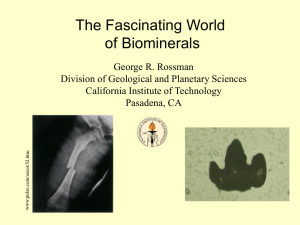

J Inorg Organomet Polym (2017) 27:1014–1021 DOI 10.1007/s10904-017-0549-1 Can Spherical Vaterite Be Biomimetic Synthesized by Using Histidine-Grafted-Chitosan as an Organic Matrix? Zhangxu Chen1 · Xianxue Li1 · Bingyun Zheng1 Received: 6 March 2017 / Accepted: 13 April 2017 / Published online: 18 April 2017 © Springer Science+Business Media New York 2017 Abstract Extensive application of vaterite in ceramics, biomedical implanting, encapsulation and drug delivery require the effectively controlling the size, morphology and polymorph of the obtained calcium carbonate. For this purpose, vaterite was synthesized by using histidine-graftedchitosan (NHCS) as an organic matrix in this research. The effects of the initial concentration of NHCS, and the aging time on the morphology and polymorph were investigated. The prepared vaterite was characterized by fieldemission scanning electron microscope, Fourier transform infrared spectrometer and X-ray diffraction. The result showed vaterite has presented as an advantage phase over calcite phase in presence of NHCS system, and the 91.6 Electronic Supplementary Material The online version of this article (doi:10.1007/s10904-017-0549-1) contains supplementary material, which is available to authorized users. * Zhangxu Chen xuzhangchen@163.com 1 Fujian Provincial Key Laboratory of Ecology‑Toxicological Effects & Control for Emerging Contaminants, College of Environmental and Biological Engineering, Putian University, Putian 351100, Fujian, People’s Republic of China 13 Vol:.(1234567890) wt% percentage of vaterite can be achieved when the initial concentration of NHCS is 1.000 mg ­L−1. Prolonging aging time from 0 to 24 h, the percentage of vaterite would be deduced from 94.4 to 86.2 wt%, in which the flaky-floret and multilayered vaterite transforms to calcite slowly. In contrast, a single crystalline rhombohedral calcite phase can only be obtained without adding NHCS in pure water system. The possible growth mechanism has been proposed by investigating the transition of crystal phase and formation of the vaterite during the growth process. The result indicates that NHCS is an effective template to biomimetic synthesis of vaterite, and provides a novel method for controlling synthesis other biomaterials. J Inorg Organomet Polym (2017) 27:1014–1021 1015 Graphical Abstract Molecular Recognition Electrostatic Interaction NHCS Formation Nucleus CO3 2- (a) 0h (b) (c) (d) Aggreation DissolutionReprecipitation DissolutionReprecipitation DissolutionReprecipitation Limited Growth Limited Growth Limited Growth (i) (h) Ca2+ CO32- Keywords Vaterite · Biomimetic synthesis · Histidinegrafted-chitosan · Template · Initial concentration · Aging time 1 Introduction Biomineralization and related bio-related processes are multifactorial, fantastic and complex processes that often become a nice guide for fabrication of functional materials and keys for understanding of biophenomena [1–3]. Biomineralization process can be effectively for biomimetic synthesis of vaterite, which plays an important role in biomedical implanting, encapsulation and drug delivery because it exhibits unique properties, such as higher dispersion, higher solubility, and smaller specific gravity than aragonite and calcite [4–6]. As is well known, calcite, aragonite and vaterite are the three common anhydrous polymorphic forms of calcium carbonate, and the thermodynamic stability decreases from calcite, aragonite to vaterite. Therefore, there is a big challenge to preparation of