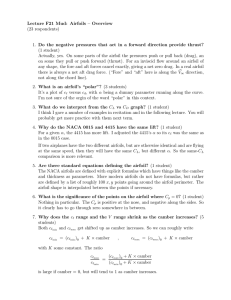

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/310481618 Camber Variations in Precast Bridge Girders Article · July 1999 CITATIONS READS 3 1,470 3 authors, including: Nur Yazdani Primus Mtenga University of Texas at Arlington Florida A&M University 119 PUBLICATIONS 691 CITATIONS 1 PUBLICATION 3 CITATIONS SEE PROFILE SEE PROFILE Some of the authors of this publication are also working on these related projects: Load Test Evaluation and Theoretical Modeling of In-Service FRP Strengthened Bridges View project Hydrocarbon Pool Fire Performance of Fiber Reinforced Polymer Retrofitted and Thermally Insulated Bridges View project All content following this page was uploaded by Nur Yazdani on 31 January 2017. The user has requested enhancement of the downloaded file. Is camber “growing” in your precast yard? Camber Variation in Precast Girders by Nur Yazdani, Primus Mtenga, and Nigel Richardson P recast prestressed concrete members usually experience camber as a by-product of a prestress force application. The camber counteracts the deflections caused by the application of dead load from the bridge deck. The Florida Department of Transportation (FDOT) has experienced slab construction problems in the field that may be associated with unexpected camber variations in prestressed highway girders. Previous experience has shown that the actual camber for wide-flanged girders such as Types V, VI, modified Type VI, and the Florida Bulb Tee are typically less than that predicted by theoretical analysis at the FDOT at the time of casting the slab. Such problems have been documented in unpublished internal studies performed at the FDOT structural design office.1,2 As suggested in the FDOT structures design guidelines, the haunch between the slab and the girder can be adjusted to compensate for camber and to maintain the required deck profile on bridges.3 The haunch provides a means of maintaining constant slab thickness. The thickness of the haunch varies with the beam camber, while the slab thickness remains constant. Another option is to lower the vertical profile of the bridge deck. Both options result in expensive modifications in the field. Several factors may influence the variation in camber experienced in precast prestressed girders. One such explanation could be a change in the cross section stiffness not accounted for in the design. This change in stiffness could be a result of the presence of unwanted and unnoticed microcracks. Crack formation cannot always be directly linked to one (a) Type III factor and instead could be a result of high tensile stresses generated by techniques used in site handling and vibrations experienced during transportation procedures. High tensile stresses can also yield cracks if the tendons are released prior to the attainment of sufficient concrete compressive strength to resist the negative moment stresses resulting from the prestressing strands and their eccentricity. Onsite variations in the magnitude of prestressing forces imparted on the girders could also influence the camber. In addition, the assumed values for prestress loss at various intervals of the girder life may not be appropriate. FDOT’s structural design office utilizes a prestressed beam program to design and review simply supported pretensioned bridge girders.4 Under the recommendations of ACI Committee 209, Creep and Shrinkage in Concrete, which studied the effects of various parameters and environmental effects on prestress loss and camber of precast girders, the FDOT inhouse prestress beam program was updated to incorporate various modifications on material properties that might affect camber output. In spite of these general modifications, the problem of camber still remains evident in girders utilized in the highways of Florida. It has been argued that it is feasible to operate with simplified deflection and cracking rules in the design of partially prestressed cracked beams.5 The use of span/depth limits to control deflection is especially attractive. It has also been contended that the presence of initial camber reduces the critical buckling load of prestressed girders while they are (b) Type IV (c) Modified Type VI Fig. 1 — Cross sections of monitored AASHTO girders, all dimensions in mm. (Note: 25 mm = 1 in.) Monitoring per i od Monitoring s it e Ty pe o f g irder N umber o f g irders May-August 1995 Si te 1, Tampa Modi fi ed AASHTO Type VI 20 September-November 1995 Si te 2, Jacksonvi l l e AASHTO Type III AASHTO Type IV 6 8 In this procedure illustrated in Fig. 2, marks were placed at both ends and the midspan along the girder centerline. From this datum, a surveying rod was held and the dumpy level was used to measure the vertical elevation. Based on the diagram in Fig. 2, the following procedure was used to calculate camsuspended during the erection process.6 Therefore, this effect should be considered in the design process. The application of the I-effective method of calculating deflections of partially prestressed members has been explored in several studies.7,8,9 In this study, the growth of actual camber in American Association of State Highway and Transportation Officials (AASHTO) girders during storage in the precasting yard was monitored. Measured cambers were also compared with