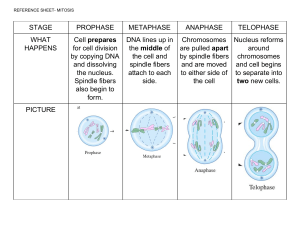

Improved Genetic Algorithm for NC Machine Tool Spindle Design

advertisement

Application of an improved genetic algorithm in the optimization design of NC

machine tool spindle

Zhiwei Xu 1, Yongxian Liu 1, Hualong Xie1 ˈPeng Tian1

1. School of Mechanical Engineering & Automation, Northeastern University, Shenyang 110004, China

E-mail: zhwxu@mail.neu.edu.cn

Abstract: In the optimization design of machine tool spindle, an improved genetic algorithm is proposed in this paper.

Through the analysis of the specific structure of the spindle and the specific force and deformation in the process of

machine tool processing, a mathematical model of the genetic algorithm optimization design of the spindle is established

in accordance with the actual use of the spindle. Genetic algorithm has the advantages of good adaptability and faster

convergence to the optimal solution. The coding methods and genetic operators are improved to compensate for their

limitations. In this paper, a real coded scheme and an improved genetic operator are adopted to optimize the structural

design of the spindle. This paper introduces the main steps and process optimization design, through the example of CNC

machine tool spindle design of Shenyang Machine Tool Co. Ltd. The experimental data show that the method can

quickly find the global optimal solution and verify the feasibility and practicality of the method.

Key Words: genetic algorithmχMachine spindleχoptimal designχCAD system

1 INTRODUCTION

Optimization design is an important research field in

modern mechanical design theory and method.

Optimization design can not only reduce the weight of

mechanical products, decrease the manufacturing cost, but

also improve the quality and performance of the products.

The optimal design method is to use the mathematical

programming method to set the optimal design parameters

on the computer, so that the design index can reach the

optimal value under the given design parameters and

restriction condition.

In the mechanical optimization design, the genetic

algorithm is an adaptive heuristic global search algorithm,

which has the incomparable advantages of the traditional

algorithm, and is easier to solve various optimization

problems. Chakraborthy [1] et al. takes the fatigue life as the

optimization objective function and uses the genetic

algorithm to describe the design optimization of a rolling

bearing with five design parameters. They have obtained the

geometrical parameters inside the bearing from different

boundary dimensions. Due to the limitation of the

traditional genetic algorithm, such as: slow solution in

genetic algorithm, strong reliance on coding scheme and

inferior robustness of the algorithm, etc., some modification

need to be made, which has become a hot issue in genetic

algorithm research.Li Gongfang [2] et al. combined the

global search ability of genetic algorithm with local search

ability of chaos optimization, and then proposed a chaos

genetic algorithm which has fast convergence speed and

high precision. GuanQi Ming [3], with the aim to optimize

the lightest weight of the machine tool spindle, used neural

network instead of finite element structural approximate

This work is supported by Science and Technology Project of Liaoning

Province under Grant No. 2011216010

c

978-1-5386-1243-9/18/$31.00 2018

IEEE

analysis. Genetic algorithm is adopted in his work to solve

the optimal mathematical model, and the structural

optimization design of the spindle is carried out. The

experimental results show that the method is a better method

for optimization.

Spindle is one of the core components of machine tools, and

its performance has a decisive impact on the processing

quality and production efficiency. How to reduce its volume

and mass, how to increase its stiffness and improve its

ability to transfer torque are the main objectives of the

optimization design of the main axis of the machine tool. In

this paper, an improved genetic algorithm is used to

optimize the spindle of CNC machine tool.