sole vaterite minerals in aqueous phases [7]. Up to date, mineralization of vaterite with various strategy has been studied. Among these, stable vaterite crystals biomimetic synthesized in presence of organic matrix, such as poly(lactic acid) [8], dopamine [9], phospholipids [10], dendrimers [6, 11], sodium bis-2-ethylhexyl-sulfosuccinate [12], protein [13], silk [14], chitosan [15–17] and amino acid [18–23] have been reported. In organic phases, organic matrix plays important roles in preventing the transformation to stable calcite. It is worthwhile to mention that both chitosan and amino acid have been independently used as organic matrix for biomimetic synthesis vaterite [18–23]. However, a clear understanding of the fundamental processes controlling the specific crystallization of calcium carbonate is still lacking. Ripening 1h 6h 12 h 24 h 0.5 h (g) NHCS (f) Calcite (e) Vaterite Especially, the mechanism and kinetics of sole vaterite phase or coexistence of vaterite–calcite phases remain a longstanding challenge in biomimetic synthesis. To approach these problems, histidine-grafted-chitosan (NHCS) can be used as a matrix for biomimetic synthesis of vaterite. In our previous research, histidine was used to modify chitosan with 1-(3-dimethylamino propyl)-3-ethyl carbodiimide hydrochloride and N-hydroxysuccinimide for preparation of NHCS powers in order to improve the solubility of chitosan and expend its application over it’s wide pH range. Furthermore, effect of the pH value on the morphology and polymorph of calcium carbonate, and mechanism of formation and stabilization at different pH values in the presence of NHCS were investigated [24]. As expected, NHCS is an effective template and pH responsive for biomimetic synthesis of vaterite. In order to supplement preparation parameters of biomimetic synthesis vaterite in presence of NHCS for providing a novel method to synthesize other biomaterials, the effects of the initial concentration of NHCS, and the aging time on the morphology and polymorph of calcium carbonate are investigated in this manuscript. The possible growth mechanism of crystal phase and formation of the vaterite during the growth process (altering aging time) has been proposed, which might provide a novel method for controlling synthesis other biomaterials. 2 Experimental Section 2.1 Materials Histidine-grafted-chitosan powder (NHCS) is synthesized according to our previously report (Supplementary Fig. S1 and Fig. S2). Sodium carbonate ­ (Na2CO3), absolute ethanol ­(C2H5OH), calcium chloride ­(CaCl2) and ammonia 13 1016 J Inorg Organomet Polym (2017) 27:1014–1021 ­(NH3·H2O) are all of analytical reagent and are purchased from Sinopharm Chemical Reagent Co., Ltd. (China). 2.2 Method of Preparing Calcium Carbonate Crystals in Absence or Presence of NHCS The calcium carbonate crystals were obtained in pure water system [24]. In a typical synthesis, 20.00 mL of ­CaCl2 (0.10 mol L−1) was adjusted to 7.0 using ammonia with constant stirring. Then, 20.00 mL of N ­ a2CO3 (0.10 mol L−1) solution was drop wise added into the above solution at room temperature, stirred for 10 min and aged for 1.0 h. Finally, the obtained white precipitates were separated by centrifugation, rinsed several times with double distilled water and absolute ethanol, respectively, and then dried under vacuum oven until a constant weight is achieved. The as-synthesized product was denoted sample 0 (S0). To investigate the effect of NHCS on the crystallization of calcium carbonate, different samples (S1–S4, S5–S9) were prepared