application of quality improvement tools in organizations 2 a.docx

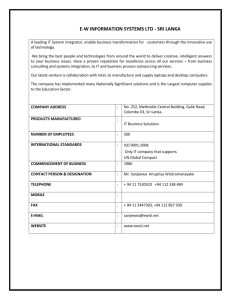

advertisement

Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 1 APPLICATION OF QUALITY IMPROVEMENT TOOLS: COMPARISON OF SRI LANKA AND UK SERVICE ORGANIZATIONS Student Name Code + Course Name Professor’s Name University Name City, State Date Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 2 Application of Quality Improvement Tools: Comparison of Sri Lankan and UK Service Organizations Introduction Total Quality Management has been around since the 1980’s with the rise of the manufacturing industries. The quality management technique was initially applied in the manufacturing sector to improve the efficiency and quality of products. The theory was anchored by quality management experts such as Deming and Juran advocating for continuous improvement in organizations. Over time, due to market dynamics the service industry was adopted in the late 20th century and dominates the labor force since over 70% of the world economy is driven by the service industries. The application of the TQM principles in a competitive market is essential for companies’ survival and not merely making profits (Yapa, 2012 p. 506). TQM implementation in organizations is varied as managers are the main drivers and the tools and techniques of quality management can be selectively applied such that it does not achieve its goals and objectives. In the Sri Lanka case study on the application of TQM service organizations, it seeks to probe how real-world managers are applying the technique in a natural environment. Sri Lanka is a service driven economy, and the study raises questions on how managers understand the TQM technique and its application (Talib et al.). The UK service industry is synonymous to that of Sri Lanka; the case study analyzes the critical success factors essential for the implementation of TQM in organizations. The study aims to compare the application of TQM in the UK and Sri Lanka service companies. Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 3 TQM in the Service Sector The technique bases its origins in the manufacturing sector, and most of its application is anchored in manufacturing processes and models. The service industry approaches issues differently, and the tools of quality management should be tailored to work best under the defined environment. TQM and other quality improvement tools are ambiguous from its definition to its applications in the field (Ram et al., 2013 p.158). Organizations and companies all over the world have varied ways of measuring total quality management as they are a vast majority of tools to be used such as Pareto diagram, fishbone diagram, customer surveys, benchmarking, self-assessment techniques and Kaizen activities among others. The technique is being applied in diverse sectors such as health, banking, transportation, hotels, profit and nonprofit organizations in the service sector. Research done in Australia Service organizations revealed there is no significant difference in most TQM practices between the two sectors of manufacturing and service. The argument brings positivity in different sectors with different approaches to the implementation and success of TQM. Sri Lankan service organizations have a positive attitude towards the adoption of TQM; doubts are however cast on the extent of understanding of the tools, practices and techniques to warrant that an organization is using effectively implementing TQM. The research attempts to find out reasons for happening for particular business activities. The literature focuses on three aspects of positivism, interpretivism and realism. Interpretivism is working on an observable social reality and law-like generalizations. The objective is to find the details of the situation and understand the reality and working behind it. The selected strategies for the research is questionnaire survey and literature review (Yapa, 2012 p. 511). The sample size of the population was 125 organizations to represent the service sector in Sri Lanka. Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 4 The study was done as a survey therefore important to get a larger population and become a representative of the wider service industry. A pilot survey was undertaken with few selected organizations and data gathered to show the true picture of the sector and data behaviour. In the UK case study, 300 questionnaires were used to cover the UK service companies, and the questionnaires were derived from leading academics in TQM (Mok et al., 2013). The service organizations in the UK and Sri Lanka are bound by the same challenges; it used the Likert scale in the questionnaire to get a better perspective of the existing situation of TQM and gathered data using the postal survey. In the Sri Lanka case study, a short questionnaire was designed, and data were analyzed using the MS Excel package as the calculations needed were only percentages. Cross-analysis was done among different organizations where the TQM had been implemented. The Survey Results The results were analyzed based on different frameworks of analyzing the quality and guided by the research objective. The level of adoption of concepts was asked to gauge the understanding of the management on issues relating to TQM hence determine its implementation level. The concepts at hand were Total quality management, Just in time, Six Sigma and Benchmarking (Oakland, 2014, p. 34). From the analysis, benchmarking is the most widely used concept in service organizations while the least implemented concept being the Six Sigma. However, there is a significant 12 percent that has never heard of TQM. Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 5 Table I: Levels of adoption of various quality related Concepts Concept Organizations Organizations Organization Organizations Organizations Not heard Heard about s Thinking Starting In place Total quality about 12% 13% about 15% 18% 41% management Just in time Six Sigma Benchmarkin 22% 29% 8% 32% 33% 13% 12% 11% 10% 9% 18% 11% 24% 8% 57% g Commitment of the organization to the TQM Each organization that follows the TQM model needs to have a quality manual that lays down the procedures, policies and practices that are directed to increase customer satisfaction and maintain consistency in the organization. 76% of service businesses in Sri Lanka have a quality manual which is a high percentage. They are ISO 9000 certified which require implementation and operation of the effective quality management system (Sallis, 2014 p. 56). The ownership is considered a commitment to the implementation of total quality and 32 percent of organizations in the selected sample have ISO certificate. Mission statement plays a critical role for its purpose, 89 percent of the organizations have a mission statement, and a further 54 percent include a set of words of quality such as excellence and total customer satisfaction in their mission statements. Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 6 Customer Satisfaction Customers are the most important assets of an organization; it is essential that customer complaints and needs should be served accordingly (Primentel and Major, 2016, p.1000). The one who reviews organization on its satisfaction is the customer and companies strive to offer the best customer experiences through quality service. Top management commitment All employees and stakeholders of organizations should contribute towards total quality management. However, top management plays a critical role in its success for continued excellence in its products and services important to the customer. An impressive 93 percent of top managers in Sri Lanka have a verbal or written communication emphasizing the importance of employees in the company (Yapa, 2012 p. 521). A number tools and techniques such as check sheet and training are the most popular with the least popular ones being fishbone diagrams and scatter diagrams. Based on the research, a good number of organizations have a good picture on TQM in Sri Lanka. 41 percent have TQM's in place, and 18 percent are in the process of implementation. More than half of the organizations have a mission statement that includes terms related to quality. The organization's commitment towards TQM is fairly good but needs to be more tangible and implement TQM concepts and techniques in these organizations (Sureshchandar, 2001, p. 351). Cross-analysis among organizations shows an impressive uptake of TQM with a positive trend and improvement. Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 7 Table II: Percentage of each category based on customer satisfaction Surveys Category No Survey Informal Survey Formal Survey Rarely Frequently After every transaction Percentage 6 16 13 54 10 The implementation cost is not a factor for non –use of the techniques as simple and inexpensive tools. The potential ignorance of the techniques is the inadequate understanding of the TQM and its implementation process and importance of the technique. To counter the issue, more quality courses need to be included in the undergraduate and postgraduate courses in universities and training institutes. Sri Lanka Standards Institute should introduce short-term training courses especially for the top management of organizations. Sri Lanka is a country with a large service sector and fierce competition, TQM principles should be adopted especially when customers are educated and demanding. The research's objective was to find the level of awareness on TQM tools and techniques. Managers in the service organizations should boost their understanding of the TQM for effective implementation in their companies. The challenge faced within the quality management space is the wide variety of tools that are used to measure quality. The tools bring discrepancies on what to settle on when evaluating total quality management in the organizations. There is a reasonable enthusiasm among the managers as 41% of organizations already implemented the technique. Literature backed techniques of fishbone diagram, Pareto analysis, quality costs are not utilized by the Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 8 organization on the ground (Bon and Mustapha, 2013 p. 103). Managers raise concerns about the complications of TQM philosophies and techniques complicating the understanding of the process. In the research, benchmarking has been widely used in in the organizations, and they benchmark with local, regional and international competitors. It is also based on questionnaire survey hence the research is subject to biases and limitations based on the technique. Table III: Percentage of Organizations use TQM tools and techniques. Tool Check sheet Yes 74% No 26% Tool Scatter Yes 24% No 76% Pareto 28% 72% diagram Histogram 33% 67% Analysis Flow chart 72% 28% Quality 34% 66% Employee 77% 23% circles Preventive 66% 34% 80% 20% suggestion scheme Analysis of maintenance 39% 61% quality cost Training of employee on quality Fishbone 20% 80% Diagrams Today, Total Quality Management is a key factor in ensuring that a business organization gains a competitive advantage. In the 1980s, TQM philosophy was being commonly applied in the manufacturing industry. However, TQM has become an essential part of securing a competitive Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 9 advantage and increasing customer satisfaction. In the United Kingdom, the service