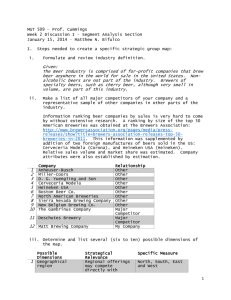

beverages Article Why Craft Brewers Should Be Advised to Use Bottle Refermentation to Improve Late-Hopped Beer Stability Carlos Silva Ferreira , Etienne Bodart and Sonia Collin * Earth and Life Institute ELIM, Université catholique de Louvain, Croix du Sud, 2 box L7.05.07, B-1348 Louvain-la-Neuve, Belgium; carlos.silva@uclouvain.be (C.S.F.); etienne.bodart@uclouvain.be (E.B.) * Correspondence: sonia.collin@uclouvain.be; Tel.: +32-10472913 Received: 28 February 2019; Accepted: 13 May 2019; Published: 4 June 2019 Abstract: The aromatic complexity of craft beers, together with some particular practices (use of small vessels, dry hopping, etc.), can cause more oxidation associated with pre-maturated colloidal instability, Madeira off-flavors, bitterness decrease, and aroma loss. As bottle refermentation is widely used in Belgian craft beers, the aim of the present work is to assess how this practice might impact their flavor. In fresh beers, key flavors were evidenced by four complementary techniques: short-chain fatty acids determination, esters analysis, XAD-2 extract olfactometry, and overall sensory analysis. In almost all of the fresh beers, isovaleric acid was the sole fatty acid found above its sensory threshold. Selected samples were further analyzed through natural aging at 20 ◦ C. The presence of yeast in the bottle minimized the trans-2-nonenal released from Schiff bases and proved less deleterious than suggested by previous studies with regard to fatty acid release and ester decrease through aging. Furthermore, according to the yeast species selected, some interesting terpenols and phenols were produced from glucosides during storage. Keywords: craft beer; bottle refermentation; AEDA; short-chain fatty acids; beer aging 1. Introduction Worldwide, over the last few decades, the production of craft beers has grown significantly, with new commercial products launched onto the market every day. Craftsmen can bring distinctive flavors to their beers by working with special malts, dual-purpose hop varieties (with or without dry hopping), spices, and/or specialty yeasts. These are known to impart fruity esters [1,2] and, in some cases, typical phenolic flavors [3] (e.g., 4-vinylguaiacol brought by phenolic off-flavor (POF(+)) yeasts). In addition, odorous heterocyclic compounds can be issued from colored malts [4,5], while hop terpenols and polyfunctional thiols bring pleasant citrus and exotic flavors to late- and dry-hopped beers [6–8]. Unfortunately, the use of small vessels and craftsmanship, by definition, lead to a higher risk of oxidation and shelf-life decrease. Beer aging has been the focus of much interest for decades, with the development of worldwide beverage exchanges. The Dalgliesh plot [9] describes aromatic changes occurring in lager beers during storage. A linear decrease in bitterness (degradation of isohumulones and/or humulinones) coincides with an increase in sweet aroma and toffee flavor, together with the well-known cardboard taint (caused by trans-2-nonenal) [10–13] and ribes off-flavor (a catty smell linked to the presence of 3-sulfanyl-3-methylbutyl formate) [14,15]. Aging of specialty beers is even more complex, with defects such as Madeira off-flavor [16], phenolic perception [17], a change in hoppy aromas [18], and a detected ether taint [19]. Bottle refermentation has been widely used by Belgian craft brewers for its carbonation effect, giving beer the desired effervescence, and also for the associated oxygen consumption, which limits Beverages 2019, 5, 39; doi:10.3390/beverages5020039 www.mdpi.com/journal/beverages Beverages 2019, 5, 39 2 of 11 oxidation and the development of related off-flavors [20–22]. About half a million yeast cells per mL are pitched into the beer before bottling, in the presence of added fermentable sugars. The beer is then kept in a warm room (20–28 ◦ C) from two to four weeks. According to Saison et al. [23], however, refermentation can be damageable, causing loss of flowery, fruity, and ester notes that are highly appreciated by consumers. Long storage can lead to