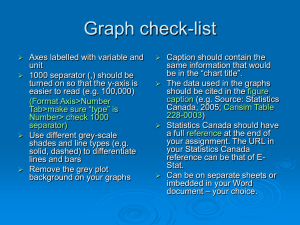

Real Separator Real Separator Guide Authors: Lucas Rojek & Dharmendra Tiwary Date: July 2004 Version: 1.0 Program Mode: HYSYS State-State & Dynamics 1 Real Separator 1 Introduction The HYSYS Separator unit operation normally assumes perfect phase separation, but it can also be configured to model imperfect separation by using the HYSYS Real Separator capabilities. The real separator offers the user a number of advantages: • • Includes carry over so that your model matches your process mass balance or separator design specifications. Predicts the effect of feed phase dispersion, feed conditions, vessel geometry, and inlet/exit devices on carry over. This document will introduce the concepts needed to use these real separator features. An example is included to demonstrate a typical real separator application. 1.1 Modeling Separators Real World Considerations In real world separators, separation is not perfect: liquid can become entrained in the gas phase and each liquid phase may include entrained gas or entrained droplets of the other liquid phase. Recent years have seen increasing use of vessel internals (e.g., mesh pads, vane packs, weirs) to reduce the carry over of entrained liquids or gases. Carry Over Option The Carry over option for steady state modeling was introduced in HYSYS 3.1. Carry over in dynamic models was added in HYSYS 3.2. 2 Real Separator capabilities like the carry over option were introduced to the HYSYS separator with the release of HYSYS 3.1. This option can be used to model imperfect separation in both steady state and dynamic simulation. Gas and liquid carry over can be specified or calculated. Three different correlations are available for this purpose. Real Separator Vessel Internals Internals used to reduce carry over can be included in your separator model with some of the provided carry over correlations. Internals used to reduce the amount of phase dispersion entering the vessel are termed “inlet devices”. Internals used to reduce liquid carry over into the outlet gas product are termed “exit devices”. “Weirs” are used to improve heavy liquid - light liquid separation in horizontal vessels. Nozzle Calculations Included with the carry over correlations are calculation methods for inlet and outlet nozzle pressure drop. Inlet and outlet devices can be included in these calculations. The user can also specify pressure drop if the carry-over option is not in use. Dynamic Models of Real Separators Some of these options (e.g. static head contribution to pressure, nozzle locations, detailed heat transfer) require a license for the HYSYS Fidelity option. The dynamic model of a separator must account for changing pressure and flow due to liquid levels, nozzle pressure drop, and heat effects. As such, vessel geometry, including internals and nozzle geometry, and heat loss parameters need to be specified. Modeling imperfect separation with the carry over option and a specifiable PV work term are also available. Level taps can also be set for monitoring the relative levels of the different liquid phases. All of these items can be set up via the Rating tab. 3 Real Separator 2 Carry Over Models 2.1 Ideal Separator By default the HYSYS separator is an ideal separator where complete separation of different gas and liquid phases is assumed and is calculated based on thermodynamic equilibrium (i.e., on the Rating tab, C.Over Setup page the Carry Over Model is set to None.). Inlet and outlet nozzle pressure drops can be specified on the Design tab, Parameters page. By default these pressure drops are set to 0. The pressure drop in the vessel itself is assumed to be negligible relative to the nozzle pressure drops and is set to zero (cannot be changed). 2.2 Specifying Carry Over on a Feed Basis The Feed Basis model allows you to specify the entrainment of each phase in the product streams as a fraction of the feed. Where fractions are specified (non-zero), the product streams exiting the separator will have multiple liquid and gas phases. For example, if you specify Fraction of Feed as 0.1 for light liquid in gas, this means that 10 mol% of the light liquid phase in the feed will be carried over into the gas product leaving the separator. As a result, the gas product vapor fraction will be less than 1.0 and contain a liquid phase. There are two checkboxes at the bottom of the Feed Basis page. Checking the Carry over to zero flow streams checkbox will ensure the specified carry over is added to the product stream even if it has no flow. Checking the Use PH flash for product streams checkbox will switch the HYSYS flash for the product streams from PT to PH; it is only needed if the user encounters flash inconsistencies with the PT flash. These two checkboxes are also available in the Product Basis and Correlation Based models. Pressure drop in the separator is specified in the same manner as discussed previously in section 2.1. 