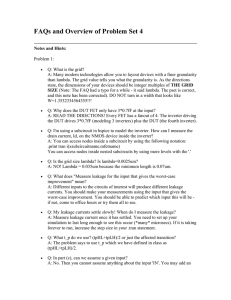

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/252022890 Indigenous development of medical electrical safety analyzer Article · May 2011 DOI: 10.1109/MeMeA.2011.5966675 CITATIONS READS 3 1,452 3 authors, including: K. Jiju Niranjan Khambete Centre for Development of Advanced Computing Deenanath Mangeshkar Hospital and Research Centre, Pune 6 PUBLICATIONS 26 CITATIONS 14 PUBLICATIONS 67 CITATIONS SEE PROFILE SEE PROFILE Some of the authors of this publication are also working on these related projects: Sleep studies View project Design and Development of Single-Phase/ Three-Phase Smart Energy Meters for Indian Power Network View project All content following this page was uploaded by K. Jiju on 11 May 2015. The user has requested enhancement of the downloaded file. Indigenous Development of Medical Electrical Safety Analyzer Jiju. K Power Electronics Group, CDAC-T Thiruvananthapuram, India jijuk@cdactvm.in Dr. Niranjan D. Khambatte Instrumentation Laboratory, SCTIMST Thiruvananthapuram, India niranjan.d.khambete@gmail.com Sreekumari. B Power Electronics Group, CDAC -T Thiruvananthapuram, India sreekumarib@cdactvm.in Abstract—In order to achieve the required high level of electrical safety of electro-medical equipment, regulatory bodies worldwide have developed standards and guidelines to control their design as well as their use in hospitals and other health care delivery settings. It is highly essential that periodic preventive maintenance and electrical safety checks on all electro-medical equipment in use be carried out and records of these be maintained. International standard for routine testing of medical equipments at hospitals and clinics is International Electro technical Commission (IEC) 62353[1]. This paper deals with the design and development of an indigenous Medical Electrical Safety Analyzer, which will conduct safety tests as per this standard. The safety tests like Earth bond test, Leakage current and Insulation tests to be conducted as per the standard are also discussed. Keywords- Medical Electrical Safety Analyzer, IEC 62353 I. INTRODUCTION Electrical Safety is one of the most important parameters of electro-medical equipment. The manufacturer of such equipment would design, fabricate, and test their equipment as per the International standards (IEC 60601) or Indian Standards (IS 13450) and obtain certification from appropriate regulatory agencies before supplying the equipment to the hospitals. The standards and guidelines also strongly recommend that hospital administration carry out inspection and electrical safety testing on all the incoming equipment to rule out any damage during transit that might compromise safety. In future use, the equipment can become unsafe due to deterioration of insulation either accidentally or through normal weathering process of the material. Therefore, in order to assess the level of electrical safety of the equipment, it is essential that hospital staff carries out periodic safety testing on all the electro-medical equipment (EME) in use. In May 2007, IEC has published a safety standard for the periodic testing of medical equipments in hospitals. This standard is termed as IEC 62353. Clinical engineers or testing agencies can effectively and conveniently carry out this task using a handy and portable Electrical Safety Analyser (ESA). This general safety for medical electrical equipment is necessary because of the particular relationship of such equipment to the patient, the operator and the surroundings. 978-1-4244-9338-8/11/$26.00 ©2011 IEEE The following aspects play an important role in this relationship: i. The inability of patient or operator to detect the presence of certain potential hazards, such as ionizing or high frequency radiation ii. Absence of normal protection to currents provided by the patient's skin, if this is penetrated or treated to obtain a low skin resistance iii. Absence of normal reactions of the patient who may be ill, unconscious, anaesthetized, immobilized etc iv. Support or replacement of vital body functions may depend on the reliability of the equipment. v. The simultaneous connection to the patient of more than one piece of equipment. vi. Combination of high power equipment and sensitive low-signal equipment often in ad-hoc combinations. vii. The application of electric circuits directly to the human body, either through contacts to the skin and/or through the insertion of probes into internal organs. viii. Environmental conditions, particularly in operating theaters, may present a combination of humidity, moisture and/or fire hazards caused by air, oxygen or nitrous oxide combined with anesthetic media and cleaning agents. II. CLASSIFICATION OF MEDICAL EQUIPMENT A. According to the type of protection against electric shock a) Equipment energized from an external electrical power source: i. Class I equipment: - Equipment protection against electric shock by additional protection to basic insulation through means of connecting exposed conductive parts to the protective earth in the fixed wiring of the installation. ii. Class II equipment: - Equipment in which protection against electric shock does not rely on basic insulation only, but in which additional safety precautions such as double insulation or reinforced insulation are provided, there being no provision for protective earth or reliance upon installation conditions. b) Internally powered equipment. B. According to the degree of protection against electric shock i. Type B equipment: - Equipment providing a particular degree of protection against electric shock, particularly regarding allowable