Engineering Economics Assignment: Fuel, Energy, Investment

advertisement

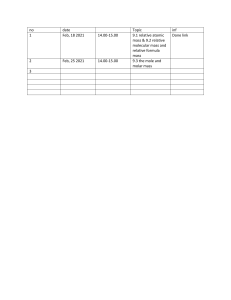

ASSIGNMENT #1 GDB3023 SEMESTER JANUARY 2021 GDB3023 ENGINEERING ECONOMICS & ENTREPRENEURSHIP JANUARY 2021 ASSIGNMENT #1 [CLO1] Name : Ismah Syamilah Binti Abdullah Fadzil Matric No : 25327 Programme : Chemical Engineering No Assignment : 1 Lecturer : Assoc. Prof. Dr Madzlan Bin Napiah Page 1 of 8 ASSIGNMENT #1 GDB3023 SEMESTER JANUARY 2021 1. Stan Moneymaker needs 15 gallons of gasoline to top off his automobile’s gas tank. If he drives an extra eight miles (round trip) to a gas station on the outskirts of town, Stan can save $0.10 per gallon on the price of gasoline. Suppose gasoline costs $3.90 per gallon and Stan’s car gets 25 mpg for in-town driving. Should Stan make the trip to get less expensive gasoline? Each mile that Stan drives creates one pound of carbon dioxide. Each pound of CO2 has a cost impact of $0.02 on the environment. What other factors (cost and otherwise) should Stan consider in his decision making? [10 Mark] 𝑆𝑎𝑣𝑖𝑛𝑔 𝑜𝑛 𝐹𝑢𝑒𝑙 = 15 𝑔𝑎𝑙𝑙𝑜𝑛 × $0.10/𝑔𝑎𝑙𝑙𝑜𝑛 𝑆𝑎𝑣𝑖𝑛𝑔 𝑜𝑛 𝐹𝑢𝑒𝑙 = $1.5 Therefore, Stan will save roughly $1.5 every time he tops off his automobile’s gas tank at the gas station on the outskirts of town. However, taking 𝐶𝑂2 penalty into consideration. 𝑆𝑎𝑣𝑖𝑛𝑔 𝑜𝑛 𝐹𝑢𝑒𝑙 = $1.5 − (8 𝑙𝑏 × $0.02/𝑙𝑏) 𝑆𝑎𝑣𝑖𝑛𝑔 𝑜𝑛 𝐹𝑢𝑒𝑙 = $1.34 Stan total of fuel saving will drop at $1.34 after the 𝐶𝑂2 penalty. 𝑆𝑢𝑔𝑔𝑒𝑠𝑡𝑒𝑑 𝑚𝑖𝑙𝑒𝑎𝑔𝑒 = $1.34/8 𝑚𝑖𝑙𝑒 𝑆𝑢𝑔𝑔𝑒𝑠𝑡𝑒𝑑 𝑚𝑖𝑙𝑒𝑎𝑔𝑒 = $0.168 𝑝𝑒𝑟 𝑚𝑖𝑙𝑒 Therefore, if Stan want to save for the fuel, he should drive $0.168 per mile or less than suggested. 𝐶𝑜𝑠𝑡 𝑝𝑒𝑟 𝑡𝑟𝑖𝑝 = (8 𝑚𝑖𝑙𝑒𝑠 ÷ 25 𝑚𝑖𝑙𝑒𝑠 ) × ($3.90/ 𝑔𝑎𝑙𝑙𝑜𝑛) 𝑔𝑎𝑙𝑙𝑜𝑛 𝐶𝑜𝑠𝑡 𝑝𝑒𝑟 𝑡𝑟𝑖𝑝 = $1.248 The cost of the extra 8 miles taken by Stan will be $1.248, therefore it shows that Stan will be able to save on fuel by making round trip. However, despite the saving made on fuel, Stan also need to consider other factors as well. The car`s maintenance also need to be taken into consideration. When looking at service intervals people look at miles driven, the higher the number of miles driven, shows that the car required services. Over the time parts in a car, especially the rubber components deteriorate over time and with the extra miles taken every time Stan fuelled up the car, this will eventually lead up to more car`s maintenance. In addition, Stan also need to consider the probability of accident occurred while he drove to the outskirt, this also includes any misfortune either it be flat tyre or getting mugged. The total lost he need to bear will cost him much more than the amount of money he saved on fuel. Page 2 of 8 ASSIGNMENT #1 GDB3023 SEMESTER JANUARY 2021 2. A typical discounted price of a AAA battery is $0.75. It is designed to provide 1.5 volts and 1.0 amps for about an hour. Now we multiply volts and amps to obtain power of 1.5 watts from the battery. Thus, it costs $0.75 for 1.5 Watt-hours of energy. How much would it cost to deliver one kilo Watt-hour? How does this compare with the cost of energy from your local electric utility at $0.10 per kilo Watt-hour? [10 Mark] Calculating AAA battery capability; 𝐶𝑜𝑠𝑡 𝑝𝑒𝑟 𝑊𝑎𝑡𝑡 ℎ𝑜𝑢𝑟 = $0.75 × 1 1.5 𝑊𝑎𝑡𝑡 𝐻𝑜𝑢𝑟 𝐶𝑜𝑠𝑡 𝑝𝑒𝑟 𝑊𝑎𝑡𝑡 ℎ𝑜𝑢𝑟 = $0.5 𝑝𝑒𝑟 𝑊𝑎𝑡𝑡 ℎ𝑜𝑢𝑟 𝐶𝑜𝑠𝑡 𝑘𝑖𝑙𝑜 𝑊𝑎𝑡𝑡 ℎ𝑜𝑢𝑟 = 1000 × $0.5 𝑝𝑒𝑟 𝑊𝑎𝑡𝑡 ℎ𝑜𝑢𝑟 𝐶𝑜𝑠𝑡 𝑘𝑖𝑙𝑜 𝑊𝑎𝑡𝑡 ℎ𝑜𝑢𝑟 = $500 𝑝𝑒𝑟 𝐾𝑊𝑎𝑡𝑡 ℎ𝑜𝑢𝑟 Comparing local electric utility and AAA battery; 𝑅𝑎𝑡𝑖𝑜 = $500 𝑝𝑒𝑟 𝐾𝑊𝑎𝑡𝑡 ℎ𝑜𝑢𝑟 $0.10 𝑝𝑒𝑟 𝐾𝑊𝑎𝑡𝑡 ℎ𝑜𝑢𝑟 𝑅𝑎𝑡𝑖𝑜 = 5000 From the calculated ratio of AAA battery and local electric utility, it shows that the cost for energy provided by the AAA batteries is 5000 times higher compared