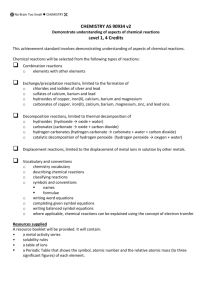

A New Method for the Quantitative

Determination of Soluble Carbonates in

Water-Based Drilling Fluids

R. L. Garrett, SPE-AIME, Exxon Production Research Co.

Introduction

The mechanism by which bicarbonate (HC03-) and carbonate (C03=) ions adversely affect a deflocculated,

clay-based drilling mud's performance (and even these

ions' true concentrations) has been a controversial point

in the industry for many years. l Under field analysis

conditions, only an estimate of carbonate concentration

in fIltrate samples is obtained by API alkalinity titrations.

Even under ideal laboratory conditions, alkalinity titrations only approximate the true carbonate content of

complex muds.

However, a reliable method that allows direct carbonate analysis of muds recently was developed. The Garrett

Gas Train/Carbonate (GGT/C03 =) method determines

total soluble carbonates as gaseous CO2 freed from the

sample upon acidification in a small, transparent, plastic

gas train. The evolved CO 2 is measured quantitatively

using a commercial gas detector tube. The GGT/C03 =

method was developed with the same concept as the

GGT/S= method for measuring sulfides, which recently

was adopted as an API permanent procedure. 2 The similar chemical behavior of the CO 2 -carbonate and

H2 S-sulfide systems in aqueous solutions allows analogous approaches to quantitative analyses and chemical treatment. Although alike in many ways, the

gas-trainldetector-tube analysis method for carbonates is

more restrictive and sensitive to detector-tube flow conditions than is sulfide analysis. These conditions are

specified later when the procedure is described.

0149-2136/78/0006-6904$00.25

© 1978 Society of Petroleum Engineers of AIME

Uses for GGT/C03 = analyses go beyond the main

application for measuring and treating accumulated carbonates in field muds and include (1) studying carbonate

generation rates caused by thermal degradation of organic additives that produce CO2 in muds (such as lignites, lignosulfonates, carboxymethyl cellulose, tannins,

and starches), (2) studying the rate of CO2 absorption

from air into a circulating mud when influenced by various equipment used to process muds, (3) analyzing soluble carbonates in commercial barite to determine if soda

ash or sodium bicarbonate are present, (4) studying the

chemical reaction efficiency between carbonates and a

given treatment material such as lime - especially useful

for field and laboratory pilot tests of problem muds, and

(5) monitoring accumulation of bacterially and chemically produced CO 2 in packer muds, ballast muds for

ships, and muds stored in tanks.

Carbonate Chemistry in Water-Based Muds

In alkaline, aqueous drilling or workover fluids, soluble

carbonates are likely to accumulate from a wide variety of

CO 2 sources. Regardless of the source, if CO2 is generated internally or enters the mud externally, it reacts

immediately with alkaline hydroxyl ions (OH-) to form

HC03- and C03= ions. A chemical eqUilibrium is established at a given temperature, which is controlled by the

H+ and OH- ion concentration or mud pH. These equilibria involve the components shown in Eqs. 1 and 2.

CO 2

+ OH- ~HC03-

.................... (1)

This paper presents a new, direct methodfor measuring soluble carbonates in a drilling fluid.

The method is designed primarily for field use in guiding mud treatments and controlling

adverse mud rheology. Laboratory data are given to verify the method's accuracy andfield

experience illustrates its usefulness in mud control.

860

JOURNAL OF PETROLEUM TECHNOLOGY

TABLE 1-S0LUBLE CARBONATE ACCUMULATION FROM THERMAL DEGRADATION OF ORGANIC MUD

ADDITIVES IN ALKALINE WATER

(Measured by GGTIC0 3 ~ Analysis)

Lignosulfonate Additive,

10lb/bbl

._--_._---Hot roll- time, hours

- temperature, of

Solution pH - before hot roll, pH

- after hot roll, pH

Carbonates ----: before hot roll, mg/liter

- after hot roll, mg/liter

Carbonate accumulation, mg/liter

Test 1

24

150

11.3

10.6

200

310

110

Test 2

24

300

11.4

8.8

150

560

410

Test 3

24

400

10.9

6.9

150

1,375

1,225

Lignite Additive,

10lb/bbl

------Test 4

24

150

11.0

10.3

440

750

310

Test 5

24

300

11.0

9.0

440

2,375

1,935

Test 6

24

400

11.9

8.9

440

2,250

1,810

All samples filtered through 0.45 ,umillipore filter before analyses to avoid solid carbonates.

+ OH- ~ C03 = + H 20 ............. (2)

HC03 -

Carbonate equilibria with pH is seen more clearly in

Fig. I for the aqueous system of 10-2 •5 moIlliter of total

carbonates in fresh water at 25°C. 3.4 Total carbonates are

the sum of (C0 2 ) + (HC03 -) + (C03 =), the "soluble

carbonates" measured by the GGT/C03 = method. The

three species coexist in various proportions, depending

on solution pH. For example, Fig. 1 shows that at low

pH, gaseous CO2 dissolved in water predominates while

HC03- and C03= concentrations are essentially zero.