yeast autolysis with release of esterases (deleterious to fruity esters) and to excretion of amino acids, peptides, and short-chain fatty acids [24–28]. When Brettanomyces strains are present in the bottle, production of isovaleric, hexanoic, and octanoic acids is especially promoted [29–31]. The aim of the present paper was to assess how bottle refermentation impacts the flavor properties of Belgian craft beers. As bottle refermentation was already known to significantly improve the release of free-hop thiols from cysteine and glutathione conjugates [22], we decided to investigate only non-dry-hopped commercial samples. First, short-chain fatty acids were investigated in 16 bottle-refermented and two unrefermented Belgian craft beers to determine whether they were present above their sensory threshold. In a few selected samples, more flavors were then analyzed through natural aging at 20 ◦ C in the dark. Esters (isoamyl acetate, ethyl hexanoate, and ethyl octanoate) were quantitated by headspace-GC-FID, and most trace aromas were monitored by GC-olfactometry after XAD-2 aroma extraction. Lastly, some cardboard defects (trans-2-nonenal) and a few other changes in aroma were evidenced by overall sensory analysis. 2. Materials and Methods 2.1. Materials Isoamyl acetate (99%), ethyl hexanoate (99%), ethyl octanoate (99%), 2-pentanol (98%), isovaleric acid (99%), hexanoic acid (≥98%), octanoic acid (≥98%), nonanoic acid (99%), and decanoic acid were purchased from Sigma Aldrich GmbH (Bornem, Belgium); n-hexanol from Acros Organics (Geel, Belgium); ethanol (99.8%) from Merck (Darmstadt, Germany); XAD-2 resin from Supelco Inc. (Bellefonte, United States of America); and sodium chloride, copper sulfate (II), and diethyl ether from VWR International (Leuven, Belgium). Authentic standard flavor compounds for olfactometry were of pure grade (purity >98%) from Sigma-Aldrich. Milli-Q water was used (Millipore, Bedford, MA, USA). 2.2. Beer Samples and Aging Procedure A total of 18 commercial, top-fermented, late-hopped beers (here listed as A–R for reasons of confidentiality) were kindly supplied by Belgian craft brewers. All were bottle-refermented, except beers A and B. Six representative samples (A–F), same lot as above, were further selected for more in-depth investigations through natural aging (20 ◦ C in the dark). The main characteristics of these beers are depicted in Table 1. Table 1. Main characteristics of the six selected craft beers. Beer Alcohol (% vol) Real Extract (◦ P) pH Bitterness (BU) Color (EBC) Sensorial Characteristics A B C* D* E* F* 6.5 12.3 7.9 8.8 8.1 7.5 4.6 6.6 5.1 5.8 4.2 3.7 4.2 4.4 4.5 4.4 4.4 4.5 15 20 21 14 29 24 12.5 25 16.5 66 14.5 15.5 Butter, apple, hop, green Alcohol, banana, cheese, phenols Butter, sulfur, hop Malt, sulfur, green Lemon, banana, apple, spicy, phenols Orange, pineapple, spicy, phenols *: with bottle refermentation. Beverages 2019, 5, 39 3 of 11 2.3. Short-chain Fatty Acid Analysis First, 100 µL of internal standard (IST—1000 mg/L nonanoic acid) was added to 10 mL of beer in a 20-mL vial flask, which was immediately closed and shaken for 10 s. Then, 300 µL of n-hexanol was added before shaking again for 5 min. Compounds were recovered in assembled n-hexanol fractions after 2 successive centrifugations (14,000 rpm) [32]. Next, 1 µL of extract was analyzed on an Agilent 6890N gas chromatograph equipped with a split injector maintained at 200 ◦ C (split ratio = 73.6). The FID (flame ionization detector) was set at 220 ◦ C. Compounds were injected into a CP-Wax 58 column (Agilent, 60 m × 0.32 mm i.d., 0.5-µm film thickness). The carrier gas was nitrogen, and the pressure was set at 60 kPa. The oven temperature was programmed to rise from 125 to 140 ◦ C at 8 ◦ C/min and then to 180 ◦ C at 15 ◦ C/min. Quantitation was done by determining the relative response of each compound to IST (done by standard addition to beer B). Results are expressed as the average of duplicates. 