Compendium of ADC

Compendium

of

Advanced Drilling Course

1

Compendium of ADC

Content

1. Well Control

1.1.

1.2.

1.3.

1.4.

1.5.

1.6.

Introduction

Well control equipment

Preparing for Killing

Five safety margins

Killing by means of the Driller’s Method

Gas solubility and its operational effects

2. Casing Design

2.1. Casing Characteristics

2.2. Typical Design of three common Casing Strings

2.2.1. Surface Casing

2.2.2. Intermediate Casing

2.2.3. Production Casing

3. Drillstring Mechanics

3.1. Drillstring Specification

3.2. Stresses in the Drillstring (Drag and Torque)

3.3. Stuck pipe

4. Directional Drilling

4.1. Planning the well

4.3. Directional drilling and necessary equipment

4.2. Estimating the trajectory

4.2.1. Survey Tool

4.2.2. Straight Trajectory

4.2.3. Curved Trajectory

5. Wellbore Stresses

5.1. Surveillance of drilling operations

5.1.1. Surface collected data

5.1.2. Downhole data collection-MWD

5.2. Wellbore instability

5.2.1. Rock mechanics

5.2.2. The Mohr circle and its shear failure envelope

5.2.3. Tensile failure

5.2.4. Summary of all failure types

5.3. LC and countermeasures

5.3.1. Main reason behind LC; narrow pressure window

5.3.2. Three countermeasures to LC

6. Modelling of Drilling Fluid Temperature

6.1. Temperature issues

6.2. Conduction

6.3. Convection

6.4. Composite overall heat transfer

6.5. Effect of high temperature

2

Compendium of ADC

7. Completion Methods

7.1. Completion. Fluids

7.2. Well completion

7.2.1. Completion Goal

7.2.1. Completion Operations

7.2.3. Completion Types

7.2.4. Completion Components

7.2.5. Pressure Expansion of Tubing

7.2.6. Well Barriers

7.3. Fracture stimulation

7.4. Acid fracturing and stimulation

7.4. Work over operations

8. Three Downhole problems

8.1. Chemical stability of the wellbore wall

8.1.1. Transport of material through shale

8.1.2. Swelling mechanisms

8.1.3. Inhibitive muds

8.2. Offshore related challenges

8.2.1. SWF

8.2.2. SG

8.2.3. Gas hydrates

8.3. Gas migration through cement

8.3.1. Hydration of cement slurry

8.3.2. Laboratory testing of cement

8.3.3. The GM problem

8.3.4. GM routes

8.3.5. Solution to GM (from SI to OFU)

References

Symbols

3

Compendium of ADC

1. Well Control

1.1. Introduction

Figure 1-1 shows, in general, how to maintain safety against drilling into threatening high pore pressure

zones.

Drilling

operation

Detect high

pressure

Yes

Adjust

mud

weight

no

Kill well

No

Detect kick.

Close well

Find

alternative

ways to handle

this situation

yes

Casing

pressure >

MAASP

Figure 1-1: General procedure to maintain safety during drilling.

There exist a number of different killing methods, while the two main methods are Driller’s and

Engineer’s Method. The Engineer’s Method is also called Wait & Weight Method, abbreviated to

W&W, but the most common method of restoring an overbalanced situation after a kick has occurred is

the Driller’s Method, which is, for ADC, the selected killing method for demonstrating the principles of

killing a well.

Gas is a much more difficult kick fluid to handle than liquids, and from here on, we only discuss gas

kicks. A small volume of gas at the bottom of a well is potentially dangerous because it expands while

approaching the lower hydrostatic pressure on its way to surface. At lower pressure, it will expand

and displace a corresponding amount of mud from the well, thus reducing the bottomhole pressure,

which in turn allows more gas to flow in from the pores. As a pedagogic simplification, the gas law is

assigned with constant temperature and compressibility, yielding:

pV = constant

(1.1)

In more advanced killing methods reality gas behavior is applied. And small influxes of gas are not

likely to be detected with standard kick-detection methods, but as gas expands on its way up the

annulus, it will most likely be noticed in the pits.

Another problem with gas kicks is that gas leads to a decrease of mud rheology, especially in OBM,

and barite may slip out of solution and thus reducing the mud weight locally. Barite must be delivered

from the supply base in adequate amounts to sufficiently increase the mud weight of the total active

4

Compendium of ADC

mud volume. A typical active mud volume for offshore operations amounts to 200 m3 in surface tanks,

and additional 200 – 400 m3 inside the well.

1.2. Well control equipment and closing procedure

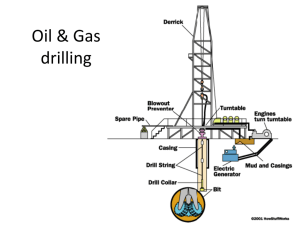

Blowout preventers and accessory equipment give the driller the capability to:

1.

2.

3.

5.

Close the borehole when high-pressure formation fluids enter it. For onshore drilling the

closing takes place just below the drill floor, for offshore drilling (from a floater) the

closing takes place at the sea floor

Control the release of high-pressure pore fluids and pump weighted mud under high pressure

into the well to restore balanced pressure situations (killing the well)

Move the drill string through a closed BOP while the well is closed and under pressure

(stripping)

Disconnect, cut off and leave the drill string inside the closed well if necessary (last resort)

Figure 1-2 gives an overview of the blowout preventer (BOP) and associated equipment on a floating

drilling rig, together with the mud circulating system.

For offshore drilling at shallow or moderate depths, the drill string and drilling components are guided

to the wellbore location along guidelines extending from a guide frame, previously placed on the ocean

floor. The blowout preventer stack is attached to the guide frame and the 20” casing.

choke manifold

ppump

flare

Degasser

pcsg

pdp

xx x

mud

pits

marine riser

Guide lines

Tool joint

BOP

Pipe ram on which drill

string is hanged off

Guide frame

Degasser

Flare

pcsg

pdp

Maring riser

Guide frame

Guide lines

Separate out gas from returning mud

Burns returning gas

Casing pressure = choke pressure = annular pressure

Drill pipe pressure = stand pipe pressure (SPP)

A connection between well head and the surface on floating rigs

A 300 ton heavy anchor for the wellhead

4 guide lines are fixed to the 4 corners of the guide frame

on which guide tools are run to guide equipment into the wellbore

Influx

Figure 1-2: Kick control on offshore rigs. Surface mud lines in red.

5

Compendium of ADC

Figure 1-3 gives an overview of well control equipment (well closing equipment).

Drill string BOP equipment:

Annular BOP equipment:

Choke manifold

Main choke

Mud pump (the piston)

xx x

back to mud pit

Kill line / Choke line

Upper kelly cock

Lower kelly cock

Inside BOP

Stored on drill floor. Flapper valve.

Installed on demand

Faile safe valve

BOP:

Annular

Reinforced rubber elements. Can close around TJ

Pipe ram

Inside BOP

Flapper valve, just above rock bit

Blind/shear ram

Figure 1-3: Well control equipment applied to close the drill string (left box) and annulus (right box).

Standard procedure for closing the well on floating rigs during drilling is (refer to Figure 1-3):

0. A kick alarm is initiated

1. Hoist up drill string at least 4 m. This will hinder fill (of cuttings and weighting material) to

block bit nozzles during killing

2. Stop pump, check for flow. Is it a real kick or a false alarm?

3. First priority-closing elements:

a. Close upper annulus first (allowing to close around TJ. Do not need to know TJ’s

position at this initial stage)

b. Close drill string if not already closed (e.g. by the piston in the mud pump)

c. Open inner and outer fail-safe valve (if not already open, in accordance with

alternative procedure) and slowly close main choke in choke manifold

d. Observe MAASP (avoid fracturing the formation during closing the BOP)

4. Close remaining valves in BOP and hang off drill string by letting a tool joint rest on the

closed ram preventer

a. Check position of the TJ closest to the closing pipe-preventer

b. Adjust position of TJ by hoisting drill string up

c. Close pipe ram preventer

d. Lower drill string carefully and hang it off and let its TJ rest on the closed pipepreventer

5. Read kick volume, shut-in drill pipe pressures (SIDPP) and of casing (SICP)

6

Compendium of ADC

1.3. Preparing for killing

We need to consider a few points before circulating out the kick volume.

Stabilized pressure just after shut-in

It is sometimes easier to view the circulating system as a U-tube like in Figure 1-4. The important point

is that the two "tubes", the drill string and the annulus, are connected at the bottom, and here the pressure

is identical. Figure 1-5 shows how the pore pressure affects the pressure in a shut-in, static well (after

pressure has stabilized, which typically takes a few minutes).

Choke valve

Drill string

Choke line

Choke line

Annulus

Drill string

BOP

Well in normal view

Well as U-tube

Figure 1-4: Well in two different views.