by using histidine-grafted-chitosan as a matrix at different initial concentration of NHCS and aging time by following the same procedures of sample 0 (S0) except that ­CaCl2 solution was replaced with NHCS/CaCl2 aqueous solutions. In detail, firstly, a series of solutions of different concentrations of NHCS (0.125, 0.250, 0.500 and 1.000 mg L−1) were prepared at 25.0 °C and pH of 7.0. Second, the different aging times of 0, 0.5, 1, 6, 12 and 24 h were applied respectively. The detailed preparation parameters were listed in the Table 1. 2.3 Characterization of 1 wt% in KBr powder) were performed and recorded with a Fourier transform infrared spectrometer (BRUKER TENSON 27, Germany) between 4000 and 400 cm−1 with a resolution of 4 cm−1. The X-ray diffraction (XRD) patterns were obtained on SmartLab 3 kW, X-ray diffractometer (Rigaku, Japan) using Cu Kα radiation at a scan rate of 4° min−1 was used to determine the identity of crystalline phase. The accelerating voltage and applied current were 30 kV and 40 mA, respectively. 3 Results and Discussion 3.1 Influence of NHCS Concentration on Calcium Carbonate Figures 1 and 2 presented the infrared spectra and XRD patterns of the calcium carbonate crystals (S0–S4) produced with different initial concentration of NHCS (0, 0.125, 0.250, 0.500 and 1.000 mg L−1) at 25.0 °C for aging 1 h, respectively. As well known, band assignment for FTIR of calcium carbonate polymorphs was well established [25–27]. These absorption bands correspond to symmetric C–O stretching mode ­ (v1), ­CO32− out-of-plane bending mode ­ (v2), doubly degenerated asymmetric C–O stretching mode ­(v3) and doubly degenerated in-plane OCO deformation bending mode ­ (v4). The spectral region between 2000 and 600 cm−1 was selected for qualitative analysis, because of severe peak overlapping of the different polymorphs of calcium carbonate in other spectral regions [28, 29]. As a The sizes and morphologies of calcium carbonate crystals were investigated by FESEM (NovaNanoSEM230, American). Calibrated pellets of calcium carbonate (in proportion b c Table 1 Preparation conditions of calcium carbonate products with sample names d Sample name Initial concentration of NHCS (mg L−1) Temperature Aging time (h) e S0 S1 S2 S3 S4 S5 S6 S7 S8 S9 0 0.125 0.250 0.500 1.000 0.250 0.250 0.250 0.250 0.250 25.0 25.0 25.0 25.0 25.0 25.0 25.0 25.0 25.0 25.0 1.0 1.0 1.0 1.0 1.0 0.0 0.5 6.0 12.0 24.0 13 745 712 876 2000 1800 1600 1400 1200 1000 800 600 -1 Wavenuber/ cm Fig. 1 FT-IR spectra of calcium carbonate particles biomimetic synthesized with different initial concentration of NHCS for aging time 1 h (a 0, b 0.125 mg L−1, c 0.250 mg L−1, d 0.500 mg L−1, e 1.000 mg L−1) 1017 C018 C116 C202 C110 C113 C 113 V 114 a C 110 C006 V 112 V 110 C 012 C012 C104 J Inorg Organomet Polym (2017) 27:1014–1021 b c d e 20 30 40 50 60 70 2-Theta /degrees Fig. 2 XRD patterns of calcium carbonate particles biomimetic synthesized with different initial concentration of NHCS for aging time 1 h (a 0, b 0.125 mg L−1, c 0.250 mg L−1, d 0.500 mg L−1, e 1.000 mg L−1) Table 2 Weight percentages of different polymorphs of calcium carbonate in presence (or absence) of NHCS Sample name Vaterite (%) Calcite (%) S0 S1 S2 S3 S4 S5 S6 S7 S8 S9 0 61.8 89.2 91.4 91.6 94.4 93.5 87.9 86.8 86.2 100.0 38.2 10.8 8.6 8.4 5.6 6.5 12.1 13.2 13.8 of NHCS remarkably increased, which was favorable to the growth of vaterite. In addition, the higher of the initial concentration of NHCS, the more vaterite amounts present, and the higher intensity ratio of bands at 746 and 