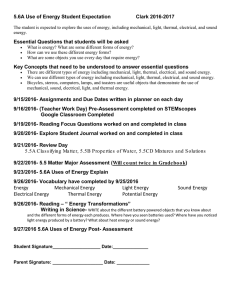

Applied Energy Symposium 2019: Low carbon cities and urban energy systems October 16-18, 2019, Xiamen, China Paper ID: 0017 THERMAL MANAGEMENT OF HYBRID ENERGY STORAGE SYSTEMS BASED ON SPATIAL ARRANGEMENT Nzeba Kalala Antoinette*, M.S. Masaki, Farshad Barzegar, Xiaohua Xia Department of Electrical, Electronic, and Computer Engineering, University of Pretoria, Pretoria 0002, South Africa ABSTRACT Temperature has a significant impact on the performance and ageing of electrochemical storages, especially the battery. It is therefore of paramount importance to understand and control their thermal stress for increased longevity. This paper presents the preliminary findings on a thermo-electric management of a battery-supercapacitor hybrid system considering the spatial layout of storage cells. The structural arrangement aims to improve the cooling characteristics of battery cells by means of heat transfer with the supercapacitor cells placed nearby. The simulation results show that the arrangement of cells and the operating mode of the battery-supercapacitor hybrid system has a considerable influence on the thermal behavior of both battery and supercapacitor cells. Keywords: Hybrid energy storage system, Thermal management, Structural arrangement, Battery, Supercapacitor 1. INTRODUCTION Nowadays, renewable energy sources (RES) and clean energy transport systems are increasingly being developed because of energy crisis and environment pollution facing the planet [1]. In this context, energy storage systems (ESS) such as battery, flywheel, supercapacitor (SC), superconducting magnetic energy storage, fuel cell and pumped hydro have gain in importance for intermittent renewable and electric transportation systems [2] – [5]. Considering their high energy density, flexibility and reliability, batteries are among the most popular energy storage systems in industrial applications. Nonetheless, their low power density dwells the main weakness of batteries. In an attempt to mitigate the effects of the low power density of batteries, control models including minimizing the battery aging factor [2, 3], and penalizing the charge and discharge operations [4] have been developed. In the absence of alternative power source, batteries must supply fast-varying and peak current demands despite the implementation of mitigating strategies. Thus, the combination of two or several energy storage technologies into a hybrid energy storage system (HESS) has been seen as a cost effective solution to offset the weaknesses of the battery-alone storage system. Battery-SC HESS is currently one of the most encountered association because of the maturity of the two technologies and the high specific power and wide operating temperature range of SC that balance the corresponding limitations of the battery [7] – [9]. However, the performance and the lifetime of both battery and SC are frequently affected by the temperature rise under certain operating and environmental conditions [6, 10, 11]. A proper thermal management of ESS is therefore of critical importance for both economic and safety reasons. In practice, the use of cooling systems and the control of heat generated by the ESS are the two main methods found in the literature on thermal management [1], [7] – [12]. The former improves heat transfer inside and around the storage device by modifying the heat transfer resistance [1, 11, 12]. The disadvantage of cooling systems such as ventilation system and pumps is their significant power consumption. The second method has a direct impact on the heat generated by the ESS and can be achieved through a reduction of current-induced heat generation of ESS [7, 8, 9]. In this category, one approach consists in the use of SC as battery current fluctuation filter, with battery thermal management as a spinoff effect [8, 9]. Selection and peer-review under responsibility of the scientific committee of CUE2019 Copyright © 2019 CUE The literature study shows that thermal management of battery-SC HESS was seldom investigated in the past. A battery thermal management using a SC have been presented in [7]. In this control strategy, the battery is disconnected whenever its temperature