Occupational Health: Workplace Safety & Well-being

advertisement

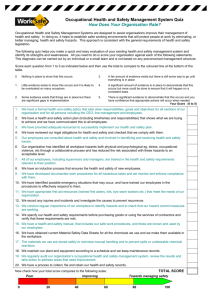

Module 3: Occupational Health Introduction Occupational Health (OH) refers to the relationship between work and health. OH specialists aim to enhance a worker’s health status, increase the productivity of a workforce, improve business performance and the economy. OH specialists have specific training and experience to understand the link between health and work. This enables them to support both workers and employers. OH focuses on three main objectives: Maintenance and promotion of workers’ health and working capacity Improvement of working environments to ensure that they are conducive to health and safety The development of work organizations/cultures in ways which support health and safety at work, promote positive social interactions and improve productivity Why is Occupational Health Important? Work is said to increase physical and mental health, enhance a worker’s sense of purpose, confidence, self-worth, independence and fulfilment. Return to work post illness or injury should, therefore, be considered as an important outcome measure when exploring treatment options and the support of working age people. Five percent of all sickness absence will become long term (ie it will last more than 4 weeks) and this accounts for almost half of the total working days lost each year. The longer a person is absent from work, the greater the chance that s/he wi ll not return to work. e.g. if an individual is absent from work for six months, there is an 80% chance that s/he will be out of work for five years, which comes at significant cost to the individual and society When poor work ability (physical or mental) is combined with one or more chronic diseases, there is an increased risk of long-term sickness absence in the working population. The risk of long-term sickness absence gradually increases based on factors associated with work that has high physical demands. Of particular importance to physiotherapists is that alongside “stress, depression and anxiety”, “other musculoskeletal problems” are some of the most commonly reported reasons for long term absence from work. The Occupational Health Team The OH team includes health professionals from a variety of backgrounds who work together to enable workers to return/remain in the workplace. 1. Occupational Health Physicians promote and protect the health and workability of workers. They focus on preventative medicine and management of illness, injury and disability related to the workplace. 2. Occupational Health Advisors are nurses with specialist training in OH. They often take on a case management role and will perform duties such as new starter health assessments, health surveillance and screening programs such as audiometry, spirometry, vision screening, hand/arm vibration assessment and shift worker assessment. 3. Occupational Health Psychologists care for psychological well-being of the individual. They are involved in supporting job satisfaction and the effectiveness of the organizations. Their role is diverse and can focus on education and training or one-to-one support and therapy. Similarly, they may be involved in advising managers and decision makers on how best to support the mental health and well-being of employees. 4. Occupational Therapists in the workplace help employees overcome barriers that prevent them from participating in work. These barriers are varied and include issues such as illness, disability, social/institutional or physical environmental issues. 5. Occupational Health Physiotherapists are often involved in the assessment of return to work, functional rehabilitation, and other clinical treatment services. They may take on health promotion and education roles, risk assessment and training, health promotion activities, as well as being involved in managing long term conditions in the workplace. Physiotherapists working in OH have the scope to develop their own practice in different directions from risk management and interventions through to case management of long-term conditions in the work place. The roles of these professions often overlap and all may be first contact practitioners. They may also be supported by ergonomists, occupational hygienists, he alth and safety consultants, HR and senior managers. Industrial Hygiene (Occupational Hygiene) Overview One of the main priorities of any workplace is to keep its employees safe and healthy. Industrial hygiene is concerned with identifying, evaluating, and controlling real or potential workplace environmental stressors or hazards that can affect the wellbeing of workers and community members. It is sometimes called Occupational Hygiene, Occupational Health or Workplace Health. Ideally, hazards are identified and controlled when a workplace is being planned, when conditions or processes change, or through yearly reviews, before they become an issue for workers. In order to help ensure proper industrial hygiene and thus the health and safety of your workers, you can employ an industrial hygienist. The role of an industrial hygienist is to “anticipate health and safety concerns and design solutions to prevent them. They are the guardians of workplace safety, applying science to identify and solve health and safety problems. Industrial hygienists also unite management, workers, and all segments of a company behind the common goal of health and safety. What is Industrial Hygiene? Industrial hygiene is the science of controlling hazardous workplace conditions to prevent employees from becoming sick or injured. Key Components of Industrial Hygiene Industrial hygiene encompasses a wide range of health and safety concerns in the workplace. Ergonomics: The goal of ergonomics (the study of people at work), is to reduce stress and eliminate injuries associated with bad posture, overuse of muscles, and repeated tasks. For example, proper ergonomics can help prevent carpal tunnel syndrome, tendonitis, and lower back injuries. Noise: Long-term exposure to noise – both wanted and unwanted sound – can lead to hearing loss for workers. Noise issues can be addressed in several ways, including designing a facility to minimize noise, separating workers from noisy machinery as much as possible, and using devices, such as ear muffs or ear plugs, to protect workers. Temperature: Both high and low temperatures can cause problems for workers. If temperatures are