SIDPP

SICP

Kill mud

Mud pressure inside

annulus (or casing)

Shut in pressure

inside drill string

Shut in pressure

inside annulus

Historic pore pressure

along the well

Mud pressure

before shut-in

Depth

Gas-kick

entered annulus

Depth of

interest

Pressure

Figure 1-5: Pressure before (left) and after shut-in.

7

Compendium of ADC

Gas percolation in a closed well

After closing the well, gas will rise due to buoyancy, but the volume remains constant in accordance

with eqn. 1.1 since the gas is not allowed to expand in a closed well. Therefore, also the pressure of the

gas bubble will remain constant. If the gas kick arrives at the surface (without fracturing the formation

or the equipment), the pore pressure has been “transported” along with the gas bubble to the surface as

shown in Figure 1-6.

SIDPP

SICP

Mu d

Gas percolating

up the annulus

without being

allowed to

expand since the

well is closed

pres

sure

Gas kick in

four different

stages during

percolation

in a

nnu

lus

befo

h

re s

ut in

Pore

Depth

pres

sure

Pressure

Figure 1-6: Pressure development as gas percolates to the surface in a closed well (assuming the formation will

withstand the high pressure).

1.4. Five Safety margins

We present five safety factors related to pressure control in a drilling well.

MAASP: Figure 1-7 demonstrates the importance of the expression called MAASP (maximum

allowable annular surface pressure). If the surface pressure rises above MAASP, the formation below

the casing shoe will fracture.

8

Compendium of ADC

SICP

MAASP

c

Fra

e

tur

pre

re

pres

ssu

Mu d

sure

Mud pressure

during LOT (r1)

in a

nnu

lus

befo

Fracture pressure (rfrac)

h

re s

Casing shoe

ut in

(r 2)

Histo

ric

Depth

pore

p

ressu

re

Pressure

Figure 1-7: MAASP.

MAASP can be estimated through eqn. 1.2.

𝑀𝐴𝐴𝑆𝑃 = (𝜌𝑓𝑟𝑎𝑐 − 𝜌2 ) ⋅ ℎ𝑐𝑠𝑔.𝑠ℎ𝑜𝑒 ⋅ 𝑔 = 𝑃𝐿𝑂 − (𝜌2 − 𝜌1 ) ⋅ ℎ𝑐𝑠𝑔.𝑠ℎ𝑜𝑒 ⋅ 𝑔

(1.2)

Here rfrac is the equivalent density that balances the fracture pressure

r1 has been applied earlier during LOT

rfrac is applied (now) while drilling into higher pore pressure

Trip Margin: A safety margin has to be added; typically 0.05 kg/l. It should at least be sufficient to

avoid swabbing during the subsequent tripping operations. An empirical formula sometimes seen is:

𝑃𝑎

Trip margin= 0.01 ⋅ 𝜏𝑦 ⁄{(𝑑𝑏𝑖𝑡 − 𝑑𝑑𝑟𝑖𝑙𝑙 𝑐𝑜𝑙𝑙𝑎𝑟 ) ⋅ 𝑔} = ( 0.01⋅20

= 40 𝑘𝑔/𝑙)

0.05⋅9.81

(1.3)

Kick margin: To protect against fracture an additional margin of typically 0.05 kg/l is subtracted from

the fracture gradient.

Riser margin: A special type of safety margin (SM) for offshore operations is the Riser Margin. When

the location has to be abandoned for some reason, the riser is disconnected at the upper connector in the

BOP, and mud in the riser is automatically replaced by sea water and an air gap.

Kick tolerance: Kick Tolerance is the maximum kick volume, Vinflux, which can be taken into the

wellbore and circulated out without fracturing the formation at the weakest point.

The involved parameters are shown in Figure 1-8. Here the gas kick is shown at time of shut-in as

Vinflux and later, during killing, when it reaches its critical position; the casing shoe, Vcs.

Vinflux = Kick tolerance

(1.4)

9

Compendium of ADC

We need to back calculate it from pfrac to Vinflux:

𝜌𝑓𝑟𝑎𝑐 + 𝑔𝑔𝑎𝑠 ∙ 𝑔 𝐻 + 𝜌1 𝑔 (hwell – hcs – H) = ppore

(1.5)

Knowing the capacity of the well and the ppore we find:

ppore Vinflux = pfrac Vcs

H = Vcs / Capcs

(1.6)

(1.7)

rmud

rcs

pfrac

Casing shoe

H

hcs

Depth

Vinflux

Pressure

hwell

ppore

Figure 1-8: Parameters involved in estimating kick tolerance

In terms of SIDPP the kick tolerance becomes:

SIDPPmax = (rCS – r1) ⋅hCS⋅g

(1.8)

It is also useful to translate it into mud weight, rkick tolerance. It is the maximum mud density that the

weakest part of the borehole can withstand in the event that a kick is taken. It increases with drilled

depth:

𝜌𝑘𝑖𝑐𝑘 𝑡𝑜𝑙𝑒𝑟𝑎𝑛𝑐𝑒 = 𝜌1 +

ℎ𝐶𝑆

ℎ𝑤𝑒𝑙𝑙

(𝜌𝑓𝑟𝑎𝑐 − 𝜌1 )

(1.9)

In casing string design one of the Load Cases applies Kick Tolerance.

10

Compendium of ADC

1.5. Killing by means of Driller’s Method

In the Driller's Method the pore fluid is displaced before kill mud is injected. This row of action

simplifies the operation. However, it requires more time for the entire operation than with the Engineer’s

method.

Annular pressure becomes higher when applying the Driller's Method, compared to applying the

W&W method, and the choke nozzles erode quicker. If there is a risk of fracturing the well at its

weakest point; below the casing shoe, the W & W-method must be chosen. W & W is used in long

openhole sections to reduce the pressure in the annulus; otherwise the Driller's Method is preferred.

In situations when the casing shoe is set deep, the gas bubble will be inside the casing before the kill

mud reaches the bit, and W&W will give no advantages. The Driller's Method is simple, and the total

time it takes is practically the same as for W & W. It is important to get started fast to avoid the pressure

increase due to gas percolation (see next page).

Killing of a well that has to be shut-in because of a kick follows three principles:

1. Bottom pressure must balance the pore pressure plus a small overbalance.

2. Bottom pressure is controlled through the drill string, which is filled with a mud of known

density.

3. After pump is turned on and running with a constant, predetermined rate, bottom pressure is

regulated with a back-pressure valve at the surface.

Six phases of the Driller’s method

Killing by means of the Driller's procedure can best be understood by dividing the operation into six

separate phases. Figure 1-9 presents the complete procedure exemplified through the following kick

situation:

Mud in use:

Depth of well (TVD):

Previously recorded circulation pressure:

Slow Circulation Rate:

Pump capacity:

SIDPP:

SICP:

Kick volume:

Annular capacity around BHA:

Drill string internal capacity:

rmud

= 1 100 kg/m3

D

= 2 000 m

pc1

= 28 bar (SCP)

SCR = 30 SPM

q

= 20 l/stroke

pSIDP = 18 bar

pSIC

= 22 bar

Vkick = 1 m3

CapBHA = 14 l/m

Capdp = 8 l/m

Bottomhole pressure must be kept constant, and pressure in annulus observed closely. 45 or 60 SPM are

common "slow circulation rates", while 30 or 40 SPM are normal on a floating rig, sometimes even 15

SPM is used when the gas is entering the choke line. Too quick expansion makes it difficult to keep

track of the change in pressure.

11

Compendium of ADC

Before any kick occurs, it is decided what circulation rate should be used to kill the well. The so-called

SCR is used to determine the friction in the system. We assume, especially for offshore operations, that

this pressure loss occurs in the choke line and the choke.

22

18

46

46

46

18

0

Casing pressure

Pump pressure

pressure

SIDPP + SCP

SCP2

SIDPP

A kick is detected

while drilling and

pump turned off

SICP

SIDPP

Hours or pump strokes

Figure 1-9: A gas kick in six stages handled by means of the Driller’s Method (without including the SM)

Phase 1: The kick has been shut in and we can use the obtained information to estimate the following

parameters: rkill and rkick.

After the close-in action is completed, the pumps seal the well at the drill string side (of the U-tube),

and at the other side by means of closed BOP and surface choke. Inside the drill string, the liquid

composition is assumed to be uncontaminated, so that the new formation pressure becomes:

12

Compendium of ADC

𝑝𝑝𝑜𝑟𝑒 = 𝑝𝑆𝐼𝐷𝑃 + 𝜌𝑚𝑢𝑑 ⋅ 𝑔 ⋅ ℎ𝑤𝑒𝑙𝑙 = 𝜌𝑘𝑖𝑙𝑙 ⋅ 𝑔 ⋅ ℎ𝑤𝑒𝑙𝑙

(1.10)

= 18 ⋅ 105 + 1 100 ⋅ 9.81 ⋅ 2 000 = 234 ⋅ 105 = 234 𝑏𝑎𝑟

𝜌𝑘𝑖𝑙𝑙 = 𝜌𝑚𝑢𝑑 +

𝑝𝑆𝐼𝐷𝑃

ℎ𝑤𝑒𝑙𝑙 ⋅𝑔

= 1 100 +

18⋅105

9.81⋅2 000

= 1 192 𝑘𝑔/𝑚3

It is always of importance to check what type of fluid that has entered the well. If only liquid (oil, water

or mud) has entered the well, the displacement procedure is simplified and will, by far, not be as critical

as for a gas kick. However, the killing procedure will still be the same.

