4.4.4.13.33 General Electrical Installations & In Hazardous Locations

advertisement

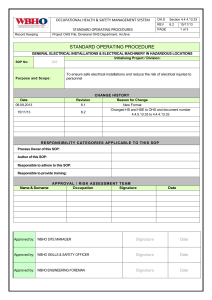

OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM STANDARD OPERATING PROCEDURES Record Keeping OH.S Section 4.4.4.13.33 REV 6.2 PAGE 15/11/13 1 of 3 Project OHS File, Divisional OHS Department, Archive STANDARD OPERATING PROCEDURE GENERAL ELECTRICAL INSTALLATIONS & ELECTRICAL MACHINERY IN HAZARDOUS LOCATIONS Initialising Project / Division: SOP No: 033 To ensure safe electrical installations and reduce the risk of electrical injuries to personnel Purpose and Scope: Date 09.09.2013 Revision 6.1 15/11/13 6.2 CHANGE HISTORY Reason for Change New Format Changed HS and HSE to OHS and document number 4.4.5.13.33 to 4.4.4.13.33 R E S PO N SI BI LIT Y C AT EG O RI E S AP P L IC AB L E T O T HI S SO P Process Owner of this SOP: Author of this SOP: Responsible to adhere to this SOP: Responsible to provide training: Name & Surname AP P R O V AL / RI S K AS S E S SM ENT T E AM Occupation Signature Date Approved by: WBHO SITE MANAGER Signature Date Approved by: WBHO SKILLS & SAFETY OFFICER Signature Date Approved by: WBHO ENGINEERING FOREMAN Signature Date OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM STANDARD OPERATING PROCEDURES Record Keeping OH.S Section 4.4.4.13.33 REV 6.2 PAGE 15/11/13 2 of 3 Project OHS File, Divisional OHS Department, Archive Only authorised, trained and competent personnel may perform this activity. Non-compliance to this SOP may result in injury or harm to yourself or others. Always use the correct PPE for this task. If you are not sure how to do this properly, ask your immediate supervisor. You have the right to refuse to do any work if the situation will endanger your own or the lives of other people. PERSONAL PROTECTIVE EQUIPMENT NEEDED FOR THIS WORK PLEASE LIST ALL THE ESSENTIAL PPE FOR THIS SOP PPE to be worn as per job requirement DEFINITIONS 1. Electrical apparatus: means all apparatus, machines and fittings in which conductors are used, or of which they form a part. 2. Earthed: means connected to the general mass of earth in such manner as will ensure at all times an immediate discharge of electrical energy without danger. 3. Flexible cable: means a cable having flexible insulated conductors and earthing conductors within a protective sheath, but shall not include signaling cable, telephone cable, blasting cable or flexible electric cord use with electrical apparatus at a voltage not exceeding 250volts alternating current on a single-phase system. SAFETY & HEALTH WARNINGS 1. Electrical Installation Safety: a. b. c. d. e. f. g. h. i. j. k. l. m. n. o. All wiring will be safe and according to the required specifications. Temporary wiring will be allowed only during a construction phase. Temporary wiring must be safe. Temporary wiring must be protected by an earth leakage device. All new temporary installations will be approved and signed off by a qualified electrician before power is switched on. No tape joints will be allowed. Unauthorised entry is prohibited to substations. All unattended substations must be kept locked at all times. Flexible cords / cables will NOT be routed through or along walls, floors or ceilings and NO unsafe All switches, plugs, jointing, fuse boxes, distribution boards and all other related equipment will be kept in a sound safe condition. Faulty electrical installations will be isolated and repaired immediately. Broken switches and sockets must be replaced immediately. No unauthorised tampering, temporary connections or damaged cables are allowed. No defective electrical installation or equipment will be used or allowed to function in that state. All machinery used on site (other than those with double insulation), must be earthed to ensure a safe path for current flow, should the housing accidentally be energised. OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM STANDARD OPERATING PROCEDURES Record Keeping OH.S Section 4.4.4.13.33 REV 6.2 PAGE 15/11/13 3 of 3 Project OHS File, Divisional OHS Department, Archive p. No openings must be allowed in DB panels. Blanks must be installed to cover openings. 2. Flameproof Equipment: a. In designated hazardous areas such as paint and flammable liquid stores, vehicle maintenance pits, spray booths and battery rooms, all electrical equipment installed must be suitable for the class of hazard involved and maintained in an effective condition by suitably Qualified Electrician b. The electrical installations in hazardous locations must be classified in terms of the SANS Code of Practice 10108 of 2005. (The Classification of hazardous locations and the selection of apparatus for use in such locations) z c. Inspections on flameproof equipment / lights / fittings must be carried out annually by a suitable Qualified Electrician and are recorded in a register.