4 Real Separator 2.3 Specifying Carry Over on a Product Basis The Product Basis model allows you to specify the entrainment in the product streams in terms of mole/mass/volume fraction or flow. For example, if you specify Frac in Product (Mole Basis) as 0.1 for the light liquid in gas, this means that the gas product will contain 10 mol% light liquid. If a phase is missing from the feed stream, checking Use 0.0 as product spec if phase feed flow is zero allows the separator to continue to calculate the carry over effect (in this case it ignores any product fraction or flow specification for that phase). The other two checkboxes function as described in 2.2 above. Pressure drop in the separator is specified in the same manner as discussed previously in section 2.1. 2.4 Predicting Carry Over Using Correlations Note that dimensions entered on the Rating! Sizing page are linked to this page; you need only make changes to one of these pages, they will be reflected on the other one. The Correlation Based model allows you to calculate the expected carry over based on the configuration of the vessel, the feed conditions and type of inlet/exit devices installed in the separator. This information is entered on the Correlation Setup, Dimensions Setup, DP/Nozzle Setup pages. The Correlation Setup group allows you to select the Correlation Calculation Type and how you want to apply the correlation. You can apply one correlation for all of the carry over calculations (Overall Correlation radio button). Alternately you can select a different correlation for each step in the carry over calculation sequence: 1. Inlet Calculations 2. Primary Gas-Liquid Separation 3. Primary Liquid-Liquid Separation 4. Exit Device (Secondary Gas-Liquid Separation) Calculations 5 Real Separator A schematic of these steps is shown in Figure 1. Figure 1. Feed Gas Product PrimaryGas/ LiquidSeparation Inlet Calculations SecondaryGas/ LiquidSeparation Oil/Gas Water/Gas Gas/Oil Oil distributioninGas Diameter vsflow Oil/Gas Oil distributioninGas Diameter vs flow Oil/Gas Oil distributioninGas Diameter vsflow Water distributioninGas Diameter vsflow Water/Gas Water distributioninGas Diameter vs flow Water/Gas Water distributioninGas Diameter vsflow Water/Oil Gas/Water Oil/Water PrimaryLiquid/ LiquidSeparation GasdistributioninOil Diameter vsflow Gas/Oil GasdistributioninOil Diameter vs flow Water distributioninOil Diameter vsflow Water/Oil Water distributioninOil Diameter vs flow GasdistributioninWater Diameter vsflow Gas/Water Gas distributioninWater Diameter vs flow Oil distributioninWater Diameter vsflow Oil/Water Oil distributioninWater Diameter vs flow Water Product Oil Product Note: Only those parts of the correlation in use that apply to the particular sub-calculation will be used. Example: If the Generic correlation is used for the Inlet device and ProSeparator is used for primary L-L and G-L separation calculations, then the user-supplied data for the generic inlet calculations (i.e., inlet split and Rossin-Rammler parameters) will be used to generate the inlet droplet distribution. The ProSeparation primary separation calculations will then be performed using these inlet distributions. As ProSeparator correlations will not be used to calculate the inlet conditions, any ProSeparator inlet setup data is ignored. Likewise, any critical droplet sizes entered in the Generic correlation will be ignored as the ProSeparator is being used for the primary separation calculations. 6 Real Separator 3 Correlation Details There are three sets of correlations available to calculate carry over: Generic, Horizontal Vessel, and ProSeparator. After you have selected the type of correlation, you can click on the View Correlation button to view its parameters. 3.1 Generic Correlation The Generic correlation provides a general method for generating the phase dispersions in the feed and for defining the separation criteria. It is a generic calculation that ignores vessel geometry. Inlet Calculations (step 1) For the inlet calculations the user must specify the percentage of each feed phase dispersed in each other feed phase and the Rossin-Rammler parameters (d95 droplet size and Rossin-Rammler index) for each dispersion. RossinRammler parameters are discussed in detail later in this document. Based on these specifications, the inlet droplet distributions of the dispersed phases are calculated. For example, the gas phase may have a light and/or heavy liquid droplet size distribution. Carry Over Calculations (steps 2-4 combined) Carry over is calculated by assuming that all droplets smaller than a userspecified critical droplet size are carried over. 3.2 Horizontal Vessel Correlations The Horizontal Vessel correlations were developed for a horizontal three-phase separator. 