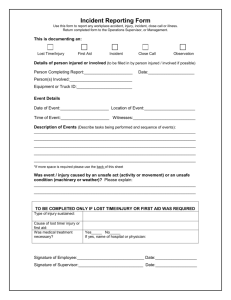

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/313239096 SAFETY MANAGEMENT SYSTEM AND METHODS OF SAFETY MEASUREMENT Research · February 2017 DOI: 10.13140/RG.2.2.26892.10882 CITATIONS READS 0 39,025 1 author: Elyas Jazayeri University of Kentucky 12 PUBLICATIONS 43 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Safety Performance through Operational Excellence View project Health Monitoring of Bridges and Structures View project All content following this page was uploaded by Elyas Jazayeri on 02 February 2017. The user has requested enhancement of the downloaded file. SAFETY MANAGEMENT SYSTEM AND METHODS OF SAFETY MEASUREMENT by Elyas Jazayeri Keywords: safety management, safety performance, measurement, construction Report submitted to graduate school Of university of Kentucky in partial fulfillment For the requirements for the degree of Master of Civil Engineering University of Kentucky Department of Civil Engineering 1 Abstract According to construction industry needs in order to improve safety performance, the definition of safety management system should be defined and the elements included in safety management system should be clarified in order to have good quality system. In order to have good quality safety management system we should have tools to measure safety within organization to understand where we stand according to safety performance and since measuring qualitative component is complex, so comparison between tools and methods of measurement should be implemented in order to get efficient safety management system (SMS). Keywords: Safety Management, System, SMS, Construction Industry, Safety Performance 2 Acknowledgement First of all, I am grateful to have the opportunity to study in peaceful environment of University of Kentucky. I would like to express deepest appreciation to Dr.Maloney and Dr.Dadi who guided me throughout the research and providing me with all necessary information and facilities. I also thank committee member Dr. Taylor who helped me achieving my master’s degree. 3 Contents Abstract ......................................................................................................................................................... 2 Acknowledgement ........................................................................................................................................ 3 Introduction ................................................................................................................................................... 5 Safety Promotion ........................................................................................................................ 10 Document and Data Information Management ........................................................................... 11 Hazard Identification and Risk ................................................................................................... 11 Occurrence and Hazard reporting ............................................................................................... 12 Occurrence Investigation and Analysis....................................................................................... 12 Occurrence Investigation and Analysis....................................................................................... 12 Safety Assurance Oversight Programs ........................................................................................ 12 Safety Management Training Requirements............................................................................... 13 Management of Changes ............................................................................................................. 13 Emergency Preparedness and Response ..................................................................................... 14 Performance Measurements ........................................................................................................ 14 Why Safety Performance Measurement ..................................................................................................... 15 Traditional Measures .................................................................................................................................. 15 Different level and types of measurement .................................................................................................. 18 Failure measure ........................................................................................................................................... 19 Before the act measures .............................................................................................................................. 19 Procedure of making safety sampling ......................................................................................................... 20 List of unsafe acts in safety sampling ......................................................................................................... 21 Objective Guidelines ................................................................................................................................... 24 Macro measures .......................................................................................................................................... 25 Audit ........................................................................................................................................................... 26 Conclusion .................................................................................................................................................. 29 References ................................................................................................................................................... 