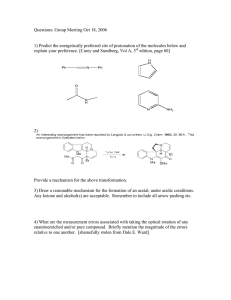

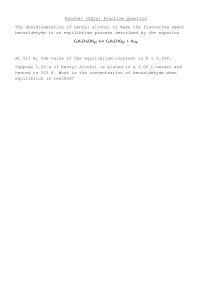

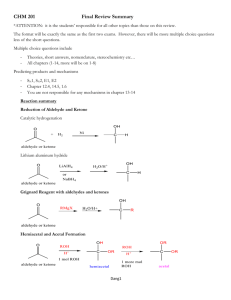

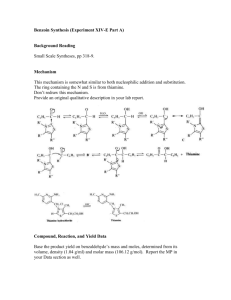

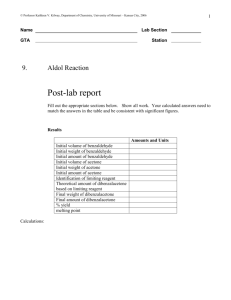

Lab report Synthesis of Benzylidene Acetal Objective: The present experiment is aimed at the synthesis of benzylidene product by the reaction of benzaldehyde with 1,1,1-tris(hydroxymethyl)ethane in the presence of catalytic sulfuric acid. The product will be purified through recrystallization and purity will be analyzed through TLC. Finally, 1H-NMR and 13C-NMR will be obtained to confirm the product and percentage yield will be calculated. Introduction: The synthesis of large organic molecules is somehow difficult as the undesired functional group can interfere in the reaction with desired functional group. To avoid this, that interfering group is protected or blocked at first, the reaction is then carried out and then that group is deprotected or unblocked. Functional groups such as alcohols, carbonyl and amines groups need to be protected in multistep synthesis and are converted into silyl alcohol, acetal/ketal and carbamates respectively. In the current experiment, the aldehyde will be protected by its conversion into acetal. Acetal formation involves the acid mediated reaction between aldehyde and two hydroxyl group/ diol. Initially, the carbonyl of aldehyde is protonated so it becomes more electrophilic followed by the attack of OH group to form hemiacetal. Protonation of hemiacetal followed by nucleophilic attack of other OH group furnishes acetal product. The use of two equivalent alcohol gives open acetal while the use of one equivalent diol gives cyclic acetal. These acetals are easy to remove when do no needed and they are very stable under reaction condition. Herein, benzaldehyde will be reacted with 1,1,1-tris(hydroxymethyl)ethane to form six-membered stable cyclic acetal. Chemical reaction: Reagent table: Table-1: Physical properties of the reagents to be used Compound Structure CAS No. # MW* (g/mol) Acetone 67-641 58 Benzaldehyde 10052-7 106 775782-6 142 1,1,1tris(hydroxymethyl)ethane 77-850 120 Petroleum ether 803232-4 82.2 Toluene 10888-3 92.14 Sodium sulfate Na2SO4 B.P (℃) Density (g/ml) 56 0.784 (MP= -97 °C) 178 1.044 (M.P = -57.12 °C) 1429 2.664 (MP = 884 °C) -1.22 (MP = 180 °C) 42-62 0.653 (MP = < -73 °C) 111 0.87 (MP = - 95 °C) Procedure: 1. A round bottom vial and magnetic stir were rinsed with acetone and dried. 1,1,1tris(hydroxymethyl)ethane (1.1 g), water (2.5 mL) and conc. sulfuric acid (10 drops) were introduced to a vial. The reaction mixture was stirred for 5 mins at room temperature to dissolve the whole solid. After the dissolution of previous contents, benzaldehyde (0.56 mL) was added to reaction mixture. This was then stirred vigorously for 15 mins so that the reaction of undissolved benzaldehyde with added reagents was ensured. 2. After 15 minutes, small pieces of crushed ice were added to the vial. The mixture was allowed to stir vigorously again. The vial was then placed in ice bath for 10 minutes after the precipitation of product started. The product was obtained by vacuum filtration using Hirsch funnel. The product was then washed with water in three portions using 2 ml water each time. 3. The crude product was added to flask (25 mL), toluene (10 mL) was introduced and the contents were heated gently. The organic solution was then dried over Na2SO4 for 5 mins to absorb water. 4. The organic solution was then decant carefully into another beaker (30 mL) containing petroleum ether (10 mL). The mixture was then allowed to stand for 5 mins in ice bath. 5. The product was then collected by vacuum filtration using Hirsh funnel. It was then washed with petroleum ether thrice using 2 mL each time. The product was dried by drawing air through it and its weight was recorded. 6. Thin layer chromatography (TLC) was performed to analyze the purity of product. Product (1/4; 25%) was dissolved in acetone (2 mL). Chromatography jar was obtained and 5 mL developing solvent (70: 30 petroleum ether: ethyl acetate) was added to the jar. TLC plate was obtained and spot of product and reactant was marked on it using capillary tubes. The TLC was placed in jar and allowed to develop. It was visualized afterwards under UV-lamp and spots were marked with pencil. 