712 cm−1 (I746/I712) responded in FTIR spectrum of the obtained calcium carbonate. The same observation can also be found by XRD analysis. The diffraction peaks occurred at 2θ = 23.0°, 29.4°, 39.4° and 47.5°, corresponding to calcite crystal face (012), (104), (113) and (018), respectively (JCPDS No. 05-0586). It indicated that calcite was also formed with different initial concentration of NHCS. Compared with S0 obtained in pure water (initial concentration of NHCS is 0, Fig. 2a), the new diffraction peaks occurred at 2θ = 24.9°, 27.0°, 32.8° and 43.8°, corresponding to vaterite crystal face (110), (112), (114) and (300), respectively (JCPDS No. 33-0268), showed that vaterite phase can be prepared (S1–S4 in Fig. 2b–e) at different initial concentration of NHCS. With increasing the initial concentration of NHCS, the intensity of the (104) face diffraction peak of calcite reduced quickly, but the intensity of the (110) face diffraction peak of vaterite increased gradually. The relative amounts of the polymorphic composition were calculated from the relative areas of the vaterite (110) and calcite (104) by using Kontoyannis equation [33] and were presented in Table 2. It can be seen that the percentage of vaterite (with the remainder being calcite) in S0–S4 were ca. 0 wt%, 61.8, 89.2, 91.4 and 91.6%, respectively. It is clear that the content of vaterite can be controlled by varying the dosage of NHCS. It increases from 61.8 to 91.6 wt% when the initial concentration of NHCS changes from 0.125 to 1.000 mg L−1. These results are in agreement with those obtained by FTIR. The above results suggest that NHCS is an effective organic matrix to biomimetic synthesis of vaterite. 3.2 Influence of Aging Time on Calcium Carbonate evident from Fig. 1, the sample 0 (S0) prepared in pure water system only showed three characteristic bands for calcite, ­v2 at 876 cm−1, ­v3 at 1435 cm−1 and ­v4 at 712 cm−1. Increasing the dosage of NHCS of 0.125, 0.250, 0.500 and 1.000 mg L−1 (S1, S2, S3 and S4), ­v2 at 876 cm−1, overlapping of vaterite and calcite absorption bands can be observed, but new bands of ­ v4 at 746 cm−1, ­v1 at −1 −1 1090 cm , ­v3 at 1450 cm corresponding to vaterite also appeared [30–32]. This confirmed that NHCS is an effective template to biomimetic synthesis of vaterite. It can be explained as following: –OH and –COO− groups of NHCS can chelate ­Ca2+ to form ­Ca2+-NHCS structure, in which ­Ca2+ can further attract C ­ O32− ions by electrostatic interaction. As a result, the number of nucleus on the surface In order to study the effect of aging time on the morphology and polymorph of calcium carbonate in presence of NHCS at the same initial concentration of NHCS (0.250 mg L−1). Different samples (S5, S6, S2, S7–S9) were prepared in presence of NHCS at different aging times of 0, 0.5, 1, 6, 12 and 24 h, respectively. Figures 3, 4 and 5 show the infrared spectra, XRD patterns and FESEM images of the as-prepared samples (S5, S6, S2, S7–S9) obtained by using histidine-grafted-chitosan as an organic matrix at different aging times, respectively. As shown from Fig. 3, the calcite characteristic bands of ­v2 at 876 cm−1 and v­4 at 712 cm−1 appeared in the above samples. Also, vaterite characteristic bands of ­v4 at 746 cm−1, ­v1 at 1090 cm−1, ­v3 at 1450 cm−1 can be 13 1018 J Inorg Organomet Polym (2017) 27:1014–1021 a b c d e f 876 2000 1800 1600 1400 1200 1000 Wavenumber /cm-1 746 712 800 600 V300 V114 V110 V112 V104 Fig. 3 FT-IR spectra of calcium carbonate particles obtained by using NHCS as an organic matrix at