30 4 Introduction There are many definitions for safety management system (SMS) but according to Safety Management International Collaboration Group the definition of Safety Management System is “A series of defined, organization-wide process that provide for effective risk-based decisionmaking related to your daily business”[1]. Due to Rafiq the benefits of Safety Management System in construction industry is: “1. reducing the number of injuries to personnel and operatives in the work place through the prevention and control of work place hazards. 2. Minimize the risk of major accidents 3. Controlling workplace risks improve employee morale and enhance productivity 4. Minimizing production interruptions and reducing material and equipment damage 5. Reducing the cost of insurance as well as the cost of employee absences 6. Minimizing legal cost of accident litigation, fines, reducing expenditures on emergency supplies 7. Reducing accident investigation time, supervisors’ time diverted, clerical efforts, and the loss of expertise and experiences.”[3] Generally safety management system elements are consist of 3 main parts: 1. Administrative Management elements 2. Operational Technical Elements 3. Cultural/ Behavioral elements. Due to OTARs[2] the broad component of Safety Management Systems are, Safety policy which is a clear statement of the management propose, intention and policies for continuous safety improvement within organization level. The other component of safety management system is Objective that is planning for reaching that goals and proposed method of the safety goal’s measurement and objective can include vision and mission as well, we should consider that the main point for making objective is motivating 5 the whole organization . The other component is defining roles and responsibilities, for instance what is senior management role or defining safety and health staff or assigning responsibilities to supervisor and superintendents. The next component of Safety Management System is identification of hazards, which includes initial hazard identification reports and safety assessment. The next element is Risk assessment and mitigation which the methods of analyzing risks will be discussed and methods for mitigating risks will be decided. The other component is Monitoring and evaluation that could be review, audit or the other method that could be applied for quality assurance. The last elements of Safety Management System due to OTARs is documentation that says document all the SMS process like existing manuals, safety records, permit and allowance or any other related thing that can be documented. [2] Due to components of SMS we can conclude that the role of management is so important because of establishing the Safety Management System and allocating and assigning resources to go through process and also maintaining the existing process. Federal Aviation Administration demonstrate four essential component for developing Safety Management System which is: Safety Policy, Safety Assurance, Safety Risk Management, and Safety Promotion. They put senior management commitment, establishing clear safety objectives, define methods and process to meet safety goals under safety policy, and also they put training, communication, system and safety communication of awareness, matching competency requirements to system requirements and the other elements for making positive safety culture under safety promotion. Evaluation of effectiveness of risk strategies, ensuring compliance with SMS requirements and the other standards and policies is under safety assurance component. Risk control based on 6 acceptable rate risk rate and need for revising risk control is under safety risk management component. [5] International Helicopter Safety Team provides their attributes for Safety Management System like below: “1) SMS Management Plan 2) Safety Promotion 3) Document and Data Information Management 4) Hazard Identification and Risk Management 5) Occurrence and Hazard Reporting 6) Occurrence Investigation and Analysis 7) Safety Assurance Oversight Programs 8) Safety Management Training Requirements 9) Management of Changes 10) Emergency Preparedness and Response 11) Performance Measurement and Continuous Improvement” [4] The other organization that defines specific elements of Safety Management System for itself is Oregan OSHA Safety and Health model which contains of seven elements. The first element is Management Commitment that is so important in every SMS, because the management commitment to protect their employees is important for the employees as they see it everywhere within the organization. Due to Oregan, OSHA, there are some methods for showing to your employees as an management that you are serious about creating a safe work place for your employees like, setting measurable objectives something like organization financial goals , the other way is assigning safety responsibilities to your staff , establishing and maintaining active way of communication which employees can tell you their issues with safety in their work place, and the most important one is showing your safety concern at each moment that you have opportunity to talk or act in front of your staff and employees. 7 The next element of Safety Management System due to Oregan OSHA is Accountability and they recommend some ways to improve and strengthen accountability like; “Employees written job description clearly state their safety and health responsibilities, employees have enough authority, education, and training to accomplish their responsibilities, employees are praised for jobs well done, and employees who behave in ways that could harm them or others are appropriately disciplined” [6]. The other element is employee involvement which is important for continuous improvement of program. These are examples of employee involvement based on Oregan OSHA: “You promote the program, and employees know that you are committed to a safe, healthful workplace. Employees help you review and improve the program Employees take safety education and training classes. They can identify hazards and suggest how to eliminate or control them. Employees volunteer to participate on the safety committee.”