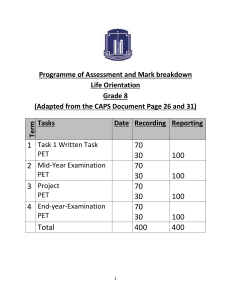

Waste Management 29 (2009) 1138–1143 Contents lists available at ScienceDirect Waste Management journal homepage: www.elsevier.com/locate/wasman Application of fluidization to separate packaging waste plastics M. Teresa Carvalho *, Célia Ferreira, Antía Portela, João Tiago Santos CERENA, Instituto Superior Técnico, Avenida Rovisco Pais 1049-001 Lisboa, Portugal a r t i c l e i n f o Article history: Accepted 5 August 2008 Available online 8 October 2008 a b s t r a c t The objective of the experimental work described in this paper is the study of the separation of PS (polystyrene) from PET (polyethylene terephthalate) and PVC (polyvinyl chloride) from drop-off points using a fluidized bed separator. This is a low-cost process commonly used in the hydro-classification of mineral ores. Firstly, experimental tests were carried out with artificial granulated samples with different grain sizes, types and sources of plastic (‘‘separability tests”). The particle settling velocities were determined under different operating conditions. Then, based on the results, the laboratory tests continued with real mixtures of waste plastics (‘‘separation tests”) and the efficiency of the process was evaluated. From a PET-rich mixture, a concentrate of PS with a 75% grade in PS was produced while the underflow was quite clear from PS (grade less than 0.5% in PS). Ó 2008 Elsevier Ltd. All rights reserved. 1. Introduction In Portugal, post-consumer packages represent almost 40% of the total domestic waste, making them an important source for the recycled materials market (Magrinho et al., 2006). Packages are made with different materials according to the desired content characteristics, price of materials, durability, storage requirements, marketing and environmental policies and many other features. Thus, for the same purpose, packages can be made, for example, of metals, glass, paper, wood or different types of plastics (Castro and Pouzada, 2003). The recycling of materials requires the separation of the different materials. In Portugal, packaging wastes are disposed by citizens at drop-off points after being separated at home according to pre-defined sets of materials. Paper packages are placed in the paper and cardboard container (blue container), while glass vessels are placed in the glass container (green container). Packages made of different types of plastic are collected together with metals in the same container (yellow container). Municipal solid waste recovery and treatment systems are responsible for the waste collection and separation (Magrinho et al., 2006). The contents of the containers are transported separately to sorting centers where the objects are separated (see Fig. 1). The feed to these sorting centers, especially in the case of the yellow containers, is a complex mixture of metals, various types of plastic and several other contaminants which were incorrectly placed in the containers. The sorted packaging wastes are then channelled towards the respective recycling industry by Sociedade Ponto Verde – SPV (Green Dot System), where they are usually sorted * Corresponding author. Tel.: +351 218 417 247; fax: +351 218 417 442. E-mail address: teresa.carvalho@ist.utl.pt (M.T. Carvalho). 0956-053X/$ - see front matter Ó 2008 Elsevier Ltd. All rights reserved. doi:10.1016/j.wasman.2008.08.009 again, to eliminate the remaining contaminants, washed and generally granulated. Currently, the separation of metals is efficiently conducted mechanically using magnetic separation for ferrous metals and electromagnetic separation (Foucault currents) for non-ferrous metals. The separation of the different polymers by type is almost always mandatory because contamination in the recycling of one type of plastic by another type can cause serious processing problems. For example, the presence of PVC in the PET extrusion process is harmful to the equipment, due to the presence of chlorine, and lowers the product quality, namely colour and viscosity (Awaja and Pavel, 2005; Navarro et al., 2008). In Portugal, the plastics used in packaging are mainly polyolefins, such as polyethylene, polypropylene and their copolymers, polyethylene terephthalate (PET), rigid and expanded polystyrene (PS) and polyvinyl chloride (PVC). The separation of low density materials, such as polyethylene and polypropylene, from the other plastics is not usually a problem, being currently separated by an air current. The similarities in physical properties, such as specific gravity, make the automatic separation of some polymers a challenging task (see Table 1). There are automatic devices, based on X-ray fluorescence, used to sort out PVC objects, and optical sorting technologies, namely near infrared spectroscopy, for the separation of plastics by type. However, these technologies are very expensive and the efficiency is limited when the process feed characteristics (e.g., size and shape of objects) deviate from the pre-established ones. An example of plastic packaging recycling is the case of PET. PET recycling plants receive a bulk load of PET packaging mostly constituted by bottles, ideally, free from PVC or other materials packaging items. Commonly, plant feed is washed and extra stages M.T. Carvalho et al. / Waste Management 29 (2009) 1138–1143 1139 wastes in an area nearby Lisbon (corresponding to almost one million people), and Selenis–Ambiente, a Portuguese PET recycling company. 