This is the basis for the GGT/C03= analysis. By acidification in the train, all C03= and HC03- ions in the sample

are converted to CO 2 gas that is freed from solution and

analyzed by a CO2-detector tube. Fig. 1 also shows that

for the approximate pH range of 6.3 to 10.3 the HC03ion predominates and above pH 10.3 the C03= ion predominates. This last pH is desirable for chemical removal

of soluble carbonates as insoluble CaC03:

Ca++ + C03= ~ CaC03~' ................. (3)

At mud pH's near 10.3, the reaction proceeds more

rapidly because the C03= ion predominates over the

HC0 3- ion. If lime is selected as the treatment chemical

for C03= removal, the mud's pH need not exceed 10.3

because OH- ions freed from lime become available to

raise pH and convert HCoa- to C03= for subsequent

removal as:

Ca (OH)2

+ C0 3=

~ CaC03~

+ 20H-,

....... (4)

-1

.z

COz+HzO

HCOi

i~

1-5

§-&

Sources of Carbonates in Muds

A widely accepted source of soluble carbonate accumulation in muds is CO 2 intrusion from formations being

drilled. As CO 2 enters an alkaline mud, it reacts with

OH- ions and soluble carbonates accumulate. Another

common (although not widely recognized) carbonate

source is thermal degrac;lation of organic additives such as

lignite and lignosulfonate, found in wells where the mud

encounters circulating or static temperatures of 300°F or

higher. Organic chemistry textbooks5 teach that CO2 is

liberated at this temperature by alkaline decarboxylation

of organic acid groups, especially from aromatic acid

molecules. Such structural groups are found in lignite's

humic acid, for example. 6 Table 1 shows carbonate levels

attained during laboratory hot-roll aging of a commercial

lignite and lignosulfonate in alkaline solutions. Lignite is

a more potent source of carbonates than lignosulfonate

because humic acid is high in aromatic carboxylic acid

groups.

Another source of CO 2 comes from air when mixed

into alkaline mud by mechanical devices such as jet

happers, mud guns, hydrocyclones, and screens. However, no quantitative data currently are available on this

source. Similarly, if rig-engine exhaust gas is bubbled

through mud to displace air as a way to reduce oxygen

corrosion, soluble carbonates can be expected to accumulate from the absorption of CO 2 •

Another source of carbonates is bacterial action on

organic matter. Fig. 2 shows carbonates generated in a

field mud stored at 70 to 75°F for more than 92 days.

Some of the mud was treated on the first day with biocide

and some was not. The biocide-treated sample still increased in carbonates, but not nearly as rapidly as did the

untreated sample.

Alkalinity Methods for Carbonate

Estimation

-7

.

-9

HC03- + OH- ~ C03 = + H20 .............. (5)

Gypsum would not produce these OH- ions. Guidelines

for lime/gypsum treatments based on GGT/C03 = results

are given later with experimental evidence of the low

stoichiometric efficiency attained for the reaction of

Eq.4.

3

4

6

7

pH

Fig. 1-Distribution of carbonate species in fresh water

containing 10-2 . 5 mol/liter total carbonates.

JUNE,1978

Alkalinity is defined as the combining power of a base as

measured by the maximum number of equivalents of an

acid with which it can react to form a salt. 7 In water and

waste-water analysis, "alkalinity" is routinely interpreted to represent C03=, HC03-, and OH- ions, although other alkaline materials are shown to contribute to

861

the alkalinity of waste waters. 7,8 In complex mud filtrates, appreciable amounts of other alkaline materials

can be present that react with the standard acid used to

measure API alkalinity. These interferences and procedurallimitations make API alkalinity methods for carbonate analysis only approximations.

API RP 13B2 offers two filtrate alkalinity tests: (1) the

conventional method of P, and M" and (2) the alternate

method of P" PI' and P 2 • For all "P-type" (phenolphthalein) alkalinities, the acid-titration end-point is

pH = 8.3; thus, P, and alternateP" PI' and P 2 titrations

encounter fewer spurious alkaline materials than does the

M, (methyl orange) titration that ends at pH = 4.3.

Consequently, the alternate method of P" PI' and P 2 is

potentially more accurate as an estimate of carbonates

than is the P, and M, method for a complex mud filtrate.

In fact, theP, and M, method long has been recognized as

error prone and was not given a quantitative interpretation in API RP 13B. RP 13B allows use of the P" PI'

and P 2 method to estimate OH-, HC03 -, and C03 =,

but precautions clearly state that interference errors may

exist.

Several technical and operational problems also occur

with the API alternate P" PI' and P 2 alkalinity as used for

carbonate measurement. The first problem arises from

the 25: 1 initial dilution of the sample. This lowers the

sample pH and makes the ionic distribution of carbonates

in the sample different from the distribution in the mud.