2.4. Static Headspace Analysis of Esters Prior to analysis, the beers were stored for 2 h at 4 ◦ C to avoid excessive foaming. The whole procedure was carried out in a cold room (4 ◦ C). Then, 40 µL of internal standard (IST, 2500 mg/L 2-pentanol) and 1.9 g of sodium chloride were added to 5 mL of beer in a 20-mL screw vial flask, which was closed immediately and kept closed until analysis. A total of 500 µL of extract were analyzed on a Thermo Finnigan Trace gas chromatograph, equipped with a splitless injector maintained at 250 ◦ C; the split vent was opened 1 min post-injection. The FID detector was set at 260 ◦ C. Compounds were injected into a VF-Wax MS column (Agilent, 60 m × 0.32 mm i.d., 0.5-µm film thickness). The carrier gas was nitrogen, and the pressure was set at 100 kPa. The oven temperature was programmed to rise from 40 to 140 ◦ C at 8 ◦ C/min and then to 180 ◦ C at 15 ◦ C/min. Quantitation was performed by standard addition (relative response of each compound to IST). Results are expressed as the average of duplicates. 2.5. Flavor XAD-2 Extraction and Gas Chromatography—Olfactometry Analytical Conditions An extraction procedure based on that of Lermusieau et al. [33], was used to recover aroma compounds from beer. First, 4 g of XAD-2 resin were added to 50 mL of beer in a 250-mL flask. The flask was sealed with a Teflon-lined cap and shaken in the dark for 2 h at 200 rpm. After extraction, the contents were poured into a glass column with a coarse frit and Teflon stopcock, and the liquid was drained off, leaving a small bed of resin, which was further rinsed with 100 mL of distilled water (4 × 25 mL). Aroma compounds were then eluted with 40 mL of diethyl ether (2 × 20 mL). The extract was dried with Na2 SO4 and concentrated to 0.5 mL in a Kuderna-Danish evaporator at 39 ◦ C. A Chrompack CP9001 gas chromatograph equipped with a splitless injector maintained at 250 ◦ C was used for the olfactometry analyses, and the split vent was opened after 0.5 min. Compounds were separated using a wall-coated open-tubular (WCOT) apolar CP SIL5 CB capillary column (Agilent, 50 m × 0.32 mm, 1.2-µm film thickness) connected to a GC-odor port at 250 ◦ C. The eluent was diluted with a large volume of air (20 mL/min) previously humidified using aqueous copper (II) sulfate solution. The oven temperature was programmed from 36 to 85 ◦ C at 20 ◦ C/min, to 145 ◦ C at 1 ◦ C/min, to 250 ◦ C at 3 ◦ C/min, and then to remain constant at 250 ◦ C for 30 min. A volume of 1 µL of extract was injected. Sniffing was performed by two experienced panelists. Serial dilutions were prepared from the initial XAD-2 extract at a ratio of 1:3n in diethyl ether. The dilution factor (FD) was calculated as 3n , n + 1 being the number of dilutions (factor 3) required for no odor to be perceived (Log3 FD values in Table 2 equal to 0, 1, 2, . . ., 10, nd if no odor detected for the undiluted extract). The difference between two Log3 FD becomes significant when above 1. Beverages 2019, 5, 39 4 of 11 Table 2. GC-olfactometric analysis of XAD-2 extracts issued from beers A, C, E, and F (fresh and after 6 months of storage at 20 ◦ C). RI: retention index; nd: not detected. Log3 FD A C E F Compound RI Odor Fresh Aged Fresh Aged Fresh Aged Fresh Aged Ethyl butyrate 778 Red fruits 1 1 4 6 nd 3 3 4 3-Methyl-2buten-1-thiol 809 Garlic, hoppy 7 8 7 8 10 10 10 10 Isovaleric acid 811 Sweat, rancid 2 2 2 2 4 5 5 5 2-Methylbutanoic acid 828 Sweat 2 2 2 2 4 5 3 6 2-Methyl-3furanthiol 850 Broth 5 7 5 2 10 10 10 10 Isoamyl acetate 854 Fruity, banana 1 1 2 2 nd nd nd nd Ethyl hexanoate 979 Fruity, candy 2 2 4 4 3 4 4 4 Furaneol 1037 Cotton candy 4 5 6 7 5 5 4 7 Linalool 1089 Flowery, coriander 7 6 6 7 nd nd 5 2 trans-2-Nonenal 1127 Cardboard nd 6 nd 5 3 4 4 5 Citronellol 1216 Fruity, flowery nd nd 1 4 3 2 nd 8 4-Vinylguaiacol 1294 Clove 3 4 4 4 5 6 4 6 γ-Nonalactone 1327 Coconut nd 3 0 4 1 2 3 5 Vanillin 1365 Vanilla 0 nd 6 7 nd 4 1 5 β-Damascenone 1374 Fruity, apricot 2 3 4 5 4 4 3 6 4-Vinylsyringol 1543 Clove 3 3 0 3 2 3 5 5 2.6. Sensory Analyses A group of 10 panelists (all trained scientists, non-smokers, and regular consumers of craft beers, including three women and seven men aged 23–55 years) scored four aging attributes on a scale of 0–4: cardboard, bread, cooked fruit, and dried fruit. A score of 0 meant the panelist did not detect the aroma, whereas a score of 4 meant the aroma was strongly perceived. 