.

Tech., vol. 28, no. 3/4, pp. 337–341, Mar. 2006.

[24] A. Simaria and P. Vilarinho, “A genetic algorithm based approach to the

mixed-model assembly line balancing problem of type II,” Comput. Ind.

Eng., vol. 47, no. 4, pp. 391–407, Dec. 2004.

[25] W. Wong, P. Mok, and S. Leung, “Developing a genetic optimisation

approach to balance an apparel assembly line,” Int. J. Adv. Manuf. Tech.,

vol. 28, no. 3/4, pp. 387–394, Mar. 2006.

[26] S. Chaudhry and W. Luo, “Application of genetic algorithms in production

and operations management: A review,” Int. J. Prod. Res., vol. 43, no. 19,

pp. 4083–4101, Oct. 2005.

[27] Z. X. Guo, W. K. Wong, S. Y. S. Leung, J. T. Fan, and S. F. Chan,

“Mathematical model and genetic optimization for the job shop scheduling

problem in a mixed- and multi-product assembly environment: A case

study based on the apparel industry,” Comput. Ind. Eng., vol. 50, no. 3,

pp. 202–219, 2006.

[28] C. Chiu and P.-L. Hsu, “A constraint-based genetic algorithm approach

for mining classification rules,” IEEE Trans. Syst., Man, Cybern. C, Appl.

Rev., vol. 35, no. 2, pp. 205–220, May 2005.

[29] S. Tsutsui and A. Ghosh, “A study on the effect of multi-parent recombination in real coded genetic algorithms,” in Proc 1998 IEEE Conf. Evol.

Comput. Anchorage, AK, pp. 828–833.

[30] A. E. Eiben, P.-E. Raue, and Z. Ruttkay, “Genetic algorithms with multiparent recombination,” presented at the 3rd Conf. Parallel Problem Solving Nature. New York, 1994.

[31] Y. K. Kim, Y. H. Kim, and Y. J. Kim, “Two-sided assembly line balancing:

A genetic algorithm approach,” Prod. Plan. Control, vol. 11, no. 1, pp. 44–

53, Jan./Feb. 2000.

[32] E. J. Anderson and M. C. Ferris, “Genetic algorithms for combinatorial

optimization: The assembly line balancing problem,” ORSA J. Comput.,

vol. 6, no. 2, pp. 161–173, 1994.

[33] Y. Y. Leu, L. A. Matheson, and L. P. Rees, “Assembly-line balancing

using genetic algorithms with heuristic-generated initial populations and

multiple evaluation criteria,” Decis. Sci., vol. 25, no. 4, pp. 581–606,

Jul./Aug. 1994.

[34] T. Bäck, “Selective pressure in evolutionary algorithms: A characterization of selection mechanisms,” in Proc. 1st IEEE Conf. Evol. Comput.,

Orlando, FL, 1994, pp. 59–62.

[35] D. E. Goldberg, Genetic Algorithms in Search, Optimization and Machine

Learning. Reading, MA: Addison-Wesley, 1989.

[36] Z. Michalewicz, Genetic Algorithm + Data Structures = Evolution Programs. New York: Springer-Verlag, 1992.

[37] G. Syswerda, “Schele optimization using genetic algorithms,” in Handbook of Genetic Algorithms, L. Davis, Ed. New York: Reinhold, 1991,

pp. 332–349.

[38] T. K. Bhattacharjee and S. Sahu, “A critique of some current assembly

line balancing techniques,” Int. J. Oper. Prod. Manage., vol. 7, no. 6,

pp. 32–43, 1987.

Z. X. Guo received the B.Sc. and M.Sc. degrees in

control theory and control engineering from Donghua

University, Shanghai, China, in 2000 and 2003, respectively. He is currently working toward the Ph.D.

degree at the Institute of Textiles and Clothing, The

Hong Kong Polytechnic University, Hong Kong.

Since 2003, he has been an Assistant Lecturer in

the College of Information Science and Technology,

Donghua University. His current research interests

include production planning and control and intelligent optimization techniques.

W. K. Wong received the Ph.D. degree from the

Institute of Textiles and Clothing, The Hong Kong

Polytechnic University, Kowloon, Hong Kong.

He has been with several southeast Asian countries, specializing in production and quality management, industrial engineering, and productivity improvement. In 1997, he joined The Hong Kong

Polytechnic University, where he is currently an Assistant Professor. He is the author or coauthor of more

than 30 scientific articles published in refereed journals and conference papers. His current research interests include production planning and scheduling, modeling of manufacturing

and management systems, and applications of artificial intelligence techniques

in the apparel manufacturing process.

S. Y. S. Leung received the M.Sc. (Clothing) degree

in advanced manufacture and the Ph.D. degree in supply chain management from Manchester Metropolitan University, Manchester, U.K., 1992 and 1998,

respectively.

He is currently an Assistant Professor at the Institute of Textiles and Clothing, The Hong Kong Polytechnic University, Kowloon, Hong Kong, where he is

also the Deputy Chair of the Departmental Learning

and Teaching Committee and the Deputy Programme

Leader of Fashion and Textile Studies. His current

research interests include discrete event simulation for clothing manufacture,

apparel supply chain management, lean and agile production, application of artificial intelligent techniques in fabric cutting, and utilization of radio-frequency

identification in fashion cross-selling. He has authored or coauthored conference and journal papers in these areas.

J. T. Fan received the B.Sc. degree in textile engineering from China Textile University (now Donghua

University), Shanghai, in 1985, and the Ph.D. degree

in clothing comfort from the University of Leeds,

Leeds, U.K., in 1989.

He is currently a Professor in The Hong Kong

Polytechnic University (PolyU), Kowloon, Hong

Kong, and is well known for his invention of the

world’s first sweating fabric manikin—“Walter,” the

development of the world’s first and largest apparel

knowledge portal (www.apparelkey.com), and his

contribution in clothing science and technology. He has authored or coauthored

extensively with more than 180 academic papers or patents.

Prof. Fan is a Fellow of the Royal Society for the Encouragement of Arts,

Manufacture & Commerce, the Textile Institute, and the Hong Kong Institution

of Textiles and Apparel. He is also the recipient of the 2001 PolyU President’s Award 2001 for his outstanding performance/achievement in research

and scholarly activities, the 2003 Distinguished Achievement Award of the US

Fiber Society, and the Gold Medal Award from the International Invention Exhibition in Geneva in 2004.

S. F. Chan received the M.Sc. degree in fiber science and technology from Leeds University, Leeds,

U.K., in 1978, and the D.B.A. degree in organizational behavior from the Southern Cross University,

Coffs Harbour, Australia, in 2002.

He has worked in the textile and apparel industries

for 17 years. In 1989, he joined The Hong Kong Polytechnic University, Kowloon, Hong Kong, where he

is currently an Assistant Professor. He is experienced

in production scheduling and quality system installation. His current research interests include using

artificial intelligence in scheduling, total quality management, and curriculum

issues.

Dr. Chan is an Associate Member of the Textile Institute, U.K., where he is

currently the Deputy Programme Leader of the M.Sc. in Quality Management.