Total carbonates are not changed by this dilution unless

CO 2 escapes as gas or ions react with impurities in the

water. The P, used with M, in the conventional nondilution titration is not the sameP, used as part of the P" PI'

andP 2 in the alternate dilute titration. This is a confusing

point that causes interpretive errors if a conventional P,

value is used in carbonate calculations using the alternate

method. A second problem involves the precise experimental technique and equipment required to measure two

volumes ofO.IN NaOH and get exactly the same volume.

The first volume is added to the solution used for PI'

containing the sample. The second volume is added to P 2

solution with water as a blank. Any volumetric difference

between the two O.IN NaOH additions is magnified

fivefold in the volume of weak (0.02N) acid used in the

PI and P 2 titrations. A third problem involves stirring

speed during PI and P 2 titrations. In this method, C03 =

precipitates as solid BaC03 before PI (sample) titration.

MOO,-----------------------------------,

.. <

//

--

...--

_A

.,., .... / NON-IIIOCIDE TREATED MUD

/"/

i:ii 4I11III

i

"

3II1II

~

I-

",,//

.....

BIDClDE TREATED MUD

•

I

-

~RD MUD FROM WELL C . UGNITHIGNIlSULFDNATE TYPE

RRST LAB ANALYSIS

I~ 11I1IlJClDE TREATMENT·

~

0

rn

D.54 ppb SODIUM TRICIILDRDPHENATE

~

~

•

m m M

ElAPSED DAYS SINCE BIOCIDE TREATMENT

~

~

Fig. 2-Carbonate accumulation in a stored field mudcomparing biocide treated with nonbiocide treated samples.

862

However, 10caJized areas oflow pH in the vessel caused

by inadequate stirring and/or too rapid acid addition

causes BaC03 to dissolve and react with the acid titrant.

Experience in laboratory and field use of PI and P 2

titrations has shown the API alternate alkalinity is a

tedious test. Comparison of GGT/C03 = with API alkalinity data using field mud samples is discussed later.

Another approach to carbonate measurement using

alkalinity, which avoids the error-prone M, titration, is a

correlation between P, and pH. The pH-P, correlation is

obtained mathematically from equilibria information, but

is accurate only for dilute water systems. A set of correlation plots would be needed to compensate for ionic

strength effects on dissociation of carbonates in highly

treated or saline muds. Proper use of the pH-P, correlation also requires reliable field pH measurements.

In general, alkalinities are not considered a sufficiently

accurate field method for quantitative carbonate analyses

of highly treated muds, where carbonate problems are

most likely to occur. A field-worthy analysis method is

needed that can measure carbonates directly - as the

GGT/C03 = analysis does. A GGT/C0 3 = test can detect

carbonates and their concentrations, thereby indicating

the level oflime or gypsum treatment needed. Often, it is

just as important to know when carbonates are not present

and when a lime/gypsum treatment is not needed. If

carbonates are absent, unnecessarily adding lime or gypsum can create a serious rheological or filtration-control

problem or worsen an existing problem.

Garrett Gas Train Carbonate Analysis

Equipment

A portable, three-chamber, transparent plastic Garrett

Gas Train is used for GGT/C03 = analyses. This is the

same gas train used for GGT/S= analyses. Other than the

gas train itself, with its attached gas-cartridge holder and

regulator, equipment needed for GGT/C03 = tests are (1)

a I-liter gas bag with an 8-mm stopcock, (2) Drager

hand-operated vacuum pump, (3) Drager No. CH30801 9 CO 2-Detector Tubes, and (4) nitrous oxide (N20)

in small pressurized cartridges as the carrier gas. (If an N2

or He gas supply is available, either can be used in place

ofN20.) Chemicals needed are 5N sulfuric acid, octanol

defoamer, and distilled water. Equipment for GGT/C0 3 =

is available through most major mud service companies

and replacement Drager tubes and N20 cartridges (the

major expendable items) are available worldwide.

Procedure

A GGT/C03 = analysis is a simple, three-stage operation.

Stage 1 is shown in Fig. 3A. The first step in Stage 1 is to

place 20 ml of deionized water in Chamber 1 with a few

drops of octanol defoamer. Chambers' 2 and 3 remain

empty as foam traps. The top is sealed on the gas train.

Carrier gas then is bubbled gently for about 30 seconds

through the water in Chamber 1 and vented to the atmosphere to purge most of the dissolved CO 2 from the water

and air from the train. Next, a fully collapsed I-liter gas

bag is attached by the hose to the outlet of Chamber 3. A

measured volume of filtrate sample (discussed below) is

injected with a hypodermic syringe and needle through

the rubber sep1tUm in the top of Chamber 1. Then, 10 ml

of 5N sulfuric acid is injected by syringe through the

septum and the gas train is rocked to mix the liquids

JOURNAL OF PETROLEUM TECHNOLOGY

in Chamber 1. Gentle, carrier-gas flow is restarted and

continued until the gas bag is full and firm to the touch,

which requires 3 to 4 minutes. The stopcock then is

closed to seal the bag.

Stage 2 (Fig. 3B) involves disconnecting the gas bag

from the train outlet and inserting a Drager No .