2. Can PS, PET and PVC be separated by gravity concentration methods? In mineral processing, the suitability of the application of gravity concentration processes to the separation of a particular set of minerals is generally evaluated by the use of a parameter, the ‘‘concentration criteria” CC ¼ ðdh df Þ=ðdl df Þ Fig. 1. Manual sorting of plastics in sorting centers (Tratolixo courtesy). Table 1 Tabled specific weight of plastics appearing in drop-off points and measured density of the plastics used in the ‘‘separability tests” Polymer Specific weight range (g/cm3)* PE PP PSvy PSus PETvy PETgr PETbl PVCvy 0.910–0.965 0.902–0.906 1.05–1.10 * 1.34–1.39 1.35–1.45 Measured density (g/cm3) 1.05 1.05 1.38 1.33 1.32 1.38 where dh, dl and df are, respectively, the specific gravity of the ‘‘heavy” and ‘‘light” species, and fluid. The fluid, usually water, can also be air, another liquid or fluid, or even a suspension of solid particles in water. According to this criterion, for instance, the separation should be easy for CC > 2.5, for a particle size down to 75 lm but impossible at any size when CC < 1.25 (Wills, 1998). The application of this criteria to mixtures of PS, PET and PVC, by direct use of the densities included in Table 1, shows that the separation between PS and PET and between PS and PVC should be easy (3.4 < CC < 7.8 and 3.5 < CC < 9, respectively) and impossible in the case of the separation of PET from PVC (1.03 < CC < 1.32). However, this criterion should be considered only as a guideline because, besides specific gravity and size, other factors such as particle shape can have a strong effect on the separation. Among the multiple separation methods and devices used in classification and gravity concentration, the hydraulic or fluidized bed classification is the simplest and theoretically most effi- Source: Billmeyer, 1984. of optical and/or manual sorting are used to eliminate items made of other materials. PET bottles, in general, contain parts, like caps and labels, made of other materials like polyolefins or paper. They are typically shredded and immersed in water where polyolefin particles float while particles of plastics with specific gravity higher than water sink. It should be emphasized that, due to the high hydrophobicity (or low surface wettability) of plastics, even plastics denser than water can float if air bubbles are present. Usually, an anti-frothing agent and other reagents must be used to prevent the flotation of denser particles and special care must be taken as well with the equipment design, namely residence time and operational conditions. If appropriate conditions are guaranteed, for a typical mixture of polyolefins, PET, PVC and PS, the material that sinks is composed of PET, PVC and PS particles. The research on adequate and low-cost technologies that can be applied to the separation of different polymers is being made by several teams worldwide. Gravity separation, electrostatic separation and froth flotation have been studied. However, the separation of PS from PET and PVC has not yet been addressed by many authors. Recently, Pongstabodee et al. (2008) used sink-float separation in a calcium chloride aqueous solution to separate PS and ABS from PET and PVC. In the present paper, the experimental work carried out to study the separability of PS from PET and PVC in tap water, using a fluidized bed separator, is described. This study is part of a wider study of the team in the search for a low-cost method to separate the different polymers received at drop-off points. This study is included in the project ‘‘SEMEC”, financed by Sociedade Ponto Verde (Carvalho et al., 2007a and Carvalho et al., 2007b). The partners of the project are CERENA, a research center of Instituto Superior Técnico, PIEP, a research center of Minho University, Tratolixo, a solid waste management system, responsible for the collection of solid ð1Þ Fig. 2. The fluidized bed classifier used. 1140 M.T. Carvalho et al. / Waste Management 29 (2009) 1138–1143 cient one (Kelly and Spottiswood, 1982). This is a low-cost process and the equipment is easy to operate and control, being operationally robust. In this process, the settling of particles is made against an upward flow of fluid. Variables affecting the process are the particle size, velocity of