different aging times (a 0 h, b 0.5 h, c 1 h, d 6 h, e 12 h, f 24 h) b C113 C012 a c d e f 20 30 40 50 60 70 2-Theta /degrees Fig. 4 XRD patterns of calcium carbonate particles obtained by using NHCS as an organic matrix at different aging times (a 0 h, b 0.5 h, c 1 h, d 6 h, e 12 h, f 24 h, C calcite, V vaterite) observed. The different ratios of vaterite to calcite formed at different aging times can be indicated from I746/I712 too. Compared with S0 obtained without addition of NHCS (S0 in Fig. 2a), vaterite phase can be successfully achieved. with NHCS as an organic matrix It is found that vaterite is the major crystal phase of calcium carbonate (S5, S6, S2, S7–S9 in Fig. 4) at different aging times with the representative crystal face for vaterite. In presence of NHCS system, the diffraction peak intensity of the (104) face of calcite increased gradually with the prolonging of the aging time. 13 To certify the ratio changes of vaterite and calcite, the percentage of each polymorph obtained at different aging times was calculated by using Kontoyannis equation [33] and are showed in Table 2. As can be seen, the percentage of vaterite in S5, S6, S2, and S7–S9 at different times are ca. 94.4, 93.5, 89.2, 87.9, 86.8 and 86.2 wt% at different aging times of 0, 0.5, 1, 6, 12 and 24 h, respectively. It is clear that the percentage of vaterite was affected by varying aging time. It decreases from 94.4 to 86.2 wt% after 24 h, in which a nearly constant percentage of vaterite was attained. In Fig. 5, FESEM images of the calcium carbonate particles obtained at various aging times clearly showed the growth process of the calcite and vaterite. The crystal phases of calcium carbonate evolved in presence of NHCS are obviously different from those in pure water system (Supplementary Fig. S3). Sole calcite particles were formed with morphologies of stacked rhombohedral in pure water system. In contrast, when NHCS was added in the medium, the as-prepared particles eventually exhibited unusual mixture of calcium carbonate with rhombohedral morphologies and spherical morphologies. When the aging time was 0 h, “flaky-floret” and multilayered calcium carbonate particles (S5, Fig. 5a) were observed with diameters and thicknesses of about 1.0–2.5 and 0.1–2.2 μm, respectively. Increasing the aging time from 0 to 0.5 h, the morphology of obtained calcium carbonate particles (S6, Fig. 5b) was similar to S5. Besides flaky-floret and multilayered crystallites, the rhombohedral calcium carbonate of about 1.9 μm × 1.9 μm × 1.9 μm in size appeared. It is worthwhile to note that the amount of multilayered crystallites decreased in this stage. With the aging time extended, the “flaky-floret” or multilayered structure disappeared completely. More and more rhombohedral calcium carbonate are obtained (S2, Fig. 5c). Meanwhile, the sizes of spherical and rhombohedral particles increased with the increase of aging time from 1.0 to 6.0 h (S7, Fig. 5d), and some spherical particles embedded in the rhombohedral ones. Aging for 12.0 h would lead to the decrease of spherical calcium carbonate, but the increase of rhombohedral calcium carbonate, which can be seen in (Fig. 5e). As the time prolonging up to 24.0 h, the morphology of the calcium carbonate tended to be stabilized (S9, Fig. 5f), rhombohedral like calcium carbonate with an average length of 4.0 μm was obtained. From the Table 2, indicated from the XRD data, large percentage of vaterite were all obtained in the as-prepared samples. It is reasonable to assign that calcite is with rhombohedral