to the local electric utility. Therefore, it is much cost saving to use local electric utility supply. Page 3 of 8 ASSIGNMENT #1 GDB3023 SEMESTER JANUARY 2021 3. Henry Ford’s Model T was originally designed and built to run on ethanol. Today, ethanol (190proof alcohol) can be produced with domestic stills for about $0.85 per gallon. When blended with gasoline costing $4.00 per gallon, a 20% ethanol and 80% gasoline mixture costs $3.37 per gallon. Assume fuel consumption at 25 mpg and engine performance in general are not adversely affected with this 20–80 blend (called E20). (a.) How much money can be saved for 15,000 miles of driving per year? (b.) How much gasoline per year is being converted if one million people use the E20 fuel? [10 Mark] (a.) How much money can be saved for 15,000 miles of driving per year? Calculating gasoline; 25 𝑚𝑖𝑙𝑒𝑠 𝑅𝑒𝑞𝑢𝑖𝑟𝑒𝑑 𝐹𝑢𝑒𝑙 = 15 000 𝑚𝑖𝑙𝑒𝑠 ÷ 𝑔𝑎𝑙𝑙𝑜𝑛 𝑅𝑒𝑞𝑢𝑖𝑟𝑒𝑑 𝐹𝑢𝑒𝑙 = 600 𝑔𝑎𝑙𝑙𝑜𝑛 𝐶𝑜𝑠𝑡 𝑜𝑓 𝑔𝑎𝑠𝑜𝑙𝑖𝑛𝑒 = 600 𝑔𝑎𝑙𝑙𝑜𝑛 × $4.00 𝑝𝑒𝑟 𝑔𝑎𝑙𝑙𝑜𝑛 𝐶𝑜𝑠𝑡 𝑜𝑓 𝑔𝑎𝑠𝑜𝑙𝑖𝑛𝑒 = $2 400 Calculating E20 𝐶𝑜𝑠𝑡 𝑜𝑓 𝐸20 = 600 𝑔𝑎𝑙𝑙𝑜𝑛 × $3.37 𝑝𝑒𝑟 𝑔𝑎𝑙𝑙𝑜𝑛 𝐶𝑜𝑠𝑡 𝑜𝑓 𝐸20 = $2 022 Amount of saving made; 𝑆𝑎𝑣𝑖𝑛𝑔 = $2 400 − $2 022 𝑆𝑎𝑣𝑖𝑛𝑔 = $378 𝑝𝑒𝑟 𝑦𝑒𝑎𝑟 (b.) How much gasoline per year is being converted if one million people use the E20 fuel? 𝐺𝑎𝑠𝑜𝑙𝑖𝑛𝑒 𝑐𝑜𝑛𝑣𝑒𝑟𝑡𝑒𝑑 𝐺𝑎𝑠𝑜𝑙𝑖𝑛𝑒 𝑐𝑜𝑛𝑣𝑒𝑟𝑡𝑒𝑑 𝐺𝑎𝑠𝑜𝑙𝑖𝑛𝑒 𝑐𝑜𝑛𝑣𝑒𝑟𝑡𝑒𝑑 𝐺𝑎𝑠𝑜𝑙𝑖𝑛𝑒 𝑐𝑜𝑛𝑣𝑒𝑟𝑡𝑒𝑑 = 600 𝑔𝑎𝑙𝑙𝑜𝑛 × 0.8 = 480 𝑔𝑎𝑙𝑙𝑜𝑛 𝑝𝑒𝑟 𝑝𝑒𝑟𝑠𝑜𝑛 = 480 𝑔𝑎𝑙𝑙𝑜𝑛 𝑝𝑒𝑟 𝑝𝑒𝑟𝑠𝑜𝑛 × 1 000 000 𝑝𝑒𝑟𝑠𝑜𝑛 = 480 𝑚𝑖𝑙𝑙𝑖𝑜𝑛 𝑔𝑎𝑙𝑙𝑜𝑛 𝑝𝑒𝑟 𝑦𝑒𝑎𝑟 Page 4 of 8 ASSIGNMENT #1 GDB3023 SEMESTER JANUARY 2021 4. During your first month as an employee at Greenfield Industries (a large drill-bit manufacturer), you are asked to evaluate alternatives for producing a newly designed drill bit on a turning machine. Your boss’ memorandum to you has practically no information about what the alternatives are and what criteria should be used. The same task was posed to a previous employee who could not finish the analysis, but she has given you the following information: An old turning machine valued at $350,000 exists (in the warehouse) that can be modified for the new drill bit. The in-house technicians have given an estimate of $40,000 to modify this machine, and they assure you that they will have the machine ready before the projected start date (although they have never done any modifications of this type). It is hoped that the old turning machine will be able to meet production requirements at full capacity. An outside company, McDonald Inc., made the machine seven years ago and can easily do the same modifications for $60,000. The cooling system used for this machine is not environmentally safe and would require some disposal costs. McDonald Inc. has offered to build a new turning machine with more environmental safeguards and higher capacity for a price of $450,000. McDonald Inc. has promised this machine before the startup date and is willing to pay any late costs. Your company has $100,000 set aside for the start-up of the new product line of drill bits. For this situation, (a.) Define the problem. (b.) List key assumptions. (c.) List alternatives facing Greenfield Industries. (d.) Select a criterion for evaluation of alternatives. (e.) Introduce risk into this situation. (f.) Discuss how nonmonetary considerations may impact the selection. (g.) Describe how a post audit could be performed. [10 Mark] (a.) Define the problem. To identify the alternatives of least cost consumption for producing newly designed drill bit on a turning machine. (b.) List key assumptions. − Drill bits are manufactured the same way regardless of the alternative chosen. − In-house technicians can