[6] The next element is hazard identification and control which is so important because first it is needed to identify existing potential dangers and then you need to go through specific processes to get rid of those. Below are the ways to correct and control dangers based on Oregan OSHA: “ An initial danger identification survey A system for danger identification( such as inspection at regular intervals); An effective system for employees to report conditions which may be dangerous ( such as a safety committee or a safety representative) An equipment and maintenance program 8 A system for review or investigation of workplace accidents, injuries and illness A system for initiating and tracking danger corrective actions A system for periodically monitoring the place of employment.”[6] The fifth element for the Safety Management System due to Oregan OSHA is Incident/accident analysis. Accidents and incident should be analyzed for performing better and continuous improvement of safety management system and most of the time accident and incidents are preventable but due to poor performance and structure of safety management could not be detected, recommendation for having powerful analysis is that to figure out what the root cause is instead of chasing accidents as well as investigating to find the problem not to find the blame and it is the hard part because it should be strengthened by the safety culture of the organization and could not be reached over a night. The other element is based on Oregan OSHA is educating and training and they consider this element as one of the parameter for continuous improvement. Employees should know about the hazard and methods of controlling the situation and steps during emergency periods to reducing the risk and eventually reducing the injuries and fatalities over a time and these kind of information generally obtained through intensive training and educating program within organization, these kind of training sessions could be held periodically for labors, supervisors as well as management. According to Texas Department of insurance there are 7 steps to develop efficient and useful training program which are: determining training needs that can be lack of knowledge, skills or the other parameter, and the second step is identifying training needs because the objective of training is to ensure that employees know what they are supposed to know. 9 Third step is identifying goal and objective for your specific training to educate employees to perform the work more safely. The other steps to develop a training program are developing learning activities, conducting the training, evaluating the program and program improvement [7]. The last element of Safety Management System regarding to Oregan OSHA is Reviewing and evaluating the safety program that you have by gathering data and information from previous accidents or near misses and comparing with current data in order to evaluate the safety program and getting information about the strong and weak point of the program by asking employees, external experts or safety supervisors. Reviewing the program periodically is necessary in order to know whether you are in a right direction toward safety objectives or not. According to implementing a SMS, IHSS provide a checklist which is a guide that attributes of a SMS are implemented, below is the checklist under the 11 section: “Management Plan: 1. Policies, objectives and 2. Policies, objectives and requirements of the SMS are published 3. Organizational structure and key individuals and responsibilities are defined 4. Elements of the SMS are defined 5. Expectations and objectives of the SMS are conveyed to employees 6. A method to identify and maintain compliance with safety and regulatory requirements Safety Promotion: 1. Senior management’s commitment to the SMS published 2. Senior management visibly demonstrates their commitment to SMS 10 3. Outputs of the SMS is communicated to all employees 4. Initial and recurrent training is provided to all personnel 5. Competency requirements are defined for those individuals in key positions 6. Training requirements are documented and periodically reviewed 7. Lessons learned are shared to promote improvement of the safety program 8. Employee safety feedback system is established 9. “Just Culture” process is in place Document and Data Information Management 1. Safety policies, objectives and SMS requirements publicized 2. Safety regulations that govern the organization identified 3. Pertinent safety and regulatory information provided to all employees 4. Documentation describing the systems for each SMS component consolidated 5. Change control system in place for applicable documents 6. Personnel are educated on changes in documents 7. Obsolete documents are promptly removed 8. Periodic review of documents Hazard Identification and Risk Management 1. Employees receive feedback on reported hazards 2. Safety data analyzed 3. Corrective actions monitored for effectiveness 4. Hazards are monitored to identify trends 5. A non‐punitive disciplinary policy in place for reporting hazards 6. Provisions for anonymous submittals of hazards 11 Occurrence and Hazard reporting 1. Employees receive feedback on reported hazards 2. Safety data analyzed 3. Corrective actions monitored for effectiveness 4. Hazards are monitored to identify trends 5. A non‐punitive disciplinary policy in place for reporting hazards 6. Provisions for anonymous submittals of hazards Occurrence