Volume gained in the pit, Vkick, represents the quantity of the formation fluid entering the well bore. The

length of the annulus occupied by the unknown fluid, which is estimated in Eqn. 1.11, and the difference

between shut-in pressures; pSIC and pSIDP, determines its gradient. The height of the fluid is determined

from the volumetric capacity, Cam, at the bottom part of the well:

ℎ𝑘𝑖𝑐𝑘 =

𝑉𝑘𝑖𝑐𝑘

𝐶𝑎𝑛𝑛

(1.11)

Previous figure showed that the bottomhole pressure can be calculated from two fluid columns; the

annulus column and the drill string column.

𝑝𝑆𝐼𝐷𝑃 + 𝑔 ⋅ 𝜌𝑚𝑢𝑑 ⋅ ℎ𝑤𝑒𝑙𝑙 = 𝑝𝑆𝐼𝐶 + 𝜌𝑚𝑢𝑑 ⋅ 𝑔 ⋅ (ℎ𝑤𝑒𝑙𝑙 − ℎ𝑘𝑖𝑐𝑘 ) + 𝜌𝑘𝑖𝑐𝑘 ⋅ 𝑔 ⋅ ℎ𝑘𝑖𝑐𝑘

(1.12)

Assuming the capacity is constant, we can find hkick and then solving for rkick yields:

h kick = Vkick / Cap BHA = 1 000 l / 14 l/m = 71 m

𝜌𝑘𝑖𝑐𝑘 =

ℎ𝑘𝑖𝑐𝑘 ⋅𝑔⋅𝜌𝑚𝑢𝑑 −(𝑝𝑆𝐼𝐶 −𝑝𝑆𝐼𝐷𝑃 )

ℎ𝑘𝑖𝑐𝑘 ⋅𝑔

=

71 ⋅9.81 ⋅1100−(22−18)⋅105

9.81 ⋅71

= 526 𝑘𝑔/𝑚3

Phase 2: Start the pump. Pump start-up procedure is difficult; well pressure may easily go below the

pore pressure, causing new, small influxes: Open the choke slowly and increase the flow rate slowly and

steadily, i.e. over a period of 15 s, until pump has reached the reduced, predetermined pump speed.

Regulate the choke so that the initial circulation pressure (ICF) at the stand pipe (SPP) becomes:

𝐼𝐶𝑃 = 𝑆𝑃𝑃 = 𝑝𝑑𝑝 = 𝑝𝑆𝐼𝐷𝑃 + 𝑝𝐶1 (+ safety margin) = ICP

(1.13)

The slow circulating rate (SCR) while killing the well (usually one-half of normal pump rate or less)

induces very small pressure drops in the annulus. The slow circulation pressure (SCP or pC1) is mostly

lost in the drill pipe, drill collar and bit nozzles, and may be disregarded in the annulus. This neglection

results in an extra safety factor against the pore pressure, equal to the annulus pressure drop.

Phase 3 and 4: Circulation out the gas: In the other end of the circulation system, the choke pressure,

pchoke, should initially be equal to 𝜃 (+ safety margin) and thereafter slowly increasing due to gas

expansion, reaching a peak value just before gas surfaces, and then quickly dropping to a value equal to

pSIDP. Figure 4 presents a graph of the choke opening:

13

Compendium of ADC

Phase 5: Filling drill pipe with heavy mud: In the last moment of phase 5 the heavy mud has reached

the bit. The original pSIDP is now reduced to zero and the friction pressure, pC1, has increased to pc2, due

to the higher resistance of the heavier mud, which also is the Final Circulating Pressure:

𝑝𝐶2 =

𝜌𝑘𝑖𝑙𝑙

𝜌1

⋅ 𝑝𝐶1 = FCP

(1.14)

The reduction of pSIDP and the increase of pC1 is assumed to be a linear change (although it in reality is

not) and are completed when DP is filled with kill mud. We want to know how long it takes:

Volume of drill string:

Strokes to bit:

Time to bit:

2000 m * 8 l/m

16 000 l / 20 l/stroke

800 strokes / 30 strokes /min

= 16 000 l

= 800 strokes

= 27 min

When this pDP-schedule is held, the pressure exerted at the bottom of the well will never be less than

ppore + SM + annular pressure loss, and no further influx of formation fluid will take place. Observe that

the casing pressure during phase 5 is constant.

Phase 6: Filling the annulus with heavy mud:

The DP has now been filled with a mud of known weight, and if the pump speed is held constant, the

pressure loss (pC2) will not be altered from this point on. If pDP (stand pipe pressure or pump pressure)

is kept equal to pC2 + SM by means of the choke, the pressure will now be under control, both in the

drill pipe and the annulus.

Offshore killing operations take typically one day.

Engineer’s Method

The Engineer’s Method is always the first optional method. An extra safety factor is added through this

method because the annular pressure will become lower compared to the Driller's Method. In the

Engineer's Method kill mud circulation is initiated as soon as possible, reducing the drill pipe or pump

pressure as soon as heavy mud enters the annulus, as illustrated in Figure 1-10.

px

Gas (h2)

Casing shoe

Depth

Original mud (h4)

Kill mud

Pressure

Figure 1-10: Comparing critical annular pressure for Driller’s and Engineer’s Method.

14

Compendium of ADC

The procedure is much quicker, and the annular pressure will be lower, but all the control functions are

similar to those in the Driller's Method.

The complete killing procedure is always administered through a kill sheet. Figure 1-11 presents a

typical example of a kill sheet. Through a kill sheet the user obtains a complete overview of pressure at

any time. Most of the necessary data are known ahead of time and entered the sheet. The slow circulation

pressure, pc1, changes whenever any of the contributing parameters change, and must be recorded at

least once a day.

The Engineer's Method differs from the Driller's method by the simple fact that the mud weight is being

increased and pumped into the well immediately, instead of first just circulating out the kick fluid.

(SCP 1)

SI

ORIGINAL MUD WEIGHT:

WELL

DEPTH

SCP

KILL SHEET

Well

MD

(SCP )

2

UP CHOKE

LINE

CHOKEL.

FRICTION

SPM

BookBoone

TVD

UP RISER

PUMP

NO 1

: .............................................

SPM

SPM

Comment : .............................................

SPM

PUMP

NO 2

CASING DEPTH

LEAK OFF TEST EQ

SHUT IN DRILLPIPE PRESSURE

(SIDPP)

MAASP

INITIAL DRILLPIPE CIRC. PRESSURE

SHUT IN CASING PRESSURE

ICP = SCP + SIDPP = ........................+.........................

(SICP)

PUMP

OUTPUT

KILL MUD WEIGHT

PIT VOLUME INCREASE

PUMP 1

r

kill =

PUMP 2

r m + SIDPP

9,81 * TVD

FINAL DRILLPIPE CIRC. PRESSURE

FCP = SCP *

CAPACITY

RKB

.......

LENGTH

DP

DC

VOLUME

X

=

X

=

SPM

SPM

r kill

rm

DRILLPIPEPRESSURE

STROKES

TOTAL DRILLSTRING VOL.

STANPIPE

PRESSURE

0

CAPACITY

........

..................

LENGTH

DC/OH

VOLUME

=

X

DC/OH

X

=

DP/CSG

X

=

CHOKELINE

X

=

TOTAL ANNULAR VOL.

.................

VOLUME

SURFACE TO BIT

PUMP OUTPOUT

/

-

BIT TO SHOE

/

-

SHOE TO SURFACE

/

-

TOTAL STROKES

STROKES

STROKES

-

Figure 1-11: An example of a simple Kill sheet. Dark green boxes indicate information known before a kick.

They must be updated at least every shift (every 12 hours). Light red boxes represent information known after

shut-in.

1.6. Gas solubility and its effect on the operation

Solubility in general

Substances dissolved in a solvent are called solutes, which can be solids, liquids or gases. If two liquids

are soluble, they are said to be miscible. Water is a good solvent due to its polar orientation. Ionic

compounds are highly soluble in water; the attractive forces between oppositely charged ions are causing

15

Compendium of ADC

individual ions to separate from its lattice. After dissolution, each dissolved ion becomes surrounded by a

shell of water molecules. The ions are said to be wetted or hydrated. Figure 1-12 shows hydration of

dissolved sodium chloride ions in water.