CH-30801 CO 2-Detector Tube between the hand pump

and gas bag. The stopcock is opened and all gas is drawn

from the bag through the tube, using 10 strokes on the

hand pump.

Stage 3 is reading the detector tube. If CO 2 was generated from C03 = and HC03 - ions in the sample, a purple

stain appears in the tube (Fig. 3C). The stain length (read

in tube units) is used to calculate the carbonates present in

the filtrate sample:

GGT/C03 = = stain length x 25,000 , . . . . (6)

sample volume

where

GGT/C0 3 =

Strain length

= tube units on Drager No. CH-3080 1

tube,

and

Sample volume

= mi .

Samples

For testing a drilling fluid, the recommended sample

for GGT/C0 3 = analysis is filtrate from the API roomtemperature filtration test. From 1 to 10 ml of filtrate is

generally enough for field muds . The filtrate should be

free of solids; therefore, the fIrst spurt of filter-press

liquid should be discarded because it could contain

CaC0 3 particles that would cause erroneously high

GGT/C03 = values. In the laboratory tests discussed here,

API filtrates also were fIltered through 0.45JL millipore

membrane filters as a precaution against solid carbonates

in the samples.

"To obtain the GGT/CO,· concentration in units of equivalents per million (epm) or

milliequivalents/liter of CO,-, subsmute 833 for 25,000 in the numerator of Eq. 6.

= mg/liter* , as COa=,

,/

f'

Fig. 3A-Stage 1 - freeing CO. from acidified filtrate in Chamber 1 into gas bag.

--

Fig. 3B-Stage 2 - drawing contents of gas bag through CO2 -detector tube using hand pump.

JUNE, 1978

863

CO 2-Analysis Tube

Recommended Tube

Although Drager CO 2-detector tubes are available for

many analytical ranges, only Tube CH-30801 is recommended for GGT/C03 = tests . Other tubes should not be

substituted. Unlike H2 S-detector tubes , the CO 2 tubes are

very sensitive to incorrect use. Tube CH-30801 requires

exactly 10 pump strokes (1 liter) of gas throughput.

Furthermore, the CO 2 within this specific volume of gas

must be distributed uniformly and the tube flow rate held

in the proper range. To satisfy these tube-chemistry requirements , the I-liter gas bag is used for capturing CO 2

in the effluent gas from the GGT to assure that CO 2 is

distributed uniformly. The gas bag then is emptied as gas

is drawn through the detector tube by the hand vacuum

pump. Ten pump strokes (exactly 1,000 ml) empties the

bag. Therefore, by using the gas bag and hand pump

together, the tube's strict conditions for accuracy are

satisfied.

The manufacturer10 states that the CH-30801 Detector

Tube has a relative standard deviation (RSD) ranging

from 15 to 10 percent, which depends on the "tube

loading" by CO2 • When the stain length is short and near

the inlet of the tube, the CO2 measurement is less accurate

(I5-percent RSD) but improves to 10-percent RSD at the

exit end of the tube's measurement range. In our tests,

where the CH-30801 was compared with known carbonates and with the gas chromatograph, the over-all

accuracy was much better than the manufacturer's stated

accuracy.

Detector Tube Chemistry/Interference

No other gases or vapors cause an interference with the

CO 2-detectortube. 9 This was confirmed in conversations

with Drager representatives . In tests of field muds and of

individual mud components in the laboratory, no evidence of any interference was found . Potential positive

errors can result from spurious CO 2 in the train. For

example, CO2 in air remaining in the train before a test or

any CO 2 dissolved in the dilution water will be recorded

as a stain by the Drager tube to give an erroneously high

C03 = analysis. In the worst case, this error could represent about 500 mg/liter C03 =. The 500-mglliter error

assumes a small (1.0 ml) sample size in Eq. 6. Purging

the train and water by flowing N2 0 for 30 seconds before

connecting the gas bag or adding the sample minimizes

this error in field practice. In the laboratory, using de-

Fig. 3C-Stage 3 -

864

gassed (boiled) dilution water is recommended.

The color developed in the CH-30801 tube is a purple

stain on a white reagent matrix . This color change occurs

at the reaction front as crystal violet (redox indicator)

detects CO2 undergoing a reaction with the hydrazine

reagent 9

CO 2

+ N2H4

crystal

NH2 • NH· COOH. ....... (7)

violet

The stain may fade slightly at the inlet end as the reaction

front proceeds through the tube. Ignore any fading at the

inlet end, but the faintest purple at the leading edge

should be included in the stain length reading used

in Eq. 6.

Notice in Fig. 3C that the tube calibration units are not

spaced evenly. This is because the CH-30801 tubes are

calibrated experimentally at the factory. The mud engineer cannot adjust the tube reading accurately in the

field for any alteration in the procedure, such as incorrect

gas volume, flow rate, or excess sample volumes, that

exceeds tube capacity.

Laboratory Verification ofGGT/C03=

Method

Two laboratory studies verified the accuracy of

GGT/C03 = analysis for different types and sizes of

samples: (1) 11 replicate GGT/C03 = determinations of a

1,000-mg/liter standard sodium carbonate solution

showed good agreement, and (2) results of GGT/C03 =

agreed well with gas chromatographic CO 2 analysis using

split-sample testing offield-mud filtrate samples.