7 Real Separator Inlet Calculations (step 1) For the inlet calculations the Horizontal Vessel correlations calculate the six types of dispersions in the feed according to an assumed efficiency of a userdefined inlet device, and user-defined dispersion fractions (termed “Inlet Hold up”; these parameters are found on the Setup!General page of the Horizontal Vessel correlation view). The droplet distribution of the dispersed phase(s) is then calculated using user-supplied Rosin-Rammler parameters just as for the Generic correlation. Please note that the droplet d95 of the liquid-liquid dispersions (i.e. heavy liquid in light liquid and light liquid in heavy liquid) is not specified but calculated using the inlet droplet d95 and the densities of the 2 liquid phases. Primary Separation–Gas-Liquid Separation (step 2) The primary gas-liquid separation is calculated from the settling velocities for each liquid (light and heavy) droplet size in the gas phase and the residence time for the gas in the vessel. A droplet is carried over if the vertical distance traveled during its residence in the vessel is less than the vertical distance required to rejoin its bulk phase. This effectively applies to horizontal vessels. Primary Separation–Liquid-Liquid Separation (step 3) The inversion point is the water fraction at which the system changes in behaviour from a water-in-oil emulsion to an oil-in water emulsion. In many cases it is observed to occur at 50-70% water; however there is no reliable means of determining the actual point and it must usually be determined experimentally. (adapted from Section A of HYSYS Upstream Option guide) 8 The primary liquid-liquid separation is also calculated using settling velocities for each droplet of liquid or gas in the liquid phases and residence time for each liquid phase. The settling velocities are calculated using the GPSA correlations for all dispersions, except for the water in oil dispersion for which the settling velocity is calculated by the method of Barnea and Mizrahi. A user defined liquid phase inversion point is used in the calculation of the appropriate liquid phase viscosities (i.e. water-in-oil and oil-in-water). A residence time correction factor can also be applied. A droplet is carried over if the vertical distance traveled during its residence in the vessel is less than the vertical distance required to rejoin its bulk phase. This effectively applies to horizontal vessels. Exit Device/Secondary Gas-Liquid Separation (step 4) The secondary separation calculations for the gas phase are defined by a userdefined critical droplet size. The gas loading factor for each device is used to calculate the size of the exit device. Real Separator 3.3 ProSeparator Correlations ProSeparator correlations are based on several SPE papers (see reference section) and proprietary research from the oil& gas industry. Maximum droplet size is determined with ProSeparator using empirical correlations. Accurate physical properties of the fluids (particularly surface tension) are very important to this calculation. The ProSeparator correlations are rigorous but are limited to calculating liquid carry over into gas. There are no calculations of liquid-liquid separation or gas entrainment in the liquid phases (they are set to zero). Light liquid and heavy liquid entrainments are calculated separately and the total carry over is the sum of the separate light and heavy liquid carry over calculations. Inlet Calculations (step 1) Minimum and maximum droplet diameter are calculated based on inlet flow conditions (inlet gas flow rate and gas/liquid phase physical properties such as density and surface tension) and inlet pipe size. The droplet distribution of light and heavy liquids in the inlet gas are then calculated using a Rossin-Rammler type distribution. Please note that ProSeparator effectively calculates its own Rossin-Rammler parameters (droplet diameters), fitting them to match the predetermined minimum and maximum droplet sizes and does not require the user to specify any of these parameters. The only user input in the inlet calculations is the ability to limit the amount of phase dispersion calculated. Primary Separation–Gas-Liquid Separation (step 2) Critical droplet size is determined from the terminal velocity of the droplets as calculated from the inlet gas velocity, vessel dimensions, and fluid properties (liquid & gas density, gas viscosity). Primary separation is based on critical droplet size; however, the critical droplet size is not user-specified but calculated based on the gas velocity through the vessel. Exit Device/Secondary Gas-Liquid Separation (step 4) Secondary separations accomplished using exit devices (e.g., demisting pad) are calculated by device specific correlations. The user can choose from vane pack or mesh pad devices. There are two different calculation methods available for each type of device. 