7. The percentage yield of product was calculated and 1H-NMR and 13C-NMR were obtained. Results: Calculation of theoretical yield: Volume of benzaldehyde used = 0.56 mL Density of benzaldehyde = 1.044 g/ mL Mass of benzaldehyde used = density × volume = 1.044 × 0.56 = 0.585 g 106 g of benzaldehyde give product = 208 g 1 g of benzaldehyde give product = 208 g / 106 g 0.585 g of benzaldehyde give product = (208 g / 106 g) × 0.585 = 1.15 g Actual yield of product = 0.880 g Percentage yield = (Actual yield / theoretical yield) × 100 = (0.880 / 1.15) × 100 = 76.52 % Rf value = distance travelled by solute/ distance travelled by solvent = 1.5/2.6 = 0.58 Rf value of product = 0.58 in (70: 30 petroleum ether: ethyl acetate) 1H-NMR Table: Assign. A B C D E F G Chemical shift ppm 7.4-7.5 5.45 3.68 3.9 4.1 0.8 1.6 Signal splitting Proton multiplet singlet doublet singlet doublet singlet singlet Aromatic protons O-CH-O CH2 CH2-OH CH2 CH3 OH 13C-NMR Table: Assign. A B C D E F G H I Chemical shift ppm 17.1 35.8 65.87 77 101.96 137.3 126.18 129.3 128.4 Discussion In this experiment, the reaction of benzaldehyde with 1,1,1-tris(hydroxymethyl)ethane in the presence of catalytic sulfuric acid is carried out to obtain benzylidene product as stable cyclic acetal possessing chair conformation. The crude product obtained was purified by recrystallization in toluene. The pure product was analyzed with TLC 70: 30 petroleum ether: ethyl acetate as solvent system. The Rf value was found to be 0.58. The percentage yield of this reaction was 76.52 %. The 1H-NMR of benzylidene product showed mutiplets of aromatic protons at 7.4-7.5 ppm. The methine C-H between two oxygens showed singlets at 5.45 ppm. The methylene CH2 of cyclic acetal was shown at 3.68 and 4.1 as doublets. The methylene proton of CH 2OH was observed at 3.9 ppm as singlet. The proton of methyl group CH3 was shown at 0.8 ppm as singlet. The hydroxyl proton of OH was shown at 1.6 ppm as singlet. The 13C-NMR of product showed the peaks of aromatic carbons in 126-129 ppm region. The methine carbon between two oxygens showed peak at 101.9 ppm. The methylene carbon of cyclic acetal was shown 77 ppm. The quaternary carbon C of cyclic acetal showed peak at 35.8 ppm. The methylene carbon of CH2OH was observed at 65.8 ppm. The carbon of methyl group CH3 was shown at 17.1 ppm. Conclusion: The benzylidene acetal product was successfully synthesized by the reaction of benzaldehyde with 1,1,1-tris(hydroxymethyl)ethane in the presence of sulfuric acid as catalyst. The percentage yield of this reaction was good i.e. 76.5%. The product was pure and its Rf value was foulnd to be 0.58 in 70: 30 petroleum ether: ethyl acetate as solvent system. The 1H-NMR and 13C-NMR data of this product was consistent with it confirming the successful formation of desired acetal. Prelab Questions: 1. Le-Chatlier’s principle governs the formation of product in this reaction. So, the reagent such as diol is taken in excess to allow forward reaction to take place. In this reaction, water, a product of this reaction is taken as solvent. The reaction cannot go backward due to excess water because the product is insoluble in it so it precipitates out. Also, ice has been added to further lower the temperature and increase insolubility of product in it. 2. 3. Through filtration the excess reagent such as 1,1,1-tris(hydroxymethyl)ethane and acidic water is removed and the crude product is obtained. Later it is washed with water to further remove reagent particles if any. The unreacted benzaldehyde was then removed during crystallization by adding the organic solution of product and toluene into petroleum ether. Later on, crystallization followed by filtration and washing with petroleum ether further removed any unreacted benzaldehyde. 4. a) b) In case of reaction of 1,3 diol with benzaldehyde the cyclic chair form of acetal is stable as phenyl occupies equatorial position. In this way 1,3-diaxial interaction is much reduced and the resulting conformation is much stable. While in case of reaction of 1,3diol with acetone, the cyclic acetal has the methyl groups both at axial as well as equatorial position. 1,3-diaxial interaction due to methyl decreases the stability of resulting acetal. Thus, the reaction of 1,3-diol with benzaldehyde is more favourable. `