exceeds a specific threshold. During this period, the SC is operated as energy buffer to supply the load. The battery is re-connected in parallel with the SC as soon as its temperature returns below the threshold. While the battery thermal behavior is modelled and analyzed, the non-consideration of thermal characteristics of the SC and possible heat transfer between the storage devices constitutes a major drawback of the proposed controller. To the best of our knowledge, there have been few previous attempts to use the spatial configuration of battery-SC hybrid system in terms of thermal management during charge/discharge. This paper presents the preliminary findings on a thermo-electric management of a battery-SC HESS considering the spatial configuration of storage cells. The structural arrangement aims to improve the cooling characteristics of battery cells by means of heat transfer with the SC cells placed nearby. The thermoelectric models of battery and SC are described in the section 2, the thermal management strategy is outlined in the section 3 and the section 4 concludes this paper. generation model and a simple model of heat transfer within and outside the system [6, 10, 14]. The total heat generation encompasses the heat generation due to ohmic losses and entropy change while the heat transfer could occur by conduction, convection and radiation phenomena. Considering the low contribution of heat generated due to entropy change under large load current, only the ohmic heat generated is considered in this study. Figure 3 shows the lumped parameters model that describes the battery and SC thermal behavior under the following assumptions: (1) the distribution of heat generated, heat transfer and temperature is uniform; (2) the core of ESS cell is composed of opaque component; (3) the convection inside the core neglected [6, 10]. The model parameters are the ESS internal and shell thermal capacitance, denoted by Ci and Cs, respectively, and the thermal resistance between the ESS core and shell, and between the ESS shell and the ambience, denoted by Rcs and Rs-a respectively. Qi is the ESS heat generated; and Ta is the ambient temperature. Ti and Ts are the ESS internal and shell temperature, respectively. The following expressions describe the thermal equivalent circuit in Fig. 3. Qi Ci Ti Ts 2. THERMOELECTRIC MODELLING OF HESS The layout diagram of an HESS consisted of a battery cell and a SC cell is shown in Fig. 1. The thermoelectric models of battery and SC cells combine their respective electrical and thermal models. Rc s dTi Ti Ts dt Cs , (1) Rc s dTs dt Ts Ta . (2) Rs a Charge/Discharge Current 2.1 Electrical models Among the various electrical models of battery and SC, the second order equivalent circuit models shown in Fig. 2 are adopted in this work. These models have a relatively simple structure, as well as an acceptable accuracy in terms of the description of the dynamic behavior of HESS [6, 10, 13]. In these models shown in Fig. 2, Rs and Ri are the series resistance of SC and battery, respectively; C is the SC capacitance; and OCV is the battery open circuit voltage function of its state of charge (SOC). The two RC networks aim to capture both short-term and long-term dynamics of ESS. Switch Control S1 S2 2.2 Thermal models The thermal model of both battery and SC is based on the energy conservative law describing the temperature dynamics of a system using the heat Battery Cell Supercapacitor Cell Fig 1 System layout diagram. 2 Copyright © 2019 CUE 3. C1 C2 R1 R2 + C1 C2 R1 R2 + Rs Ri C OCV = f(SOC) - (a) - (b) Fig 2 (a) Dynamic electric model of SC (b) Second order equivalent circuit model of battery. Rc-s Ti Qi Ts Rs-a Ta Cs Ci Fig 3 Thermal model of ESS. In order to illustrate the effect of thermal interaction between a battery cell and a SC cell disposed side by side as illustrated in Fig. 4(a), the thermal model of the entire system is designed as shown in Fig. 4(b). Here, the subscripts b and s denote battery and SC, respectively. The thermal resistance Rbs exhibits that the presence of heat transfer from the battery to SC or reversely, depending on temperature gradient between the two cells. The heat generated is computed as the total power