-

+

-

-

-

-

+

+

+

+

-

+

Na+

+

-

- -

- +

-

-

-

Cl

+

+

+

=

+

+

+

+ +

- +

- -

O

D+

-

D+

H

D-

Strong attraction. Several

layers of water molecules

+

H

Weak attraction. No permanent

structure of water molecules

+

Water molecules are weak dipoles

Figure 1-12: Hydration of sodium chloride in water. In still-standing water many layers of water molecules will

form around the ions.

Ionic compounds are not soluble in non-polar liquids, such as oil. The internal attraction between

multivalent ions (number of valences > 1) like CaCl2 and CaCO3 are much stronger than between univalent

ions. Covalent compounds are soluble or miscible if they are polar. Examples of soluble covalent

compounds include sugar, alcohol and starch.

Gas solubility in brine / gas solubility in pure water

Polar water molecules attached to dissolved salt ions reduce the number of free water molecules (water

activity is being reduced). One effect of reducing the number of free water molecules is seen as the water’s

ability to dissolve gas. It is reducing dramatically as shown in Figure 1-13.

Dissolved salt (%)

Figure 1-13: Gas solubility vs. salt content (Petrucci (1989)).

Solubility of gas in liquids

Temperature: The solubility of gases will slightly increase with increased temperature as indicated in

Figure 1-13.

Pressure: Pressure generally affects the solubility of gas in liquid more than temperature, and, as noted in

Figure 1-14, the effect is always the same: The solubility of gas increases with increasing gas pressure.

16

Compendium of ADC

pgas

xgas

Figure 1-14: Effect of pressure of the solubility of a gas. The solubility of gas molecules in the liquid solvent

increases with increased pressure - the color become lighter (free after Petrucci (1989)).

Gas concentration, xgas, in terms of the mol fraction of gas dissolved in liquids [atm/(atm/mol fraction)]

is proportional to the gas pressure, pgas, above the solution. The proportionality strength is taken care by

Henrys constant H:

𝑥𝑔𝑎𝑠 = 𝑃𝑔𝑎𝑠 ⁄𝐻

[molgas / molliq]

(1.15)

If the need to quantify the solubility arises, mol fraction must be translated to mass of gas, mgas:

𝑀𝑔𝑎𝑠

𝑚𝑔𝑎𝑠 = 𝑥𝑔𝑎𝑠 ⋅ 𝑀

𝑙𝑖𝑞𝑢𝑖𝑑

[ggas / gliq]

(1.16)

Equilibrium is reached between the gas above and the dissolved gas within a liquid when the rates of

evaporating molecules and rate of condensation of the gas molecules become equal.

Operational problems related to dissolved gas

Behavior of

gas in WBM

5

ol

ss

In voir

er

s

re

0.5

Di

ga

s

in

50

Fr

ee

Volume og gas (m )

500

re

se

rv

ve

oi

Li

r

be d g

a

ra

s

tio in

n

o f mu d

M

ga

os

s

tg

st

ar

as

ts

lib

er

at

e

Fr

d

ee

ga

s

A small gas kick, taken in OBM produces a relative small initial increase in annulus pressure and in pit

level as the kick is being circulated to the surface, because dissolved gas behaves like liquids. Gas will

later come out of solution as gas pressure decreases while the kick is being circulated up the annulus.

The gas dissolved in OBM is then released in large volumes as the mud reaches shallow depths as

indicated in Figure 1-15. Unfortunately, these phenomena can lead to inappropriate decisions since the

behavior is quite different from kicks in WBM.

At

bo

At

tto

m

Distance travelled

su

rfa

c

e

Figure 1-15: Volumetric behavior of methane swabbed in during connections while tripping out, dissolved in

OBM and later circulated out, un-detected until liberation as mud reaches shallow depths.

Dissolved gas is related to the volume of gas at standard condition pr. volume of liquid solvent, the gasliquid ratio, Rs (s refers to standard conditions). When oil is the solvent, it is referred to as gas oil ratio

(GOR). Figure 9-20 exemplifies the GOR of methane.

To account for the situation described in Figure 1-16, Rs must first be calculated at the bit depth:

𝑅𝑠 = 𝑞𝑔𝑎𝑠 ⁄𝑞𝑚𝑢𝑑

(1.17)

17

Compendium of ADC

If 𝑅𝑠,𝑏𝑖𝑡 ≤ 𝑅𝑠.𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑒𝑑 then all the formation gas is dissolved in the mud and the free gas volume

fraction is zero. If, on the other hand, a large enough amount of gas enters the wellbore, so that the

value of Rs,bit exceeds 𝑅𝑠,𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑒𝑑 , then the mud becomes saturated with gas and any excess appears as

free gas.

Rs (sm3/m3)

Rs, saturated

100

Free gas +

saturated

liquid

50

Dissolved

gas, under

saturated

p (bar)

0

0

100

200

300

Figure 1-16: Rs for CH4 in Mentor oil vs. well pressure at 100 0C, translated to SI-units.

We want to demonstrate the important effects of gas kicks in OBM. Assume the following situation:

A small gas kick enters the well:

Well depth:

Influx period

Mud pump rate:

Mud density:

Mud temperature:

1 m3

2 000 m

3 minutes

2 000 l/min

1.5 kg/l

100 0C

Question: Will the gas dissolve or be “free” at time of influx?

Bottom pressure:

1500 ∙ 9.81 ∙ 2000

= 294 * 105 Pa

3

Mud volume pumped: 2 m /min ∙ 3 min

= 6 m3

Gas ratio at standard conditions: Rs=Vgas/Vmud = (1m3∙294 bar /1 bar) /6 m3 = 49 Sm3 / m3

From Figure 1-16, we see that all the gas will be dissolved.

Question: When will the oil be saturated and gas begins to liberate?

a) At the moment of influx the pressure and oil require Rs to be 100 to be fully saturated,

i.e. twice as high as 49, i.e. the kick volume needed to be 2 m3.

b) Or, alternatively, the 1m3 gas kick with Rs of 49 passes the pressure corresponding to

point of full saturation at 170 bar. For the given mud density this corresponds to a depth

of around 1 140 mTVD.

18

Compendium of ADC

2. Casing Design

2.1. Casing characteristics

The most important performance properties of casing include its rated resistance of axial tension, burst

pressure, and collapse pressure. Axial tension loading results primarily from the weight of the casing

string itself, suspended below the point of interest. Body yield strength is the tensile force required to

cause the pipe body to exceed its elastic limit. Similarly, burst strength is the minimum internal

pressure that will cause the casing to rupture in the absence of protective external pressure and axial

tensile loading. Collapse pressure rating is the minimum external pressure that will cause the casing to

collapse in the absence of protective internal pressure and axial compressional loading. Other

characteristics like geometry, are presented in the lecture notes and in the Data Book.

API has adopted a casing grade designation to define the strength characteristics of the pipe body. The

grade code consists of a letter followed by a number. The letter designation in the API-grade code was

selected arbitrarily to provide a unique designation for each grade of casing, now adopted as the API

standards. The number designates the minimum yield strength of the steel in thousands of psi. Based

on considerable test data, the minimum yield strength should be computed as 80% of the average yield

strength observed. API - casing grades are (with yield strength in ‘psi’) equals to the grade number *

1000). Nine standard grades are available: H-40, J-55, K-55, C-75, L-80, N-80, C-90, C-95 and finally

P-110.

As an introduction to the upcoming discussion further down, Figure 2-1 indicates how a casing is

designed. It also indicates that the complete casing string can be composed of multiple sections with

different steel grade, wall thickness, and coupling types. A “Combination String”, as opposed to a

single grade steel, is the most economical solution. E.g. at the bottom of the well the tensile load is

negligible, and an inexpensive steel grade is sufficient, while at the surface the tensile load is

maximum.

2.2. Typical design of three common casing strings

Load vary with depth. The quality and strength of casings are related to load, and likewise the cost of

casing; the larger the load the higher the quality, and, the higher the costs. Since casings are expensive,

every operator will therefore seek the most economical design; high quality in the bottom and at the

surface, lower quality in the middle. A casing string will thus be designed with several different

qualities and weights, a Combinaiton String.

In the paragraphs to follow we have summarized the information given in the SPE textbook Applied

Drilling Engineering. It will increase your understanding and insight of casing design if you study the

relevant pages in ADE in parallell to, or better, ahead of the classroom teaching. Let it also be clear

that the examplified Load Cases differs between operators.

19

Compendium of ADC

Figure 2-1: Design of casing string with respect to tension. As indicated, the quality of the casing differs vs.

depth. A string composed of more than one specific casing quality is termed a Combination String.

2.2.1. Surface casing (20”)

For the surface casing the load situation is presented in Figure 2-2. It can be summarized through the

following worst-case senarios:

Burst load – is represented by a well control condition; A large kick (with closed BOP) is in the

process of being circulated out, then closed in.

