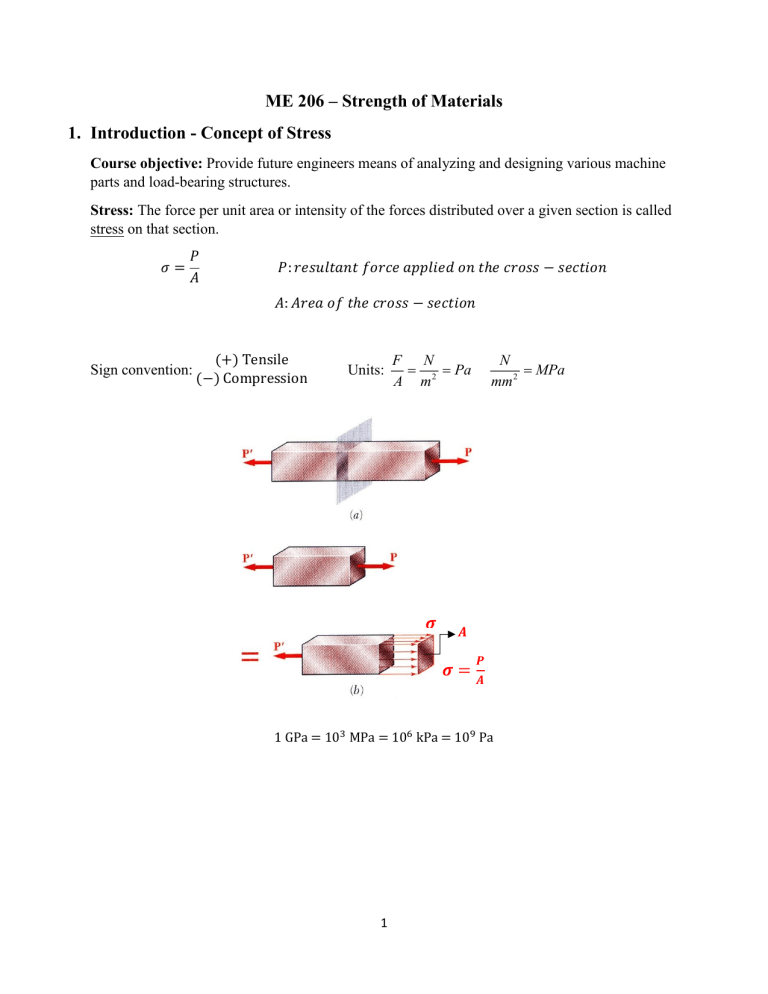

ME 206 – Strength of Materials 1. Introduction - Concept of Stress Course objective: Provide future engineers means of analyzing and designing various machine parts and load-bearing structures. Stress: The force per unit area or intensity of the forces distributed over a given section is called stress on that section. 𝜎= 𝑃 𝐴 𝑃: 𝑟𝑒𝑠𝑢𝑙𝑡𝑎𝑛𝑡 𝑓𝑜𝑟𝑐𝑒 𝑎𝑝𝑝𝑙𝑖𝑒𝑑 𝑜𝑛 𝑡ℎ𝑒 𝑐𝑟𝑜𝑠𝑠 − 𝑠𝑒𝑐𝑡𝑖𝑜𝑛 𝐴: 𝐴𝑟𝑒𝑎 𝑜𝑓 𝑡ℎ𝑒 𝑐𝑟𝑜𝑠𝑠 − 𝑠𝑒𝑐𝑡𝑖𝑜𝑛 Sign convention: (+) Tensile (−) Compression Units: F N = = Pa A m2 𝝈 N = MPa mm 2 𝑨 𝝈= 𝑷 𝑨 1 GPa = 103 MPa = 106 kPa = 109 Pa 1 Type of problems: P (load) and A (area) given → determine σ and choose appropriate material with 𝜎 < 𝜎𝑦𝑖𝑒𝑙𝑑 σ (Stress) and A (area) given → determine the load bearing capacity. σ (Stress) and P (load) given → determine the size of the cross-section (A). Tensile Stress Consider a bar of uniform cross-section that is loaded in tension. If we take a section of this bar, there will be an internal load P to provide the static balance. This internal load will not be a point load, it will be a distribution over the cross section, resulting in stress over the cross section. When the internal load is perpendicular to the cross-section, then stress over this cross-section is called normal stress. In reality, stress can vary with position. Therefore, we can write: 𝑃 = ∫ 𝑑𝐹 = ∫ 𝜎𝑑𝐴 𝐴 𝐴 The stress variation is more significant next to a point load. As you move away from the point load, stress distribution becomes more uniform and gets closer to the average value. In this course, in these type of loading conditions, we will assume uniform stress distribution for simplicity. 𝜎 = 𝜎𝑎𝑣𝑒 = 𝑃 𝐴 In real applications, be careful when analyzing regions close to a concentrated load. 2 𝒅 𝑭 = σ dA 𝒅𝑨 Note that this uniform stress assumption is valid when the line of action of the concentrated load passes through the centroid (geometric center) of the section. In other words, there should not be any bending moment over the cross section that is analyzed. Consider the below example: From the equilibrium of A⸍B, the internal forces at section B are: A M=Pd force P applied at the centroid of the cross-section moment M of magnitude M = Pd. B A⸍ A⸍ The stress distribution has to be equivalent to P and M combined, therefore the stress can no longer be uniform. We will learn how to get the stress distribution in such cases later in the semester. 