the pulp, overflow volume fraction of solids, overflow and underflow pulp densities and pulp viscosity. Fig. 2 shows the fluidized bed classifier used in the study. In this process, the device is fed with a suspension of particles in water. A supplementary flow of ‘‘hydraulic water” is added near the bottom of the device. This should have an adequate flow rate so the particles with lower settling velocities can be carried upwards, to the ‘‘overflow”, and the particles with higher settling velocities sink, becoming part of the ‘‘underflow”. In the present case, the upward velocity must be determined in order that the PS particles are carried upwards, to the ‘‘overflow”, and PET and PVC particles settle, becoming part of the ‘‘underflow”. Various authors have worked on the theory of sedimentation and fluidization (for a concise analysis see, for example, Kelly and Spottiswood (1982), Wills (1998) or Burt (1984). Fundamental models should lead to accurate predictions. However, these models are too complex and rely on empirical relationships which can be taken only as guidelines or are valid only in particular cases such as spherical particles. The estimation of settling velocities can be made, but its utility is limited and it does not avoid the experimental determination. In the case under study, it should be taken into account that the process feed is heterogeneous even within the particles of a specific plastic, because: – The density of one type of plastic can vary, within limits, depending on the additives that are present and on the origin of the particle (e.g., bottles, boxes, trays). Moreover, the additives can change the chemical properties of particles and, consequently, the surface chemical properties, with possible modification of contact angle/hydrophobicity. – Even when coming from the same object, two particles within the same size fraction can have a different shape. For example, the thickness of a bottle is not uniform (the neck and the bottom are thinner than the body of the bottle). – The particle ‘‘history”, namely contact with contaminants, can play an important role in the separation because the contaminants can affect the physical and chemical properties of the surface and, therefore, the particle settling behaviour, due to changes in the contact angle. 3. Experimental In a first phase, experimental tests (‘‘separability tests”) were carried out to determine the settling velocity of particles of the three types of plastic for different upward stream velocities. Two particle size intervals were tested. To evaluate if the ‘‘origin” and ‘‘history” of the particles influenced the results, samples of particles of the same plastic but with different origin were composed. The particles of each plastic were continuously introduced into the device and the settling velocities were determined. Based on the results obtained in the first phase, the laboratory tests continued with real mixtures of waste plastics (‘‘separation tests”). In these tests, the equipment was continuously operated for 20 min. After that time, both products (overflow and underflow) were collected and sent to PIEP for chemical analysis. The recoveries and grades were then computed and the efficiency of the process evaluated. 3.1. Apparatus The laboratory-scale fluidized bed device used in the study was constructed specifically for this study (see Fig. 2). The vessel is a Perspex cylindrical column with 80 cm height and 4.5 cm diameter. A scale on the column wall is used for the settling velocity calculations. The suspension of plastic particles, fed by a variable speed peristaltic pump from a stirred tank, is introduced at 39.2 cm from the top. The particles settle against an upward current of hydraulic water, used to fluidize the bed, introduced near the bottom of the column. The feed flow rate was kept constant during the experimental study, equal to 2 l/min, with 10% solids in weight. This was the value that permitted the normal operation of the pump without clogging. The hydraulic water flow rate, manually controlled by a rotameter, was kept constant during each test but changed from test to test. The lower density particles rise to the ‘‘overflow” launder on the top of the device. The denser particles are discharged through an outlet at the bottom of the column. 