•

•

All mud in the casing is kicked out, replaced by formation gas

Outside pressure is defined by normal pore pressure for that area (cement is degraded

and permeable

Collapse load – is represented by the most severe lost-circulation situation

•

•

•

LC leads to lowering of mud level inside the cemented casing, but the beneficial effect

of drilling fluid dropping only until the BHP = pore pressure at loss zone

Max possible external pressure is defined by the mud applied previously while RIH

with casing (beneficial effect of cement is ignored)

Detrimental effect of axial tension is considered (combined load)

20

Compendium of ADC

Axial tension – The casing is stuck close to bottom (we simplify and assume at the very bottom)

•

•

•

Axial load after cementing is difficult to establish. Assume therefore it to be equal to

its own weight buoyed by hydrostatic pressure existing at the time when max collapse

pressure was encountered

A small amount of pull force is required to pull casing free; Fpull

Combination string is designed. With differential wall thickness, buoyancy is most

accurately estimated by use of the pressure-area method

MUD

Figure 2-2: Load cases of surface casing.

We want to take you through 4 stages of casing design, starting with a depth-pressure graph, ending up

with the design of the surface casing.

Stage 1 - Original pressure situation: In Figure 2-3 we the original pressure situation, before kick

and losses occur.

Surface BOP

P

Sea bed

Conductor

Pore pressure

Drilling fluid pressure

Fracture pressure

Overburden pressure

Surface

casing

DEPTH

Loss Zone

P

Figure 2-3: Original depth–pressure situation for surface casing after drilling next well section.

21

Compendium of ADC

Stage 2 - Load Case: With basic information from stage 1 we are redy to present the load case. This

is shown in Figure 2-4.

0

Surface BOP

P

P

COLLAPSE

BURST

Sea bed

hsee

hmud

Gas inside csg

Mud pressure outside csg while RIH (r1)

Conductor

Pore pressure

outside csg

hcs

Surface

casing

Mud pressure inside casing

while drilling at bottom

and loosing mud (r2)

Mud

P

DEPTH

DEPTH

hLC

Pfrac

hBH

Ppore

P

Figure 2-4: Load situation for Surface Casings. Burst (left) and collapse (right).

Now follows a summary of how to estimate load for three load types; burst, collapse and tension, all in

agreement with the load cases above and as presented in Figure 2-4. The subs o, i, BH, cs, and surf

denotes; outside, inside (of casing), Bottom Hole, casing shoe, and surface, respectively.

Burst

Pi, cs =

Pi,surf =

Po,cs =

Po,surf =

Pfr,cs

Pi,cs – rgas . g . hcs

rpore . g . hcs

Collapse

Fluid level falls until PBH = Ppore,BH = r2 . g . (hLC - hmud) →we can find hmud

Pi,cs = r1 . g . (hcs - hmud)

Po,cs = Pmud while RIH = r1 . g . hcs

Po,surf = Pi,surf =

Tension

W=

BF =

wcs . hcs . BF + Fpull

1 – rmud / rsteel

As indicated earlier, it is recommended to estimate buoyancy in accordance to exposed areas, and not

like in the line above which gives only an average value.

Stage 3 - Load Line → Combined String: The next step is to find the load-line for surface casings.

Surface casings are shallow, and the axial tension is therefore not critical, but we need it in order to

correct the collapse pressure (combined stress). The load line equals the difference between the outer

22

Compendium of ADC

and the inner pressure in the casing, multiplied by the safety margin (SM). The strength data of burst

and collapse are given in psi or in Pa. We are now ready to compare the load-line with casing

strengths. Figure 2-5 represents this process, including the resulting design.

P

BURST

BURST

P

COLLAPS

N80

COLLAPSE

COMBINED

N80

H40

(Po – Pi) * SM

(Pi – Po) * SM

C75

C75

Po - Pi

Pi - Po

K55

K55

K55

C75

C75

N80

K55

P

H40

C75

N80

K55

H40

P

C75

Figure 2-5. Load-line (including SM) for burst (left) and collapse (middle). Corresponding grades (strengths)

are marked as well. The combined design, the most economic one, is shown to the right.

Stage 4 – Combined Load: Now we have produced first version of surface casing design, and we are

ready to adjust for combined load. To do so we retrieve the graph of combined collapse and tensile

load and presented in Figure 2-6. By combining collapse and axial tension, collapse resistance

becomes lower, and casing design will have to be adjusted.

→ FT (%)

Figure 2-6: Effect of axial tension on collapse strength.

The axial tensile load factor, FT , gives axial load in % of maximum allowable tensile strength; y, of

the strongest casing element (the upper one).

23

Compendium of ADC

FT = Tensile Load / body tensile yield strength = Wcsg / y

Wcsg can be estimated when grades and lengths are known.

Wcsg = wN80 . LN80 + wC75 . LC75 + wK55 . LK55

C75

N80

K55

H40

By taking FT to be, e.g. 0.55, for illustrative purposes, at the surface, where the tension is maximum,

we can read from Figure 2-6 that the Collapse Strengthening Factor equals 0.6. At the bottom of the

casing string the tension is zero, and the Collapse Strengthening Factor is here 1.0. With this

information, Figure 2-7 combines the new strengths with existing load-line.

* 0.6

P

COLLAPS 0

COLLAPS 1

COLLAPSE

COMBINED 1

COMBINED 0

BURST

N80

N80

N80

H40

H40

C75

K55

C75

C75

K55

K55

C75

N80

C75

K55

H40

C75

C75

K55

P

Figure 2-7: Combined load-design after 1. iterative step. Collapse strength has changed from initial design

step (Collapse 0) to Collapse 1, leading to adjusted design; Combined 1. Burst is here assumed unaffected by

tension. We now observe that we need a slightly stronger casing to compensate for the reduced collapse

resistance caused by simultaneous tension.

It results in a new, slightly adjusted design, with adjusted lengths and grades. With new depth of the

individual grade-weight casings, an iterative procedure is necessary to find the adjusted axial tension

vs. new depths. The iteration process continues until the axial load factor stabilizes.

2.2.2. Intermediate casing (13 3/8”)

Design of intermediate casing follows similar procedure as for surface casing; to reach final depth

safely. More critical than for surface casing is now the burst load. The situation is also here based on

underground blowout, just below the casing shoe, while drilling deeper, and a gas kick is circulated

out (with closed BOP), as illustrated in Figure 2-8.

24

Compendium of ADC

Figure 2-8: Burst load for intermediate casing.

The reason for the higher pressure is a combination of larger depth and relatively higher pore pressure

as illustrated in Figure 2-9.

Surface BOP

P

Sea bed

Conductor

Pore pressure

Drilling fluid pressure (r2)

Fracture pressure

Surface

casing

Intermed.

csg

P

Figure 2-9: Initial depth–pressure situation for intermediate casing while drilling next well section.

Since, for the intermediate casing, especially the burst is critical, details of the load case are:

Burst: Max surface internal casing pressure is limited to the rated BOP pressure (typically 10 or

15 000 psi for offshore operations):

•

Drilling fluid (r2) is still inside the casing (assume 50 % emptied by escaping gas from

underground blow out)

25

Compendium of ADC

•

•

•

Max pressure at lost-circulation zone = Pfrac, referred to as Pinjection, plus a safety margin due to

pressure drop within the fracture, DPfrac

Gas density varies with depth (actually with pressure) and can be estimated by the operator

Here we simplify by assuming it to be constant equal to 0.3 kg/l

MW is defined by pore pressure at next casing depth (r2)

Collapse load is like the surface casing’s: If a severe LC zone is encountered near the bottom of the

next interval, and no other permeable formations are present above the LC zone, the fluid level in the

well MAY fall until BHP = Ppore of the LC zone, i.e. to the level called hmud.

For intermediate and for production casing the depths are large and the tensile is therefore critical.

Surface BOP

P

Sea bed

Gas inside casing,

stabilized after shut-in

Sea bed

Pore pressure

outside casing (r1)

Conductor

Surface BOP

P

hmud

Conductor

Mud inside csg (r2)

Mud pressure in-side

csg defined by shoe

frac P, supported by

deepest pore P

Surface

casing

Pfrac + DPfrac

Intermed.

csg

hBH

Surface

casing

Mud pressure

outside csg (r1)

Intermed.

csg

Shut-in gas will maintain pore P through

percolating gas

P

P

Figure 2-10: Load situation for intermediate Casings. Burst (left) and of collapse (right). We observe

that collapse load is often negligible for the intermediate casing.

Estimation of the load details follows the same principles as for surface casing, and the resulting loadline for intermediate casing will be constructed similarly. The first design step is obtained by

computing the load-lines and compare them with the available casing grades (strengths).

The final design includes the iterative process related to combined load.

