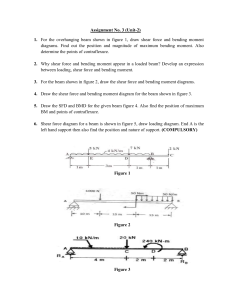

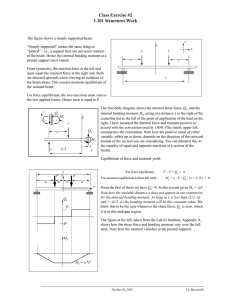

STRESS CONCENTRATION INTRODUCTION • Development of the basic stress equations for tension, compression, bending, and torsion – Assumption: no geometric irregularities occurred in the member under consideration. • But it is quite difficult to design a machine without permitting some changes in the cross sections of the members. In developing a machine it is impossible to avoid changes in cross-section, holes, notches, shoulders etc. Stress Concentration and Causes • Mathematical analysis and experimental measurement show that in a loaded structural member, near changes in the section, distributions of stress occur in which the peak stress reaches much larger magnitudes than does the average stress over the section. • This increase in peak stress near holes, grooves, notches, sharp corners, cracks, and other changes in section is called stress concentration. • Any discontinuity in a machine part alters the stress distribution in the neighborhood of the discontinuity so that the elementary stress equations no longer describe the state of stress in the part at these locations. • Stress concentrations can arise from some irregularity not inherent in the member, such as tool marks, holes, notches, grooves, or threads. • The section variation that causes the stress concentration is referred to as a stress raiser. • ……….. Then how to quantify this phenomenon ?..... INTRODUCTION • Example – Rotating shafts must have shoulders designed on them so that the bearings can be properly seated and so that they will take thrust loads. – Shafts must have key slots machined into them for securing pulleys and gears. INTRODUCTION • Example – A bolt has a head on one end and screw threads on the other end, both of which account for abrupt changes in the cross section. – Other parts require holes, oil grooves, and notches of various kinds. Let’s look back the theory of uniform stress • The assumption of a uniform distribution of stress is frequently made in design. • The result is then often called pure tension, pure compression, or pure shear. • The stress is said to be uniformly distributed with = Let’s look back the theory of uniform stress This assumption of uniform stress distribution requires that : The bar be straight and of a homogeneous material The line of action of the force contains the centroid of the section The section be taken remote from the ends and from any discontinuity or abrupt change in cross section Let’s look back the theory of uniform stress • Direct shear is usually assumed to be uniform across the cross section, and is given by = • The assumption of uniform stress is not accurate, particularly in the vicinity where the force is applied, but the assumption generally gives acceptable results. Normal Stress for Beams in Bending: Assumptions The equations for the normal bending stresses in straight beams are based on the following assumptions • The beam is subjected to pure bending. Means – Shear force is zero – No torsion – Axial loads are present For most engineering applications it is assumed that these loads affect the bending stresses minimally. • The material is isotropic and homogeneous. • The material obeys Hook’s law. Normal Stress for Beams in Bending: Assumptions • The beam is initially straight with a cross section that is constant throughout the beam length. • The beam has an axis of symmetry in the plane of bending. • The proportions of the beam are such that it would fail by bending rather than by crushing, wrinkling, or sidewise buckling. • Plane cross sections of the beam remain plane during bending. Normal Stress for Beams in Bending: Analysis • • • A portion of a straight beam acted upon by a positive bending moment M shown by the curved arrow showing the physical action of the moment together with a straight arrow indicating the moment vector. Elements of the beam coincident with the neutral plane have zero stress. The bending stress varies linearly with the distance from the neutral axis, y, and is given by where I is the second-area moment about the z axis. Normal Stress for Beams in Bending: Analysis • Designating σmax as the maximum magnitude of the bending stress, and c as the maximum magnitude of y often written as where Z = I/c is called the section modulus Shear Stress for Beams • For a beam segment of constant cross section subjected to a shear force V and a bending moment M at x, the net force in the x direction will be directed to the left with a value of • For equilibrium Shear Stress for Beams • Define the first moment of the area A′ with respect to the neutral axis • The transverse shear stress, which is always accompanied with bending stress. Torsion • Any moment vector that is collinear with an axis of a mechanical element is called a torque vector, because the moment causes the element to be twisted about that axis. • The angle of twist, in radians, for a solid round bar where T = torque , l = length, G = modulus of rigidity J = polar second moment of area • Shear stresses