3.2. Materials As mentioned before, the composition of the material from the drop-off points is a mixture of plastics from different sources. The same type of plastic can have different characteristics, such as concentration and type of additives, depending on the origin or manufacturer. Furthermore, particles of one type of plastic, coming from the same object, can have a different shape. To evaluate if these characteristics affect the behaviour of the particles, different plastics coming from different sources were tested in the ‘‘separability tests”. The study was conducted with samples of granulated virgin (non-used) packages of PET, PVC and PS (subscript vy). To evaluate if a previous contact with food or other substance could affect the separation (by changing the surface wettability, for example), the behaviour of virgin PET and PS was compared with used/waste PET and PS. The used PET samples came from two different sources; one from soda bottles, which was constituted mainly by green particles (subscript gr), and the other from water bottles, which was constituted mainly by light blue particles (subscript bl). Regarding PS, a mixture of different types of packages (subscript us) was used. The samples were received from suppliers already shredded. The density of the plastics is listed in Table 1. The densities were measured using an analytical balance Scaltec SBC31 with a Kit for density determination SDK01. For the ‘‘separation tests”, a representative sample was collected by Tratolixo at the drop-off points. It was then taken to Selenis Ambiente where it was washed and shredded and the polypropylene and polyethylene particles were separated by immersion in water. The resulting mixture of PET, PVC and PS was then classified by screening into six size fractions. Table 2 presents the composition of the mixture obtained. Three size fractions represent more than 90% of the mixture. These were used in the experimental work. The coarser fraction Table 2 Composition of the mixture of plastics from drop-off points after polyolefin separation Size range (mm) PET (%) PVC (%) PS (%) Weight (%) 0–2 2–4 4–5.6 5.6–8 8–10 >10 84.14 88.18 91.14 95.33 95.48 95.32 12.74 8.41 6.62 3.55 3.07 3.74 2.72 2.91 1.63 0.67 0.97 0.47 5.7 28.6 33.3 29.4 2.2 0.7 1141 M.T. Carvalho et al. / Waste Management 29 (2009) 1138–1143 The performance of the process was assessed by calculating the recovery (%) and grade (%) of each polymer in each process product. After each experiment the products were dried, weighed and analysed (Santos et al., 2007). The grade is calculated by dividing the mass of the polymer in the product by the total mass of the product, and the recovery is computed dividing the mass of the polymer in the product by the mass of the same polymer in the feed. 4.1. Separability tests PVC vy 150 100 50 PETvy PS vy 0 0 20 40 60 80 100 120 140 160 Hydraulic water superficial velocity (cm/min) Fig. 4. Settling rate for different hydraulic water flow rates for tests carried out with different plastics (size fraction, 2–4 mm). The results of tests made with different size fractions (see Fig. 5) show that there are no significant differences in the settling rate when this variable changes, as the slight differences exhibited have no statistical significance (taking into account the relative standard deviation). This can be due to the proximity of these two size fractions. Fig. 6 depicts the values obtained in tests carried out with plastics from different origins. It is apparent from this figure that used PS particles do not have a significantly different settling rate from virgin PS ones. In contrast, the origin of PET can have a considerable effect on the settling rate of particles. The results obtained lead to the conclusion that the process is driven to a great extent by plastic density and, probably, by particle shape. From Fig. 5, it could be anticipated that it should be easy to separate PS from PET. Unexpectedly, it was found that, at least for part of the feed, the separation of PET from PVC by fluidization techniques could be possible. However, if the relative standard deviations are considered, this might not be so, as the settling rate intervals overlap. 4.2. Separation tests As mentioned before, the ‘‘separation tests” were carried out with ‘‘real mixtures” of the granulated waste plastics. The ‘‘separability study” showed that the utilization of a hydraulic water velocity higher than 79 cm/min would result in an overflow product rich in PS and an underflow product mainly constituted by PET and PVC. 100 80 PETvy 60 40 PSvy 20 0 0 20 30 60 80 100 120 140 160 Hydraulic water superficial velocity (cm/min) Fig. 5. Settling rate as a function of hydraulic water flow rates in tests carried out with two different size fractions of virgin PET and PS: 2–4 mm (dashed line) and 4– 5.6 mm (solid line). 