2.2.3. Production casing (7 “)

The production casing is set at final depth of the well. The pressure-depth situation at this depth is

already presented in Figure 2-9. The loads situation of production casings is illustrated in Figure 2-11,

and specified in more details below.

26

Compendium of ADC

Figure 2-11: Burst (left) and collapse load for production casings

Burst load:

•

•

•

Initial shut-in BHP = Ppore, and gas is produced: For simplification assume rgas = 0.3 kg/l

The tubing may fail (leak) at any depth; Pi = Ptubing

Completion fluid density (MW) is left outside casing

Collapse:

•

•

Late in the reservoir’s life the reservoir pressure is depleted down to normal water pressure

Leak in tubing causes loss of completion fluid. Casing is considered empty!

Axial tensile load:

•

•

Assume no axial support except for buoyancy

Assume a minimum pull force of 50 ton or approximately 50 kdaN

The further casing design process is identical with the already presented designs of casings above, and

design is therefore reserved for your future.

Data Book contains a full example of load cases for all three casing sizes.

3. Drillstring mechanics

27

Compendium of ADC

3.1. Drillstring Specification

For sub-chapter 3.1. we refer you to the lectures and to the Data Book.

3.2. Stresses in the drillstring

First we present the drag model for a straight borehole, illustrated in Figure 3-1.

F2

b

FN

W

F1

Ff

Figure 3-1: Drag conditions for a drillstring element in a straight borehole. Inclination angle should be b.

𝐹2 = 𝐹1 + 𝑤 ⋅ (𝑐𝑜𝑠 𝛽 +/−𝜇 ⋅ 𝑠𝑖𝑛 𝛽)

(3.1)

The plus/minus sign is valid while pulling / lowering the string.

Conditions for sliding we have when downward force equals resisting force. In this manner we can

determine the angle of repose, or angle of sliding, bs;

cos bs = . sin bs

bs = 1/ . tan-1 bs

(3.2)

Sliding of the drillstring will take place, according to eqn. 3.2, if the well inclination is lower than

what is shown in the list below:

0.15

0.20

b

84.4

78.7

For a curved borehole the model will have to include the effect of bending. Force in a curved borehole

are presented in Figure 3.2. The momentum or bending torque has also two components; local bending

caused by a curved wellbore with radius of curvature equal R, and, existing momentum in lower end

of the element, M1;

M2 = M1 + . w . R . sin b

()

28

Compendium of ADC

F2

a2 2

R

M2

FN

w

F f = 2 . FN

M1

1

a1

F2

Figure 3-2: Forces acting on a string element in a curved wellbore. Normal force, FN, is also called side force.

Incl. = b.

Analytical model

First, we present an analytical model, consisting of change of weight, mechanical friction and bending

stress along a small string element;

𝑑𝐹 = [−𝜇 ⋅ 𝐹 + 𝑤 ⋅ 𝑅(𝑠𝑖𝑛 𝛽 + 𝑐𝑜𝑠 𝛽)] ⋅ 𝑑𝛽

(3.4)

Along an infinitesimal element we may assume w = 0. Eqn. 3.4 then reduces to:

𝑑𝐹 = −𝜇 ⋅ 𝐹 ⋅ 𝑑𝛽

(3.5)

Rearanging;

𝑑𝐹

𝐹

= −𝜇 ⋅ 𝑑𝛽

(3.6)

Integrating along the complete angular change and including the initial stress F1 at the start of the

angular change, yields;

𝐹 𝑑𝐹

1 𝐹

∫𝐹 2

𝛽

= − ∫𝛽 2 𝜇 ⋅ 𝑑𝛽

1

(3.7)

resulting in this solution;

[𝑙𝑛𝐹2 −𝑙𝑛𝐹1 ] = −𝜇[𝛽2 − 𝜃𝛽1 ]

(3.8)

Changes in azimuth, a, are likewise added as (a2 – a1) to eqn. 3.6. By raising to the power of e on

both sides simplifies the solution;

𝑙𝑛𝐹2

𝐹

𝑒 𝑙𝑛𝐹1 = 𝐹2 = 𝑒 −𝜇(𝛽2 −𝛽1 )

1

(3.9)

29

Compendium of ADC

Rearranging we obtain the answer in radians or in angular degrees;

𝐹2 = 𝐹1 ⋅ 𝑒 −𝜇(𝛽2 −𝛽1 ) = 𝐹1 ⋅ 𝑒 −𝜇⋅

2⋅𝜋⋅(𝛽2 −𝛽1 )

360

(3.10)

Figure 3-3 shows examples of eqn. 3.10.

2 = 90

= 0.2

F2

1 = 0

F1

D

45

90

180

F2 / F1

1.17

1.37

1.87

Figure 3-3: Exemplifying the analytical model.

Discrete model

For smooth curved hole-sections, the analytical model can be used. However, borehole trajectories are

normally not smooth (inconsistent changes in inclination and azimuth), and therefore a discrete model

is better serving the need. We include changes both in azimuthal and vertical direction.

Axial force

𝐹2 = 𝐹1 + 𝑤 ⋅ 𝑐𝑜𝑠 𝛽 +/−𝜇 ⋅ 𝐹𝑁

(3.11)

Local bending momentum, also called bending torque

𝑀2 = 𝑀1 + 𝜇 ⋅ 𝑟 ⋅ |𝐹𝑁 |

(3.12)

The side force (or normal force) are composed of two sides in right angel tripod;

FN = √(𝐹1 ⋅ 𝛥𝛼 ⋅ 𝑠𝑖𝑛 𝛽)2 + (𝑤 ⋅ 𝑠𝑖𝑛 𝛽 + 𝐹1 𝛥𝛽)2

(3.13)

A negative value means that the normal force FN is reduced since F will tend to lift the drillstring off

the low side of the well in the build-up section. When FN = 0 the string does not touch the walls; the

string behaves like a catenary chain. The friction factor f represents the average condition of the

contact area between two observation points.

The side force has now four sources; its own weight, the existing force at the lower end, axial friction

force, and added force through the curvature, due to bending.

The calculation starts at the bottom and proceeds stepwise upward. Each short element contributes to

small increments of axial load. Since the 3D curvature is decomposed into two perpendicular planes,

the normal force is the vector sum of these two components. The vertical component has two

elements; the weight and the tension.

FN = [(Ft . Da . sin β)2 +/- (Ft . D + w . sin β)2]0.5

(3.15)

30

Compendium of ADC

Tension increment now becomes + for POOH and – for RIH:

DFt = w . cos β + FN

(3.16)

Bending increment:

DM = FN R

(3.17)

When drillstring elements are small, e.g. 100 ft, the error caused by assuming that tension, F1, does not

change over the length of the element, is neglectable. Estimated bending momentum along the bend,

translate to peripherical stress and add to existing axial tension.

3.3. Stuck pipe

Stuck pipe has been the failure type that has caused oil companies the most in terms of lost nonproductive time (NPT). With the introduction of Top Drive, the failure rate decreased, especially with

respect to differential stuck pipe, since the string can be kept rotating while tripping.

The two types of stuck, mechanical and differential, have different causes. Differential stuck pipe is

caused by high difference between wellbore pressure and the pore pressure. This pressure difference is

enabled by a pressure tight filter cake. Mechanical stuck pipe is caused by mechanical restrictions in

the wellbore. Whenever the resistance of moving the drill string axially becomes too large (DHKL >

15 – 20 tons), it might be necessary to stop and clean (ream) the hole, if possible in accordance with

Best Practice. Neglecting to do so may make the situation worse, including failures like stuck pipe.

Downhole restriction can have several causes.

1. Wellbore restrictions

a. Accumulated cuttings and cavings

b. Blocks. Blocks are large, irregular pieces of rock fragments originating either

from the wellbore or its wall or from cement. The wall may be chemically

unstable, surpassing the collapse pressure or be mechanically disturbed by the

drillstring

2. Wellbore wall restriction

a. Swelling shale

b. Creeping fm

c. Key seat

Details on these matters are presented in the lectures. Please show up there. Take good notes. Ask

questions. Why not.

31

Compendium of ADC

4. Directional drilling

There are many reasons for drilling directional wells, including:

•

•

•

•

•

•

Side-tracking existing wells (because of hole problems or fish or reaching new targets)

Restricted surface locations

To reduce number of offshore platforms

To reach thin reservoirs (using horizontal or multilateral drilling)

Salt dome drilling (direct the well away from the salt dome to avoid casing collapse)

To avoid gas or water coning problems

Before the actual drilling takes place, the trajectory must be planned.

4.1. Planning the trajectory

Which trajectory to be chosen depends on factors like; how many main targets and which geology

could secure an economical project. The surface location is known. Given the location of the target, it

is possible to calculate the best trajectory. The well profile is projected in the vertical plane as shown

in Figure 4-1. This figure also describes the various sections and parameters of a directional well.