Investigation and Analysis 1. Employees receive feedback on reported hazards 2. Safety data analyzed 3. Corrective actions monitored for effectiveness 4. Hazards are monitored to identify trends 5. A non‐punitive disciplinary policy in place for reporting hazards 6. Provisions for anonymous submittals of hazards Occurrence Investigation and Analysis 1. Investigations conducted to determine root cause 2. Person(s) conducting the investigation technically qualified 3. Investigations identify what can be done to prevent future occurrences 4. Both the immediate causal factors and the contributory factors identified 5. Investigations include looking at organizational factors 6. Acts of “omission” and “commission” identified 7. Investigation reports provided to manager that has accountability and authority Safety Assurance Oversight Programs 12 1. Evaluations of operational processes conducted at regular intervals 2. Checklists are utilized to conduct safety evaluations 3. Contractor activities included in safety oversight programs 4. Processes evaluated by a non‐stakeholder 5. Results and corrective actions documented 6. Positive observations documented 7. Findings categorized 8. Results and corrective actions shared with all employees 9. Available technology used Safety Management Training Requirements 1. Safety orientation for all new employees 2. Competency requirements documented 3. Training requirements documented 4. Regularly scheduled safety meetings 5. Key personnel continuously educated on safety management best practices Management of Changes 1. Operational procedures analyzed 2. Changes in location, equipment or operating conditions analyzed 3. Maintenance and operator manuals are posted with current changes 4. Personnel are made aware of and understand any changes 5. Level of management with authority to approve changes identified 13 Emergency Preparedness and Response 1. Plan is readily available at work stations 2. Plan is relevant and useful 3. Emergency response plan periodically tested 4. Be updated when contact details change 5. Personnel briefed on the plan and their responsibilities 6. Training in emergency response procedures provided 7. Responsibilities defined for immediate response personnel 8. Responsibilities defined for secondary response personnel 9. Responsibilities defined for site security and accident investigation 10. Procedures for next of kin notification 11. Procedure for claims and insurance 12. Procedures for aircraft recovery Performance Measurements 1. Safety performance monitoring used as feedback to improve the system 2. Address individual areas 3. Are SMART (Specific, Measurable, Achievable, Results Oriented, Timely) 4. Linked to the organization’s business performance measures”[4] The most concentration of this report is safety measurement in Safety Management Systems so the last item which is performance measurement is highlighted throughout the report. 14 Why Safety Performance Measurement The important question is why should we measure the safety performance? There are many answers to this question and according to HSE, measurement is one of the four part of plan, do, check and act management system [8]. The other reason that could be mentioned for measuring safety performance is to get early warning sign and act rapidly if emergency action is needed, the other reason is that safety measurement could be the input for bonus and incentive program that is implemented in organization, the other reason is that measuring can alter our future behavior so it is necessary and also measuring safety performance is considered as a navigational tool. The main purpose of measuring safety performance is to check the current status of safety as well as observing progress with current safety management system in comparison with past, in the other way safety performance measurement is a benchmarking tool. There are lots of question related to measurement of safety performance like, what should we measure? Is OSHA incident records are reliable to decide on our safety performance on that? Which kind of measurement tools are need in organization? How can we select specific measurement tool for specific type of industry? Why OSHA recordable is not best safety metric? What are advantages and disadvantages of traditional method of measuring? Do we have effective measure in our organization? How much measurement should we have for each kind of hierarchy level in organization? Traditional Measures For many reasons in most of organization they still use traditional safety measures like OSHA incident rate which is number of incidents per 200,000 man-hours work in each organization and 15 the other measurement method which is so similar to OSHA incident rate is American National Standard Institute (ANSI) which is the amount of incidents per 1 million man-hour work. Based on SLCCC, injuries that requires physician to treat them (if physician does not perform treatment it is not a recordable injury) and also when workers become unconscious during his or her job, it should be considered as recordable injuries. The way of calculation of OSHA incident rate is easy and it is calculated as it mentioned above based on 200,000 man-hour works, as an example when the company has 10 employees and each of them works for 2000 hours annually so the sum of the man hour works is 20,000 and if the company had 2 incident records in that year, the incident record is multiplying 200,000 by two, over 20,000 and it is equal to 20, which means in the last year in every 100 employees, 20 of them have been involved in incidents. As it is obvious the IR is so high and it is because of the size of organization and when the size of company or organization is bigger, this rate is become more meaningful. The other rate which is used for calculating lost time cases is called LTC, which