dissipated in the battery as well as SC cells, as follows: Qib (Vb OCV ) I b , (3) Qis (VS U C ) I S , (4) where Vb and Vs are battery and SC terminal voltage, respectively, Uc is the SC capacitance voltage, Ib and Is are the current value flowing through battery and SC, respectively. THERMAL ANALYSIS STRATEGY By assuming that, the SC is fully charged initially and able to supply the discharge current for the entire simulation duration, the evolution of internal and shell temperatures of both the battery and SC as a function of time are collected for the following operating conditions by means of switch control: S1 = 1 and S2 = 0: the battery in standalone mode S1 = 0 and S2 = 1: the supercapacitor in standalone mode S1 = 1 and S2 = 1:the battery and SC in parallel mode S1 and S2 set sequentially to 1 and 0 or 0 and 1, respectively: the switching mode. During standalone and parallel modes, the thermal behaviors of both battery and SC are analyzed when the two devices are relatively far from each other, i.e., Rbs →∞, and when they are relatively close to each other, 0<Rbs<∞. The results from the two cases are thus compared to illustrate the influence of the spatial configuration of battery and supercapacitor cells in a hybrid system. 3.1 Case Study The HESS consists of a prismatic battery cell with a nominal capacity of 30 Ah and a prismatic SC cell with a nominal capacity of 3000F. The height, width and thickness of the two cells are 182, 100, and 32 mm, respectively [10]. The electrical and thermal parameters of the battery cell are taken from [10], while the electrical and thermal parameters of the SC cell are taken from [13] and [15], respectively. Table 1 gives a summary of these parameters. The thermal resistance Rbs is computed considering the thermal conductivity of air, which is equal to 0.03 [15]. The space between the two cells and their initial temperature are set to 1 mm and 20oC, respectively. Figure 5 (a) and Fig. 5 (b) gives respectively the curve of the charge/discharge current applied to the HESS and the operating sequence of battery and SC during switching mode. Rbc-s Tsb Tib Rbs Qib Cib Rsc-s Tis Rss-a Rbs-a SC Tss Qis Csb Ta Ta Css Cis Bat (a) (b) Fig 4 (a) Structural arrangement of ESS (b) Thermal model of HESS. 3 Copyright © 2019 CUE Table 1. Battery and SC parameters. Battery Cell Supercapacitor Cell Value Parameter (unit) Value Ri (Ω) [R1 (Ω), C1 (F)] [R2 (Ω), C2 (F)] 0.0135 [0.008, 1875] [0.006, 100000] Rs (mΩ) [R1’ (mΩ), C1’ (F)] [R2’ (mΩ), C2’ (F)] 0.8216 [0.3146, 627] [0.3883, 1843] [Cib (J/K), Csb (J/K)] [Rbc-s (K/W), Rbs-a (K/W)] [287.77, 30.8] [0.5776, 0.8333] [Cis (J/K), Css (J/K)] [Rsc-s (K/W), Rss-a (K/W)] [580 , 30.8] [2.6, 0.8333] (A) Parameter (unit) (a) (b) Fig 5 (a) Charge/Discharge current (b) Operating sequence of battery and SC in switching mode. 3.2 Simulation results and discussions (oC) (oC) The above proposed thermal management strategy is implemented and simulated in the MATLAB/Simulink environment. Figure 6 (a) shows the comparison of Tib obtained in the standalone mode, the separate mode with thermal connection to SC, and the switching mode. It is observed that the thermal connection allows the heat transfer from the battery (hottest device) to the SC (coldest device), which results in a decreased battery internal temperature. This can also be seen from the comparison of Tsb for the same three cases as illustrated in Fig. 6 (b). It is important to notice that the higher temperature difference between Tib and Tis as well as the (a) (b) Fig 6 (a) Battery internal temperatures (b) Battery shell temperatures. 4 Copyright © 2019 CUE (oC) (oC) (a) (b) (oC) (oC) Fig 7 Influence of the distance between the two cells (a) Battery internal temperatures (b) Battery shell temperatures. (a) (b) Fig 8 (a) SC internal temperature in switch mode and internal and shell temperatures in standalone mode (b) Battery internal temperatures in parallel mode (Is = 0.3I). smaller spacing between the two ESS will result in more heat transfer from battery to SC. Figure 7 (a) and Fig.7 (b) give respectively Tib and Tsb for three different distances between the two cells. Figure 8 (a) gives Tis and Tss for SC in the standalone mode without any thermal connection to the battery and Tis in the switching mode. In the latter, the increase in Tis is seen during battery operating periods because Qis is zero in this case and thus the more heat is transferred from battery to SC. In order to illustrate the influence of the structural configuration of HESS when SC is used for load fluctuation filter, Tib is obtained when there is no thermal connection and when the latter is considered. It is found that besides the decrease of Tib with SC filtering, the spatial arrangement proposed in this work allows the further reduction of Tib as shown in Fig. 8 (b). 