too high, workers are vulnerable to heat stroke or heat exhaustion; heat stroke is a medical emergency that requires immediate attention. Indoor air quality: Indoor air quality can be impacted by many factors, including pollution from machines or tools inside the building, highway pollution outside the building, dusts from mechanical processes, or gasses. Poor air quality can cause issues ranging from chronic coughs to nausea to severe headaches. Proper ventilation is important to ensure that fresh air is brought into the work area and air filtering in an HVAC system can help remove contaminants from the air. Chemical exposure: Chemical hazards can take many forms, from liquid to fumes to dusts, and can be absorbed, inhaled, or ingested into a worker’s system. Some common chemicals that can potentially be hazardous are cleaning products, gasoline, and pesticides. Radiation: There are two types of radiation – non-ionizing radiation and ionizing radiation. Ultraviolet (UV) radiation and laser radiation are the types of non-ionizing radiation most likely to cause safety concerns, usually burns, for workers; UV radiation is a particular problem for outside workers, such as gardeners. Biological hazards: Living organisms such as fungi, viruses, and bacteria, can enter the body and cause both acute and chronic infections. Workers who deal with plants or animals and laboratory or medical workers are particularly at risk for biological hazards, but all workers can be at risk for hazards such as mold, and bacteria that cause Legionnaire’s disease. Proper hygiene such as hand washing, ventilation, personal protective equipment such as gloves or respirators, and in certain cases, isolation of the hazard, can all help minimize the risks associated with biological hazards. Eliminating or Controlling Hazards: Once hazardous conditions have been identified there is a systematic approach to eliminating or minimizing the potential hazard. This starts with designing the hazard out of the process or operation, providing local exhaust ventilation, establishing proper work practices, providing proper personal protective equipment (PPE) and applicable administrative measures. Optimizing these components of industrial hygiene through monitoring and analyzing hazards and engineering solutions to minimize those hazards will help control potential health risks that impact both workers and your organization. Importance of Industrial Hygiene Industrial hygiene is essential because it helps protect employees from several types of injuries and illnesses, including: Nonfatal illnesses: Skin, lung and gastrointestinal diseases like anthrax are common occupational hazards in agricultural operations, and blood-borne illnesses like hepatitis B and C are common occupational hazards in medical settings and laboratories. Industrial hygiene can help prevent the transmission of these diseases and many others. Respiratory conditions: Respiratory conditions like chronic bronchitis, asbestosis and pneumonitis are common occupational hazards, especially in industries like mining where inhaling dust is common. Industrial hygiene can help by mandating the use of personal protective equipment (PPE) which provides respiratory protection and improves working conditions. Skin diseases: Skin diseases like dermatitis, eczema, rashes and blisters are common in industries where workers' skin comes into contact with hazardous chemicals. Industrial hygiene can help by mandating PPE and offering guidelines about how chemicals are used, labeled and stored in the workplace. Poisoning: Poisoning can occur if workers accidentally ingest toxic chemicals like pesticides, herbicides, formaldehyde or cleaning agents. Workers might also absorb those chemicals through their skin. Industrial hygiene can help by mandating how poisons are used, labeled and stored. Hearing loss: Hearing loss can occur when employees are exposed to highdecibel sounds in environments like airports or at construction and mining sites where detonations occur. Industrial hygiene can help by mandating personal PPE, measuring hazards with sound level meters and offering guidelines about noise exposure in the workplace. Repetitive stress injuries: Repetitive stress injuries occur when employees perform the same motions many times throughout the workday. Industrial hygiene can help by offering guidelines about correct posture and lifting techniques and mandating breaks for employees engaged in repetitive tasks. Economic Effects of Absenteeism Industrial hygiene has benefits for employers as well. When employees miss work because of illness or injury, employers tend to suffer losses: Lost productivity: Absenteeism in the workplace leads to lost productivity. When employees are absent, they cannot do the same amount of work, and scrambling to cover shifts in one area may lead to staffing shortages in another. And even when employees return, they may be slower and less productive because they still don't feel their best. Diminished morale: High numbers of injuries and illnesses in the workplace tend to put a damper on employee morale. Plus, decreased employee morale can lead to even further diminished productivity, as well as distractedness, which can result in a vicious cycle of injury. Lost profits: Too costly of absenteeism for companies per year for each hourly worker and each year for salaried employees. These costs include wages paid during sick leave, the high cost of replacement workers and the profit losses associated with reduced production. Workplace Health Hazards and Control Every workplace has hazards. As an employer, you have a legal responsibility to look after your employees’ safety and protect them against health and safety hazards at work. In order to manage workplace health and safety and help prevent accidents and sickness absence, it’s important to identify, monitor and reduce the risk associated with workplace hazards. Most Common Hazards in a Workplace There are many types of workplace hazards, which tend to come under six main categories: o physical hazards – the most common workplace hazards, including vibration, noise and slips, trips and falls; o ergonomic hazards – physical factors that harm the musculoskeletal system, such as repetitive movement, manual handling and poor body positioning; o chemical hazards – any hazardous substance that can cause harm to your employees, such as skin irritation, respiratory system irritation, blindness, corrosion, and