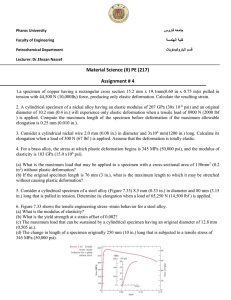

` TENSILE STRENGTH OF MATERIALS Experiment # 1 Rodger Louis T. Maunes I. OBJECTIVES To evaluate the values of ultimate tensile strength, yield strength, % elongation, % area of reduction and Young's Modulus of the selected metals when subjected to tensile loading. To be able to show load-extension and stress-strain relationships and represent them in graphical forms. To understand the principle of a tensile testing and gain their practices on operating the tensile testing machine to achieve the required tensile properties. II. APPARATUS/MATERIALS Universal Testing Machine (UTM) Vernier Caliper Mild Steel Specimen III.THEORITICAL BACKGROUND AND RELATED LITERATURE Tensile test is known as a basic and universal engineering test to achieve material parameters such as ultimate strength, yield strength, % elongation, % area of reduction and Young's modulus. The tensile testing is carried out by applying longitudinal or axial load at a specific extension rate to a standard tensile specimen with known dimensions (gauge length and cross sectional area perpendicular to the load direction) till failure. The applied tensile load and extension are recorded during the test for the calculation of stress and strain. When a specimen is subjected to an external tensile loading, the metal will undergo elastic and plastic deformation. Initially, the metal will elastically deform giving a linear relationship of load and extension. These two parameters are then used for the calculation of the engineering stress and engineering strain to give a relationship as illustrated in figure 1 using equations 1 and 2 as follows: ` 𝐹 σ = 𝐴𝑜 ε= …(1) 𝐿𝑓−𝐿𝑜 𝐿𝑜 ∆𝐿 = 𝐿𝑜 …(2) where: σ is the engineering stress ε is the engineering strain F is the external axial tensile load Ao is the original cross-sectional area of the specimen Lo is the original length of the specimen Lf is the final length of the specimen The unit of the engineering stress is Pascal (Pa) or N/m2 according to the SI Metric Unit whereas the unit of psi (pound per square inch) can also be used. During elastic deformation, the engineering stress-strain relationship follows the Hook's Law and the slope of the curve indicates the Young's modulus (E) E 𝜎 ...(3) 𝜀 Young's modulus is of importance where deflection of materials is critical for the required engineering applications. This is for examples: deflection in structural beams is considered to be crucial for the design in engineering components or structures such as bridges, building, ships, etc. The applications of tennis racket and golf club also require specific values of spring constants or Young's modulus values. By considering the stress-strain curve beyond the elastic portion, if the tensile loading continues, yielding occurs at the beginning of plastic deformation. The yield stress (σy) can be obtained by dividing the load at yielding (Fy) by the original cross-sectional area of the specimen (Ao) 𝐹𝑦 σy = 𝐴𝑜 ...(4) ` Figure 1. Stress-Strain Relationship Diagram A 0.2% off-set method is a commonly used method to determine the yield stength. σy(0.2%) is found by drawing a parallel line to the elastic region and the point at which this line parallel to the slope of the stress-strain curve in the linear section, having an intersection on the x-axis at a strain equal to 0.002 as illustrated in Fig. 2 Figure 2: The determination of the yield strength at 0.2% offset. ` Beyond yielding, continuous loading leads to an increase in the stress required to permanently deform the specimen as shown in the engineering stress-strain curve. At this stage, the specimen is strain hardened or work hardened. If the load is continuously applied, the stressstrain curve will reach the maximum point, which is the ultimate tensile strength (UTS, σ TS). At this point, the specimen can withstand the highest stress before necking takes place. This can be observed by a local reduction in the cross-sectional area of the specimen generally observed in the centre of the gauge length. σTS = 𝐹 𝑚𝑎𝑥 ...