modify the old machine so its life span will match that of the new machine. − The revenue per unit will be the same for either machine. − Breakdowns of the machines are not frequent. − The previous employee’s data provided are correct. (c.) List alternatives facing Greenfield Industries. − Modify the old machine for producing the new drill bit using in-house technicians with the price of $40 000. − Buy a new machine for $450,000. − Modify the machine at McDonald Inc. at $60 000. − Outsource the work to another company, whereby it may or may not provide services at lower price. (d.) Select a criterion for evaluation of alternatives. The produced drill bit on a turning machine will be cost effective. Provided the item has superb quality and can be delivered on time. Page 5 of 8 ASSIGNMENT #1 GDB3023 SEMESTER JANUARY 2021 (e.) Introduce risk into this situation. − The old machine could be less reliable than a new one. − The old machine could cause environmental hazards. − Fixing the old machine in-house could prove to be unsatisfactory. − The old machine could be less safe than a new one. (f.) Discuss how nonmonetary considerations may impact the selection. Non-monetary Considerations includes safety, environmental concerns, quality/reliability differences, “flexibility” of a new machine, job security for in-housework, image to outside companies by having a new technology (machine). (g.) Describe how a post audit could be performed. Post Audit can be performed through several asked questions, − Did either machine (or outsourcing) fail to deliver high quality product on time? − Were maintenance costs of the machines acceptable? − Did the total production costs allow an acceptable profit to be made? Page 6 of 8 ASSIGNMENT #1 GDB3023 SEMESTER JANUARY 2021 5. A deep-water oil rig has just collapsed into the Gulf of Mexico. Its blowout-preventer system has failed, so thousands of barrels of crude oil each day are gushing into the ocean. List some alternatives for stopping the unchecked flow of oil into the Gulf. [10 Mark] Since a fire engulfed the Deepwater horizon rig in the Gulf of Mexico on April 20, engineers have attempted a number of techniques to slow or stop the torrent of oil leaking from the wellhead 5,000 feet below the surface. (Retrieved from New York Times, 2010) Repairing the blowout preventer Officials use remotely operated submersibles to try to activate the blowout preventer, a stack of valves at the wellhead meant to seal the well in the event of a sudden pressure increase. A crucial valve had never fully deployed, and efforts to activate the device after the explosion are unsuccessful. Chemical Dispersant Crews inject chemical dispersant into the oil as it flows from the main leak underwater. The dispersant, conventionally used on the water surface, is intended to break the oil into small droplets, reducing its buoyancy. The full impact of chemical dispersants on the underwater ecology is unknown. The E.P.A. later orders BP to change to a less toxic chemical than originally used. Drilling Relief Wells BP begins drilling the first of two relief wells that may later be used to inject mud and cement into the existing well. Lowering Containment Dome Workers lower a four-story steel box over the larger leak. But when crews discover that the dome’s opening is becoming clogged with an icy mix of gas and water, it is set aside on the seabed. Attaching a Tube After two false starts, BP engineers successfully insert a mile-long tube into the broken riser pipe to divert some of the oil to a drill ship on the surface. Over nine