STL261S Assignment 1 Stress and strain & Torsion of Shafts 2021(1)

advertisement

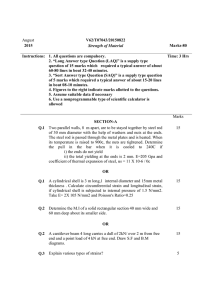

ENGINEERING FACULTY DEPARTMENT OF MECHANICAL ENGINEERING COURSE: National Diploma in Mechanical Engineering (D3MCHE) SUBJECT: STRENGTH OF MATERIALS II - STL261S Assignment 1: Stress & Strain and Torsion of Shafts DATE: 04 May 2021 DUE DATE: 18 May 2021 WEIGHTING: 20% EXAMINER: MODERATOR: M. LUDICK………………………………… S. MAKHOMO / W. BOSHOFF……………………. INSTRUCTIONS 1. 2. 3. 4. 5. 6. 7. DOCUMENT TO BE TYPED OR NEATLY HANDWRITTEN. NO LATE SUBMISSIONS WILL BE ACCEPTED. DRAW SKETCHES TO ASSIST IN SOLVING THE PROBLEMS. DRAWINGS MUST BE DONE IN PENCIL. CALCULATIONS CAN BE TYPED OR HANDWRITTEN NEATLY IN INK (BLUE \ BLACK) ONLY. YOU MAY WORK INDIVIDUALLY OR IN GROUPS OF UP TO FIVE (5) MEMBERS MAXIMUM. ANY FORM OF COPYING WILL RESULT IN ALL INVOLVED GROUPS TO GET ZERO MARKS! SURNAME & INITIALS STUDENT NUMBER 1………………………………… …………………………………….. 2………………………………… …………………………………….. 3………………………………… …………………………………….. 4………………………………… …………………………………….. 5………………………………… …………………………………….. STL261S – Assignment 1: Stress & strain and Torsion of Circular Shafts Question 1 A bicycle chain consists of a series of small links, where each is 12 mm long between the centres of the pins (see figure). You might have to observe a bicycle chain and observe its construction. The pedal crank arm has a length L = 162 mm centre to centre as shown and the sprocket (toothed gearwheel) radius R = 90 mm. 1.1 1.2 Calculate the tensile force T in the chain due to a force F = 800 N applied to one of the pedals. /4/ Calculate the average shear stress τ in the pins. /6/ [10] Question 2 A force P of 70 N is applied by a rider (cyclist) to the front handbrake of his bicycle. (P is the resultant of an evenly distributed hand pressure). As the handbrake pivots at A, a tension T develops in the 460 mm long brake cable (cross-sectional area = 1.075 mm2), which elongates by 0.214mm. 2.1 Determine the stress in the cable. /3/ 2.2 Determine the strain in the cable. /2/ 2.3 Determine the modulus of elasticity of the cable. /3/ 2.4 What material is used to manufacture the cable? Motivate your answer. /2/ [10] Question 3 A uniform beam, 1 metre long, is suspended in a horizontal position by two vertical support rods as shown in the figure below. Rod A has a diameter of 12 mm and manufactured from steel with Esteel = 200GPa. Rod B has a diameter of 16 mm and is made from copper with Ecopper = 100 GPa. This simply supported beam is to carry a motor vehicle engine and gearbox weighing 10 kN. 3.1 Determine the distance ‘x’ from the left-hand support ‘A’ in order for the beam to remain in a horizontal position. /7/ 3.2 Calculate the stress in each rod due to the applied load. /4/ 3.3 Calculate the movement (extension) of the support wires under this 10 kN load. /2/ 3.4 Will the rods be able to withstand the applied load? Motivate your answer. /2/ 500 mm 300 mm A B x 10 kN 1000 mm [15] Question 4 Two solid shafts, 50 mm in diameter, are connected by a rigid flange coupling. The coupling has a pitch circle diameter of 95 mm and the coupling bolt diameter is 11 mm. The bolts and the shafts are to have the same maximum shear stress. 4.1 Calculate the number of bolts required. /4/ 4.2 If the maximum working shear stress is limited to 55 MPa, calculate the maximum power that can be transmitted by the coupling at 700 r/min. /4/ 4.3 If the overall angle of twist is not to exceed 10, what must be the length of the shaft assembly? (Ignore the effects of the coupling). /2/ [10] Question 5 A transmission shaft has gears attached to it and is subjected to the torques as shown below. The shaft has a diameter of 40 mm and is made from steel with G = 80 GPa. 5.1 Calculate the maximum shear stress in the shaft. . 5.2 Determine the angle of twist of end B with respect to end A. /10/ /5/ [15] TOTAL = [60] STL261S: Stress & Strain and Torsion MARKING CRITERIA – 2021: Assignment 1 1.1 1.2 2.1 2.2 2.3 2.4 Question 1 Tensile force T Shear stress τ 4 6 Question 2 Stress in cable Strain in cable ECable Cable material Motivation 3 2 3 1 1 Question 3 3.1 3.2 3.3 3.4 x - distance Stress in each rod Wire extension Δl Load carrying capability of rods Motivation 7 4 2 1 1 Question 4 4.1 4.2 4.3 No. of Bolts Max Power transmitted Overall shaft assembly length 4 4 2 5.1 5.2 Question 5 Max shear stress τ in shaft Overall angle of twist θ 10 5 Graduate Attribute GA1 Problem solving TOTAL % 5 65