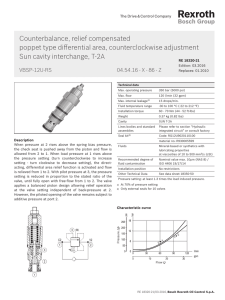

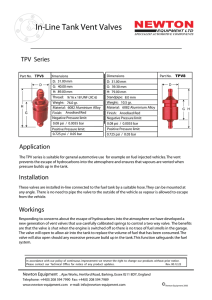

Model 7000 Model 7200 Pressure Relief Valves For Fire Sprinkler Systems ½" ¾" The AGF Manufacturing Inc. Models 7000 and 7200 are UL Listed/FM Approved pressure relief valves designed specifically for fire sprinkler systems. Both models relieve excess system pressure caused by surges or temperature changes. The Models 7000 and 7200 comply with the requirements of NFPA-13 that stipulate a pressure relief valve be installed on all gridded systems and downstream of all pressure reducing valves. The Model 7000 has a ½" MIPT inlet and FIPT outlet and is included with our Models 1011A, 1011T, 2511A, and 2511T TESTanDRAIN® valves, Models 3011A and 3011ASG Inspector’sTEST® valves, and 1¼" – 6" Model 8011 RiserPACK®s. The Model 7200 has a ¾" MIPT inlet and FIPT outlet and is included with our 1" Model 8011 Residential RiserPACK®. Features include: •U L Listed and FM Approved. •B ronze body with stainless steel spring. • Integral flushing handle to remove debris causing leaks through valve seat and disc. •F actory rated at 175 PSI.* •1 65 PSI, 185 PSI, 195 PSI, 205 PSI, 225 PSI, and 250 PSI ratings are also available for the Model 7000.* Model 7000 Model 7200 * Note: It is important to note that the pressure rating of the relief valve indicates an operating range of pressure for both opening and closing of the valve. Standard relief valves are required to OPEN in a range of pressure between 90% and 105% of their rating. The valves are required to CLOSE at a pressure above 80% of that rating. The relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet. Dimensions C A B Model SIZE A B C 7000 ½" 13⁄4" (44 mm) (25 mm) 1" 35⁄16" (83 mm) 7200 ¾" 13⁄4" (44 mm) (25 mm) 1" 35⁄16" (83 mm) USA Patent and Other Patents Pending AGF Manufacturing Inc. 100 Quaker Lane, Malvern, PA 19355 Phone: 610-240-4900 Fax: 610-240-4906 www.testandrain.com Job Name:__________________________________ Architect:____________________________________ Engineer:____________________________________ Contractor:__________________________________ Reliability, Versatility, Code Compatibility TESTANDRAIN, INSPECTORSTEST, and RISERPACK are registered trademarks of AGF Manufacturing Inc. CS7000 3/08 The Model 7000 Pressure Relief Valve is available with the following ratings: 165 PSI 175 PSI 185 PSI 195 PSI 205 PSI 225 PSI 250 PSI The Model 7000 Pressure Relief Valve is also used on the following AGF products: M1011A TESTanDRAIN® M2511A TESTanDRAIN® M1011T TESTanDRAIN® M2511T TESTanDRAIN® M3011A Inspector’sTEST® M3011ASG Inspector’sTEST® 1¼" – 6" M8011 Commercial & Residential RiserPACK® The Model 7200 Pressure Relief Valve is also used on the following AGF product: 1" M8011 Residential RiserPACK® 2/23/2017 VQDI.EX4533 ­ Valves, System Pressure Relief VQDI.EX4533 Valves, System Pressure Relief Page Bottom Valves, System Pressure Relief See General Information for Valves, System Pressure Relief AGF MANUFACTURING INC EX4533 100 QUAKER LN MALVERN, PA 19355­2479 USA Model 7000 pressure relief valve, 1/2 in. inlet pipe size, for a set pressure rating of 175 psig. With a relief set point of 175 psig and an inlet pressure of 175 psig, the nominal flow rate is 0.11 gpm. Model 7200 pressure relief valve, 3/4 in. inlet pipe size, for a set pressure rating of 175 psig with a maximum pressure rating of 175 psig. Last Updated on 2007­08­16 Questions? Print this page Terms of Use Page Top © 2017 UL LLC The appearance of a company's name or product in this database does not in itself assure that products so identified have been manufactured under UL's Follow­Up Service. Only those products bearing the UL Mark should be considered to be Certified and covered under UL's Follow­Up Service. Always look for the Mark on the product. UL permits the reproduction of the material contained in the Online Certification Directory subject to the following conditions: 1. The Guide Information, Assemblies, Constructions, Designs, Systems, and/or Certifications (files) must be presented in their entirety and in a non­ misleading manner, without any manipulation of the data (or drawings). 2. The statement "Reprinted from the Online Certifications Directory with permission from UL" must appear adjacent to the extracted material. In addition, the reprinted material must include a copyright notice in the following format: "© 2017 UL LLC". http://database.ul.com/cgi­bin/XYV/template/LISEXT/1FRAME/showpage.html?name=VQDI.EX4533&ccnshorttitle=Valves,+System+Pressure+Relief&objid=1… 1/1