2 OPTIMIZATION DESIGN MODEL

SPINDLE OF MACHINE TOOL

OF

A spindle is generally a hollow stepped shaft. In the process

of optimizing the structure parameters of the spindle, the

stepped shaft is simplified into a uniform shaft with

equivalent diameter. The structural analysis and

optimization design is carried out by the discretization

processing and the selecting appropriate optimization

design method

2.1 Design Variable

A design can be represented by a set of basic parameters,

such as the length of the component, the size of the section,

the weight of the component, etc.. The optimal design of a

specific problem can be expressed as a column vector[4]:

X = [ x1 , x 2 , x3 , " , x n ]T

In the optimization design, the n-dimensional vector space

described by the coordinate axis of each design variable is

called the design space, and one point of the design space is

a design scheme.

4361

According to the above theory, the design variables of the

multi-support machine tool with concentrated force and

torque are designed with the inner diameter dimension G, the

outer diameter dimension D and the length of each section

of the shaft L as the design variable [L L = Q , n is

the number of design variables of the model. As shown in

figure 1.Therefore, the optimum design variable of spindle

is:

In the design of machine tool spindle, according to the

design requirements, and the working condition and load

condition of spindle, maximum stiffness and minimum

volume are the target of design. This can not only meet the

requirements of the spindle drive, but also can reduce

weight, save material and reduce cost. Fig. 2 is a simplified

drawing of the main axle load

If I [ is used as a function to reflect the spindle stiffness,

; = >G '' " ' Q // " /P @7

and I [ is a function that reflects the spindle volume, then

the objective function of the spindle optimization can be

expressed as:

I [ = ωI [ + ωI [

㸦1㸧

where, ω ࠊ ω are weighting factors, which reflect the

importance

of

each

sub

objective

function.

I [

Fig.1 The spindle structure

N =

2.2 Object Function N =

The objective function is the function relation between the

optimal target and the variable that the design problem is to

be achieved. The function relation which can make the

design optimization is also the evaluation criterion of

comparing the merits of the design scheme, so it is also

called

the

evaluation

function,

denoted

as

I [ or ) [ ,which is to emphasize its dependence on

design variables, such as life, weight, price, etc. The

objective function can be written as:

I [ = I [ [ [ " [ Q

For multi-objective functions, n objective functions can be

listed independently:

I [ = I [ [ [ " [ Q

I [ = I [ [ [ " [ Q

#

#

IQ [ = IQ [ [ [ " [ Q

To convers the multi-objective problem into a

single-objective problem a comprehensive objective

function expression can be established

Q

I [ =

ω IM [

¦

M

L

=

N + N )D /

(, D

,

I [

=

¦

π

' L − G

× /L

+

D

)

N D

> + $

+

+

N$

N % /

/

Where, K1 indicates the bending deformation of the spindle

itself at the end of the shaft

K2 represents the displacement of the spindle end caused by

the deformation of the bearing

F is the cutting force

N $ is the stiffness of the front support

N % is the stiffness of the rear support

Therefore, the objective function can be expressed as:

I [ = ω

)D /

)

N D D

+ + > + $ +

+ @

(, D

N$

N% /

/

+ ω ¦

π

'L − G × /L

(2)

In the design of machine tool spindle, according to the

design requirement of spindle, the constraints are divided

into static constraints and dynamic constraints. The static

constraints includes cutting force deflection constraint,

strength constraint, angle constraint, torsion deformation

constraint and design variables boundary constraint;

dynamic constraint includes first order vibration frequency

constraints and so on.

=

where, ωL is the weighting factor of item M 㸪 it is a

nonnegative real number, whose value is chosen according

to the importance of the index in the optimization design.

3 OPTIMIZATION DESIGN PROCEDURES

In accordance with the mathematical model of the optimal

design of the spindle established above, the fitness function

of the genetic algorithm is constructed. According to the

practical problems, the appropriate coding method is

selected to improve the corresponding genetic operators,

and then the optimization design of the spindle is carried out

based on the improved genetic algorithm.

3.1 Chromosome Encoding

Fig.2 The simplified diagram of spindle load

4362

The standard genetic algorithm uses binary encoding.

Binary encoding is the genetic space that maps the solution

of the original problem into 0 and 1 encoding strings.