9 Real Separator 3.4 Rossin-Rammler Parameters/Distributions 3.4.1 Particle Size Analysis In order to properly analyse the particle size distribution in a system, the engineer must characterize these particles by collecting particle size measurements. Where such data is not available the engineer can resort to known typical values for the system in question. As a last resort the default values provided in HYSYS can be used but great care should then be taken in interpreting the results. Aspentech’s Process Manuals provide a great overview on particle analysis; more information and further references can be found there. The complete topic of particle size analysis has been discussed by Allen (1981), and this work is an excellent starting point to explore the subject in greater depth than can be provided in this overview. A recent summary of the range of most modern techniques available for the characterisation of particles in liquids has been given by Svarovsky (1990). 3.4.2 Particle Size Distributions Particle size distributions (PSD) can be expressed as discrete statistics (e.g. histograms) or as continuous mathematical functions: Gaussian (classic bellcurve) and Rossin-Rammler distributions are just 2 examples of the latter. These mathematical functions usually have 2 paramaters: 1 related to “central tendency” (e.g. mean , median , or mode) and 1 related to the amount of “spread” (e.g. standard deviation). For more information on particle size distributions and distribution functions please refer to the Process Manuals Mini Manual 1 (Gas & Particle Properties). 10 It must be emphasized that the use of continuous size distribution functions to represent experimental data is almost always a compromise, since measured data rarely fit the models exactly. However, distribution functions have the advantage that they enable the comparison of a large amount of data using a few basic parameters. An important feature is the ability to represent the size distribution in cumulative form as a straight line by means of a scaling that is constructed so as to linearise the cumulative size distribution function. Real Separator Rossin-Rammler distributions are defined by: F = exp(-d/dm)x) (1) Where: F = fraction of droplets larger than d dm is related to d95 x = RR index d95 = 95% of droplets are smaller than this diameter for the specified dispersion RR Index = exponent used in the RR equation (also known as the “spread parameter”) * mode = is the commonly occurring diameter (peak of the histogram / frequency curve), as compared to other different measures of central tendency such as mean or median diameters. ** spread is a measure of degree of deviation from the central tendency; its value is characteristic of the substance / system being considered Another way of expressing this is: ln(F) = (-d/dm)x or ln (ln(1/F)) = B + x ln(d) (2) Where: B = constant = ln (1/dm) Therefore plotting ln(ln(1/F) against ln(d) can be used to calculate the R-R parameters. Should such a plot not yield a straight line, it would follow that the particle distribution cannot be adequately described by the Rossin-Rammler function. For more information on particle size analysis and particle size distributions please refer to the Aspentech Process Manuals. 3.4.3 Modified Rossin-Rammler Distributions used in HYSYS Real Separator HYSYS Real Separator correlations ask the user for d95 data rather than dm. d95 represents the diameter for which 95% of droplets are smaller than this diameter. Note: if required dm can be relatively simply calculated from d95 as follows: dm = d95 / (-ln(1 - 0.95))^(1/x) (3) 11 Real Separator 4 Pressure Drop Calculations The Horizontal Vessel correlations also include pressure drop methods based on momentum loss. If a Correlation Based carry over model is selected, these methods can be selected on the DP/Nozzles Setup page for the calculation of inlet and exit nozzle pressure drop. If no method is selected then the userspecified pressure drops (Design!Parameters page) are used instead. 