theoretical cambers generated by the in-house program used by the FDOT. Research significance Camber growth with time is an inherent property in precast prestressed bridge girders. Accurate prediction of field camber is essential in avoiding subsequent problems with deck construction. This study was focused on evaluating the actual growth of camber with time, and the variations with theoretical camber. The research results can be utilized in better prediction of camber in AASHTO bridge girders during storage. Field monitoring To monitor the actual camber experienced in the field, camber values were measured from various Florida prestressing yards, including two permanent yards in north and central Florida. At the first site, located in Tampa, a total of 20 modified AASHTO Type VI girders were monitored for camber. Data were obtained at different stages of the girder life, which were: initial camber, immediate camber after removal from the bed, and camber during storage at the yard. At the second site in Jacksonville, a total of 14 standard AASHTO girders were monitored, including six AASHTO Type III and eight AASHTO Type IV girders. The cross sections of the three girder types studied are shown in Fig. 1. Table 1 is a summary of the girders studied and the approximate time periods for which they were monitored. A number of experimental procedures were tried to measure the field camber of the prestressed girders. A method involving a dumpy level and a surveying rod was chosen for reasons of accuracy, convenience, and practicality. ber from field data: δH3 = δH4 - δH1 (Eq. 1) in which, δH1 = δH2 / 2 δH2 = relative elevation of girder ends δH3 = camber at midspan δH4 = elevation at midspan A taut string used as a datum is a common technique used to measure camber, and was initially tried for this study. Even when high-strength piano wire was used, it was impossible to eliminate the sag in the string. This difficulty was especially pronounced for large span girders. The technique chosen was far more accurate than the procedure currently utilized by the precast yard. Typical concrete average compressive strengths at prestress transfer and at 28 days for the monitored girders are presented in Table 2. The AASHTO Type III girders were prestressed with straight strand 1862 MPa (270 ksi) stress relieved tendons. These girders spanned a distance of 21.34 m (70 ft) and were erected on a bridge over a waterway. The Type IV girders were also prestressed using 1862 MPa straight strand, stress relieved tendons. The span length for these girders measured approximately 31 m (100 ft). The modified AASHTO Type VI girders were designed for a span of 43.6 m (143 ft) with 50 straight strand low relaxation 1862 MPa tendons and 14 post-tensioned strands. The post-tensioning for these girders was completed during placement at the site. Time int e rv a l Ac t ua l ca mber, mm G ro w t h in ca mber , % F D O T p r e d i c te d ca mber , mm G ro wt h in F D O T ca mber , % D i f f e re nce be t we e n f ie ld a nd F D O T ca mber , % I nit ial 32.8 32.0 6 1 month 50.0 52 46.7 46 7 2 months 54.5 60 50.0 56 9 an in-house check of girders designed for Florida’s highways. In general, the FDOT beam program complies with AASHTO Specifications for Highway Bridges, American Railway Engineering Association Specifications, ACI Building Code Requirements for Reinforced Concrete, FDOT Structures Design Guidelines, and FDOT Standard Specifications. A camber summary of the beam up to a period of 240 days and allowable stresses are included in the output file. In addition, information regarding elastic and time-dependent shortening effects is included in the output summary. Moments, shears, and stresses experienced during service loads are also provided. Prestress losses in the FDOT beam program are approximated using the AASHTO guideline 9.16.2.10 In the FDOT beam program, the theoretical camber for AASHTO girders is predicted by the conjugate beam approach. The FDOT beam program was used in this study to predict theoretical camber in AASHTO Types III, IV, and modified VI girders. Design values of strengths and dimensions were utilized for camber prediction purposes. Camber results The average camber results obtained from the field monitoring and the theoretical models are presented in Fig. 3, 4, and 5, and Tables 3, 4, and 5, for AASHTO Types III, IV, and modified Type VI girders, respectively. The time dependent growth rates of camber (based on initial camber) and the differences between the actually measured and theoretically predicted cambers are also included in Tables 3, 4, and 5. It is observed from these tables that both the actual and the theoretical cambers grow significantly with time in precast prestressed bridge girders. As seen from Table 3 and Fig. 3, measured average camber at 1 month grew about 52% over the initial camber in the AASHTO Type III girders. Subsequently, the rate of camber growth slowed, and at 2 months, the actual camber grew by an additional 8%. The camber growth predicted by the theoretical model lagged the actual camber growth at various time intervals. For AASHTO Type III girders, camber recorded at each time interval was greater than that derived from the FDOT program. At the initial stage, differences between the recorded and the predicted