Analysis of Known Carbonate Solutions

Table 2 shows the sample size used, tube stain length

observed, and the GGT/C03 = concentration calculated

from Eq. 6 for 11 replicate analyses of a 1,OOO-mg/liter

C03 = solution. Sample-size variation of this 1,000mglIiter solution allowed different stain lengths and

thus tested the Drager tube's precision with different

CO2 loadings. The greatest error (±6 percent) occurred

when a hypodermic syringe instead of a pipette was used

to measure the sample into Chamber 1. Otherwise, the

repeat analyses all were within a few percent of each

other. (A disposable syringe and needle are recommended to measure and to inject the sample for field use

for reasons of simplicity, speed, and to avoid contamination, despite the potential error in volume measurement.)

Laboratory tests were performed to determine the CO 2

stain length in Drager CO2 -detector tube compared with unused tube.

JOURNAL OF PETROLEUM TECHNOLOGY

TABLE 2-REPLICATE ANALYSES USING GGT/C03 = METHOD OF A

WATER SOLUTION CONTAINING 1,000 MG/LITER SOLUBLE CARBONATES

Analysis

Stain Length on

Drc:igerTube

(tube units)

Sample Size'

(ml)

Carbonates

(mg/liter)

1

2

3

4

5

6

7

8

9

10

11

0.095

0.100

0.150

0.150

0.170

0.280

0.270

0.040

0.040

0.080

0.080

2.5 s

2.5 s

4.0s

4.0s

4.0s

7.0s

7.0s

1.0p

1.0p

2.0p

2.0p

950

1,000

938

1,000

1,063

1,000

964

1,000

1,000

1,000

1,000

Error

JEercent)

-5

0

-6

0

+6

0

-4

0

0

0

0

'Sample volumes measured by syringe (s) are less accurate than when using a pipette (p).

residual in Chamber 1 after 1 liter of carrier gas bubbled

through the sample. Presumably all carbonates (as CO2 )

are swept out and captured within this I-liter gas flow

volume. To verify this point, a second and third I-liter

gas bag were used consecutively to trap any CO2 remaining in the sample after the firs t bag had been filled. In the

normally expected concentrations of carbonate ions in a

sample, 100 percent of the CO 2 was captured in the first

liter, and none was found in the second gas bag. In more

concentrated test solutions, about 90 percent was captured in the first bag and the remaining 10 percent was

found in the second liter volume, with none in the third

bag. For most field-mud filtrate samples where carbonates are moderate to low, we expect essentially all to be

converted to CO2 and detected by this procedure. In

extreme cases of high carbonates in muds, residual carbonates may be left in Chamber 1 of the train, but this

error should be insignificant to practical mud-control

treatments .

Split-Sample Comparison With Gas

Chromatography

Table 3 shows the results of split-sample analyses of

field-mud filtrates using the GGT/C03 = method and a

separate laboratory's CO 2 analysis using gas chromatography (GC). The general procedure followed in this study

was to obtain a sufficient filtrate volume to perform two

GGT/COa= tests. This volume was split into two portions

processed through the Stage 1 GGT procedure in quick

succession. The effluents from the two tests were cap·

turedin I-liter gas bags. One gas bag was analyzed by GC

in Exxon Production Research Co. 's hydrocarbon

analysis lab. The other gas bag was analyzed (described

in Stages 2 and 3) using Drager CO 2-detector tubes. To

enhance the GC's CO2 -measurement sensitivity, helium

carrier gas was used in both the GC and GGT flow

systems. Using the ideal gas law, the GC CO2 analyses

were converted into equivalent milligrams of C03 = per

liter of original filtrate used in the GGT. This gave

a direct comparison of GC with GGT/C0 3 = results

(Table 3).

Table 3 indicates the excellent agreement obtained

between GC and GGT/C0 3= analyses for a mud sample

from Well C. The average absolute difference between

the two methods was 73 mg/liter, a 3.9-percent deviation, which is less than Drager's guaranteed deviation (10

to 15 percent) for the tube. 9 For Well B mud samples,

agreement between the two methods was generally very

good, except for one case where GC was lower than

GGT/C0 3 = by 25 percent (821 mg/liter). (The GC

laboratory changed operators in the last test of Well B

samples, when the 821-mg/liter difference occurred.) In

the case with a 36-percent deviation, this result is not

considered unsatisfactory because the absolute difference

is only 125 mg/liter, or within the precision of the tube. In

general, agreement between GGT/C03 = and GC was

better than Drager's guaranteed precision and is considered suitable verification of the method for field muds

TABLE 3-COMPARISON OF CARBONATE ANALYSES OF FIELD MUD FILTRATES BY

GGTIC0 3 = WITH GAS CHROMATOGRAPHY

Mud

Density

(Ib/bbl)

WeliC

mud

WellS

mud

11.6

12.2

12.3

10.1

10.4

11.3

11.8

11.7

16.0

18.1

18.6

18.8

Carbo.ll ates DeterminEld as C0 3 GGT/C03 =

Gas Chromatography

(mg/liter)

~!Iiter)

2,500

2,517

2,125

2,208

1,875

2,065

750

759

1,125

1,180

2,500

Not available

1,000

475

344

1,188

4,125

5,000

Average difference

-71

-3.9

911

350

330

1,146

3,304

Not available

89

125

14

42

821

9.8

35.7

4.2

3.7

24.8

Average difference

JUNE, 1978

Difference

(mg/liter)

(percent)

-17

-0.7

-83

-3.8

-190

-9.2

-9

-1.2

-55

-4.7

- - , ..