leakage current and reliability of the protective earth connection ii. Type BF equipment: - Type B equipment with floating type applied part (F-type applied part) iii. Type CF equipment: - Equipment providing a degree of protection higher than that of BF equipment against electric shock particularly regarding allowable leakage currents, and having an F- type applied part. Equipment intended for direct cardiac applications shall be of CF type III. TESTS ACCORDING TO IEC 62353 The main tests to be conducted are i. Earth bond test ii. Insulation resistance measurement iii. Leakage current measurements Earth bond test : This tests the integrity of the low resistance connection between the earth conductor and any metal conductive parts, which may become live in case of a fault on CLASS I medical devices. The normal resistance value is in milliohms. A constant current signal is applied to the Device Under Test (DUT) for this test. Insulation resistance measurement : Measures the insulation resistance between the mains and various points of the medical equipment, which may come into contact with patient/user.The normal range is in megohms. A test signal of 500 volt DC is applied to the DUT. be shoted and an equivalent voltage generated by the analyzer will be connected as prescribed in the standard. For all these tests different categories are there and all together 23 tests can be done with the system. IV. PASS/FAIL LIMITS OF IEC 62353 The pass fail limits of the standard are provided below. TABLE I. PASS/FAIL LIMITS OF IEC 62353 Earth bond resistance measurement Equipments with non-detachable power cord 0.3 Ω Equipments with detachable power cord 0.2 Ω Insulation resistance measurement Insulation resistance in all Should be > 0.1 M Ω measurements Leakage current measurement (RMS in mA) Equipment Type Type B Type BF Applied Applied Part Part Equipment Leakage – Alternative method Type CF Applied Part Class 1 1 1 1 equipment Class 2 0.5 0.5 0.5 equipment Equipment Leakage – Direct or differential method Class 1 0.5 0.5 equipment Class 2 0.1 0.1 equipment Patient Leakage current – Alternative method 0.5 0.1 Class 1 & 2 0.05 Patient Leakage current – Direct method 0.05 Class 1 & 2 0.05 0.05 V. PRINCIPLE OF OPERATION The equipment under test is to be connected to the analyzer and the test parameters are measured by applying test signals, according to the standard. Leakage current measurement : Measures the leakage current passing through the earth conducter or the patient connections. The normal range values are in milli/micro amperes. As per standerd the system can test different leakage currents in different conditions, they are Direct method: Measures true leakage that would occur whilst the medical equipment is in typical use, this will give highest accuracy on low leakage current measurement. The DUT will be powered ON from mains through the analyzer. Differential method: Measures the total leakage current and DUT does not need to be isolated during measurement. The DUT will be powered ON from mains through the analyzer and the measurement is taken as the difference between line and neutral currents. Alternative method: This test provide highest safety for person doing the test. Here the supply inputs of the DUT will DUT ESA Figure 1. Connection between Device Under Test (DUT) and Electrical Safety Analyzer During safety testing the DUT is to be powered from the analyzer. All patient leads should also be connected, in order to measure the leakage currents. The analyzer conducts tests either manually or automatically and displays the results for each test. All test signals are generated by the analyzer and applied to the DUT and measurements are taken from the corresponding test points. VI. SYSTEM DESIGN & ARCHITECTURE The developed system having mainly three parts, they are power supply module, a controller PCB and a Relay PCB. The controller used is PIC microcontroller. Various relays are used to apply test signals required for the tests and to take measurements from the corresponding points. The measurements are done with a digital multi meter IC having 22000 counts resolution. The microcontroller interface with the measurement circuits is through a serial data link, by which it can accept the measured data for processing. The user interface is through an LCD/Keypad combination or through a PC. The test voltages are generated by the power circuits according to the requirements of the standard. Figure 3. Block diagram of Controller PCB Signal amplifier & Gain controller: This circuit amplifies low voltage sine wave generated by programmable wave form generator and its gain is controlled. CPLD & Relay driver: To reduce the hardware volume and for the design flexibility the digital logic circuits are implemented with a 100 pin CPLD chip. Darlington Transistor Array drivers are used for driving relays. Instrumentation circuit: A high accurate (22000 counts resolution) digital multi meter IC used in measurements circuit. Figure 2. System architecture of Medical Electrical safety Analyzer Figure.2 shows how the medical electrical safety analyzer is implemented. The power supply module generates the supply voltages for the PCBs. The relay PCB contains various relays for applying the input signals and for measurement of parameters from different points. The controller PCB contains the PIC microcontroller and its associated circuits. The LCD/Keypad interface enables the user to select the tests and view the measurements, test pass/fail status etc. The PC/Laptop interface provides data logging to record the test results of various equipments through USB. A Bluetooth interface is provided for remote