industry is a critical element that plays an important role in the economy. TQM critical factors for success These are the factors that throw into the success of the efforts put in place for the total quality management in the various organization. The critical factors that lead to the success of TQM implementation are the following: Focus on the customer This factor entails the analysis of complaints from the customers, the requirements from the customer both externally and internally and their contentment. The employees have always thought on the kind of needs that their customers possess since several customers have different needs with a variety of expectations on how they are going to get satisfied (Hing Yee Tsang and Anthony, 2001, p.135). The TQM key goal should be, getting to understand the needs of a customer, satisfying their needs according to their expectation and even surpassing the consumer‘s needs and expectation on a continuous basis. Unremitting improvement This factor entails the activities that continuously improve the processes, systems and the continuous check on the performance of the employees. The recognition of opportunities that require improvements and the revision of the issues on quality are also covered in this factor (Akgun et al., 2014 p. 890). The performance of both the employees and the process, need to be continuously monitored and enhanced. The main element of TQM programme is the continuous improvement in the product and service quality; this is used majorly in the eradication of Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 10 defective products, reduction in the time of production and reduction of waste caused by extreme inconsistency. Moreover, several organizations are trying to reduce all the activities that are not adding value to minimum by continuously improving the total performance of their business and focusing in the areas of functionality and aspect of their operation. Employee involvement and teamwork This factor deals with the teamwork structures, implementation of teams with improved quality, the involvement of employees in various activities that are of quality and team rewards. Firms need to put to use the skills and the abilities that their employees possess for better achievements. For problems to be solved within a company people from the different department should work in unison as a team, and for this to be achieved communication between the employees should be empowered (Ab Talib and Abdul Hamid, 2014, p. 34). Furthermore, dedication, appreciation and recognition are required to enable the employees to inspire themselves and to achieve the goals set for the company. The management needs to keep attention on what their employees suggest because they employees understand the daily issues better. The employee should also build trust with their employer by managing, controlling and improving all the process that is within their responsibility. Recognition and commitment of top management The factor covers the support and the awareness of the top management in the implementation of quality improvement project and quality management system. The management commitment entails the expression and upholding of a compelling and a clear vision for future and giving a strategic kind of leadership in the company (Chang, 2016, p. 23). The victory achievement of a quality improvement program depends on the commitment of the top management. Unless the Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 11 top management is devoted, it will be very difficult to influence the subordinate staff where most of the workload is done. Training and development This factor is based on the availability and accessibility of the training programmes to the employees and the education of the subcontractors and the suppliers of the company. The training programme focuses on topics such as statistical improvement techniques, teamwork and quality related topics. Training is the basic essential practice that organizations use to impart new skills that are required in accomplishing the principles of quality, in their employees (Hing Yee Tsang and Anthony, 2001, p.152). After the establishment of quality management system, proper training of employees at all levels is provided to gain skills and knowledge of carrying out their roles and responsibilities in the quality management system. Quality systems and policies For continuous improvement to be experienced, the features of total quality management which include: the techniques and tools used in predictions, analysis and correlation of actions need to be in place. Measures such as performance improvements, control charts and quality improvement teams are used in process control (Dale, 2015, p.21). These measures give more information on the performance of the processes and people and hence provide a prediction on how to motivate them for a quality performance in future. In addition to those basic elements, there are methods that are used to interpret and obtain the greatest use of the data such as the Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 12 check sheets, control charts and stratification. In data evaluation methods such as regression analysis, variance and experimental design are employed. Supervisory leadership It covers the styles of leadership in a company such as training of employees and delegation of duties. The management leadership sets a firm foundation for the execution of TQM in an organization by providing a conducive environment where quality total quality management is practice. The management needs to support their employees in their daily activities by encouraging them to learnt and to the risks, and this will improve their innovation and creativity (Goetsch and Davis, 2014). Despite the fact that they support their employees, the management should review the description of the job and its performance in order of upholding the quality of the work. Good communication between the management and staff should exist. Above all, the managers should learn to reward their employees for participating in quality activities for their motivation. Communication The discussion includes the communication and cooperation between departments and the crossfunctional teams used for solving problems and in the continuous improvement of quality projects. Under the TQM philosophy, communication is very important because the members of staff at different levels are assigned the responsibility of ensuring that there are continuous quality improvements on the projects they undertake (Garcia et al., 2014 p. 2190). Therefore, the employees will always require feedback so that they can establish whether their previous strategy Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 13 on quality improvement was effective or not. The staff need capacities building so that they can control whatever they do and have authority to even implement improvement at all levels. The management should also give guidance to ensure that the organizational objectives are achieved. Supplier management and partnership Quality of the products cannot be achieved if the raw materials are not of high quality and this is usually the case in the manufacturing industry. Thus, it is important to develop a long-term working relationship with the suppliers to enjoy a competitive advantage (Campos et al., 2014 p. 11). Some of the benefits of such long-term relationships include; the suppliers become more concerned with the needs of the customers, they become willing to be involved in product design, it improves information sharing and constant flow of supplies and price stability. Measurement and getting feedback It is important to make the necessary measurements against both internal and external indicators. The organizations always need to analyze feedback to help improve the quality of product or service continuously (Mitra, 2016, p. 58). Customer surveys, internal and external benchmarks must be established to help in measurement of results. Through such measurements, the company can understand customer needs as well as expectations from the organization. Cultural change Every company needs to establish a culture of continuous improvement to ensure that the employees fully participate in the quality improvement programs, which are within their areas of speciality. The cultural change needs to change people's behaviours and attitudes in different ways. For example, every member of the organization needs to engage in quality improvement Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 14 projects, the employees should themselves inspect their work, quality check systems must be put in place to ensure that any defective product or service does not proceed to the next stage. Every employee must be committed to customer satisfaction, improvement process must also involve the customers and suppliers, mistakes must be treated as chances for improvement while sincerity and honesty need to be the integral part of business (Hing Yee Tsang and Anthony, 2001, p.135). All the above are the success factors for Total Quality Management. All of them help increase business performance and customer satisfaction. However, research shows that there is no guarantee that they will lead to success that is why they need to be considered as a whole. If they operate independently, they may not result in quality improvement at the end of the day. Methodology The research on the UK service companies involved 300 well-structured questionnaires that were delivered to the participating companies. Likert scale was used to establish the exact situation of TQM in the service industry. The sector included water and power supplies, insurance, employment agency, hotels and banking (Kuipers et al, 2014 p. 5). The advantage of the method used was that many organizations were reached over a short period. Besides, the postal surveys were employed in sending the questionnaires to different organizations. From the research, Tsang found out that 36% of the respondent companies had implemented TQM while 64% had partially implemented it as shown in the figure below. Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 15 Implementation of TQM by UK companies partially implemented fully implemeted The study about TQM in the service organizations in the UK considering about 11 factors and 59 variables. This research concurs with other research papers that most service companies focus more on external customer management rather than the internal suppliers and internal customers. The supplier management or partnership was then ranked very low because most service industries focus on customers and solving customer problems and not the suppliers. It then means that customer focus is critical during the implementation of TQM, especially within the service industry. Furthermore, the service industry players offer the services in a supply chain management manner. Quality improvement is important and can be effectively applied in organizations. Tying in his research used companies in the service industry in the UK to establish the application of TQM. From the research, it emerged clearly that TQM can be an effective source of competitive advantage only if it is applied in the right way. Managers of all levels should actively be involved in the TQM implementation and can be extended to cover hospitals, hotels, higher education and private NGO’S. Total Quality Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 