100 150 80 2-4mm 60 4-5.6mm 40 20 0 PETvy PETbl PETgr PVCvy PSvy PSus Plastics type Fig. 3. Settling rate relative standard deviation for different types of plastics and two size fractions (tests carried out with hydraulic water velocity = 79 cm/min). Settling rate (cm/min) Settling rate relative standard deviation (%) Each one of the ‘‘separability tests” was carried out with just one type of plastic classified in a closed size interval. The tests were performed with six types of plastics and two different size fractions. Three hydraulic water flow rates were used. Plastic types: PETvy, PETgr, PETbl, PVCvy, PSvy, PSus. Size fractions: 2–4 mm and 4–5.6 mm. Hydraulic water superficial velocity: 47, 79 and 141 cm/min Each test was repeated 10 times. Figs. 4–6 present the average settling rates obtained, whereas the relative standard deviations (or variation coefficients), obtained in the tests performed with superficial velocity of the hydraulic water of 79 cm/min, are depicted in Fig. 3. In this figure it can be observed that relatively high values of the variation coefficients were obtained mainly in tests carried out with virgin plastics. It is apparent that there is no correlation between variation coefficients and the type of plastic or particle size. The high values of the variation coefficients show that there are variables beside density and grain size that affect the settling rate of particles. In the case of virgin plastics, probably the most important variable is particle shape. This agrees with the conclusions of Pascoe and Hou (1999) who showed that the selective separation of PVC from PET, using a Larcodems separator, is affected by particle thickness (particle shape). Fig. 4 shows the values of average settling rates of particles of virgin PET, PVC and PS, in tests conducted with three different hydraulic water flow rates. As expected, when the flow rate of hydraulic water is increased, the settling rate decreases. When the hydraulic water flow rate is 141 cm/min, the PS does not settle, being transported directly to the overflow. It was observed that PVC particles are faster to settle than PET ones although they have the same density. This was attributed mainly to the difference in particle shape as PVC particles were visually found to be more spherical than PET ones. This different behaviour of both types of plastic indicates that a significant proportion of PET can be potentially separated from PVC through gravity separation processes. Settling rate (cm/min) 4. Results and discussion 200 Settling rate (cm/min) (5.6–8 mm) leads to frequent obstruction of the laboratory equipment therefore the results presented here represent only the fractions 2–4 mm and 4–5.6 mm. 125 100 PETgr 75 50 PETbl PETvy PSus 25 0 PSvy 0 20 40 60 80 100 120 140 160 Hydraulic water superficial velocity (cm/min) Fig. 6. Settling rate as a function of hydraulic water flow rates in tests carried out with different types of PET and PS (size fraction, 4–5.6 mm). 1142 M.T. Carvalho et al. / Waste Management 29 (2009) 1138–1143 100 60 40 PVC 20 PET 0 20 40 60 80 100 120 140 Hydraulic Water Supeficial Velocity (cm/min) Firstly, three sets of tests were carried out, one with the hydraulic water velocity lower than 79 cm/min and two with higher velocities. Fig. 7 shows that the recovery of PS in the overflow is about 50% when the hydraulic water velocity is slightly higher than 79 cm/min. In this case, more than 10% of PVC is recovered in the overflow too. When the hydraulic water velocity was increased, the recovery of the three plastics in the overflow increased too. This process is continuously operated; therefore, it is possible that small air bubbles are generated and introduced with the feed. As the plastics are highly hydrophobic, the particles, unselectively, adhere to the air bubbles rising to the top of the device. For the same reason, if not well wet, particles stick together, forming aggregates of mixed plastics. To prevent these occurrences, some tests were performed where the mixture of plastics, before being fed to the elutriator, was conditioned with chemical reagents. Tests were made with three reagents: (1) an anti-frother agent, from Macdermit, (2) MS4, from Macdermit, and (3) CaLS, from Aldrich. The first two reagents are commonly used in the recycling industry in the separation of PET from polyolephines, MS4 being the commercial name of a reagent used as a depressor of PET, to reduce the wettability of this plastic. CaLS is commonly used in the separation of plastics by froth flotation (see, for example, Pascoe and Hou (1999), Le Guern et al. (2000), Pongstabodee et al. (2008)). The results depicted in Fig. 8, referring to tests performed with 2–4 mm mixtures, show that the pre-conditioning of the mixture of plastics with CaLS leads to benefits in separation. PET and PVC are almost completely discharged in the underflow while more than 50% of the PS is transported to the overflow. When the 4– 5.6 mm fraction is used, the results are even better (see Fig. 9). The results, presented in Table 3, show that it is possible to separate a considerable percentage of the PS from the other polymers. In the size range 2–4 mm, a PS enriched product, with a 68% grade 100 PET PVC PS 60 40 20 0 anti-frothing CaLS MS4 PS 70 60 50 40 30 20 10 Fig. 7. Recovery of the three plastics in the overflow for different hydraulic water velocities (size fraction, 2–4 mm). 