-~.

218

15.6

865

and for the correctness of the analytical factor (25,000)

calculated from Drager's calibration for CO 2 in air

mixtures.

Comparison of GG T /C0 3 = With Alkalinities

Errors reasonably can be expected when alkalinity measurements are used for estimating carbonates in muds.

The PrMf combination has potentially more errors than

does the Pr P r P 2 series or Pr pH correlations because M f

requires titration to a low pH and encounters more interferences in a mud filtrate.

Comparison WithMf

Fig. 4 shows laboratory data comparing GGT/C0 3 =

analyses with M f alkalinities for field mud filtrates from

Wells A and B. Note that for the two different field muds

a linear relationship was obtained for GGT/C0 3 = vs M f .

Mf has a positive intercept at about 2.0-ml standard acid

when GGT/C0 3= concentration trends to zero, indicating

that alkaline materials other than hydroxyl and carbonate

ions are titrated down to a pH 4.3 end-point. The upper

range of these data also supports the industry's rule-ofthumb that when Mf exceeds about 5 ml, soluble carbonate levels can be rather high.

Comparison ofP" PH andP 2

Calculated total carbonates based on the API alternate

alkalinity method are shown in Fig. 5 as compared with

GGT/C03 = analyses. Again, the field mud samples were

from Wells A and B and filtrates were tested under

laboratory conditions. Well A had close agreement between GGT/C0 3 = and alkalinity-estimated carbonates.

However, Well B had about 200-percent difference with

considerable data scatter. Both sets of data trend toward

the zero-zero intersection of Fig. 5. Since the P-type

alkalinity titrations to pH 8.3 did not encounter major

interferences from other soluble materials in the two

filtrates, the PrpH concept of carbonate measurement

appears practicable. This is contrasted with M f intercept

of2 ml (Fig. 4) when carbonates were near zero.

Field Experience With GGT/C03 =

The GGT/C03= method is being used on deep wells by

Exxon affiliates in several operating areas. Operators

other than Exxon have also used the GGT/C03 = procedure through various mud service companies in Texas,

Wyoming, and Louisiana.

Fig. 6 shows field results of a 37-day period where a

clay-based, lignite-lignosulfonate, fresh-water mud was

monitored daily for soluble carbonates using GGT/C0 3 =

analyses. Early in this period, casing was set and cement

was drilled, during which time the mud was weighted

from 12.5 to 16.0 parts per gallon using barite. On Day

14 the mud weight was increased again to 17.7 parts per

gallon. Excessive gel strengths caused concern from Day

1 and were attributed to soluble carbonates; however,

lime was not approved as a mud treatment until Day 8,

when an independent GGT/C03 = analysis verified the

presence of excessive carbonates. The mud property that

was most adversely affected by the carbonates and that

also markedly improved with lime treatments was the

Fann lO-minute gel strength. In Fig. 6c, the lime treatment (plotted downward) is seen to follow the downward

trends of gel strengths and GGT/C03 = analyses. From

Day 17 on, the soluble carbonate concentration leveled

out. A few days later, gel strengths stabilized and lime

additions continued on a more routine basis thereafter.

The GGT/C0 3 = concentration in this stable period

trended near 400 mg/liter, which is considered "background" carbonate values for field testing. (Dissolved

CO 2 in ordinary distilled water gives about 200- to

500-mg/liter carbonates.)

Most field experience with GGT/C03 = analyses has

been favorable. In early usage, there were cases of experimental error at the rig resulting from equipment leaks

and mistaken procedure. With familiarity of the test,

most of these problems have been solved. An API task

group now is evaluating the new method in detail with the

aim of adopting GGT/C0 3 = as an API test procedure.

Carbonate Treatment Guidelines

Removing carbonates from a deflocculated, clay-based

12

~

2600

~

iii

2200

~

.....

cc

1800

•

.5 2400

10

S

c:3

CI:

:::;

.;;:

8

~

S

~

z 6

::::I

~

-'

CI:

~

FIELD MUD FILTRATE SAMPLES FROM:

• WELL A

• WELL B

o~

o

1200

ffi

z0

1000

aI

800

5

600

aI

400

........

::::I

0

.....

en

200

I~

'/~

/1/

/ !~

/ I~

1/

-II

1/

il •

;/

FIELD MUD FILTRATE SAMPLES FROM:

• WELL A

• WELL B

__~__~~~~__~~~

1000

2000

3000

4000

5000

SOLUBLE CARBONATES BY GGT/COj (mg/II

Fig. 4-Correlation of API alkalinity, M r, and soluble carbonates

measured by GGT/C03 ~ analyses.