3 Shear Stress When transverse forces P and P⸍ are applied to a member AB as shown above, the internal force P is parallel to the cross-section. This type of stress is called shear stress. Shear force divided by the area gives the average shear stress: 𝜏𝑎𝑣𝑒 = 𝑃 𝐴 Similar to the above discussion for tensile stress, in reality, τ is not uniform. τ is zero at the surface and it exceeds τave at the center. In this course, we will focus on τave for learning purposes. Shear stresses are commonly found in bolts, pins and rivets used to connect various structural members. Bearing stress Bearing stress is the type of stress that occurs as a result of contact pressure. Bolts, pins, rivets and similar members create these type of stress on the bearing surface of the member in contact. 4 𝜎𝑏 = 𝑃 𝑃 = 𝐴 𝑡×𝑑 𝐴 = 𝑡 × 𝑑: Projected area of the rivet hole Stress on an oblique plane under axial loading In two-force members, axial forces create normal stress whereas in pins and rivets, the transverse forces lead to shear stress. Over an oblique cross-section, both stresses might exist at the same time. Consider the above two-force member subjected to axial forces P. Let’s take a section forming an angle θ with respect to the normal plane and draw the free body diagram of the left part. → 𝐹 : normal force → 𝜎 = 𝐴0 𝐴0 = 𝑐𝑜𝑠 𝜃 → 𝐴𝜃 = 𝐴𝜃 𝑐𝑜𝑠 𝜃 𝑉 = 𝑠𝑖𝑛 𝜃 → 𝑉 = 𝑃 𝑠𝑖𝑛 𝜃 𝑃 Therefore, 𝜎= 𝐹 𝐴𝜃 → 𝑉 : shear force → 𝜏𝑎𝑣𝑒 = 𝐹 = 𝑐𝑜𝑠 𝜃 → 𝐹 = 𝑃 𝑐𝑜𝑠 𝜃 𝑃 𝐹 𝑃 𝑐𝑜𝑠 𝜃 𝑃 = = 𝑐𝑜𝑠 2 𝜃 𝐴0 𝐴𝜃 𝐴0 𝑐𝑜𝑠 𝜃 𝜏𝑎𝑣𝑒 = 𝑉 𝑃 𝑠𝑖𝑛 𝜃 𝑃 = = 𝑐𝑜𝑠 𝜃 𝑠𝑖𝑛 𝜃 𝐴0 𝐴𝜃 𝐴0 𝑐𝑜𝑠 𝜃 For the special cases of 0, 45 and 90 degrees: 𝜃 = 0° → 𝜎 = 𝜎𝑚𝑎𝑥 = 𝑃/𝐴0 𝜃 = 90° → 𝜎 = 0 𝜃 = ±45° → 𝜎 = 𝑃/2𝐴0 𝜏𝑎𝑣𝑒 = 0 𝜏𝑎𝑣𝑒 = 0 𝜏𝑎𝑣𝑒 = 𝑃/2𝐴0 5 𝑉 𝐴𝜃 Stress under general loading conditions: Components of stresses Consider a body subjected to several loads/forces to determine the stress distribution at point Q within the body. First pass a plane parallel to yz-plane that contains point Q. ⃗⃗⃗⃗𝑥 acts perpendicular to the plane containing ∆𝐴 𝛥𝐹 ⃗⃗⃗⃗⃗𝑥 acts parallel to the plane containing ∆𝐴. 𝛥𝑉 𝑥 ⃗⃗⃗⃗⃗𝑥 ⃗⃗⃗⃗⃗ 𝛥𝑉 𝑦 is the component of 𝛥𝑉 along y axis. ⃗⃗⃗⃗⃗𝑥 along z axis. ⃗⃗⃗⃗⃗𝑧𝑥 is the component of 𝛥𝑉 𝛥𝑉 Now, we can write the three stress components generated by these forces: F x x = lim A→ 0 A xy = lim A → 0 xz V y x A Vz x = lim A→ 0 A In subscript xy: x is denotes the normal vector of the surface (first subscript) and y indicates the direction of the stress component (second subscript). 6 Sign Convention Consider a small cube centered at Q with stresses exerted on each face of the cube. Now, cut a section at Q parallel to the xy-plane. From moment equilibrium ∑ 𝑀𝑧 = 0, we find 𝜏𝑥𝑦 ∆𝐴 − 𝜏𝑦𝑥 ∆𝐴 = 0 → 𝜏𝑥𝑦 = 𝜏𝑦𝑥 Similarly, 𝜏𝑦𝑧 = 𝜏𝑧𝑦 and 𝜏𝑥𝑧 = 𝜏𝑧𝑥 Therefore, to define the stress state at a point within a member, we need 6 components. 𝜎𝑥 , 𝜎𝑦 , 𝜎𝑧 : Normal Stresses 𝜏𝑥𝑦 , 𝜏𝑥𝑧 ,𝜏𝑦𝑧 : Shear Stresses 7