(5) 𝐴𝑜 After necking, plastic deformation is not uniform and the stress decreases accordingly until fracture. The fracture strength ( σ fracture) can be calculated from the load at fracture divided by the original cross-sectional area, Ao. σfracture = 𝐹 𝑓𝑟𝑎𝑐𝑡𝑢𝑟𝑒 ...(6) 𝐴𝑜 Ductility is the degree of plastic deformation that a material can withstand before fracture. A material that experiences very little or no plastic deformation upon fracture is termed brittle.Tensile ductility of the specimen can be represented as % elongation or % reduction in area as expressed in the equations given below ∆𝐿 % Elongation = 𝐿𝑜 x 100 %RA = 𝐴𝑜−𝐴𝑓 𝐴𝑜 ∆𝐴 x 100 = 𝐴𝑜 x 100 where Af is the cross-sectional area of specimen at fracture. ...(7) ...(8) ` IV. PROCEDURE 1. In order to conduct a tensile test, the proper specimen must be obtained. This specimen should conform to ASTM standards for size and features. 2. Mark two reference points on the specimen using a dark or permanent pentel pen. The reference length is usually greater than 50mm. Measure the initial diameter and reference gauge length using a vernier caliper. 3. Set the tensile load to be applied. For this set-up use a maximum load of 3000kg. 4. If the load pointer does not coincide with the zero reading on the force display, adjust the load pointer to zero by sliding the chrome coated counterweight found behing the stiffness. 5. Mount the specimen using the appropriate specimen grips which are interchangeable depending on the size and the shape of the specimen at its clamping edge. Grips for flat bars are different from round specimen. 6. Once loaded, the machine can then be used to apply a steady, continuous tensile load. 7. Data is collected at pre-determined points or increments during the test. Data include the applied load and change in gage length. The load is generally read from the machine panel in pounds or kilograms. 8. Once data have been collected, the tensile stress developed and the resultant strain can be calculated. Safety: • Never use a machine if you are not trained or not familiar with it. Ask your supervisor. • Never work alone – Always use “Buddy System.” • Never use machine when Impaired - Be Sober and Smart. • Never start work If you cannot do the job safely- Just don’t do it. • Never wear open toe Shoes -Use closed-toe shoes in the shop. • Never work with unnecessary things - Always remove or secure anything that might get caught in moving machinery. • Never bring hands close to sharp objects – Always keep your hands at a safe distance from sharp tools. • Never be shy to seek help –Always Ask ` • Never leave your work area in mess – Always clean up after yourself. ` V. DATA AND RESULTS Length of reduced section (A): 56 mm Gauge length (G): 50 mm Diameter (D): 12.5 mm Table 1: Load and Deformation Final length: 64.3 mm Final diameter: 10.8 mm ` Load vs Deformation Diagram 2500 Load 2000 1500 1000 500 0 0 5 10 15 20 Deformation VI. DATA ANALYSIS As the load increases, the deformation also increases. There are instances during the experiment wherein the load decreased but the deformation still continued to increase but at a slower rate compared to instances of higher load. VII. CONCLUSION The load applied to the tested material is directly proportional to the deformation of said material. This implies that the deformation increases as the load also increases. ` VIII. REFERENCES 1.) Tensile Strength. Retrieved from https://en.wikipedia.org/wiki/Tensile_testing. 2.) Mallick, Rajib B. El-Korchi, Tahar. (2018). Pavement Engineering - Principles and Practice (3rd Edition) - 15.2.3 Tensile Strength. CRC Press. Retrieved from https://app.knovel.com/hotlink/pdf/id:kt00CXYCOE/pavementengineering/tensile-strength. 3.) Zhang, Haimei. (2011). Building Materials in Civil Engineering - 8.2.1.2 Elasticity. Woodhead Publishing. Retrieved from https://app.knovel.com/hotlink/pdf/id:kt00918SZ9/building-materialsin/elasticity. 4.) Wypych, George. (2013). Handbook of Material Weathering (6th Edition) - 13.30 Elongation. ChemTec Publishing. Retrieved from https://app.knovel.com/hotlink/pdf/id:kt00CXGKV1/handbook-materialweathering/elongation.