3. Results and Discussion 3.1. Short-Chain Fatty Acids GC analyses revealed considerable variability of short-chain fatty acid profiles among fresh Belgian craft beers (Figure 1). Most samples contained isovaleric acid (Figure 1a) at a concentration above its threshold (1 mg/L) [34]. In all cases, on the other hand, hexanoic (Figure 1b), octanoic (Figure 1c), and decanoic acids (Figure 1d) were below their sensory thresholds (10, 10, and 5 mg/L, respectively [35]). A good correlation (R2 = 0.72) was found, as expected, between the concentrations of hexanoic acid and octanoic acid (Figure 2). Beverages 2019, 5, 39 Beverages 2019, 4, x FOR PEER REVIEW Beverages 2019, 4, x FOR PEER REVIEW 5 of 11 5 of 11 5 of 11 Octanoic acid (mg/L) Octanoic acid (mg/L) Figure 1. Concentrations of isovaleric (a), hexanoic (b), octanoic (c), and decanoic (d) acids (mg/L) in Figure 1.Belgian Concentrations of The isovaleric (a), hexanoic (b), octanoic (c),the and decanoic (d) (d) acidsthreshold (mg/L) in in 18 fresh1. craft beers. dotted(a), lines in each(b), graph indicate compound sensory Figure Concentrations of isovaleric hexanoic octanoic (c), and decanoic acids (mg/L) 18fresh freshBelgian Belgiancraft craft beers. The dotted lines in each graph indicate the compound sensory threshold (Thr.). 18 beers. The dotted lines in each graph indicate the compound sensory threshold (Thr.). (Thr.). 12 12 10 10 8 8 6 6 4 4 2 2 0 0 0 0 R² = 0.7281 R² = 0.7281 2 4 6 Hexanoic acid (mg/L) 2 4 6 Hexanoic acid (mg/L) Figure 2. Correlation between the concentrations (mg/L) of octanoic acid and hexanoic acid (in Figure 2. Correlation between the concentrations (mg/L) of octanoic acid and hexanoic acid (in eighteen Figure 2.fresh Correlation between the concentrations (mg/L) of octanoic acid and hexanoic acid (in eighteen beers: A–R). fresh beers: A–R). eighteen fresh beers: A–R). In acids were determined after 3, 6, 12 In aa representative representativeset setofofbeers beers(A–F), (A–F),short-chain short-chainfatty fatty acids were determined after 3, and 6, and In aofrepresentative set of beers (A–F), short-chain fatty acids were determined after 3, 6, and 12 months natural aging (Figure 3). No increase in isovaleric, hexanoic, octanoic, or decanoic acid 12 months of natural aging (Figure 3). No increase in isovaleric, hexanoic, octanoic, or decanoic acid months of natural observed aging (Figure 3). No increase in isovaleric, hexanoic, octanoic, isorthe decanoic acid concentration concentration was was observed over over the the aging aging period. period. Worth Worth mentioning, mentioning, however, however, is the significant significant concentration was observed over the aging period. Worth mentioning, however, is the significant decrease in octanoic acid in beer C (Figure 3C). This was the only beer tested here in decrease in octanoic acid in beer C (Figure 3C). This was the only beer tested here in which which the the decrease in octanoic acid in beer C (Figure 3C).before This was theInonly beer tested here in which the concentration aging. concentration of of this this compound compound reached reached 99 mg/L mg/L before aging. In conclusion, conclusion, bottle bottle refermentation refermentation concentration of this compound reached 9 mg/L beforenatural aging. In conclusion, bottle refermentation does does not not cause cause significant significant release release of of fatty fatty acids acids through through natural aging aging and and thus thus does does not not negatively negatively does not cause significant release of fatty acids through natural aging and thus does not negatively impact flavor. impact flavor. impact flavor. Beverages 2019, 5, 39 Beverages 2019, 4, x FOR PEER REVIEW 6 of 11 6 of 11 Unrefermented Isovaleric acid Hexanoic acid Octanoic acid Decanoic acid A 8 6 4 2 10 Concentration (mg/L) Concentration (mg/L) 10 B 8 6 4 2 0 0 Fresh 3 months Fresh 6 months 12 months 3 months 6 months 12 months Bottle-refermented 10 C Concentration (mg/L) Concentration (mg/L) 10 8 6 4 2 6 4 2 0 0 Fresh 3 months 6 months 12 months Fresh 3 months Fresh 3 months 6 months 12 months 10 10 E Concentration (mg/L) Concentration (mg/L) D 8 8 6 4 2 0 F 8 6 4 2 0 Fresh 3 months 6 months 12 months 6 months 12 months Figure 3. Concentrations (mg/L) of isovaleric acid (▲), hexanoic acid (■), octanoic acid (●), and Figure 3. Concentrations (mg/L) of isovaleric acid (N), hexanoic acid (), octanoic acid (), and decanoic decanoic acid (♦) in fresh beers (A–F) and their evolution during natural aging (3, 6, and 12 months). acid () in fresh beers (A–F) and their evolution during natural aging (3, 6, and 12 months). Variation Variation coefficients under 5%. coefficients under 5%. 3.2.Esters Esters 3.2. Esterswere weredetermined determinedon onthe thesame samesampling samplingofofcraft craftbeers beers(A–F) (A–F)ininthe thecourse courseofofone oneyear yearofof Esters 2= 2 = 0.86) was again observed between naturalaging aging(Figure (Figure4).4).For Forfresh freshbeers, beers,a astrong strongcorrelation correlation(R(R natural 0.86) was again observed between theconcentrations concentrations ethyl hexanoate and ethyl octanoate (Figure although did the ofof ethyl hexanoate and ethyl octanoate (Figure 5a), 5a), although thesethese esterester levelslevels did not not correlate well the withhexanoic the hexanoic and octanoic concentrations (Figure hexanoate correlate well with and octanoic acids acids concentrations (Figure 5b,c). 5b,c). Ethyl Ethyl hexanoate and and ethyl octanoate, were found very to close tosensory their sensory thresholds (0.20.9 and 0.9 mg/L, respectively ethyl octanoate, were found very close their thresholds (0.2 and mg/L, respectively [36]) in allsamples fresh samples and remained relatively stableaging, during aging, with no significant in[36]) all fresh and remained relatively stable during with no significant differencedifference between between the unrefermented and B) and bottle-refermented (C–F) samples. On the otherthe hand, the the unrefermented (A and B)(A and bottle-refermented (C–F) samples. On the other hand, fruity fruity banana-like wasto found to be partially degraded throughout the of storage banana-like isoamylisoamyl acetate acetate was found be partially degraded throughout the year ofyear storage in all in allexcept beersBexcept B (characterized byhigher a much higher level of ethanol, 1). trend The similar trend beers (characterized by a much level of ethanol, Table 1). TheTable similar observed in A and C–F esters can be broken down even without releaseupon of esterases Aobserved and C–F in confirms thatconfirms esters canthat be broken down even without the release ofthe esterases yeast upon yeast In all of the beers, the isoamyl acetate concentration remained above the sensory autolysis. In autolysis. all of the beers, the isoamyl acetate concentration remained above the sensory threshold threshold (0.5after mg/Lone [37]) after one year. (0.5 mg/L [37]) year. Beverages 2019, 5, 39 Beverages 2019, 4, x FOR PEER REVIEW 7 of 11 7 of 11 Concentration (mg/L) 6.0 Isoamyl acetate Ethyl hexanoate Ethyl octanoate A 4.5 3.0 1.5 0.0 Concentration (mg/L) Unrefermented 6.0 B 4.5 3.0 1.5 0.0 Fresh 3 months 6 months 12 months Fresh 3 months 6 months 12 months Bottle-refermented 6.0 C Concentration (mg/L) Concentration (mg/L) 6.0 4.5 3.0 1.5 Fresh 3.0 1.5 3 months 6 months 12 months 6.0 E Concentration (mg/L) Concentration (mg/L) 4.5 0.0 0.0 6.0 D 4.5 3.0 1.5 0.0 Fresh 3 months 6 months 12 months Fresh 3 months 6 months 12 months F 4.5 3.0 1.5 0.0 Fresh 3 months 6 months 12 months Figure 4. Concentrations (mg/L) of isoamyl acetate (▲), ethyl hexanoate (■), and ethyl octanoate (●) Figure 4. Concentrations (mg/L) of isoamyl acetate (N), ethyl hexanoate (), and ethyl octanoate () in in fresh beers (A–F) and their evolution during natural aging (3, 6, and 12 months). Variation fresh beers (A–F) and their evolution during natural aging (3, 6, and 12 months). Variation coefficients coefficients under 5%. under 5%. Beverages 2019, 5, 39 8 of 11 Beverages 2019, 4, x FOR PEER REVIEW 0.8 (a) Ethyl hexnaoate (mg/L) Ethyl octanoate (mg/L) 1.2 8 of 11 1.0 0.8 0.6 0.4 0.2 R² = 0.8665 0.0 0.0 0.2 0.4 0.6 Ethyl hexanoate (mg/L) Ethyl octanoate (mg/L) 1.2 0.8 (b) 0.7 0.6 0.5 0.4 0.3 0.2 0.1 R² = 0.2476 0.0 0 2 4 Hexanoic acid (mg/L) 6 (c) 1.0 0.8 0.6 0.4 0.2 R² = 0.0985 0.0 0 2 4 6 8 Octanoic acid (mg/L) 10 Figure 5. 