The radius of curvature is the most common method to estimate the trajectory in the curved section.

When performing survey after the well is drilled, survey intervals are typically every 30 m. Generally,

we divide wellbore trajectories into 3 main types:

Build and Hold

Build-Hold and Drop

Continuous build

Figure 4-1: Type of directional wells.

To carry out the geometric planning for a Type I well, the following information is required:

32

Compendium of ADC

AZIMUTH, a The azimuth of a wellbore at any point is defined as the direction of the wellbore in

a horizontal plane measured clockwise form a north reference. Azimuths are expressed in angles

form 0-360°, measured form north = zero.

INCLINATION ANGLE, b The inclination angle of a well at any point is the angle the wellbore

forms between its axis and the vertical.

KICK-OFF POINT: The kick off point is defined as the point below the surface location where

the well is deflected from the vertical. The position of the kick off depends on several parameters

including: geological considerations, geometry of well and proximity of other wells.

BUILD UP AND DROP OFF RATES: The optimum build and drop off rates in conventional

directional wells are in the range of 1.5° to 3° per 100 ft, although much higher build rates are used

for horizontal and multilateral wells.

4.2. Estimating the trajectory.

Two of the most applied methods for trajectory estimation follow below.

4.2.2. Tangential Method, for straight sections

In this model the wellpath is assumed to be a straight line, defined by the inclination and the azimuth

at the lower survey station (station 1), as seen in Figure 4-2. Notice that the angels measured at

station 2 are not used in the analysis.

Station 2

DZ

b

N

DN

DH

DE

a

E

Figure 4-2: A 3D projection of the trajectory.

From Figure 4-2 it can be seen that:

DZ = L * cos b

(1)

DH = L * sin b

(2)

DE = DH * sin a

()

DE =DH * cos a

()

33

Compendium of ADC

This method gives clearly large errors in wellbores when the well direction is changing significantly

between stations. In wells where even over relatively short intervals there can be significant changes

in azimuth and inclination, this method is not recommended. Alternative method are the Average

Tangential Method (taking the average inclination and azimuth in two consecutive stations), or the

radius of curvature if the well forms a continuous curvature.

4.2.3. Radius of Curvature Method

This method assumes that the wellpath is not a straight line but a circular one, both in the vertical

and in the horizontal planes. The arc is tangential to the inclination and azimuth at each survey

station. See Figure 4-3.

Here we compare the complete circle with the small sector created by drilling between two

measuring stations, the Measured Length (DL), and the angle change (Da). During building

inclination, it is called Build Up Rate (BUR). In general, we call it Dog Leg, which, for a circle is

constant. Any deviation from the constant BUR we call Dog Leg Severity (DLS). Eqn. 4.4 compares

a full circle with a segment or an arc of the circle

2R / 360 = DL / Da

()

Figure 4-3: A well curved in two planes.

The wellpath can therefore be described as an arc in both planes.

In the vertical plane:

Angle change in the horizontal plane = a2 – a1. For a circle, we have:

(a2 – a1) / 360 = DL / (2 Rz)

(4.5)

Rz can be found from solving eqn. 4.1.

Rz = L * / (a2 – a1) * (180/)

(4.6)

Knowing Rz we may now calculate DZ:

DZ = Rz * sin a2 – Rz * sin a1 = R (sin a2 – sin a1)

(4.7)

34

Compendium of ADC

Substituting for Rz, the vertical increment becomes:

DZ = L / (a2 – a1) * 180/ * (sin a2 – sin a1)

(4.8)

The horizontal increment can be found through:

DH = Rz (cos a1 – cos a2)

(4.9)

In the Horizontal plane:

Angle change in the vertical plane = b2 – b1. For a circle, we have:

(b2 – b1) / 360 = DH / (2 Rh)

(4.10)

Rh can be found by solving eqn. 3.10: Rh = DH / (b2 – b1) * 180/

DN = Rh * sin b2 – Rh * sin b1 = Rh (sin b2 – sin b1)

(4.11)

Substituting for Rh:

DN = DH / (b2 –b1) * 180/ * (sin b2 – sin b1)

(4.12)

Substituting for Rh:

DN = Rz (cos a1 – cos a2)/ (b2 –b1) * 180/ * (sin b2 – sin b1)

(4.13)

Substituting for Rz:

DN = DL * / (a2 – a1) * (180/)2 * (cos a1 – cos a2) * (sin b2 – sin b1)/ (b2 –b1)

(4.14)

Note that DL = MD and that Da/MD = BUR in degree/m

4.3. Directional drilling vs. equipment

We present the directional equipment along with the activity of developing the directional wellbore.

a. Making the initial deflection from vertical

The initial deflection can be achieved by means of two different equipment systems:

1. Whip stock (see Figure 4-4)

The original way of deflecting the wellbore was by means of the whip stock. The mechanical

whipstock is permanently anchored in the well and oriented towards in the desired direction.

Most whip stock are set on the bottom of the hole or on top of a high-strength cement plug,

but some are set in the open hole.

35

Compendium of ADC

Figure 4-4: Deflecting from vertical with a Whipstock.

2.

Bent sub + mud motor (see Figure 4-5)

After vertical, when start on the kick off section, the rotary assembly is replaced with a

steerable motor. The steerable motor is usually a positive displacement mud motor inside a 1º

to 3 º bent housing. When mud is flowing, the motor rotates the bit, but not the drill string.

This type of drilling is called sliding mode.

Figure 4-5. The bent sub (deflection device) and the mud motor.

b. Drilling the curved section

The curved section can be directionally drilled by means of three different equipment systems:

1.

Bent sub + mud motor

36

Compendium of ADC

2.

BHA for directional drilling. Manipulate Only possible to change inclination.

Fulcrum (increase I) of pendulum (dropping I) assembly Downhole adjustable stabilizer. Used

instead of standard BHA

3. Rotary steerable system

For option 2. and 3. See more detail further below:

c. Drilling the tangent section

The tangent section can be achieved by means of two different equipment systems:

1.

Bent sub + mud motor (sliding drilling; the drill string does not rotate)

2.

Standard BHA. Use the packed hole assembly (see below)

BHA for directional drilling

Stabilizers and drill collars are the main components used to control hole inclination, as shown in

Figure 4-6. There are three ways in which the BHA may be used for directional control:

Pendulum Principle

Fulcrum principle

Packed hole stabilization principle

→ Decreases I

→ Increases I

→ Holds I

Pendulum Principle: The pendulum technique makes the angle drop, especially on high angle wells

where it is usually very easy to drop angle. The pendulum technique relies on the principle that the

force of gravity deflects the hole back to vertical.

Fulcrum Principle: This is used to build angle (or increase hole inclination) by utilizing a near bit

stabilizer to act as a pivot or a fulcrum of a lever. More WOB will increase the rate of angle build.

Packed Hole Stabilization Principle: This is used to hold or maintain hole inclination and direction

and are typically used to drill the tangent section of a well. The packed BHA relies on the principle

that two points will contact and follow a sharp curve, while three points will follow a straight line.

Packed BHA have several full gauge stabilizers in the lowest portion of the BHA, typically three or

four stabilizers, making the BHA stiff.

37

Compendium of ADC

Figure 4-6: BHA-manipulation to control inclination.

Rotary steerable systems (RSS):

Several solutions of RSSs are completing, and to exemplify we present the Autotrack. It combines an

automated downhole guidance system, formation evaluation sensors and two-way communication

with the surface. The steering direction is defined by pressure distributed selectively to three stabilizer

pads on the non-rotating sleeve. Any deviation from the programmed well path is automatically

corrected through closed-loop control without interrupting drill string rotation.

38

Compendium of ADC

Figure 4-6: Autotrack DDM.

5. Wellbore Stresses

The objective of measurements is to enable maintaining an efficient and trouble-free operation.

5.1. Surveillance of the drilling process

When

a failure occurs, symptoms, which are seen in the drilling data, is followed by a diagnosis of the

failure. This will help reducing non-productive time (NPT). On average NPT is typically in the range

of 15 % of the total rig time but can become higher during drilling of complex wells. Detection of

symptoms followed by diagnosis is especially important in complex wells. Time-based drilling data

can be evaluated and transformed into useful symptoms for automatic diagnosis.

Concepts often applied in conjunction with surveillance are:

Symptom: A deviation of the expected or normal performance

Normal state: The state when the process or the data are performing as expected

Error state: Error is a state in which a process or a hardware is less functional, but do not cause any

immediate loss of time

Failure state: Failure is a state in which a significant unplanned stop in the process occurs or the process

becomes less efficient and thus a significant NPT is involved. NPT is normally the result of a

repair activity, the activity necessary to bring the process back from failure state to normal state

5.1.1. Surface collected data

Surface recorded data in real-time are more common than downhole data. Figure 5-1 presents typical

variations of common drilling parameter.