12 Real Separator 5 Tutorial Examples 13 14 Process Overview Real Separator Real Separator Workshop Process Description In this workshop, a 3-phase Separator is used to separate an oil/water/gas mixture. Entrained liquids in the gas product have been identified as a potential process issue. The HYSYS Real Separator will be used to account for liquid entrainment in the model. Carryover of liquids can be troublesome, especially if the gas is then passed through a turbine/compressor where liquid droplets can cause major damage to the internals of the machine. We will determine if a demisting pad is appropriate to prevent carryover and how to size it appropriately. Build an Ideal Separator 1. Open the SS Real Separator.hsc case. 2. Create a stream called Water, and specify its temperature and pressure to be the same as To LP Sep Clone with a flowrate of 4000 kg/h. 3. Add a Mixer and provide the following information: In this cell… Connections Name Inlets Outlet Parameters Automatic Pressure Assignment Enter… MIX-100 To LP Sep Clone Water Feed Set Outlet to Lowest Inlet 4. Add a 3-phase Separator and specify it with the following information: In this cell… Connections Name Inlets Vapour Light Liquid Heavy Liquid Enter… V-101 Feed Vapour LLiquid HLiquid 15 Real Separator 5. Open the separator unit operation and select the Worksheet tab. What is the vapour fraction and molar flow of the product stream? Vapour ______________________ Light Liquid ______________________ Heavy Liquid ______________________ Add Carryover Effects Let us say that we know (from a plant mass balance or as a design assumption) that approximately 800 kg/h of liquid is entrained in the vapour stream. How do we specify this in our model and ensure an accurate mass balance? 1. Select the Rating tab. Click on the C.Over Setup page to bring up the carryover models, and choose Product Basis as the active model. 2. Enter the entrainment data. Select Specification By: Flow and choose Basis = Mass. Enter 800 kg/h for Light liquid in gas. 3. Examine the product streams and the C.Over Results page and compare to the ideal separation case. What is the vapour fraction of the vapour product stream? ______________ What is the rate of liquid carryover (kgmole/h)? ________________________ 16 Real Separator Using the Carryover Correlations The Setup and Results views will be different depending on which correlation is used. Refer to page 6 for a detailed description of each correlation and its required parameters. As an alternative to specifying the carryover, we can use correlations to predict the carryover: 1. Return to the C.Over Setup page and change the model selection to Correlation Based. For steps 2 – 4 select the appropriate radio button. 2. Correlation Setup (radio button): a) Select Overall Correlation and choose the “ProSeparator” correlation. b) Click the View Correlation button to enter inlet and separation parameters. In this case, the Inlet setup page can be left as is. The ProSeparator correlations will calculate the inlet dispersion without the need for further information. Since we do not have an exit device, we need to set this for the ProSeparator correlation: select the Vap. Exit Device page; select Mesh Pad; enter thickness = 0.0. Close the View Correlation window. 3. Dimensions Setup (radio button): Enter the vessel dimensions as length 8.0 m, diameter 3.0 m, light liquid level 1.5 m. Vessel dimensions can also be entered on the Sizing page of the Rating tab. Data on these two pages is linked. 4. DP / Nozzle Setup (radio button): Enter the following values for nozzle location (this is the horizontal or radial distance from the feed location): Feed 0.0 m, Vapour 6.0 m. Keep the default values for nozzle diameter and height. 17 Real Separator 18 Real Separator Analyze the Results There are several pages where useful results are displayed: a) Open the Worksheet tab. What is the vapour fraction in the Vapour stream? ___________ b) Open the Rating tab and select the C.Over Results page. To view the carryover details, click the View Dispersion Results button. You should see results similar to this: We need to eliminate all droplets larger than 50 microns (0.05 mm). Do we need an exit device to do secondary separation? _____ Open the Rating tab and select the C.Over Setup page. Click the View Correlation button and open the Results tab. Adding a Secondary Separation Device 1. Open the Rating tab and select the C.Over Setup page. 2. Click the View Correlation button and open the Setup tab. 3. Select the Vap. Exit Device page; select Mesh Pad and enter a thickness of 150.0 mm. What effect does this have on the carryover? __________________ 19 Real Separator Exercise 1 It is expected that the inlet hydrocarbon flow to the separator may vary by up to 25%. Anticipating that the separator may not be able to handle this increased flow, the engineer decides to model the new conditions in the separator and design a demister pad to remove the larger droplets. 