5. Correlations (mg/L) (a)(a) ethyl octanoate andand ethyl hexanoate, (b) Figure Correlationsbetween betweenthe theconcentrations concentrations (mg/L) ethyl octanoate ethyl hexanoate, ethyl hexanoate and hexanoic acid, and (c) ethyl octanoate and octanoic acid (in six fresh beers: A–F). (b) ethyl hexanoate and hexanoic acid, and (c) ethyl octanoate and octanoic acid (in six fresh beers: A–F). 3.3. Olfactive Analysis of XAD-2 Extracted Flavors Samples A, A,C,C,E,E, and F blond (all blond to the avoid the complexity special malt-derived and F (all beersbeers to avoid complexity of specialofmalt-derived molecules molecules largely investigated [5,17]) were subjected XAD-2 resin extraction largely investigated elsewhere elsewhere [5,17]) were subjected to XAD-2toresin extraction followedfollowed by GCby GC-olfactometric analysis. Beer odor intensities were determined by theextract aromadilution extract olfactometric (GC-O)(GC-O) analysis. Beer odor intensities were determined by the aroma dilution To focus on beer flavor-active compounds, Table22 only only those analysis analysis (AEDA)(AEDA) [38]. To[38]. focus on beer flavor-active compounds, we we listlist in inTable compounds whose FD was as high as that of ethyl ethyl hexanoate, hexanoate, an ester known to be present in the the samples at concentrations concentrations close close to to its its sensory sensory threshold. threshold. 3-Methyl-2-buten-1-thiol 3-Methyl-2-buten-1-thiol(Log (Log33FD FD== 7–10, a pleasant hoppy flavor here but also known as skunky at aa much much higher higher level level[22]), [22]),2-methyl-3-furanthiol 2-methyl-3-furanthiol(Log (Log33FD FD == 2–10, broth), broth), furaneol furaneol (Log (Log33FD = = 4–7, cotton FD = 2–7, flowery/coriander) emerged as the most potent odorants in cotton candy), candy),and andlinalool linalool(Log (Log 3 FD = 2–7, flowery/coriander) emerged as the most potent odorants 3 all four beers. TheThe persistent detection of 4-vinylguaiacol (Log(Log 3–6) in allinsamples indicates that in all four beers. persistent detection of 4-vinylguaiacol FD = 3–6) all samples indicates 3 FD 3= that POF(+) strains bybrewers. the brewers. POF(+) strains had had beenbeen usedused by the already mentioned mentioned above, even in bottle-refermented bottle-refermented beers (C, E, and and F), F), isoamyl isoamyl acetate acetate As already (Log33FD ==1–2, in E F due thetostrong previous odor) and ethyl hexanoate (Log3FD (Log 1–2,undetectable undetectable inand E and F to due the strong previous odor) and ethyl hexanoate = 2–4) showed good stability through aging, with no significant changes in FD. On the other hand, (Log FD = 2–4) showed good stability through aging, with no significant changes in FD. On the other 3 the red-fruit ethyl ethyl butyrate was produced during storage in the beers (from not hand, the red-fruit butyrate was produced during storage inbottle-refermented the bottle-refermented beers (from detected to Log 3FD3= 3 in E and fromfrom 4 to 46 to in 6beer C). C). not detected to Log FD = beer 3 in beer E and in beer Although trans-2-nonenal trans-2-nonenalshowed showedan anincrease increasein in all all four four beers beers during during aging, aging, the the highest highest FD jump Although was observed observed for for the the unrefermented unrefermented A A (from (fromnot notdetected detectedto toLog Log33FD FD = = 6). was interesting result result was the strong increase, especially in aged beer F, F, of compounds suspected An interesting released during storage through through glucoside glucoside hydrolysis: hydrolysis: citronellol, 4-vinylguaiacol, vanillin, and to be released β-damascenone [39,40]. [39,40]. In Inthis thiscase, case,the theselected selected yeast clearly brought flavors F, explaining β-damascenone yeast clearly brought newnew flavors