develop throughout the cross section are given by with Torsion • The assumptions used in the analysis are The bar is acted upon by a pure torque, and the sections under consideration are remote from the point of application of the load and from a change in diameter. Adjacent cross sections originally plane and parallel remain plane and parallel after twisting, and any radial line remains straight. The material obeys Hooke’s law. What is stress concentration??? Any discontinuity in a machine part alters the stress distribution in the neighborhood of the discontinuity so that the elementary stress equations no longer describe the state of stress in the part at these locations. Such discontinuities are called stress raisers, and the regions in which they occur are called areas of stress concentration. How to Estimate SCF • Difficult to determine SCF, theoretically, due to complex geometric shapes. • SCFs are found using EXPERIMENTAL TECHNIQUES Photo-elasticity, electrical strain-gauge methods • Finite Element Methods use very fine mesh at the SC region and transition of mesh from rest of the part to SC region must be gradual How to Estimate SCF • Photoelasticity is an experimental method to determine the stress distribution in a material. • The method is mostly used in cases where mathematical methods become quite cumbersome. • Unlike the analytical methods of stress determination, photoelasticity gives a fairly accurate picture of stress distribution, even around abrupt discontinuities in a material. • The method is an important tool for determining critical stress points in a material, and is used for determining stress concentration in irregular geometries. (Source: wikip) Photo elasticity technique • Suppose a small circular hole subjected to tensile stress • In photo elasticity technique, an identical model of the plate is made of epoxy resins. • The model is placed in a circular polariscope and loaded at the edges. • It is observed that there is a sudden rise in the magnitude of stresses in the vicinity of the hole. • The localized stress in the neighbourhood of the hole are far greater than the stress obtained by the elementary equations Difficulty to Estimate SCF • Most stress-concentration factors are found by using experimental techniques. • Though the finite-element method has been used, the fact that the elements are indeed finite prevents finding the true maximum stress. • Grid and strain-gauge methods both suffer from the same drawback as the finite-element method. Distribution of elastic stress • The distribution of elastic stress across a section of a member may be – Uniform as in a bar in tension – Linear as a beam in bending – Even rapid and curvaceous as in a sharply curved beam • Stress concentrations can arise from some irregularity not inherent in the member, such as tool marks, holes, notches, grooves, or threads. • The nominal stress is said to exist if the member is free of the stress raiser. • This definition is not always honored. Check the definition on the stress-concentration chart or table you are using. Theoretical stress-concentration factor • A theoretical, or geometric, stress-concentration factor or is used to relate the actual maximum stress at the discontinuity to the nominal stress. The factors are defined by the equations = = =used for normal stresses =used for shear stresses • The nominal stress or is more difficult to define. • Generally, it is the stress calculated by using the elementary stress equations and the net area, or net cross section. But sometimes the gross cross section is used instead, and so it is always wise to double check your source of or before calculating the maximum stress. Example: Thin plate loaded in tension • Thin plate in tension or simple compression with a transverse central hole. Net tensile force = t =thickness of the plate Nominal stress is = = Charts of Theoretical Stress-Concentration Factors Refer Shigley’s book Recommendation to apply stressconcentration factors In static loading, stress-concentration factors are applied as follows. • In ductile (ε ≥ 0.05 ) materials – Stress-concentration factor is not usually applied to predict the critical stress, because plastic strain in the region of the stress is localized and has a strengthening effect. • In brittle materials (ε < 0.05 – Geometric stress concentration factor is applied to the nominal stress before comparing it with strength. Gray cast iron has so many inherent stress raisers that the stress raisers introduced by the designer have only a modest (but additive) effect. Design suggestion stress-concentration factors • Stress concentration is a highly localized effect. In some instances it may be due to a surface scratch. • If the material is ductile and the load is static, the design load may cause yielding in the critical location in the notch. • This yielding can involve strain strengthening of the material and an increase in yield strength at the small critical notch location. • Since the loads are static and the material is ductile, that part can carry