operation by Mobile/ PDA. A test probe can be connected to touch the DUT parts as and when required for various tests. Figure 3 shows the functional block diagram of controller PCB. PIC18F4550 is the brain of the system. The controller PCB is having six other functional modules as given below. Communication drivers: It contains serial communication drivers and its related circuitry for TTL to RS232C conversion. Sine wave generator: It is a programmable wave form generator based circuit configured to produce 50Hz sine wave. Figure 4. Block diagram of Relay PCB Figure 4 briefly explains the main functional blocks in Relay PCB, having the following circuit modules Constant current source: This will generate a constant current above 200mA for Earth Bond test. Current sensor: A Hall Effect current sensor is used for high accuracy measurement of leakage current. Rectifier: A bridge rectifier is used for generating 500VDC for insulation measurement. Body model: It is the electrical equivalent of human body as per IEC standard. Power amplifier: Class AB power amplifier used for power amplification of sine wave. Transformer: It is a low frequency step-up transformer to boost sine wave voltage to generate 250VAC and 500VDC. VII. TEST SIGNALS GENERATION i. 12V, 210 mA for Earth bond test (Constant current source). ii. 500 V DC, 0.1 mA for Insulation resistance measurement. iii. 250 V AC, 50Hz for leakage current measurement (Alternative method) communication algorithms. It also handle data processing and manipulation. VIII. MEAUREMENTS The measurements are taken from various points of the DUT according to the test requirements. For measuring leakage currents, a human body model (MD) is required and its electrical equivalent circuit is shown in Figure 5 R1 Z C1 R2 V Voltage Measuring Instrument R1 = 10kΩ ± 5%, R2 = 1kΩ ± 5%, C1 = 0.015μF ± 5% Figure 5. IEC Body Model (1kΩ) Figure 7. A typical test configuration for measuring applied part leakage current using direct method is shown in Figure 6. Controller software algorithm X. FEATURES i. Referred standard : IEC 62353 ii. Measurement resolution : 22000 counts iii. User interface : Graphical LCD and keypad iv. Other optional interfaces : USB and Bluetooth v. Utility software supporting OS : Windows and Linux XI. Figure 6. Measuring circuit for the measurement of Applied Part Leakage Current for Class I - Direct Method Appropriate combinations of relays are switched under the control of software for applying the input signals and for taking measurements from the DUT, as per the requirements of each and every test. IX. PERFORMANCE ANALYSIS The proto models of the system are tested and evaluated against IEC 62353 standard requirements in a national accreditation laboratory. Measurements are compared with those taken by a high precision standard (Agilent U1252A) digital multi-meter, having resolution of 50000 counts. This comparison will show the accuracy of developed Medical Electrical Safety Analyzer in measurements. CONTROL SOFTWARE The embedded software developed with C language in MPLAB IDE with Microchip’s C18 compiler. PC side graphical user interface is developed with C# in Microsoft Visual studio 2008 for windows and Glade GUI tool for Linux. For in-circuit programming of the CPLD, Altera’s Quartus II 9.0 IDE is used. Figure 6 shows the simple flow of controller software. It is written in C language and compiled with Microchip’s C18 compiler. This software contains LCD, USB and other serial TABLE II. MEASUREMENT COMPARISON Developed system Standard DMM Earth Bond Resistance (Ω) 0.3933 0.390 0.5624 0.560 6.9920 6.790 Equipment Leakage Current (Alternative method) in mA 0.0086 0.009 0.7861 0.803 2.4880 2.500 Equipment Leakage Current (Direct method) in mA 0.0067 0.007 1.7970 1.815 9.0500 9.200 Equipment Leakage Current (Differential method) in mA 0.0172 0.018 0.8331 0.846 4.3750 4.480 Figure 11. Medical Electrical Safety Analyzer Figure 12. DUT and user interface connection points Applied Part Leakage Current (Alternative & Direct method) in mA 0.0095 0.010 0.1159 0.117 2.6470 2.520 Insulation Resistance ( kΩ) 49.850 51.24 273.10 276.0 2711.0 2643 XII. PHOTOS Figure 13. System connected with a medical equipment XIII. CONCLUSION Figure 8. Controller PCB Through this development an indigenous model of the portable medical elecrtical safety analyser is made first time in India. Internationally, only very few test equipments based on IEC62353 standards are available. Bluetooth connectivity for mobile applications is an added feature. The price of the system is much less than that of imported equivalents. This will enable hospitals in developing countries to buy and do the routine electrical safety testing of medical equipments, thus reducing the hazards for patients, physicians and other clinical staff. REFERENCES Figure 9. Relay PCB [1] [2] [3] [4] [5] [6] Figure 10. Inernal view of safety analyzer unit View publication stats International Electrotechnical Commission “International Standard IEC 62353” First edition 2007-05 A.F.G. Taktak, M.C. Brown, “Evidence based analysis of field testing of medical electrical equipment” Proceedings of the 28th IEEE EMBS Annual International Conference New York City, USA, Aug 30-Sept 3, 2006 John Backes, Rigel Medical, “ A practical Guide to IEC 62353” Bapco, “ Electrical safety made easy” Hasan Al-Nashash, “Electrical safety of medical equipment” Frans Provoost, Sjef Cobben, Eindhoven University of Technology, Jeroen van Waes, Holland Railconsult, Maarten van Riet, Nuon Technical Projects and Consultancy, Lex van Deursen, Eindhoven University of Technology, “Aspects on grounding”, www.leonardoenergy.org, April, 2004