to F,to explaining why why some consumers prefer the six-month-aged efficiency of the yeast β-1,3-glucanase some consumers may may prefer the six-month-aged beer.beer. TheThe efficiency of the yeast β-1,3-glucanase or or β-glucosidase should be taken into account to predict the amounts inaglycons which aglycons can be β-glucosidase should be taken into account to predict the amounts in which can be released released through aging. Linalool (detected in fresh beers A, C, and F) was the sole hop terpenol found Beverages 2019, 5, 39 Beverages 2019, 4, x FOR PEER REVIEW 9 of 11 9 of 11 through aging. Linalool beers A, C, andterpenol F) was biotransformations the sole hop terpenol found to to decrease in beer F (Log3(detected FD from 5intofresh 2), suggesting yeast in the bottle decrease in beer F (Log FD from 5 to 2), suggesting yeast terpenol biotransformations in the bottle [41]. [41]. 3 3.4. Sensory Analyses Analyses 3.4. Sensory Beers Beers A–F A–F were were investigated investigated by by aa trained trained panel panel while while fresh fresh and and then then after after 33 and and 66 months months of of storage. As suspected from the GC-olfactometry results, unrefermented beers A and B developed storage. As suspected from the GC-olfactometry results, unrefermented beers A and B developed a arelatively relativelyintense intensecardboard cardboardflavor flavor(trans-2-nonenal), (trans-2-nonenal),already alreadystrongly strongly perceived perceived after after 33 months months (Figure 6). Despite the increase in FD for furaneol and β-damascenone after 6 months (Figure 6). Despite the increase in FD for furaneol and β-damascenone after 6 months of of storage, storage, the the attributes attributes bread, bread, dried dried fruit, fruit, and and cooked cooked fruit fruit remained remained absent absent or or relatively relativelyweak. weak. A 3 2 F B 1 0 E C D Fresh 3 months 6 months Figure 6.6. Spider Spiderdiagram diagramofof cardboard flavor intensity in fresh (●),naturally and naturally and 6 Figure cardboard flavor intensity in fresh (), and aged (3aged and 6(3 months) months) beers (A–F). beers (A–F). 4. Conclusions Bottle refermentation of craft beers can be promoted for its ability both to protect beer against against oxidation, (this protection is required to avoid colloidal instability, bitterness decrease, and aroma bitterness loss) and to avoid the accumulation of trans-2-nonenal through enzymatic reduction to nonenol and nonanol. inin thethe bottle proved notnot so deleterious as itas regards fatty fatty acid nonanol. Moreover, Moreover,the thepresence presenceofofyeast yeast bottle proved so deleterious it regards excretion and ester hydrolysis during the first year of storage, while leading to the release of interesting acid excretion and ester hydrolysis during the first year of storage, while leading to the release of terpenols phenolsand from aglycons. interestingand terpenols phenols from aglycons. Author Conceptualization, S.C.; S.C.; Data Data curation, curation, C.S.F., C.S.F., E.B., E.B., and and S.C.; S.C.; Formal Formal analysis, analysis, C.S.F., C.S.F., E.B., E.B., Author Contributions: Contributions: Conceptualization, and S.C.; Writing—original draft, C.S.F. and S.C. and S.C.; Writing—original draft, C.S.F. and S.C. Funding: This research received no dedicated funding. Funding: This research received no dedicated funding. Conflicts of Interest: The authors declare no conflicts of interest. Conflicts of Interest: The authors declare no conflicts of interest. References References 1. 1. 2. 2. 3. 3. Pires, E.J.; Teixeira, J.A.; Brányik, T.; Vicente, A.A. Yeast: The soul of beer’s aroma—A review of flavour-active Pires, E.J.; Teixeira, J.A.; Brányik, T.; by Vicente, A.A. Yeast: soul of beer’sBiotechnol. aroma—A2013, review flavouresters and higher alcohols produced the brewing yeast.The Appl. Microbiol. 98, of 1937–1949. active esters and higher alcohols produced by the brewing yeast. Appl. Microbiol. Biotechnol. 