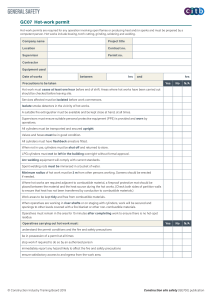

HEALTH & SAFETY PROCEDURE Page 1 of 3 PREVENTION MANUAL Card No PREV-001 Version 2021-04-18 Permit for Hot-work and burning The reference of this card is HS(G)5 Hot work, HS(G)48, HS(G)51, HS(G)65 and in accordance with PUWER 1998 REGULATIONS. Hot work means any work requiring the use of electric arc or gas welding equipment, cutting, burning equipment or other forms of naked flame, as well as heating or spark generating tools, brazing, torch cutting, grinding, soldering, regardless of where it is carried out inside the site. Hot-work permits are required for any operation involving a Hot Work and must be prepared by a competent person. Whenever possible, a space such as a workshop where conditions are deemed safe should be designated for hot work to be performed in and first consideration given to performing any hot work in that space. In such a dedicated place and under normal conditions a permit is not mandatory. The manager, or person in charge, should be responsible for deciding whether hot work, is justified and whether it can be conducted safely. Hot work job should take account of any additional company or local laws and regulations that may be applicable inside the site where the work is carried out. The work area should be carefully prepared and isolated before hot work commences. Isolation of the work area and fire precautions should be continued until the risk of fire no longer exists. Company name Project title Location Contract no. Supervisor Permit no. Contractor Equipment used Date of works Between (Date/Hours) hrs And (Date/Hours) Precautions to be taken hrs Yes No N/A Has a risk assessment of the proposed work been carried out? (Use dedicated form if required) Hot work must cease at least half hour before end of shift. Areas where hot works have been carried out should be checked before leaving site. Services affected must be isolated before work commences. Isolate smoke detectors in the vicinity of hot works. A suitable fire extinguisher must be available and be kept close at hand, at all times. Supervisors must ensure suitable personal protective equipment (PPE) is provided and worn by operatives. All cylinders must be transported and secured upright. Valves, hoses and all equipment must be in good condition. Work site secured, ventilated, under inert atmosphere if required All cylinders must have flashback arrestors fitted. When not in use, cylinders must be shut off and returned to store. LPG cylinders must not be left in the building overnight without formal approval. Arc welding equipment will comply with current standards. Spent welding rods must be immersed in a bucket of water. Minimum radius of hot work must be 2 m from other persons working. Screens should be erected if needed. PREVENTION MANUAL HEALTH & SAFETY PROCEDURE HEALTH & SAFETY PROCEDURE Page 2 of 3 PREVENTION MANUAL Card No PREV-001 Version 2021-04-18 Permit for Hot-work and burning Where hot works are required adjacent to combustible material, a fireproof protective mat should be placed between the material and the heat source during the hot works. (Check both sides of partition walls to ensure that heat has not been transferred by conduction to combustible materials.) Work areas to be kept tidy and free from combustible materials. When operatives are working in riser shafts or on staging with cylinders, work will be secured and openings to other levels covered with a fire blanket or other non-combustible materials. Emergency procedure for any problem agreed and prepared by advance Operatives must remain in the area for 15 minutes after completing work to ensure there is no hot-spot residue. Operatives carrying out hot work must: Yes No N/A understand the permit conditions and the fire and safety precautions be in possession of a permit at all times stop work if required to do so by an authorised person immediately report any hazard likely to affect the fire and safety precautions ensure satisfactory access to and egress from the work area. Protection or safety clothes and equipment worn by the working staff Safety helmets Safety boots Leather apron Overalls Gloves Spectacles Visor Leather gauntlets ADDITIONAL SPECIAL MEASURES PREVENTION MANUAL HEALTH & SAFETY PROCEDURE HEALTH & SAFETY PROCEDURE Page 3 of 3 PREVENTION MANUAL Card No PREV-001 Version 2021-04-18 Permit for Hot-work and burning Confirmation by contractor’s supervisor: I confirm that the precautions specified above will be complied with and I will ensure that the persons carrying out the work described above are fully briefed on the safe method of work. Name Position Signature Date Confirmation by operator: I understand the precautions to be taken in carrying out the hot works. Name Position Signature Date Site management authorisation: I certify that the above work can commence with the precautions listed above. Name Position Signature Date Cancellation of permit by operator: (Note: hot works must cease at least half hour before end of shift.) I confirm that the work has been completed and the area has been checked and is safe. Name Position Signature Date Signature Date Cancellation of permit by site management Name Position Inspection of area covered by hot-work permit by fire warden/site management after cancellation of permit Name Position Inspection completed after Signature hr(s) Date Clearance of permit The work for which this permit to work was issued is now completed/suspended and all people under my charge have been withdrawn and warned that it is no longer safe to work on the apparatus detailed in this permit to work. All work equipments, tools, test instruments etc have been removed Person in charge :……………………………………………………………… Date : …………………….. Time : …………………………... PREVENTION MANUAL Role : …………………………………………………. Signature : ………………………………………………………….. HEALTH & SAFETY PROCEDURE