is number of lost time cases multiplying by 200,000 and divided by number of man- hour work. Like the previous example if we assume that both incident cases had lost days related to incident we come up with LTC rate of 20 again and it means that in every 100 employees 20 of them had suffered lost time due to their injuries related to incidents. The other rate which is used to calculate the amount of lost days due to incident is called LWD rate that is calculated by multiplying number of lost days by 200,000 and dividing by number of man-hour works and eventually you obtain LWD rate which should be used only in large companies in order to get meaningful number. Assuming there were 4 days lost due to 2 incident 16 that we had in the company, we get 40 days which means for every 100 employees, 40 days were lost due to their injuries related to incidents. The other quantitative rate is DART, which is calculating the number of incidents that had one or more lost days or restricted days which resulted to transfer employee to different job, and it is calculated by multiplying number of DART incidents by 200,000 and dividing it by number of man hour works. And the outcome will be number incident in lost, restricted days or transferring employees to the other job in every 100 employees. The other rate which is used to give a company an average of number of lost days per incident is called Severity rate which is calculated by dividing number of lost work days by total number of recordable incidents that the result is average number of day lost for every recordable incident which this rate is used by few number of companies because it only gives you the average number of lost days. OSHA will use recordable incident rates to compare safety performance in specific classification of company with their past safety performance [9]. Some disadvantages of using traditional measurements are [10]: In smaller organization the validity of data is low Doesn’t say that much about whether the company is progressing or not This kind of measurement doesn’t say about the way of fixing safety issues Most of the time they measure luck instead of the real fact within organization Cannot relying on accuracy of data Lots of paper work and bureaucracy in filing and incident record keeping in order to incident rate measurement Near misses are not reported most of the time and this decreases the accuracy of data 17 OSHA data are not predictive and cannot predict future incidents based on current data Different level and types of measurement Different types of measurement should be useful for different type of level within organization and based on the responsibility and duties, types and methods of measurements are different for them. We should address that output from safety measurement most of the time is needed by internal sections within organization like, CEO, supervisors, superintend and, stake holders, meanwhile these kind of information is necessary and should be reported to external organizational and agencies outside like insurance companies or union and the other types of external organization. Outcome from safety performance measurement is so important for companies and organization which work as a member for bigger organization to report their safety condition. High hazard companies’ work under certain type of licensing and permitting that due to safety performance measurement outcome, their activities should be continued or suspended. All safety measurement results are different for any types of purposes that were mentioned above. Based on Dan Peterson there are two general types of measurement which are micro measures and macro measure. Most of the time macro measures are needed by upper management because of: Determining the effectiveness of safety program and answering to questions like: is the system better today or not? Or which elements of our Safety Management System are working and which are not? Where should we invest and put effort for our future safety program? Providing cost benefit ratio of the safety program 18 To analyze the necessity of maintaining and repairing some units of safety program or eliminating some units which are useless Result measures are needed all the time by upper management and, result measure and activity measure is needed by middle management and for supervisors and employees, just activity measures are needed. Activity measure which was mentioned in middle management is a bit different with activity measurement in supervisor activity, middle manager most of the time their responsibility is to motivate their supervisors and the activity measure in this case could be, do they meet their supervisors regularly and do they monitor their work’s quality or not. The advantages of activity measures for supervisors are: [10] They are flexible and suitable for objective setting approaches “Activity measurement measures the presence rather than the absence of safety”[10] They are simple and easy to use They are most valid type of measurement in order to measure the supervisor performance Failure measure The outcome of injury record keeping is the most popular part of failure measure and it is necessary to measure upper management safety performance and due to that, injury records should be broken down by unit. Before the act measures This type of measure usually measure and assess supervisor work or a kind of work group before the possible accident occurs. As an example when the work environment is periodically inspected to measure whether he or she is doing right or not. 19 The other example of before the fact measure is safety sampling that supervisor’s communication between his or her employees will be measured in order to get information about how safely employees are working. Safety sampling is one of the best tools for this kind of measurement. Safety sampling measures the effectiveness of line manager’s safety activities but not regarding to accident. It is motivational tool for supervisor and line manager because for he/she is important that hen sample is taken his/her employees are working safely and to get this they try to implement safety activities like training before any action, inspecting and using suitable personal protective equipment(PPE). Procedure of making safety sampling 1. Prepare a list of unsafe acts: In each specific job site there are list of unsafe acts that contains act that occur in the job site which can lead to accidents, we should have a complete list of unsafe acts in order to go through safety sampling. Each unsafe act should have number or code in order to report it easily. 