camber was about 6% on average. At the 1 and 2 month stages, camber variations between 4 to 12% were evident. A few Type III girders exhibited actual camber variations of nearly 15% from the expected results of the FDOT program. Fig. 4 and Table 4 illustrate the average measured and theoretical camber variations in AASHTO Type IV girders. All eight Type IV girders monitored reflected camber increase over the time period of storage. Similar to the Type III girders, the Type IV girders experienced significant camber growth within a 1 month interval. The camber growth decreased for subsequent time intervals. Measured camber values in the Type IV girders showed 0 to 4% variation as compared to the predicted initial camber from the FDOT program. At the 1 month and 2 month time intervals, camber variations of 1 to 5.5% and 2 to 9% were evident in these girders, respectively. Fig. 5 and Table 5 show the average camber variations in the modified AASHTO Type VI girders. After an initial surge in camber growth during the first month, the AASHTO Type VI girders demonstrated subsequent decreased camber growth rates. Field camber values in these girders varied by 1 to 5.5%, 2 to 7.5%, 2 to 9%, and 3 to 20% from the theoretical values for the initial, 1 month, 2 month, and 3 month intervals, respectively. Camber in AASHTO Type VI girders did not grow as quickly during the first month as in the smaller girders. But unlike the smaller girders, the camber growth did not decrease substantially in subsequent months. Statistical techniques were used to determine if the measured cambers varied significantly from the expected cambers. Assuming the predicted camber value from the FDOT program as the population mean, the t statistic as shown below was utilized to test the mean:11 t = [(X −µ ) n ]/ S (Eq. 2) in which, X = sample mean µ = population mean S = sample standard deviation n = sample size Table 4 — Average variation in camber for AASHTO Type IV girders Time int e rv a l Ac t ua l ca mber, mm G ro w t h in ca mber , % F D O T p r e d i c te d ca mber , mm G ro wt h in F D O T ca mber , % D i f f e re nce be t we e n f ie ld a nd F D O T ca mber , % I nit ial 58.1 56.6 3 1 month 81.6 40.4 79.5 40.5 3 2 months 87.1 49.9 84.3 48.9 3 Note: 25 mm = 1 in. The following hypotheses were tested: Ho : µ = µo null hypothesis HA : µ > µo alternate hypothesis The null hypothesis will be rejected if t > tα, where α is the level of significance. Based on various statistical parameters and the values of the t-statistics at 2.5% and 1.0% levels of significance (which correspond to 97.5% and 99% confidence levels, respectively), it was found that at 97.5% confidence level, the test statistic is greater than the acceptable value for all girders and all time intervals. Therefore, the null hypothesis must be rejected. As the girder becomes larger, the difference between the theoretical and actual camber also increases. These observations are also valid at the 99% confidence level, except for the isolated case of the Type III girder at initial conditions. This means that the measured cambers are indeed significantly greater than the predicted camber from the FDOT beam program, although they are within acceptable engineering accuracy. Discussion The field data suggest that AASHTO precast girders experience increased camber due to creep, which takes place with time as expected. Creep is impacted by the large prestressing forces, eccentricity, change in concrete strength and the modulus of elasticity as the concrete continues to cure and increase in strength. It is unlikely that abnormal stresses were imparted to the girders during handling, because they were removed from the precast bed to storage and to trucks/barges from storage according to industry recommendations. The two test sites contained numerous potholes and ruts, which may impart impact loads from the transport vehicles to the tested girders. These vibrations may have caused additional tensile stresses and cracking in the girders. Thus the possibility of microscopic cracking exists at this stage. The importance of this stage might prove to be critical in design procedure and should be explored. In general, actual camber increased by more than 50% in most of the girders monitored in the 2 month period. It is possible that the problem of additional field camber is more involved than the inherent assumptions. The presence of unwanted microcracks causes a reduction in the effective cross-sectional area of the girder, leading to a decrease in the eccentricity of the prestressing force. If tensile cracks are allowed, a modified approach must be implemented that accounts for the changes in the cracked section. New and improved methods are available that could be used to modify the existing techniques for predicting camber.7 The platform for this modification is that of the Effective Moment of Inertia method. Other factors such as temperature range, humidity, mix proportions, and quality control in casting, which are not accounted for in FDOT’s software, may cause the differences observed between the actual and theoretical cambers. The measured cambers varied from the predicted cambers by about 1 to 15% during storage. Statistical tests showed that the FDOT beam program consistently predicted lower camber values than the