866

1400

a:

•J

1600

~

I

,"/

2000

>aI

<

4

/ /

I /

I

SOLUBLE CARBONATES BY GGT/C03' (mg/I)

Fig. 5-Comparison of soluble carbonates estimated from API

alkalinities, Pfi P" and P 2 with those measured by Garrett Gas

Train analysis.

JOURNAL OF PETROLEUM TECHNOLOGY

mud typically involves adding lime or gypsum to precipitate C03 = as CaC03 . Adding lime to a solids-laden mud,

especially in a hot well, is a procedure that can create

severe rheological and filtration-control problems if excessive lime is used. Therefore, two tests are important as

an aid for avoiding incorrect lime/gypsum treatment. (1)

A GGT/C03 = analysis should indicate that soluble carbonates are strongly present. Up to 500 mglliter of carbonates is not likely to cause a mud problem; but levels

above 1,000 mglliter (depending on mud density, solids

present, etc. ,) may create a mud problem. (2) If appreciable carbonates are measured, a pilot test series with a

range of treatments should show whether lime (or gypsum) will reduce the soluble carbonates and also improve

the mud's properties. The former may occur, but not

necessarily the latter. Experience has shown that carbonate problems often are coupled with, or even mistaken

for, excessive amounts of low-gravity colloidal solids.

These solids may be the more significant factor. Solids

and contamination problems are coupled and exhibit

TABLE 4-LlME/GYPSUM PROCEDURE

100 mg/liter C03 ~

- - - - - - - - - - -

Treat With

O.043lb/bbllime

or

{

0.1011b/bbl gypsum

Note: 100 mg/liter COa - ~ 3.3 epm ~ 3.3 milliequivalents/liter.

similar characteristics, such as poor response to deflocculant treatment, high yield points and gel strengths, and

high fluid loss and poor filter cake quality. High M f

values or M f/Pf ratios are traditional carbonate indicators.

Most symptoms also could result from excess calcium

in a mud, especially if Pf and Mf values are incorrect or

are ignored.

Therefore, before adding lime to a mud, the mud

engineer should be sure that carbonates are present.

Furthermore, detecting soluble calcium by API-hardness

titration is no assurance that carbonates really are absent

because calcium (and magnesium, the hardness ions) can

be present and soluble in organic-chelate form but will be

0

en

z

250

CI

~-

Ci fa' 500

Ci~

c:e

101-

:IE

::::i

c.LlME TREATMENTS

750

1000

50

:z:

Ic:J

Z

40

b.l0'GELSTRENGTHS

101

1:11: !O'

1;;;5

30

.... CI

101'"

c:J .....

.!@.

20

!:

:IE

...0

10

0

I

I

I

I

I

I

I

...I

...I.

5000

4000

3000

c.i

z

a. SOLUBLE CARBONATES

2000

CI

u=

~"";;,

CI &:

II

1000

r

~-

Ic:J

c:J

500

" BACKGROUND "

CARBONATE LEVEL - - - -

O~____~~~~~~~~~~-L~~~-L~~~~~~~~~~~-L~~-L~~-J

12

16

20

24

28

32

36

TIME ELAPSED (DAYS)

Fig. 6-A field example -

JUNE,1978

Garrett Gas Train used to measure carbonates in mud filtrate, effect on mud rheology, and removal by lime

treatment.

867

TABLE 5-LlME TREATMENT EFFICIENCY TO REMOVE SOLUBLE CARBONATES

(Measured by GGTICOa= Analysis of Pilot Test Samples of Field Muds)

WellCMud

Slaked lime added -Ib/bbl in mud

-Ib/bbl in liquid

Hot rolled - time, hours

- temperature, OF

Carbonates - before, mg/liter

- after, mg/Hter

Carbonates removed - actual, mg/liter

Theoretical carbonates removed,' mg/liter

Actual/theoretical COa= reduction

(18.1-lb/gal density,

60.0 vol. percent

liquid-phase retort)

Test

Test

Test

1

3

_120040

0.80

1.60

0.67

1.33

2.66

16

16

16

300

300

300

1,750

1,750

1,750

1,125

750

500

1,000

1,250

625

3;100

6,200

1,550

0040

0.32

0.20

Well B Mud

(18.8-lb/gal

density, 55.6

vol. percent

liquid-phase

_~.r:!L.._

Test

Test

4

5

1.20

2.10

2.16

3.78

19

19

180

180

6,500

6,500

4,900

3,700

1,600

2,800

5,020

8,780

0.32

0.32

'Based on stoichiometric efficiency ofO.043lb/bbl Ca(OH), to reduce CO,,' by 100 mg/liter in liquid phase, assuming the reaction Ca++

CO,,· .... CaCO" t .

unavailable to react with carbonate ions in the filtrate.