2. Taking the sample: we should assign an inspector to take the sample by using the list of unsafe acts in his/her hand and go through the line and observe and monitor each employee separately and wait until you can determine whether he/she is performing their job safe or not. When you write down any unsafe act for each employee the determination could not be changed. 3. Validating the sample: for validating the sample we should have minimum number of 4(1−𝑝) observation which is obtained by this formula; N= 𝑦∧2∗𝑝 , which N is total number of observation required, p is percentage of unsafe observation and y is the desired accuracy. 20 As an example if we want to have + or – 10% accuracy and we had 126 observation and the total amount of unsafe acts which were observed is 32, so based on this equation we should have minimum of 1200 observation to get that accuracy. 4. Reporting to management: safety sampling report should include total percentage of unsafe activities by each department separately. Report should contain percentage of unsafe activities by supervisor and foreman. It should also contain the types of unsafe activities which were observed. [10] List of unsafe acts in safety sampling List of unsafe acts in safety sampling could be items like: incorrect gripping, improper footwear, improper pouring, wearing rings, standing in front of machines, walking under the load, improper lifting, improper material handling, feet under loads, improper and unsafe loading, loosing material and falling material from hand, improper dumping, lack of PPE, repairing moving machine, ladder not tied, unbraced forms, working in height without support, uncovered rebar, it should be considered that list of unsafe acts should be detailed in depth, instead of just mentioning general items and any additional unsafe item that the observer cannot find that in the unsafe acts list should add that to the list that for future observing that unsafe act has specific item for itself. In front of each unsafe act in safety sampling worksheet, there are columns for department names that each unsafe item could be related to department associated with that easily. Measurement is divided into two broad categories which are micro measures and micro measures which is obvious that micro measurement is related to middle management, 21 supervisory and line employees and macro measurement is related to measurement in whole organization and give general status of the organization which is upper management concern. Based on Dan Peterson the key driver at the lower level of organization is performance to goal and there are several categories in order to set goals: 1. Routine Goals: there are related to routine, regular and repetitive works and as an example for the supervisor it might be a goal related to number of incidents or inspections. 2. Project Goals: these kind of goals are related to the new or special project or something that is not regular or repetitive and special kind of activities are needed to reach the goal. 3. Creative Goals: These kind of goals could be related to some activities that should be implemented in order to innovate or improve in specific part of management system. 4. Personal Goals: these kind of goals are less common but it is used in order to improve personal skills to get more effectiveness in activities. We should be aware that in the organization, most of the time the goals are in more than one category it means that the goal could be in both routine and project. The first thing for setting an objective is identifying and measuring our objective that whether they are good or not. Good objective should be in below criteria based on Dan Peterson: 1. Zeroing of Objectives: Good objective aims at the specific and in detail area and not in broad and general range, generalizing the objective makes it useless. 2. Individuality of Objectives: “This refers to the specificity of the objective to the subordinate for whom it is set. An individual objective is one that requires results and performances that the individual subordinate can do alone. This means that the 22 subordinate must have enough control over those things that need to be done to attain the objective. An objective for the staff safety director to improve the record in department A is and objective that is not individual to the safety director because, to attain the objective, that director is dependent on the performance of the supervisor of department A” [10]. 