the loads satisfactorily with no general yielding. In these cases the designer sets the geometric (theoretical) stress concentration factor to unity. Stress-concentration factors in static loading of a ductile material • In static loading stress concentration is not so serious as in brittle materials because in ductile materials local deformation or yielding takes place which reduces the concentration. • This is the reason designers do not apply in static loading of a ductile material loaded elastically, instead setting = 1. • When using this rule for ductile materials with static loads, be careful to assure yourself that the material is not susceptible to brittle fracture in the environment of use. • The usual definition of geometric (theoretical) stress centration factor for normal stress and shear stress is = = • Since your attention is on the stress-concentration factor, and the definition of or stress is appropriate for the section carrying the load Stress-concentration factors in static loading of a brittle material • Brittle materials do not exhibit a plastic range. A brittle material “feels” the stress concentration factor or , which is applied by using = = • An exception to this rule is a brittle material that inherently contains micro discontinuity stress concentration, worse than the macro discontinuity that the designer has in mind. • Example: Sand molding introduces sand particles, air, and water vapor bubbles. The grain structure of cast iron contains graphite flakes (with little strength), which are literally cracks introduced during the solidification process. When a tensile test on a cast iron is performed, the strength reported in the literature includes this stress concentration. In such cases or need not be applied. How to mitigate SC/ Design to Minimize SC • Force should be transmitted from point to point as smoothly as possible. The lines connecting the force transmission path are sometimes called the force (or stress) flow. • Sharp transitions in the direction of the force flow should be removed by smoothing contours and rounding notch roots. • When stress raisers are necessitated by functional requirements, the raisers should be placed in regions of low nominal stress if possible. • When notches are necessary, removal of material near the notch can alleviate(make less severe) stress concentration effects. • A type of stress concentration called an interface notch is commonly produced when parts are joined by welding. Smoothen the force flow Smoothen the force flow Sharp transitions in the direction of the force flow should be removed by smoothing contours and rounding notch roots Guiding the lines of stress by means of notches that are not functionally essential is a useful method of reducing the detrimental effects of notches that cannot be avoided. These are termed relief notches. When notches are necessary, removal of material near the notch can alleviate stress concentration effects Grooves near a hole can reduce the stress concentration around the hole A type of stress concentration called an interface notch is commonly produced when parts are joined by welding THINK ?? Which one has the lowest SC in each group? Example-1 The 2-mm-thick bar shown in the figure is loaded axially with a constant force of 10 KN. The bar material has been heat treated and quenched to raise its strength, but as a consequence, it has lost most of its ductility. It is desired to drill a hole through the center of the40 mm face of the plate to allow a cable to pass through it. A 4 mm hole is sufficient for the cable to fit, but an 8mm drill is readily available. Will a crack be more likely to initiate at the larger hole, the smaller hole, or at the fillet? Example-1 Solution: Since the material is brittle , the effect of stress concentration near the discontinuities must be considered. Dealing with the hole first, for a 4mm hole, the nominal stress is = = = = 139 MPa The theoretical stress concentration factor taken from table with d/w=4/40=0.1 is 2.7 The maximum stress is = = =2.7(139) = 380 MPa Similarly for an 8mm hole = = = = 156 MPa The theoretical stress concentration factor taken from table with d/w=8/40=0.2 is = 2.5 The maximum stress is = =2.5(156) = 390MPa though the stress concentration is higher with 4 mm hole, in this case the increased nominal stress with 8 mm hole has more effect on the maximum stress. Example-1 Solution: For the fillet, = = = 147 MPa The theoretical stress concentration factor taken from table with D/d=40/34=1.18 and r/D=1/34=0.026. Then = 2.5 The maximum stress is = =2.5(147) = 368MPa The crack will most likely occur with the 8 mm hole, next likely would be 4 mm hole, and least likely at the fillet. Example-2 Find the maximum stress induced in the following cases taking stress concentration into account: a)A rectangular plate 60 mm × 10 mm with a hole 12 diameter as shown in Figure (a) and subjected to a tensile load of 12 kN. b) A stepped shaft as shown in Figure(b) and carrying a tensile load of 12 kN. Example-2 Solution: Example-2 Solution: Thank you