actual measured camber. It is interesting to note that the test t-statistics increased significantly from initial conditions to the 1 and 2 month intervals. Therefore, it is possible that the difference between the actual camber values and the predicted camber may become greater at later stages, such as under service conditions. Unfortunately, because service camber data could not be measured, no comparisons could be made for that stage. Conclusion The following conclusions and recommendations are made based on the theoretical modeling and results gathered: 1. This investigation has shown that the actual camber in Florida’s precast prestressed bridge girders increases significantly during storage at precast yards. This increase is due to creep effect and is expected. The camber increase is maximum during the first month in storage. The camber growth rate diminishes in subsequent months. 2. Camber in larger AASHTO girders such as the modified Type VI does not grow as quickly as in the smaller girders during the first month in storage. However, the camber growth rate in the larger AASHTO girders does not decrease Table 5 — Average variation in camber for modified AASHTO Type VI girders Time int e rv a l Ac t ua l ca mber, mm G ro w t h in ca mber , % F D O T p r e d i c te d ca mber , mm G ro wt h in F D O T ca mber , % D i f f e re nce be t we e n f ie ld a nd F D O T ca mber , % I ni t i a l 76.4 74.1 3 1 month 100.0 30.9 96.0 29.6 4 2 months 123.8 62.0 115.4 55.7 7 3 months 133.3 74.5 120.3 62.3 11 substantially in subsequent months, as is the case for smaller girders. 3. The variation between field camber and the theoretically predicted camber for AASHTO Types III, IV, and modified VI girders is in the 3 to 11% range on the average during storage in the precasting yard. For individual girders, the difference can be as high as 20% during storage in the precast yard. The actual camber is significantly greater than theoretical values for the monitored girders. 4. The actual measured cambers were found to be significantly larger than the corresponding FDOT predicted values for all monitored girders up to 4 months after casting. Apparently there is loss of girder stiffness in the field not properly accounted for in the FDOT software. The stiffness loss could be due to microcracks caused by vibrations induced during transportation. Another reason could be cracking due to low concrete tensile strength at initial stages. 5. Additional research is needed to determine actual camber in AASHTO girders under service conditions. The effect of microcracks on the reduction of girder moment of inertia also needs investigation. Acknowledgment The study reported herein was funded by a research grant from the Florida Department of Transportation. References 1. Nichols, B., and Ausley, M., “Camber Analysis for the Tampa Grandy Bridge,” Presentation at the annual FDOT Structural Design Meeting, Orlando, Fla., 1993. 2. Bowman, H., “Camber Analysis for Alligator Creek Bridge,” FDOT Internal Report, 1993. 3. “Structures Design Guidelines,” FDOT Structures Design Office, July 1997. 4. “The Design and Analysis of Simple Span Prestressed Concrete Beams Computer Program, Users Manual,” V. 2.5, FDOT Structures Design Office, May 1994. 5. Scholz, H., “Simple Deflection and Cracking Rules for Partially Prestressed Members,” ACI Journal, V. 88, No. 2, March-April 1991, pp. 199203 . 6. Peart, W. L.; Rhomberg, E. J.; and James, R.W., “Buckling of Suspended Cambered Girders,” ASCE Journal of Structural Engineering, V. 118, No. 2, February 1992, pp. 505-527. 7. Tadros, M. K.; Ghali, A.; and Meyer, A. W., “Prestress Loss and Deflection of Precast Concrete Members,” PCI Journal, V. 30, No. 2, Jan.-Feb. 1985, pp. 114-141. 8. Branson, D. E., and Trent, H., “Application of the I-Effective Method of Calculating Deflections of Partially Prestressed Members,” PCI Journal, 62-77, 1982. 9. Teng, S., and Branson, D. E., “Initial and Time-Dependent Deformation of Progressively Cracking Non-Prestressed and Partially Prestressed Concrete Beams,” ACI Structural Journal, V. 90, No. 5, Sept.Oct. 1993, pp. 480-481. 10. American Association of State Highway and Transportation Officials, Standard Specifications for Highway Bridges, Washington D.C., 1995. View publication stats ACI member Nur Yazdani is a professor of civil engineering at the Florida A & M University-Florida State University College of Engineering. He is a member of ACI Committees 343, Concrete Bridge Design — Joint ACI-ASCE; 123, Research; and 201, Durability. His research interests include prestressed concrete members, bridge design, and rehabilitation. Primus Mtenga is an assistant professor of civil engineering at the Florida A & M University-Florida State University College of Engineering. His recent research in the area of structural analysis and design and construction materials has included structural system reliability and performance of bio-composites. Nigel Richardson is a PhD student at the Florida A & M University-Florida State University College of Engineering. His past research has involved prestressed girders and moisture effects on cupping forces in lumber. Current interests include engineering mechanics and numerical modeling of the behavior of materials commonly used in structural engineering applications.