3. Measurability of Objective: objectives should be measurable to everybody could be assessed by his/her management as well as himself. As an example becoming better supervisor in next month is immeasurable and neither upper manager nor him/herself cannot asses that whether he reaches the objective or not. 4. Reality of the objectives: Objectives should be based on the previous performances and data or the other valid facts. Objectives should not be like wish and dream and if they are not based on valid and true facts they become useless. According to Dan Peterson, there are three additional factors for good objective which will be discussed below: 1. “It would be leveled; that is, it should be aimed directly at the organizational level of the person. A goal that speaks to the results of a supervisor’s department in a specific area is at the supervisor’s level if he or she is the direct supervisor of that department. Requiring a supervisor to help the corporation attain the desired frequency rate is not an objective that speaks to a supervisor’s level. An objective at the supervisory level would spell out specific action that he or she can carry out that will help attain the goal. 2. It must be understood both by the superior and the subordinate. If it is not clearly grasped by both sides, it is a poor objective. Misunderstandings are one of the biggest reason for unattained objectives. 23 3. It must be mutually agreed upon by both parties. Neither party to the process may impose his or her will on the other. Without mutual agreement, the objective is relatively useless” [10]. Based on Pierce, setting the objective has six guidelines; Objective Guidelines 1. Set goal and objective is a part of planning 2. Objective and goal should be worded clearly without any misunderstanding 3. Goals and objectives should be realistic and based on real facts 4. Accomplishing goal and objective should be under that person or department responsibility 5. Objective and goal should be assigned to someone or department 6. Goals and objectives should have determined completion date [11] According to ISHN article, objectives and goals should have these attributes: 1. Defined by employees: Needed improvement in each part should be considered for employer and in that area he or she should suggest objective and goal offers that employee can select between those options the one that can fit in that. 2. The acronym SMART is used in order to easily tells the attribute of good objective and it stands for (“S” for specific, “M’ for motivational, “A” for attainable, “R” for relevant and “T” for track able. 3. The objectives and goals should be achievable but challenging 4. Objective should be few in number and should have flexibility. 5. Objectives and goals should be reviewed periodically. [12] 24 There are some possible reasons why objectives and goals are not meet in organizations: 1. The first factor is that the objective is not constructed well and so in many cases this is the main reason for not reaching the goal. 2. The second reason for not reaching the goal is that the employees don’t have sufficient skill to perform that job and reach that goal so lack of ability is the other important factor for not reaching the objective. 3. There might be a change in subordinate following the agreement on reaching the objective. 4. There might be some important problems and issues related to executive line like lack of material and resources or equipment to reach the objective. Macro measures As we discussed before, the macro measurement is exclusively for top management within an organization and at top level of management all of the results that could be a concern is result measures instead of performance measures which is related to middle management, line managers and supervisors. Although these kind of measurement are called lagging indicators and just after act will be measured but at top level of management we are focusing more on result measures. There are three kind of methods for measuring safety within organization which are: incident and accident rate like what should be reported to OSHA which was discussed completely before in this report. The other two methods for measuring safety in organization from macro level standpoint are audit and perception surveys [10]. 25 Audit Audit is a way to evaluate effectiveness and to asses compliance in a workplace. Organizations do audit in order to identify what regulation is applied to their organization according to the safety standards and safety agencies, auditing is a way to assess the current safety management system in place and evaluate the methods used to achieve the objectives in the safety management system. Based on SASA, there are at least 6 type of audit related to health and safety which are: health and safety audit, walk around audit, health and safety management audit, project health, safety and environmental auditing, process safety audit, and product safety audit [13]. As an example in health and safety management audit based on Croner’s the item below will be looked at: 1. “Does the company have adequate procedures for identifying specific H&S requirements which apply to its undertakings? 2. Are the procedures followed and are responsibilities set out clearly and understood? 3. Does the company's H&S policy documentation include adequate procedures for identifying hazards which exists at the workplace, and for assessing regularly the risks to employees and others affected by the workplace and workplace activities in order to identify the measures needed to avoid their exposure to risks of harm? 4. Are adequate risk assessment procedures also set out for hazards of products and /or services supplied by the company in order to identify the measures needed to avoid risks of harm to people such as distributors, customers, end-users and members of the public? 5. Are the procedures in 3 and 4 followed, and are responsibilities set out clearly and understood? 26 6. Does the company have adequate procedures for setting, reviewing and revising as necessary its health and safety standards for meeting specific H&S requirements and for meeting its general duties to protect employees and others form risks identified in the company's risk assessments? 7. Do the procedures for setting company standards include the identification of measurable targets which can be audited to monitor the level of compliance with company standards? 