4. CONCLUSION A thermal management strategy based on the spatial arrangement for a battery-SC hybrid system was presented in this paper. The considered configuration of battery and SC cells into HESS may achieve an effective thermal management of battery and SC. The simulation 5 Copyright © 2019 CUE results show that the thermal connection between the two cells allows the heat transfer from the battery (hottest device) to the SC (coldest cell). It is further noteworthy that the higher temperature difference between Tib and Tis as well as the smaller spacing between the two ESS will result in more heat transfer from battery to SC. Therefore, the temperature of the battery cell is reduced and its lifetime as well as its safety will be increased. ACKNOWLEDGEMENT The authors gratefully acknowledge the support for this work provided by the Organization for Women in Science for Developing World (OWSD). REFERENCE [1] Jouhara H, Khordehgah N, Serey N, Almahmoud S, Lester SP, Machen D, Wrobel L. Applications and thermal management of rechargeable batteries for industrial applications. Energy. 2019;170:849-61. [2] Wu Z, Tazvinga H, Xia X. Demand side management of photovoltaic-battery hybrid system. Applied Energy. 2015;148:294-304. [3]Tazvinga H, Zhu B, Xia X. Optimal power flow management for distributed energy resources with batteries. Energy conversion and management. 2015;102:104-10. [4] Zhu B, Tazvinga H, Xia X. Switched model predictive control for energy dispatching of a photovoltaic-dieselbattery hybrid power system. IEEE Transactions on Control Systems Technology. 2014;23(3):1229-36. [5] Sichilalu S, Tazvinga H, Xia X. Optimal control of a fuel cell/wind/PV/grid hybrid system with thermal heat pump load. Solar Energy. 2016;135:59-69. [6] Chiang CJ, Yang JL, Cheng WC. Temperature and stateof-charge estimation in ultracapacitors based on extended Kalman filter. Journal of Power Sources. 2013;234:234-43. [7] Shin D, Poncino M, Macii E. Thermal Management of Batteries Using Supercapacitor Hybrid Architecture With Idle Period Insertion Strategy. IEEE Transactions on Very Large Scale Integration (VLSI) Systems. 2018;26(6):115970. [8] Masaki MS, Zhang L, Xia X. A hierarchical predictive control for supercapacitor-retrofitted grid-connected hybrid renewable systems. Applied Energy. 2019;242:393-402. [9]Choi ME, Kim SW, Seo SW. Energy management optimization in a battery/supercapacitor hybrid energy storage system. IEEE Transactions on Smart Grid. 2011;3(1):463-72. [10] Zhang C, Li K, Deng J, Song S. Improved realtime state-of-charge estimation of LiFePO4 battery based on a novel thermoelectric model. IEEE Transactions on Industrial Electronics. 2016;64(1):654-63. [11] Voicu I, Louahlia H, Gualous H, Gallay R. Thermal management and forced air-cooling of supercapacitors stack. Applied Thermal Engineering. 2015;85:89-99. [12] Al Sakka M, Gualous H, Van Mierlo J, Culcu H. Thermal modeling and heat management of supercapacitor modules for vehicle applications. Journal of Power Sources. 2009;194(2):581-7. [13] Zhang L, Wang Z, Hu X, Sun F, Dorrell DG. A comparative study of equivalent circuit models of ultracapacitors for electric vehicles. Journal of Power Sources. 2015;274:899-906. [14] Shin D, Chung SW, Chung EY, Chang N. Energyoptimal dynamic thermal management: Computation and cooling power co-optimization. IEEE Transactions on Industrial Informatics. 2010;6(3):340-51. [15] Wang K, Li L, Yin H, Zhang T, Wan W. Thermal modelling analysis of spiral wound supercapacitor under constant-current cycling. PloS one. 2015;10(10):1-11. https://doi.org/10.1371/journal.pone.0138672 6 Copyright © 2019 CUE