1. Increase the flowrate of the To LP Sep Clone stream by 25%. 2. Select the C.Over Results page, then click the View Dispersion Results button. What is the Total Carryover with no mesh? With 150mm of mesh? _______________________________________________________ What is the removal efficiency of 50 micron droplets? _______________________________________________________ Based on this predicted dispersion, the engineer decides to install a thicker mesh pad. How would you suggest the engineer use HYSYS to determine the correct thickness? Perform the analysis yourself; how thick should the mesh pad be? _______________________________________________________ Now what is the vapour fraction of the Vapour product stream? ________________________________________________________ 20 Real Separator Exercise 2 Connect the real separator into the two-stage compression loop to replace the ideal separator that is currently in use. Keep the Water feed stream connected. Is the real separator still capable of stopping 50 micron drops reaching the compressor suction? Carryover in Dynamic Models Please open sample case “Dynamic Real Separator.hsc”. This case is based on the one you have been working on, but dynamic specifications, controllers and strip charts have been added as needed. Specifically, the following changes were made to the model: 1. Valves were added to all boundary streams (e.g. Feed0 and VLV-100 were connected to the Feed stream). 2. Pressure-flow specifications were set on all boundary streams (you will find these specifications on the Dynamics tab of each boundary stream, e.g. Feed0 has a pressure specification of 30.05 kPa). 3. Dynamic specifications were set on the separator: All dynamic specifications used in this example or the separator were already entered on the Rating tab. a. Sizing & carry over data were left the same. b. Heat loss left at none c. Level taps and PV Work term options were not used 4. Strip charts were created for 2 sets of variables (open the databook tabs titled Variables to see the list of variables and Stripcharts to view the strip chart configurations): The Vessel Conditions strip chart tracks vessel pressure, temperature, and liquid level. The Carry Over strip chart monitors liquid phase flow out of the vapour nozzle, as well as inlet flow rate to the vessel. 5. Finally controllers were added to the alternate sample case called Controlled Dynamic Real Separator.hsc. 21 Real Separator Demonstration 1. 2. 3. 4. Open Dynamic Real Separator.hsc. Click on the strip charts to bring them to the foreground. Click the Dynamic Mode button. Start the Integrator. When the liquid carryover flow achieves a steady value, stop the integrator. 5. Change the position of VLV-100 to 25% open. Re-start the integrator. When the liquid carryover flow achieves a steady value stop the integrator. 6. Change the position of VLV-100 to 75% open. Re-start the integrator. When the liquid carryover flow achieves a steady value stop the integrator. Is the mesh pad thick enough to account for all process conditions? _________________________________________________________________ A thick pad creates more pressure drop; are there other mitigations to consider?________________________________________________________ 7. Open Controlled Dynamic Real Separator.hsc; repeat the same exercise. What effect does controlling the liquid level have? ________________________________________________________________ 6 Reference Horizontal Vessel: GPSA, Vol 1, 10th Ed., January 1990. Separation Mechanism of Liquid-Liquid Dispersions in a deep-layer Gravity Settler, E. Barnea and J Mizrahi, Trans. Instn. Chem. Engrs, 1975, Vol 53. Droplet size spectra generated in turbulent pipe flow of dilute liquid-liquid dispersions, A J Karabelas, AIChE, 1978, vol. 24, No. 2, pages 170-181. ProSeparator Model: Society of Petroleum Engineers papers: SPE36647 – Separator Design and Operation: Tools for Transferring "Best Practise" SPE21506 – Proseparator – a novel separator/scrubber design program 22 Real Separator Rossin-Rammler Distributions: Aspen Process Manuals – Mini Manual 1: Gas & Particle Properties; Part 8 – Particle Size General References: Aspen Process Manuals – Gas Cleaning Manual: Vol 1 – Introduction Vol 2 – Demisting Vol 10 – Applied Technology 23