Through the calculation of the fitness function the suitable

The 30th Chinese Control and Decision Conference (2018 CCDC)

solution is found when the fitness of the individual reaches a

given threshold, and then the decoding process is reduced to

the solution of the actual problem. Real number coding is

using real numbers directly to encode the solution of the

problem. It is a direct natural description of the continuous

parameter optimization problem, and there is no encoding

and decoding process. In a real coded case, a real parameter

vector corresponds to a chromosome, a real number

corresponds to a gene, and a real value corresponds to an

allele.

Real coding eliminates the hidden trouble that due to

insufficient coding accuracy possible solutions that have

better fitness values but fail to represent in the search space.

The real coded genetic algorithm has the ability to make use

of the gradient of continuous variable functions. In addition,

real coded encoding can eliminate the Hamming cliff in

binary coding.

3.2 Produce Initial Population

The vector ; .M is used to represent the design variable

vectors corresponding to the gene chain of the j-th

individuals in the K-th generation group, and the random

real numbers are generated by the UDQGYDO functions in

MS VC++6.0 between RAND_MIN and RAND_MAX.

void GA::initialize()

{

double lbound[11];

double ubound[11];

for (i = 0; i < NVARS; i++) // Initialization variable gene

{

for (j = 0; j < POPSIZE; j++)

{

population[j].fitness = 0;

population[j].rfitness = 0;

population[j].cfitness = 0;

population[j].lower[i] = lbound[i];

population[j].upper[i]= ubound[i];

population[j].gene[i] =

randval(population[j].lower[i],population[j].upper[i]) ;

// The initial population is randomly generated in the

interval of design variables

}

}

}

The function UDQGYDO generates [min, max] random

floating numbers which fill individuals gene chains one by

one. The random number generated by UDQGYDO is

uniformly distributed between [min, max], so that the

original population is produced throughout the solution

space.

the next generation, while individuals with lower fitness are

less likely to pass on to the next generation. It is important to

establish an adaptive evaluation function HYDOXDWH [ . The

evaluation of the individual's advantages and disadvantages

is to obtain the function value H M of the adaptive

evaluation function HYDOXDWH [ of each individual. The

evaluation criteria for each individual are as follows: the

greater the fitness value, the better the vector ; M of the

design variable.

In this paper, the penalty function is used to transform the

constrained optimization problem into the penalty function

of unconstrained optimization problem, and the constrained

optimization problem is transformed into an unconstrained

problem. For individuals who do not meet the constraint

conditions, a small fitness value is given, and the

corresponding adaptive evaluation function is:

HYDOXDWH ; = I ; + S ;

Where , S ; is a penalty function.

Penalty function method belongs to the indirect method to

solve the problem of optimization, In genetic algorithms,

the number of infeasible solutions in the iteration is limited

by adding penalty terms to the fitness function, at the same

time the amount of non feasible solutions are allowed in

order to preserve the excellent individuals and the diversity

of the population.

In the static penalty function method, the number of

penalty factor parameters is very large, and the choice of

parameters has a great impact on the search efficiency. At

the same time, the value of the appropriate penalty factor

will change with the evolution process.Therefore, the static

penalty factor can not guarantee that the search is feasible.

This paper chooses the dynamic penalty function method to

deal with the constraint problem.

The dynamic penalty function method can dynamically

adjust the penalty factor as it evolves, and its penalty

function is written as㸸

S ; = FW

α

P

J Mβ ;

¦

M

㸦3㸧

=

Where , t is for evolutionary algebra, usually F = 㸪

α = β = ࠋ

Therefore, the fitness function of the spindle of the machine

tool can be constructed as follows:

HYDOXDWH [ = I [ + S [

= ω

ω

N D D

)D /

)

+ +

>+ $

+

+ @

(, D

N$

N % /

/

π

¦ 'L

− G × /L + FW α

+

(4)

P

J Mβ ;

¦

M

=

3.4 Operation of Genetic Operators

3.3 Construct the Fitness Function

The probability of a genetic algorithm that is proportional to

individual fitness determines how many individuals in the

current population are inherited to the next generation.