morphologies and vaterite is with flaky-floret, multilayered structure and spherical eventually. The similar results can also be found in the reported researches [34, 35]. The growth process of the stacked rhombohedral calcite and microspherical vaterite can be J Inorg Organomet Polym (2017) 27:1014–1021 1019 Fig. 5 FESEM images of calcium carbonate particles obtained by using NHCS as an organic matrix at different aging times (a 0 h, b 0.5 h, c 1 h, d 6 h, e 12 h, f 24 h, the scale bar is 500 nm) explained by Ostwald ripening mechanism [36]. Lengthening the aging time introduced the decrease of spherical like calcium carbonate, but the increase of rhombohedral like calcium carbonate. Moreover, the content of the vaterite in the obtained calcium carbonate decreases, and part of the vaterite begins to dissolve and transfer to calcite. Therefore, it indicates that NHCS is a good matrix to control biomimetic synthesis of vaterite by using it as soft template within aging time of 24 h. 4 Proposed Mechanism of Vaterite A possible illustration is proposed in Fig. 6 for the the transition of crystal phase and formation of the vaterite at different aging times. As shown, the mechanism of “molecular recognition”–“electrostatic interaction”–“formation nuc leus”–“aggregation”–“ripening”–“dissolution-reprecipitation–limited growth” is proposed to explain the development of crystal phases and formation of the vaterite during 13 1020 J Inorg Organomet Polym (2017) 27:1014–1021 Molecular Recognition Electrostatic Interaction NHCS Formation Nucleus CO3 2- (a) 0h (b) (c) (d) Aggreation DissolutionReprecipitation DissolutionReprecipitation DissolutionReprecipitation Limited Growth Limited Growth Limited Growth (i) (h) Ca2+ CO32- Ripening 1h 6h 12 h 24 h 0.5 h (g) NHCS (f) Calcite (e) Vaterite Fig. 6 Schematic sequence illustrating the transition of crystal phase and formation of the vaterite at different aging times the growth process. First, the pI of NHCS is 6.54 (Supplementary Fig. S4). In addition, the pKa of chitosan is 6.30 and the pKa of active-center histidine imidazole group is 6.00 [37, 38]. When the pH value of NHCS system is 7.0 (pH > pI(NHCS)), deprotonation of hydroxyl group, imidazole group and amino groups leads to the whole NHCS carrying with negative charges (−10.8 mV) [24], this presents that a specific interaction does exist between NHCS and calcium ions. As a result, NHCS can capture and collect ­Ca2+ ion from ­CaCl2 solution (Fig. 6a) by molecular recognition (Fig. 6b), which leads to the enrichment of ­Ca2+ near the surface of NHCS. Meanwhile, these calcium ions can further attract more ­CO32− ions by electrostatic interaction, thus remarkably increasing the number of nucleus (Fig. 6c). The increase of the degree of supersaturation favors the nucleation of precipitation according to the Gibbs–Thomson formula of classical nucleation theory [39]: (1) where J and S are the nucleation rate and degree of supersaturation, respectively, and both A and B are constants. According to the Eq. (1), nucleation rate increases along with the increase of supersaturation degree [32]. Thus, as NHCS is added into ­CaCl2 solution, numerous nucleuses will form in the supersaturation zone on the surface of NHCS. High supersaturation on NHCS leads to increase of the nucleation rate as well as the nucleation number. These nucleuses then grow into nanoflakes and nanolayers rapidly. Large amount of crystal nucleus will facilitate the formation of nanoflakes and nanolayers and the refinement of precipitation. Due to their high surface