explosions; o biological hazards – bacteria, viruses, insects, animals, etc. that can cause health effects, such as hepatitis, dengue, malaria, HIV/AIDS and Legionnaire’s disease; o safety – these are hazards that create unsafe working conditions, such as exposed wires or a damaged carpet might result in a tripping hazard. These are sometimes included under physical hazards; and o psychosocial hazards – include those that can have an adverse effect on an employee’s mental health or wellbeing, such as sexual harassment, victimization, stress and workplace violence. Common health risks Some of the most common health risks associated with workplace hazards include: o breathing problems; o skin irritation; o damage to muscles, bones and joints; o hearing damage; o reduced wellbeing. How to Prevent Workplace Hazards The best way to protect yourself and your employees from workplace hazards is to identify and manage them and take reasonable steps to prevent their potential to harm. In order to control workplace hazards and eliminate or reduce the risk, you should take the following steps: o identify the hazard by carrying out a workplace risk assessment; o determine how employees might be at risk; o evaluate the risks; o record and review hazards at least annually, or earlier if something changes. What is a health control program? A hazard control program consists of all steps necessary to protect workers from exposure to a substance or system, the training and the procedures required to monitor worker exposure and their health to hazards such as chemicals, materials or substance, or other types of hazards such as noise and vibration. A written workplace hazard control program should outline which methods are being used to control the exposure and how these controls will be monitored for effectiveness. Control Strategies and Measures Any hazard prevention and control program involve measures related to the work environment and measures related to the workers. Efficient control strategies usually rely on a combination of engineering (technical) control measures (e.g., quieter equipment and enclosures) and health/personal measures (e.g., work practices). Ways to Control Hazards and Risk in the Workplace Every workplace has safety risks and hazards, from manufacturing facilities to offices to construction sites and beyond. How to identify and control these risks is unique to every industry. Many risks and safety hazards are not always obvious. Rather, you may only discover them after they’ve caused an issue. 1. Strengthen Your Safety Culture A strong safety culture is at the heart of any safety-conscious organization. You can’t promote a safe workplace by yourself, so it’s essential you build a company culture around safe practices. When everyone participates in maintaining a risk-free environment, everyone wins. 2. Get Leadership Buy-In Company leaders should be at the core of your safety initiatives. Their positions as leaders set the example for the rest of your team. Keep in mind they also have the potential ability to thwart or support your efforts. They need to see the value behind your ideas and initiatives in order to give you their total support. 3. Implement a Hazard Identification and Assessment Plan One of the most effective ways you can find and manage workplace risks and hazards, build your safety culture, and gain support from company leaders is to implement a hazard identification and assessment plan. This plan is an actionable step-by-step process devoted specifically to helping you find and mitigate potential workplace health and safety risks. According to OSHA, steps of the plan include the following: Collect and Review Existing Information on Workplace Hazards Take some time to review your records of previously noted hazards and incidents. This information should give you a good starting point for your ongoing investigations. Inspect the Workplace for New or Existing Hazards The workplace is an evolving dynamic. New hazards can prevent themselves at any time, especially at your company brings in new equipment, employees, or processes. Make time to regularly inspect the workplace for any new hazards that may have arisen. Even the simple moving around of equipment can lead to potential risks that weren’t there the day before. Identify Potential Health Hazards Finding potential health risks is more complicated than safety risks because you’re not always able to physically view them. Rather, you must consider environmental concerns, chemical risks, ergonomic risks, and other factors that could have an effect on someone’s health days, weeks, or even years later. Conduct Thorough Incident Investigations You should already have a plan in place to conduct incident investigations, but reviewing this information can also help you mitigate future risks and safety hazards. These reports can give you better insight into locating risks and understanding what’s already being done to combat them from occurring again. Identify Hazards for Nonroutine or Emergency Occurrences Every company has the one-in-a-million type risks that aren’t likely to occur, but could. It’s important you don’t neglect such risks, because in the rare event they do happen, you’ll need an action plan to handle them. These might include fires or explosions, hazardous spills, medical emergencies, or even violence between employees. Identify the Nature of Hazards and How to Prioritize Them The final part is understanding how certain risks can lead to additional hazards. You should evaluate each risk and hazard by determining the severity of the outcome, how many workers will be exposed, and the likelihood of the event occurring. From this information, you can better prioritize the hazards so that you address the most serious first. Each of the steps in OSHA’s Hazard Identification and Assessment Plan model can be made easier by using the right tools. For example, risk assessment software gives you a central data storage system that can give you insights into every aspect of your safety program. You can create checklists, assign tasks, and record observations that pertain to each of the above steps in the plan. 4. Measure Your Plan’s Impact Over Time Finally, you should be prepared to measure the effectiveness of your plan and activities over time. Your goal should be to make a difference in your company’s safety, so measuring your success over time can help you know where you need to fill any gaps.