8. Are the procedures in 5 and 6 followed and are responsibilities set out clearly and understood? 9. Does the company have adequate procedures for planning, implementing, controlling, monitoring and reviewing the measures identified in 3 and 4? 10. Does the company have adequate procedures for carrying out H&S audits to check that the procedures in 9 are followed and that the measures in 3 and 4 are effective?”[14] Based on Dan Peterson, the Idea and concept of audit came from long time ago and after a while became more popular as we can see today many examples packaged audit like Nosa International System in South Africa, British Safety Council System and International Standard Organization which is called ISO. According to Dan Peterson, there are nine elements identified by National Safety Council and these are Management’s credibility, Supervisory performance, employee involvement, employee training, employee attitudes and behavior, communications, accident investigation procedure, hazard control, and stress. As we discussed about the methods of measurement in the organizations like perception survey and audit, there are some metric measurement for above items that will be mentioned below: 27 Management’s Credibility: The best methods for measure this parameter are perception survey and audit but beside that there are some metrics for measurement management’s credibility like percentage of health and safety meetings that top management are attended in that or percentage of safety objectives that achieved based on the schedule. Supervisory Performance: the best way to measure this parameter is perception survey but beside that we can mention some metric to measure this like, number of weekly, monthly or daily safety meeting held by supervisor. Employee involvement and participation: the best way o measure this factor is perception survey although beside this method there are some metrics to measure this parameter like number of peer observation or amount of employee who participate in safety meetings. Employee training: like previous parameter the best way to measure this factor is perception survey but beside that some metrics could be mentioned in order to measure this factor like the amount of budget which is assigned for health and safety training or percentage of employees that have special training near the usual training. Employee attitude and Behavior: Like previous factor that the best way to measure them is perception survey, the best way to measure this parameter is also perception survey and the other metrics that should be considered as methods of measurements are: percentage of participation in any safety observation or percentage of those observation that accomplished on schedule. Communications: Additional metrics for measuring this parameter beside perception survey could be number of safety meetings or effectiveness of rewards. Accident investigation procedures: Both audit and perception survey are best ways to measure accident investigation procedure and beside these two ways they are some metrics methods to 28 measure this parameter like percentage of accidents that organization could investigate to get root cause or average time from when incident happens till investigation get completed or the average time from incident occurs till that issue get corrected. Hazard Control: Both perception survey and audit are best methods for measuring hazard control item but beside that there are metric methods for measuring like number of accidents or incident that demonstrate the failure in planning or percentage of design staff that has some special training in ergonomics. Stress: some metric methods to measure this item could be average over time or number of safety audits that was carried out. Conclusion According to the definition and advantages and disadvantages of methods of measurement which were discussed in this paper, we can conclude that most of the types of measurements are useful but implementation and quality of these kind of measurement should be considered first and after that it should be mentioned that we should make sure that each specific type of measurement is related and needed by specific level within organization and mixing up these measurement types with unrelated level of organization can cause issue and inaccurate vision from the section under measurement. 29 References 1. Safety Management System International Collaboration Group, Safety Management System Principle 2. Air Safety Support International, Safety Management System Component, 2006 3. Choudhry, Rafiq M., Dongping Fang, and Syed M. Ahmed. "Safety management in construction: Best practices in Hong Kong." Journal of professional issues in engineering education and practice 134.1 (2008): 20-32. 4. Safety Management System Toolkit, International Helicopter Safety Symposium, Quebec, Canada, 2007 5. Federal Aviation Administration (FAA), Safety Management System Components, 2009 6. OSHACADEMY, Elements of a Safety Management System 7. Texas Department of Insurance Division of Worker’s Compensation Workplace Safety, Safety Training Program Development, HS94-35C (9-07) 8. A Guide to Measuring Health & Safety Performance, Health & Safety Executive (HSE), December 2001 9. Incident Rate, Rochester Institute of Technology website 10. Petersen, Dan. Measurement of safety performance. American Society of Safety Engineers, 2005. 11. Safety Goals and Objectives, American Society of Safety Engineers, 3009, page 14-20 12. Geller, Using Performance Objectives and Corrective Feedback, Safety Performance Solutions, ISHN’01-11 13. “What are Safety Audit?” , The Society of Accredited Safety Auditors Limited website 14. Croner’s Guide to Health and Safety, Croner CCH Group Ltd, United Kingdom, 2005 15. Safety Audit/Inspection Manual, American Chemical Society Committee on Chemical Safety, Washington, 2000 30 View publication stats