16 Management is a culture that should be engrained in organizations and not simply added to the work processes. Extensive communication with the top managers to drive the culture to the employees is important. Each organization varies based on the quality tools being applied; managers should tailor the TQM principles to suit the unique process in their organizations and allow for accountability with international bodies such as ISO and government agencies such as the Sri Lankan quality management institute. It is imperative that the central role of all quality management tools is focused on the customer (Chang, 2016, p. 24). The happiness of a customer leads to more prospects and more business, therefore, customer satisfaction is central as that is the main objective. Service organizations around the world are dynamic and need checks and balances; quality focus is important as it gives a competitive advantage among other players in the sector. Innovation in the company with a focus on quality and enhancing customer experience is essential to the success of any organization. References Ab Talib, M.S. and Abdul Hamid, A.B., 2014. Application of critical success factors in supply chain management. International Journal of Supply Chain Management, 3(1). Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 17 Akgün, A.E., Ince, H., Imamoglu, S.Z., Keskin, H. and Kocoglu, İ., 2014. The mediator role of learning capability and business innovativeness between total quality management and financial performance. International Journal of Production Research, 52(3), pp.888-901. Bon, A.T. and Mustafa, E.M., 2013. Impact of total quality management on innovation in service organizations: Literature review and new conceptual framework. Procedia Engineering, 53, pp.516-529. Boulter, L., Bendell, T. and Dahlgaard, J., 2013. Total quality beyond North America: A comparative analysis of the performance of European Excellence Award winners. International Journal of Operations & Production Management, 33(2), pp.197215. Campos, A.C., da Costa Mendes, J., Albino Silva, J. and Oom do Valle, P., 2014. Critical success factors for a total quality culture: A structural model. Tourism & Management Studies, 10(1). Chang, J.F., 2016. Business process management systems: strategy and implementation. CRC Press. Dale, B., 2015. Total quality management. John Wiley & Sons, Ltd. García, J.L., Maldonado, A.A., Alvarado, A. and Rivera, D.G., 2014. Human critical success factors for kaizen and its impacts in industrial performance. The International Journal of Advanced Manufacturing Technology, 70(9-12), pp.2187-2198. Goetsch, D.L. and Davis, S.B., 2014. Quality management for organizational excellence. Upper Saddle River, NJ: pearson. Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 18 Hing Yee Tsang, J. and Antony, J., 2001. Total quality management in UK service organisations: some key findings from a survey. Managing Service Quality: An International Journal, 11(2), pp.132-141. Illés, B.C., Szuda, C. and Dunay, A., 2017. Quality and management–Tools for continuous and systematic improvement of processes. Kuipers, B.S., Higgs, M., Kickert, W., Tummers, L., Grandia, J. and Van der Voet, J., 2014. The management of change in public organizations: A literature review. Public Administration, 92(1), pp.1-20. Kuei, C.H. and Lu, M.H., 2013. Integrating quality management principles into sustainability management. Total Quality Management & Business Excellence, 24(1-2), pp.62-78. Mitra, A., 2016. Fundamentals of quality control and improvement. John Wiley & Sons. Mir, F.A. and Pinnington, A.H., 2014. Exploring the value of project management: linking project management performance and project success. International journal of project management, 32(2), pp.202-217. Mok, C., Sparks, B. and Kadampully, J., 2013. Service quality management in hospitality, tourism, and leisure. Routledge. Molina-Azorín, J.F., Tarí, J.J., Pereira-Moliner, J., López-Gamero, M.D. and Pertusa-Ortega, E.M., 2015. The effects of quality and environmental management on competitive advantage: A mixed methods study in the hotel industry. Tourism Management, 50, pp.41-54. Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 19 Oakland, J.S., 2014. Total quality management and operational excellence: text with cases. Routledge. Paltayian, G., Georgiou, A.C., Gotzamani, K. and Andronikidis, A., 2017, October. Combining Quality Management Tools With Quantitative Approaches to Improve e-Banking Οperations. In Global Conference on Services Management (GLOSERV 2017) (p. 273). Pimentel, L. and Major, M., 2016. Key success factors for quality management implementation: evidence from the public sector. Total Quality Management & Business Excellence, 27(910), pp.997-1012. Sallis, E., 2014. Total quality management in education. Routledge. Sureshchandar, G.S., Rajendran, C. and Anantharaman, R.N., 2001. A conceptual model for total quality management in service organizations. Total quality management, 12(3), pp.343363. Talib, F., Rahman, Z. and Qureshi, M.N., 2013. An empirical investigation of relationship between total quality management practices and quality performance in Indian service companies. International journal of quality & reliability management, 30(3), pp.280-318. Ram, J., Corkindale, D. and Wu, M.L., 2013. Implementation critical success factors (CSFs) for ERP: Do they contribute to implementation success and post-implementation performance?. International Journal of Production Economics, 144(1), pp.157-174. Yapa, S., 2012. Total quality management in Sri Lankan service organizations. The TQM journal, 24(6), pp.505-517. Application of Quality Improvement Tools: Comparison of Sri Lanka and UK service Organizations 20