energy, the nanoflakes and nanolayers have the tendency to aggregate. Consequently, the “flaky-floret” or multilayered J = A exp −B(ln S)−2 13 particles by nanoflakes and nanolayers are observed in Fig. 5a in the initial stage (at aging time 0 h, Figs. 5a, 6d). As time progresses (aging time 0.5 h), these metastable vaterite phase bounded by NHCS aggregate continuously into “spherical-like” vaterite particles. On the other hand, those crystal nucleuses unbounded by NHCS or its surface grows into rhombohedral calcite phase (Figs. 5b, 6e). With the aging time going, metastable vaterite can transform into calcite through a solvent-mediate process [40]. Considering Ostwald ripening mechanism [36] and the solubility products of the different polymorphs (vaterite, 1.22 × 10−8 M2; aragonite, 4.61 × 10−9 M2; calcite, 3.31 × 10−9 M2 at 25 °C, respectively) [41], the phase transformation of vaterite to calcite is a thermodynamically feasible process. Thus, the “dissolution-reprecipitation-limited growth” will take place and the metastable vaterite particles begin to dissolve as aging time progresses (Fig. 6f). After aging for 1.0 h, the dissolved particles reprecipitated again and its surface is adsorbed by NHCS molecular, so the initial crude “flakyfloret” or multilayered vaterite disappeared completely during ripening. It is worth noting that lots of crude elliptical or spherical vaterite structures are formed by the reprecipitated particles and get more smooth and regular, and the crystallite size of the metastable vaterite structures is making up of large crude spherulites increased from ~100 nm to ~2 μm. Meanwhile, those unbounded crystal nucleuses lead to the simultaneous growth of few rhombohedral calcite phase (Figs. 5c, 6f). In summary, morphology and polymorph of the coexistence of vaterite-calcite is controlled by NHCS and leads to limited growth near the surface of NHCS. On the other hand, coexistence of vaterite–calcite growth is controlled by Ostwald ripening to keep the thermodynamics and dissolve dynamic balance in NHCS system (Figs. 5d–f, 6g–i). The NHCS molecule plays an J Inorg Organomet Polym (2017) 27:1014–1021 important role in the formation and stabilization of vaterite within aging time of 24 h. 5 Conclusion The sole rhombohedral calcite is easily obtained in pure water system, while spherial vaterite phase can be obtained and can be relatively stable in presence of NHCS system. Various morphologies of vaterite can be obtained by using organic matrix of NHCS, such as “flaky-floret”, multilayered and crude spherical structures. As the aging time progresses to 24 h, the percentage of vaterite reaches 86.2 wt%. The spherical vaterite can be biomimetic synthesized by using histidine-grafted-chitosan as an organic matrix. Acknowledgements This work is supported by the National Science Foundation of China (21103095, 21206079), Fujian Provincial Natural Science Foundation (2015J01057, 2015J01644, 2017J01590, 2017J01710), Scientific Research Plan of Education Bureau of Fujian Province (JAT160431), Projects of Putian University (2015060, 2016015, 2016065). References 1. Z.T. Wang, P. Huang, O. Jacobson, Z. Wang, Y.J. Liu, L.S. Lin, J. Lin, N. Lu, H.M. Zhang, R. Tian, G. Niu, G. Liu, X.Y. Chen, ACS Nano 10, 3453–3460 (2016) 2. M. Okaniwa, Y. Oaki, H. Imai, Bull. Chem. Soc. Jpn. 88, 1459– 1465 (2015) 3. E. Firlar, T. Perez-Gonzalez, A. Olszewska, D. Faivre, T. Prozorov, J. Mater. Res. 31, 547–555 (2016) 4. A. Sarkar, S. Mahapatra, J. Mater. Chem. A 2, 3808–3818 (2014) 