80 PVC 80 PS 0 Recovery (%) PET 90 80 Recovery (%) Recovery (%) 100 No reagents Fig. 8. Recovery of the three plastics in the overflow when reagents are used (size fraction, 2–4 mm; hydraulic water velocities, 94 cm/min). 0 anti-frothing CaLS MS4 No reagents Fig. 9. Recovery of the three plastics in the overflow when reagents are used (size fraction, 4–5.6 mm; hydraulic water velocities, 126 cm/min). Table 3 Separation results Feed Grade Overflow (%) Recovery Size range (mm) PET (%) PVC (%) PS (%) 2–4 4–5.6 2–4 4–5.6 2–4 4–5.6 88.18 91.14 21.72 28.79 0.22 0.29 8.41 6.62 3.33 3.57 0.24 0.53 2.91 1.63 74.72 67.52 54.50 83.22 (the feed grade in PS was 2.9%), corresponding to 55% of the PS present in the feed, was obtained. In the size range 4–5.6 mm (the feed grade in PS was 1.6%), the recovery of PS in the overflow was higher (83%) than in the previous case but the grade was lower (68%) due to the slightly higher recovery of PET and PVC in this product. Depending on the desired purity of products, cleaning stages for the overflow and/or underflow must be added. 5. Conclusions The experimental work reported in this paper was carried out to evaluate the possibility of separation of PS from PET and PVC, from shredded packaging waste, by fluidization. Firstly, the most adequate upward flow velocity was determined. It was observed that the particle shape and surface wetting/hydrophobicity of plastics affect the behaviour of particles. The study followed with the separation of real wastes collected at the drop-off points. In the size range 2–4 mm, a PS enriched product with a 68% grade (the feed grade in PS was 2.9%), corresponding to 55% of the PS present in feed, was obtained. In the size range 4–5.6 mm (the feed grade in PS was 1.6%), the recovery of PS in the overflow was higher (83%) than in the previous case but the grade was lower (68%), due to the slightly higher recovery of PET and PVC in this product. It was concluded that the wettability of plastics must be assured before separation can take place. The best results were achieved with the pre-conditioning of the feed with CaLS as wetting agent. It was shown that it is possible to decrease the contamination level of PS in the PET product, below Portuguese recycling industry specifications, through a simple and low-cost process. It is also possible to produce a concentrate of PS in the overflow. Depending on the desired purity of the PS product (in Portugal there are no specifications for such a product), one or more cleaning stages must be added. Acknowledgments The authors acknowledge Sociedade Ponto Verde for the financial support of the study included in SEMEC project, Tratolixo for M.T. Carvalho et al. / Waste Management 29 (2009) 1138–1143 the sample collection, Selenis–Ambiente for the sample preparation, and PIEP (Department of Polymers of Minho University) for the products analysis and density measurements. References Awaja, F., Pavel, D., 2005. Recycling of PET. European Polymer Journal 41 (2005), 1453–1477. Billmeyer Jr., F.W., 1984. Textbook of Polymer Science. John Wiley & Sons. Burt, R.O., 1984. Gravity Concentration Technology. Elsevier. Carvalho, M.T., Santos, L., Simões, P., Costa, A., 2007a. Semec Pilot Project: Mechanized Recovery of Granulated Plastics from Packaging, Proceedings of the IFAC Workshop MMM 2007, Quebec, Canadá, 21–23 August 2007. Carvalho, M.T., Agante, E., Durão, F., 2007b. Recovery of PET from Packaging Plastics Mixtures by Wet Shaking Table. Waste Management Journal 27 (2007), 1747– 1754. Castro, G., Pouzada, S., 2003. Embalagens para a Indústria Alimentar. Instituto Piaget. 1143 Kelly, E.G., Spottiswood, D.J., 1982. Introduction to Mineral Processing. John Wiley & Sons, Inc. Le Guern, C., Conila, P., Houot, R., 2000. Role of calcium ions in the mechanism of action of a lignosulphonate used to modify the wettability of plastics for their separation by flotation. Minerals Engineering 13 (1), 53–63. Magrinho, A., Didelet, F., Semião, V., 2006. Municipal solid waste disposal in Portugal Waste Management 26 (12), 1477–1489. Navarro, R., Ferrándiz, S., López, J., Seguí, V.J., 2008. The influence of polyethylene in the mechanical recycling of polyethylene terephtalate. Journal of Materials Processing Technology 195 (1–3), 110–116. Pascoe, R.D., Hou, Y.Y., 1999. Investigation of the importance of particle shape and surface wettability on the separation of plastics in a Larcodems separator. Minerals Engineering 12 (4), 423–431. Pongstabodee, S., Kunachitpimol, N., Damronglerd, S., 2008. Combination of threestage method and selective flotation technique for separation of mixed postconsumer plastic waste. Waste Management 28, 475–483. Santos, L., Paiva, Machado, M.C., Bernando, C.A., 2007. Analysis of plastics from municipal solid waste by thermogravimetry and fourier transform infrared spectroscopy, Procs. Conferência Materiais 2007, Porto, Portugal. Wills, B., 1998. Mineral Processing Technology. Elsevier.