days, the tube siphons off about 22,000 barrels of oil, which is just a fraction of the total spill. The Top Kill and Junk Shot In a procedure called the top kill, engineers pump heavy drilling mud into the well with hopes that the weight of the fluid overcomes the pressure of the rising oil. In another technique called the junk shot, objects including golf balls and pieces of rubber are injected into the blowout preventer. Both techniques fail to plug the leak. Another Attempt to Cap the Well Engineers position submarine robots to shear the collapsed riser pipe so that a domeline cap could be placed over the blowout preventer to funnel some of the leaking oil to a tanker on the surface. Beginning to Capture some Oil A cap is placed over the top of the blowout preventer to funnel oil and gas to a surface ship. Methanol is pumped into the cap to prevent the formation of icy hydrates that could block the milelong pipe rising from the cap. Oil continues to billow from under the lip and through four open vents on top of the device. Engineers are unable to close all the vents as originally planned. Page 7 of 8 ASSIGNMENT #1 GDB3023 SEMESTER JANUARY 2021 Capturing more Oil A second containment system begins siphoning oil and gas from the leaking well. BP estimates the system will carry 5,000 to 10,000 barrels a day to the surface, supplementing the roughly 15,000 barrels collected daily by a containment cap on top of the blowout preventer. Using equipment originally put in place to inject heavy drilling mud during the failed top kill procedure last month, the new system extracts oil and gas directly from the blowout preventer, passes it through a manifold on the seafloor and pipes it up to the Q4000 surface vessel. The Q4000 has no storage capacity and burns the oil and gas. A Better Cap BP replaces the cap put in place on June 3 with a tighter one that could potentially stop the flow of oil from the well. The new cap has some of the same types of components as the blowout preventer. Adding more Capacity After days of delays due to weather, the Helix Producer, a production vessel on the surface, begins collecting oil. BP officials say that they eventually expect to have a total of four vessels on site to collect and process oil and gas. The Q4000 will be replaced by another vessel, Toisa Pisces, which will be connected to one of two floating risers that can be disconnected in the event of a hurricane. Testing the Well; Ensure it is Intact A new capping assembly stops the flow of oil for the first time. Engineers begin monitoring pressure in the well to determine its integrity. Static Kill Engineers successfully pump mud through a valve on the blowout preventer and into the existing well’s metal casing pipe in a procedure similar to the failed top kill. They are able to pump mud slower and at lower pressure because a new cap atop the well has stemmed the flow of oil. Mud forces the oil and gas back down into the reservoir. Cement is also pumped in to seal the well. Making Progress on the Relief Well BP engineers continue developing a more specific plan on how to complete the bottom kill with minimal risk. When engineers pumped cement into the Macondo well's metal casing pipe during the static kill last month, it is possible that cement also entered the annulus, the space between the pipe and the bore hole. The Bottom Kill The federal government has finally declared the Macondo well dead after nearly five months of failed attempts and semi-successes by BP engineers to permanently plug the leaking well in the Gulf of Mexico. Page 8 of 8