Individuals with higher fitness are more likely to pass on to

3.4.1 Selection Operator

Proportional Model is a playback random sampling method.

The basic idea is that the probability that each individual is

selected is proportional to its fitness size. The idea of

The 30th Chinese Control and Decision Conference (2018 CCDC)

4363

optimal preservation strategy is to copy the individuals with

the highest fitness in the group to the next generation

without pairing and crossing.

The combination of these two methods can ensure that the

optimal individuals are not destroyed by genetic operations

such as crossover and mutation. At the same time, the global

search ability of the algorithm is not deteriorated, so as to

avoid gene loss, improve global convergence and

computational efficiency.

3.4.2 Crossover Operator

In genetic algorithms, individuals need to be paired in a

group before cross computing. The commonly used pairing

strategy is a random pairing, in which M individuals in a

group form M/2 pairs of paired individuals in a random way,

and crossover is performed between two individuals in these

paired individuals.

The way chromosome coding directly affects the design of

crossover operators. For real coded chromosomes, the

arithmetic crossover method can be used. It is a linear

combination of two individuals producing two new

individuals. Therefore, this paper chooses the dynamic

arithmetic crossover method, and its main operation is:

1 to determine the coefficients of a linear combination of

two individuals.

2 to produce new individuals in a linear combination.

If two individuals make arithmetic intersections

between ; LW

and ; MW , the two new individuals generated after the

Initialization

Initial population

generation

Calculating initial

population

Fitness value

Does it satisfy the

stopping criteria?

Yes, decoding

optimum

solution

no

Elite proportional

selection operation

crossover operation are:

Dynamic arithmetic

cross operation

­; W + = α; W + − α

M

° L

®

W +

°̄; M

= α; LW + − α

Uniform mutation

operation

; LW

; MW

Where , α is a variable determined by the number of

evolutionary generations

3.4.3 Mutation Operator

The operation of uniform mutation is to replace the random

numbers in a certain range and replace the original gene

value in each locus of the individual coding string with a

smaller probability. The uniform mutation method makes

the search points can move freely in the entire search space,

so it can increase the diversity of the population; In the

meanwhile, uniform mutation method is generally for the

real number encoding, so the method of uniform mutation is

adopted in this paper.

3.5 The Implementation of Genetic Algorithm

The operation flow of the genetic algorithm is shown in

figure 3. The specific implementation steps are as follows:

First step, the initial population is randomly generated, and

the number of individuals is certain, and each individual is

coded as a real number system of chromosomes;

Second step , calculate the fitness of the individual and

determine whether it conforms to the optimization criteria.

If the output is in line with the optimal individual and the

4364

optimal solution represented, it will be finished; otherwise,

proceed to the third steps;

Third step 㸪the optimal selection strategy and fitness ratio

selection method are adopted to select the regenerative

individual according to the fitness;

Fourth step, a new individual is generated according to a

certain crossover probability and dynamic arithmetic

crossover;

Fifth step , generate new individuals according to the

probability of variation and the method of uniform

variation;

Sixth step, a new generation of population produced by

crossover and mutation, returns to the second step.

Calculating new

populations

Fitness value

Fig.3 The procedure of Genetic algorithm

4 OPTIMIZATION DESIGN EXAMPLE

4.1 Optimization Calculation of Machine Tools

Taking SSCK40-750 machine tool developed by Shenyang

Machine Tool Co., Ltd. as an example, the optimization

design based on improved genetic algorithm is carried out.

The main motor power SSCK40-750 type machine, the

minimum speed UPLQ = U PLQ , the main cutting force

(perpendicular to the plate) ) = 1 , side cutting

force ) = × ) = 1 (radial force, parallel and

slide), feed force ) = × ) = 1 ,

torque 0 = 1 ⋅ PP , Poisson's ratio ν = ,

Young's modulus ( = × ,

density ρ = × − NJ PP .

The spindle structure of the machine tool is shown in Figure

1.

