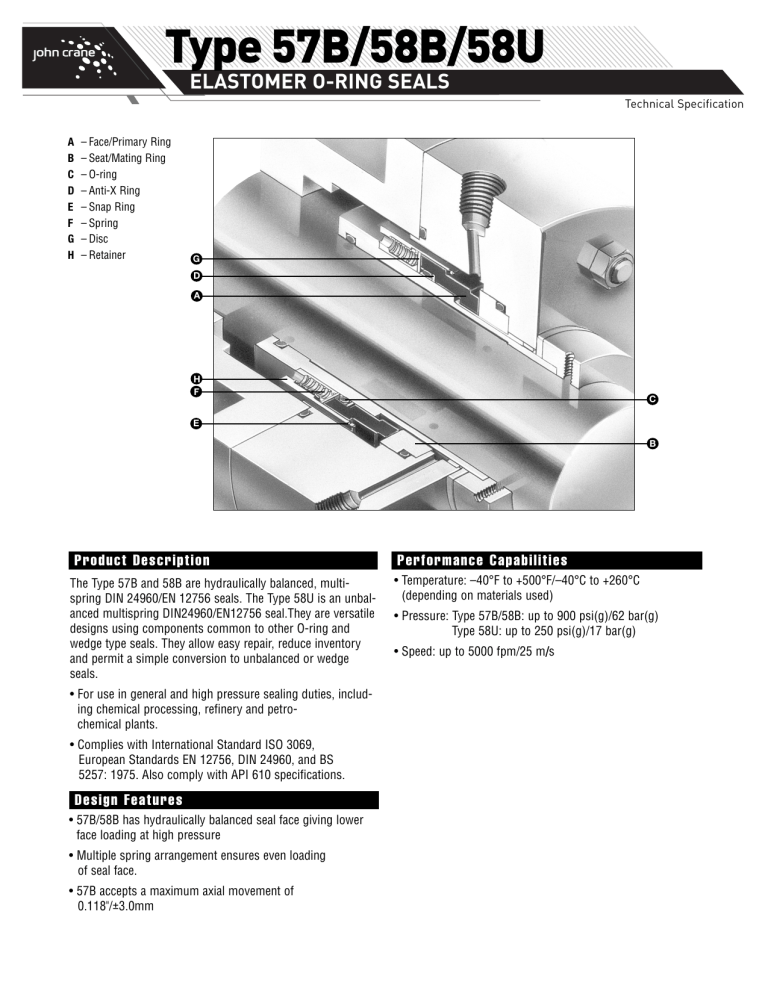

Type 57B/58B/58U ELASTOMER O-RING SEALS Technical Specification A B C D E F G H – Face/Primary Ring – Seat/Mating Ring – O-ring – Anti-X Ring – Snap Ring – Spring – Disc – Retainer G D A H F C E B Product Description The Type 57B and 58B are hydraulically balanced, multispring DIN 24960/EN 12756 seals. The Type 58U is an unbalanced multispring DIN24960/EN12756 seal.They are versatile designs using components common to other O-ring and wedge type seals. They allow easy repair, reduce inventory and permit a simple conversion to unbalanced or wedge seals. • For use in general and high pressure sealing duties, including chemical processing, refinery and petrochemical plants. • Complies with International Standard ISO 3069, European Standards EN 12756, DIN 24960, and BS 5257: 1975. Also comply with API 610 specifications. Design Features • 57B/58B has hydraulically balanced seal face giving lower face loading at high pressure • Multiple spring arrangement ensures even loading of seal face. • 57B accepts a maximum axial movement of 0.118"/±3.0mm Performance Capabilities • Temperature: –40°F to +500°F/–40°C to +260°C (depending on materials used) • Pressure: Type 57B/58B: up to 900 psi(g)/62 bar(g) Type 58U: up to 250 psi(g)/17 bar(g) • Speed: up to 5000 fpm/25 m/s Type 57B/58B/58U ELASTOMER O-RING SEALS Technical Specification Type 58U Typical Arrangement For ease of installation, the lead-in edge of the shaft or sleeve should be chamfered as shown. D3 D4 D1 L3 Alternative method of drive. Pin to be press fit in driving collar or impeller, and to engage in seal retainer as shown. L1K* Type 58U Dimensional Data (mm) Seal Size (mm) 14 16 18 20 22 24 25 28 30 32 33 35 38 40 43 45 48 50 53 55 58 60 63 65 68 70 75 80 85 90 95 100 Seal Size Code 0140 0160 0180 0200 0220 0240 0250 0280 0300 0320 0330 0350 0380 0400 0430 0450 0480 0500 0530 0550 0580 0600 0630 0650 0680 0700 0750 0800 0850 0900 0950 1000 D1h6 14 16 18 20 22 24 25 28 30 32 33 35 38 40 43 45 48 50 53 55 58 60 63 65 68 70 75 80 85 90 95 100 D3 24 26 32 34 36 38 39 42 44 46 47 49 54 56 59 61 64 66 69 71 78 80 83 85 88 90 95 104 109 114 119 124 D4 26 28 34 36 38 40 41 44 46 48 49 51 58 60 63 65 68 70 73 75 83 85 88 90 93 95 104 109 114 119 124 129 D5 18.4 20.4 24.5 26.5 28.5 30.5 31.5 34.5 36.5 38.5 39.5 41.5 45.0 47.0 50.0 52.0 55.0 57.0 60.0 62.0 67.5 69.5 72.5 74.5 77.5 79.5 83.5 89.5 94.5 99.5 104.5 109.5 NOTE: Dimensions apply to all seal and seat types unless otherwise indicated. *When used with a BP, BO, BC and BD mating ring. D6 2.5 2.5 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 L1(K)* 35.0 35.0 37.5 37.5 37.5 40.0 40.0 42.5 42.5 42.5 42.5 42.5 45.0 45.0 45.0 45.0 45.0 47.5 47.5 47.5 52.5 52.5 52.5 52.5 52.5 60.0 60.0 60.0 60.0 65.0 65.0 65.0 L3 23.0 23.0 24.0 24.0 24.0 26.7 27.0 30.0 30.0 30.5 30.5 30.5 32.0 32.0 32.0 32.0 32.0 34.0 34.0 34.0 39.0 39.0 39.0 39.0 39.0 45.5 45.5 45.0 45.0 50.0 50.0 50.0 L45 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 Type 57B/58B/58U ELASTOMER O-RING SEALS Technical Specification Hydrostatic Pressure Limits Materials of Construction SEAL COMPONENTS MATERIALS Description Standard Options Primary Ring/Face Resin-Impregnated Carbon Graphite Sintered Silicon Carbide Antimony Impregnated Carbon Graphite Snap Ring Set Screw Disc Retainer Springs 316 Stainless Steel Alloy 400 (Monel®) Alloy C-276 (UNS N10276) Anti-X Ring Pure PTFE — Secondary Seal O-Ring Nitrile Fluorocarbon Ethylene Propylene Perfluoroelastomer Monel is a registered trademark of Inco Alloys International, Inc.