39

Compendium of ADC

Parameter variation

Soft stringer encountered

Making a cnx

Hook Load

Bl o

picall

ht, ty

ig

e

w

Dead offshore

n

50 to

ck

Wiper trip

po

y

f.b

Of

si t

ion

om

ott

n

tio

fric

tes

t

time (h)

0

0.5

1.0

1.5

Figure 5-1: Variation in common surface data vs. time. In presented example we can observe soft stringer,

wiper trip and off-bottom test.

Surveillence of the drilling process in order to detect symptoms of the common failure; mechanically

stuck pipe. Downhole restrictions leading to mechanical stuck pipe can have (at least) two different

causes:

1. Wellbore geometry restriction:

a. Accumulated cuttings or cavings

b. Blocks restriction (blocks are large, irregular pieces of rock fragments either from

unstable wellbore or from cement)

2. Wellbore wall geometry restriction; swelling of shale or creeping wellbore

Table 5-1 presents some of the symptoms, which are characteristic for mechanical stuck pipe, enabling

us to distinguish between other failure types.

Table 5-1: Example of restrictions and interpretation of common drilling events related to stuck pipe (but also

to other failures).

Event

Plugging annulus

Symptom

• Intermittent ‘spiky’ or increased SPP

• Torque fluctuations

• Overpull / Took Weight

Cuttings-load formation •

•

•

Gradual increase of ECD

Low cuttings level expected at surface

ROP decreases

Comments

If close to plugging the annular path,

pressure spikes are seen

Packoff may be broken through before the

formation fractures

Need data agents to see these small

deviations / signatures

Increased RPM will increase cuttings level

The symptom called overpull is a signature of an irregular hook load that show sudden increments

during POOH as indicated in Figure 5-2.

40

Compendium of ADC

Normal HKL

Signature of

restriction

Figure 5-2: Overpull experienced when hook load (HKL) deviates from its normal level during tripping.

Tripping activity is seen by the upwards movement of the block position (BPOS).

5.1.2. Downhole data collection – MWD

The first measurements-while-drilling (MWD) to be introduced commercially to the drilling industry

were directional data, and almost all the applications took place in offshore wells. Achieving reliable

readings in the harsh downhole environment was one of the challenges of MWD, as for the later

Logging While Drilling (LWD) technology. Another challenge was to provide wireline-quality

measurements.

MWD includes more detialied data stored in its tool memory. The tool have three major

subcomponents:

•

•

•

Power system → battery and turbine

Directional sensors → array of three orthogonal flux-gate magnetometers and three

accelerometers

Telemetry system → mud pulsing or, more resent, acoustic system

A large part of all lost-time incidents lasting longer than 6 hours are caused by failures related to

drilling mechanics. Therefore, effort is made to ensure that information related to drilling mechanics

are acquired. Such parameters are WOB, torque, vibrations, shocks and temperature.

If the oscillation-level or shock-frequency exceed a pre-determined threshold, a warning is transmitted

to the surface. The driller can then take corrective actions (such as altering WOB or RPM) and observe

whether the stick-slip, or the bouncing, or the whirling of the bit has stopped on the next data

transmission.

Good hole cleaning can be difficult to achieve. Cuttings tend to build up on the lower side of the

borehole. If buildup is not identified early enough, loss of ROP and sticking problems can result. A

downhole annulus pressure measurement (PMWD) can monitor backpressure while circulating, and,

assuming that flow rates are unchanged, it can precisely identify when a wiper trip should be

performed to clean the hole. PMWD can also help monitoring the MW, and optimize the equivalent

circulating density (ECD). Let it be said that also the surface parameter called stand pipe pressure

(SPP) will give the same information if it is evaluated carefully (through surveilling by a data agent).

Historically, drilling-dynamics-LWD measurements have not been commercially successful. Many rig

site staff choose to rely on surface measurements and on own experience. Two reasons for discrediting

41

Compendium of ADC

the integrity of LWD systems is several false alarm.

5.2 Wellbore Instability

Many drilling problems are related to wellbore instability. Wellbore instability is related to chemical

and to mechanical imbalance. In present chapter we will concentrate on the mechanical part.

Shear and tensile failure mechanisms are the two largest concerns, especially when drilling in shale.

These problems are time-consuming and expensive to fix. It is especially offshore that the rig costs are

high. Despite great efforts to reduce borehole instabilities, they remain a serious concern. Mechanical

instability can be classified into two groups;

1. Stress-related instability

o Tensile failure occurs at too high mud weight (MW). The stress in the tangential

direction is larger than the critical tensile stress T. Fractures are detected at the

surface as lost circulation. The losses will increase with increasing mud pressure,

and ranges from minor to total loss

o Compressive-failure occur at too low MW: The crushing of the wellbore wall

(shear failure) will worsen with decreasing pressure, ranging from small amounts

of cavings (breakouts) to total wellbore collapse

o Creep: Wellbores that stay open for a long time (weeks) exhibit a slow plastic

“flow”, tending to close the wellbore. It is especially claystone and Halite (NaCl)

which creep under stress. Anhydrite on the other hand, is strong and immobile.

Creep is potentially useful for creating a supportive barrier around the casing

2. Existing weakness in the formation

The failure mechanisms presented in paragraph 1 are valid also for formations with

weaknesses, only their rock properties are different from normal formations.

o Faults and stress zones crossing the wellbore may represent a weakness: Preexisting fracture and cracks are especially observed in limestone, chalk and in

brittle shale

o Inter-bedded formations: Between lithology changes, bedding angle close to

wellbore angle, anisotropy, heterogeneity, and strength anisotropy

o Naturally weak formations: Coal beds, conglomerate

o Unconsolidated formation: Shallow, loose sand, gravel, silt

To evaluate latter types of instabilities we are dependent on information that can indicates what type of

weakness has been encountered. Weakness in the formation, like sand and gravel often lack cementation

material and are referred to as an unconsolidated formation, a problem that occurs mainly at shallow

depths. The problem with unconsolidated formations is that they cannot be supported by hydrostatic

overbalance from the drilling fluid alone, and may fall into the hole and pack off around the drill string.

To drill such weak formations, at shallow depths, the mud should provide a high-quality filter cake to

help consolidate the formation so that hydrostatic pressure can "push against" and stabilize the annular

wall.

42

Compendium of ADC

5.2.1. Rock mechanics

Creating a circular hole and thus introducing drilling fluids to stable formations creates stress

concentration. This stress concentration, which differs from the far-field stresses, could exceed the

formation strength, resulting in failure. The circular hole also represents a free surface that replaces the

natural confinement, which can reduce the formation strength and trigger inelastic and time-dependent

failures.

Introducing foreign fluids into the formation may create a localized, elevated pore pressure. It can also

reduce the cohesive strength of the formation, depending on the fluid interaction with the formation

matrix. The foreign fluids will also change the capillary forces.

Before presenting mechanical failures, we present some important rock mechanical characteristics.

Loading-unloading

The formation and the cement sheath of the wellbore construction is exposed to cyclic loading and

unloading. The stress-strain relationship describes the way the formation’s framework of granular

material responds to the applied load, whether the material exhibits elastic or plastic, brittle or ductile,

stains-softening or strain-hardening behavior during loading.

Poro-elasticty

Poro-eslasicity is referring to the effective stress. This concept suggests that the pore pressure helps

counteract the mechanical stress carried by the grain-to-grain contact. In materials with no porosity,

like volcanic rocks, the vertical stress, z, is identical with the overburden stress, ovb:

z = ovb

(5.1)

In porous material, like in most sedimentary rock, the pore pressure, pp, supports the vertical stress;

parts of the overburden weight are carried by the fluid.

z-eff = ovb – pp

(5.2)

Viscoelasticity

“Creep” is a viscoelastic property or a time-dependent phenomenon that significantly contribute to

many instability problems. Especially if the wellbore stays open (un-cased) for more than a week.

Fracture toughness

Fracture toughness is a material property that reflects the rock resistance of an existing fracture to

propagate. For radial or “penny-shaped” fractures to propagate, depends on the tensile strength, T.

Shale and chalk have lower fracture toughness than limestone and sandstone.

Near-wellbore stress field

A wellbore drilled through a rock formation introduces a new stress field at the wellbore proximity. If

we assume a homogenous, isotropic rock mass, and further assuming that a mud cake differentiates the

wellbore pressure, pmud, from the reservoir pressure, pp, then the small extra, near wellbore stress is

defined by:

43

Compendium of ADC

add = pmud – pp

(5.3)

Tensile strength

In this course we limit ourselves to apply far-field stresses. This is a major simplification, and not

possible to do when studying stresses on the wellbore wall in detail. For the study of tensile stress, we

introduce and summarize important factors involved in fracture initiation in Figure 5-3. When

wellbore pressure surpasses the fracture pressure of the formation, a tensile fracture occurs.