The 30th Chinese Control and Decision Conference (2018 CCDC)

According to formula (1), the optimum design variable of

this machine tool spindle is

; = >G ' ' ' ' ' // / / / @7

According to the formula (2), the objective function of the

optimal design of the spindle of the model machine is:

I [ = ω

+ ω

π

¦

N D

)D /

)

D

+ +

+

+ @

> + $

N$

N % /

/

(, D

D

)D /

)

N D

+ +

> + $

+

+ @ is the

Where,

(, D

N$

N % /

/

rigidity of the spindle of this type of machine tool.

π

¦

L

'L − G

=

Initial

value

/mm

Optimization

value /mm

L

HYDOXDWH [ = I [ + S [

N D

)D /

)

D

+ +

+

+ @

> + $

(, D

N$

N % /

/

+ ω

Optimized

parameter

is the spindle volume of this type of

× /L

machine tool

/ = / + / , D = / + / + /

According to the formula (4), the fitness function of

constructing the corresponding genetic algorithm is:

= ω

Table 1 The contrast diagram between optimization of data

and original data

' L − G × /L

L =

The maximum evolutionary algebra is selected

MAXGENS = 500. The optimized design of the spindle is

carried out by using the improved genetic algorithm in this

paper, and the optimized results are shown in Table 1.

The maximum evolutionary generation value is chosed

MAXGENS=500. The optimization design of the spindle is

carried out by using the improved genetic algorithm in this

paper, and the optimization result is given by table 1.

π

¦

L

' L − G × /L + FW

=

α

Optimized

parameter

Initial

value

/mm

Optimization

value /mm

d

65

70

L1

62

65

D1

95

90

L2

35

39

D2

100

98

L3

42

44

D3

103

102

L4

105

106

D4

105

103

L5

188

187

D5

110

107

In order to verify the static and dynamic characteristics of

the optimized spindle, it is necessary to establish a finite

element analysis model of the optimized spindle, and

perform corresponding performance analysis, as shown in

Figure 4.

¦ J Mβ ;

M

=

Where , J M [ is a constraint function

4.2 Result Analysis

The number of design variables of the spindle is 11,

considering the quality and efficiency of genetic

optimization. Therefore, the population size POPSIZE =

100 is selected. In order to increase the new crossover

probability in the process of genetic optimization, the

crossover probability is PXOVER = 0.8;To improve the

diversity of groups on the basis of the evolution of groups to

prevent the loss of important information, so select the

mutation probability is PMUTATION = 0.15;

Table 1 is the spindle design parameters optimized before

and after optimization of the comparative data. After

optimization, the stiffness is increased by 6.8% and the

volume is reduced by 4.3% .It can be seen that the

optimization effect is obvious after the optimization design,

which shows the feasibility and superiority of this method.

At the same time, through the example design and the result

analysis, it also shows that the machine tool spindle

structure designed by the optimized design method is more

reasonable, which fully shows the benefit and application

value of the genetic algorithm in the optimization design of

the machine tool spindle components.

REFERENCES

[1]

[2]

[3]

[4]

[5]

I. Chakraborthy, K. Vinay, S.B. Nair, R. Tiwari, Rolling

element bearing design through genetic algorithms,

Engineering Optimisation 35 (6) (2003) 649-659.

Li Hongfang. Chaotic genetic algorithm and structural

optimization design, [D], Tianjin University, 2004

Guan Qiming, Yin Jian, Li Yi, et al. Implementation of

genetic algorithm for optimal design of dynamic

characteristics of machine tool spindle. Journal of Guizhou

University of Technology (NATURAL SCIENCE

EDITION), Vol. second, thirty-third: February, 85-882004

Shen Liang. CAD expert system for helical gear design -genetic algorithm optimization design [D], 2004

Shantanu Gupta, Rajiv Tiwari, Shivashankar B. Nair,

Multi-objective design optimisation of rolling bearings using

genetic algorithms, Mechanism and Machine Theory, 2007

Fig. 4 Cloud chart of displacement

The 30th Chinese Control and Decision Conference (2018 CCDC)

4365