Table 4 shows the pounds per barrel oflime or gypsum

that, if added at liquid phase (filtrate) concentration,

theoretically could remove 100 mg/liter cas = from the

liquid phase.

The theoretically correct lime treatment as predicted

by GGT/COs= analysis usually is an undertreatment in

practice because calcium from the lime is consumed by

components other than carbonates. Calcium ions react

with clays, lignite, and other chemicals present in a mud.

Experience from laboratory tes'ts indicates that only

part of reagent-grade Ca(OH)2 reacts to reduce soluble

carbonates in highly treated lignosulfonate field muds.

Table 5 shows the results obtained by GGT/COs =

analyses. Samples of field mud that had appreciable

soluble carbonates were treated with known amounts of

lime and hot rolled at either 300 or 180°F to allow the

cas = and the Ca++ from the lime to react. The percentages of soluble 'carbonates actually removed in terms of

the theoretically expected reduction in carbonates was

found rather low - 30 to 40 percent. Note, however, that

some additional carbonates probably were generated

during the 300o Phot rolling (conditions of Tests 1,2, and

3 of Table 5). In Tests 4 and 5, carbonate generation at

180°F probably was not significant. The main point of

this study is that added lime does not react only to remove

the carbonates in a complex mud. This is supported by

field experiences reported by field mud engineers, who

say that three to four times more lime may be required to

improve a mud's performance than that predicted by

various carbonate tests, including GGT/COs = tests.

Pilot tests of lime (or gypsum) treatments should be

conducted in sealed cells in a rolling oven at bottom-hole

circulating temperature, allowing 2 hours or more for the

chemical reactions to occur. Lime (or gypsum) test additions should be multiples of the stoichiometric treatment,

based on GGT/COs= analysis (calculated from Table 5).

A four-test series is recommended to include a possible

treatment range. Assume, for example, that GGT/COa=

analysis of a filtrate was 1,160 mg/liter COa= that called

for a 0.5-lb treatmentoflime per barrel of liquid phase in

the mud. A suggested four-cell test series with lime

would be (1) 0 lblbbl as a blank, (2) 0.5 lblbbl, (3) 1.0

lblbbl, and (4) 2.0 lblbbl. In this series, the blank allows a

clear comparison of untreated mud properties with the

868

+

three levels of lime treatments. The stoichiometrically

predicted treatment level of 0.5 lblbbllikely will be an

actual undertreatment. The 1.0 lblbbl of lime may be near

the correct treatment and the 2.0 lblbbllikely is an overtreatment. Results of rheological and filtration tests plus

further GGT/CO a= analyses of the pilot samples will

indicate the correct amount of lime to add to the mud for

removing most of the carbonates.

Acknowledgments

The author thanks the management of Exxon Production

Research Co. for permission to publish this study and

several individuals who provided support and consultation. F. G. Scanlan and A. B. Pearson performed most of

the laboratory studies. G. G. Binder and D. E. O'Brien

gave their support in many ways. L. A. Carlton, P. J.

Trahan, and others at Exxon Co., U.S.A., provided the

drilling wells for mud samples and helpful advice for

early field testing of the GGT/COa= method. L. A. Carlton and M. R. Annis continually contributed their experience of carbonate occurrences in muds throughout this

investigation.

References

1. Green, B. Q.: "CarbonatelBicarbonate Influence in Waterbase

. Drilling Fluids," Pet. Eng. (May 1972).

2. API Recommended Practice

Standard Procedure for Testing

Drilling Fluids. API RP 13B, 7tIred., API, Dallas (1978).

3. Strumm, W. and Morgan, J. J.:AquaticChemistry, John Wiley &

Sons, Inc., New York (1970) Chap. 4.

4. Deffeyes, K. S.: "Carbonate Equilibria, A Graphic and Algebraic

Approach," Limnology and Oceanography (1965) 10, 412.

5. Fuson, R. C.: Advanced Organic Chemistry. John Wiley & Sons,

Inc., London (1954) 210-212.

6. Lignin Structure and Reactions, Advances in Chemistry Series 59,

ACS, Washington, D.C. (1966).

7. Glossary of Drilling Fluid and Associated Terms, Bull. Dll, 1st

ed., API (1965).

8. Standard Methods for the Examination of Water. Sewage and

Industrial Wastes. 10th ed., American Public Health Assn., Inc.,

New York (1955).

9. Detector Tube Handbook. 3rd ed., Dragerwerk, AG, Lubek,

W.Gennany(1976)4,42,182.

10. Garrett, R. L.: "A New Field Method for the Quantitative Determination of Sulfides in Water-Base Drilling Fluids," J Pet. Tech.

(Sept. 1977) 1195-1202; Trans., AIME, 263.

JPT

Original manuscript received in SoCiety of Petroleum Engineers office Sept. 9, 1977.

Paper accepted for publication Nov. 22,1977. Revised manuscript received Jan. 30,

1978. Paper (SPE 69(4) was presented atthe SPE-AIME 52nd Annual Fall Technical

Conference and Exhibition, held in Denver, Oct. 9-12, 1977.

JOURNAL OF PETROLEUM TECHNOLOGY