5. D.B. Trushina, T.V. Bukreeva, M.V. Kovalchuk, M.N. Antipina, Mater. Sci. Eng. C 45, 644–658 (2014) 6. J.R. Lakkakula, R. Kurapati, I. Tynga, H. Abrahamse, A.M. Raichur, R.W.M. Krause, RSC Adv. 106, 104537–104548 (2016) 7. E.G. Stephen, Geochim. Cosmochim. Acta 67, 1659–1666 (2003) 8. T. Kasuga, A. Obata, H. Maeda, Y. Ota, X.F. Yao, K. Oribe, J. Mater. Sci. 23, 2349–2357 (2012) 9. S. Kim, C.B. Park, Langmuir 26, 14730–14736 (2010) 10. J.W. Xiao, Z.N. Wang, Y.C. Tang, S.H. Yang, Langmuir 6, 4977–4983 (2010) 11. D.B. Trushina, T.V. Bukreeva, M.V. Kovalchuk, M.N. Antipina, Mater. Sci. Eng. C 45, 644–658 (2014) 12. B. Yang, Z.D. Nan, Mater. Res. Bull. 47, 521–526 (2012) 13. A. Sergeeva, R. Sergeev, E. Lengert, A. Zakharevich, B. Parakhonskiy, D. Gorin, S. Sergeev, D. Volodkin, ACS Appl. Mater. Interface 7, 21315–22325 (2015) 1021 14. L.J. Liu, X.L. Zhang, X. Liu, J. Liu, G.Z. Lu, D.L. Kaplan, H.S. Zhu, Q. Lu, ACS Appl. Mater. Interface 7, 1735–1745 (2015) 15. J.W. Xiao, Y.C. Zhu, Y.Y. Liu, H.J. Liu, Y. Zeng, F.F. Xu, L.Z. Wang, Cryst. Growth Des. 8, 2887–2891 (2008) 16. D.Z. Yang, K. Yu, Y.F. Ai, H.P. Zhen, J. Nie, J.F. Kennedy, Carbohydr. Polym. 84, 990–996 (2011) 17. X.D. Chen, M.H. Xin, M.C. Li, Z.X. Chen, Z.Q. Chen, Chin. J. Mater. Res. 30, 31–37 (2016) 18. A.J. Xie, Y.H. Shen, C.Y. Zhang, Z.W. Yuan, X.M. Zhu, Y.M. Yang, J. Cryst. Growth 285, 436–443 (2005) 19. P. Krattiger, N. Nassif, A. Volkel, Y. Mastai, H. Wennemers, H. Cölfen, Colloids Surf. A 354, 218–225 (2010) 20. B. Njegic-Dzakula, G. Falini, L. Brecevic, Z. Skoko, D. Kralj, J. Colloid Interface Sci. 343, 553–563 (2010) 21. M.A. Hood, K. Landfester, R. Mun˜oz-Espı′, Cryst. Growth Des. 14, 1077–1085 (2014) 22. H. Lu, M.A. Hood, S. Mauri, J.E. Baio, M. Bonn, R. MuñozEspí, T. Weidner, Chem. Commun. 51, 15902–15905 (2015) 23. Y.H. Lai, L.S. Chen, W.C. Bao, Y.H. Ren, Y.X. Gao, Y.W. Yin, Y.F. Zhao, Cryst. Growth Des. 15, 1194–1200 (2015) 24. Z.X. Chen, M.H. Xin, M.C. Li, J.P. Xu, X.X. Li, X.D. Chen, J. Cryst. Growth 404, 107–115 (2014) 25. C.E. Weir, E.R. Lippincott, J. Res. Natl. Bur. Stand. 65A, 173– 183 (1961) 26. B. Schrader, D. Bougeard (eds.), Infrared and Raman spectroscopy (VCH, Weinheim, New York, 1995) 27. N.V. Vagenas, A. Gatsouli, C.G. Kontoyannis, Talanta 59, 831– 836 (2003) 28. S. Gopi, V.K. Subramanian, K. Palanisamy, Mater. Res. Bull. 48, 1906–1912 (2013) 29. R. Ševčík, M. Pérez-Estébanez, A. Viani, P. Šašek, P. Mácová, Powder Technol. 284, 265–271 (2015) 30. T. Siva, S. Muralidharan, S. Sathiyanarayanan, E. Manikandan, M. Jayachandran, J. Inorg. Organomet. Polym. (2017). doi:10.1007/s10904-017-0520-1 31. V. Kumar, A. Dev, A.P. Gupta, Composites 56, 184–188 (2014) 32. I. Polowczyk, A. Bastrzyk, T. Kozlecki, Physicochem. Probl. Miner. Process. 49, 631–639 (2013) 33. C.G. Kontoyannis, N.V. Vagenas, Analyst 125, 251–255 (2000) 34. N. Feoktistova, J. Rose, V.Z. Prokopović, A.S. Vikulina, A. Skirtach, D. Volodkin, Langmuir 32, 4229–4238 (2016) 35. E. Tolba, W.E.G Müller, B.M.A. Elhady, M. Neufurth, F. Wurm, S.F. Wang, H.C. Schrödera, X.H. Wang, J. Mater. Chem. B 4, 376–386 (2016) 36. H. Zhang, J.F. Banfield, J. Phys. Chem. Lett. 3, 2882–2886 (2012) 37. S.R. Payne, M. Heppenstall-Butler, M.F. Butler, Cryst. Growth Des. 7, 1262–1276 (2007) 38. J.Y. Wang, Biochemistry (China Higher Education Press, Beijing, 2008) 39. P. Wan, Y. Zhao, H. Tong, Z.Y. Yang, Z.H. Zhu, X.Y. Shen, J.M. Hu, Mater. Sci. Eng. C 29, 222–227 (2009) 40. Y.L. Su, H.R. Yang, W.X. Shi, H.X. Guo, Y. Zhao, D. Wang, Colloid Surf. A 355, 158–162 (2010) 41. A. Sarkar, S. Mahapatra, Cryst. Growth Des. 10, 2129–2135 (2010) 13