2013, 98, 1937– [CrossRef] [PubMed] 1949. Saerens, M.G.; Verstrepen, K.; Thevelein, J.; Delvaux, F. Ethyl esters production during brewery fermentation: Saerens, Verstrepen, K.; Thevelein, J.; Delvaux, F. Ethyl esters production during brewery A review. M.G.; Cerevisia 2008, 33, 82–90. fermentation: A review. Cerevisia 33, 82–90. B.; Delvaux, F.R. Ferulic acid release and 4-vinylguaiacol Coghe, S.; Benoot, K.; Delvaux, F.;2008, Vanderhaegen, Coghe, S.; Benoot, Delvaux, Vanderhaegen, B.; Delvaux, Ferulic acid release andin4-vinylguaiacol formation during K.; brewing andF.; fermentation: Indications forF.R. feruloyl esterase activity Saccharomyces formation during brewing and fermentation: Indications for feruloyl esterase activity in Saccharomyces cerevisiae. J. Agric. Food Chem. 2004, 52, 602–608. [CrossRef] [PubMed] cerevisiae. J. Agric. Food Chem. 2004, 52, 602–608. Beverages 2019, 5, 39 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 10 of 11 Coghe, S.; Martens, E.; D’Hollander, H.; Dirinck, P.J.; Delvaux, F. Sensory and instrumental flavour analysis of wort brewed with dark specialty malts. J. Inst. Brew. 2004, 110, 94–103. [CrossRef] Vandecan, S.M.G.; Daems, N.; Schouppe, N.; Saison, D.; Delvaux, F. Formation of flavor, color, and reducing power during the production process of dark specialty malts. J. Am. Soc. Brew. Chem. 2011, 69, 150–157. [CrossRef] Gros, J.; Peeters, F.; Collin, S. Occurrence of odorant polyfunctional thiols in beers hopped with different cultivars. First evidence of an S-cysteine conjugate in hop (Humulus lupulus L.). J. Agric. Food Chem. 2012, 60, 7805–7816. [CrossRef] Kankolongo Cibaka, M.-L.; Ferreira, C.S.; Decourrière, L.; Lorenzo-Alonso, C.-J.; Bodart, E.; Collin, S. Dry hopping with the dual-purpose varieties Amarillo, Citra, Hallertau Blanc, Mosaic, and Sorachi Ace: minor contribution of hop terpenol glucosides to beer flavors. J. Am. Soc. Brew. Chem. 2017, 75, 122–129. Kankolongo Cibaka, M.-L.; Decourrière, L.; Lorenzo-Alonso, C.-J.; Bodart, E.; Robiette, R.; Collin, S. 3-Sulfanyl-4-methylpentan-1-ol in dry-hopped beers: first evidence of glutathione S-Conjugates in hop (Humulus lupulus L.). J. Agric. Food Chem. 2016, 64, 8572–8582. [CrossRef] Dalgliesh, C.E. Flavour stability. In Proceedings of the European Brewery Convention: Proceedings of the 16th Congress, Amsterdam, The Netherlands, 1977; pp. 623–659. Noël, S.; Liegeois, C.; Lermusieau, G.; Bodart, E.; Badot, C.; Collin, S. Release of deuterated nonenal during beer aging from labeled precursors synthesized in the boiling kettle. J. Agric. Food Chem. 1999, 47, 4323–4326. [CrossRef] Lermusieau, G.; Noël, S.; Liegeois, C.; Collin, S. Nonoxidative mechanism for development of trans-2-nonenal in beer. J. Am. Soc. Brew. Chem. 1999, 57, 29–33. [CrossRef] Zufall, C.; Racioppi, G.; Gasparri, M.; Franquiz, J. Flavour stability and ageing characteristics of light stable beers. In Proceedings of the European Brewery Convention Congress, Prague, Czech Republic, 2–5 October 2005; p. 30. Silva Ferreira, C.; Thibault de Chanvalon, E.; Bodart, E.; Collin, S. Why humulinones are key bitter constituents only after dry hopping: comparison with other Belgian styles. J. Am. Soc. Brew. Chem. 2018, 76, 236–246. [CrossRef] Clapperton, J.F. Ribes flavor in beer. J. Inst. Brew. 1976, 82, 175–176. [CrossRef] Thi Thu, H.T.; Nizet, S.; Gros, J.; Collin, S. Occurrence of the ribes odorant 3-sulfanyl-3-methylbutyl formate in aged beers. Flavour Fragr. J. 2013, 28, 147–179. Scholtes, C.; Nizet, S.; Collin, S. How sotolon can impart a Madeira off-flavor to aged beers. J. Agric. Food Chem. 2015, 63, 2886–2892. [CrossRef] [PubMed] Scholtes, C.; Nizet, S.; Collin, S. Guaiacol and 4-methylphenol as specific markers of torrefied malts. Fate of volatile phenols in special beers through aging. J. Agric. Food Chem. 2014, 62, 9522–9528. [CrossRef] [PubMed] Thi Thu, H.T.; Kankolongo Cibaka, M.-L.; Collin, S. Polyfunctional thiols in fresh and aged Belgian special beers: fate of hop S-cysteine conjugates. J. Am. Soc. Brew. Chem. 2015, 73, 61–70. Vanderhaegen, B.; Neven, H.; Daenen, L.; Verstrepen, K.J.; Verachtert, H.; Derdelinckx, G. Furfuryl ethyl ether: important aging flavor and a new marker for the storage conditions of beer. J. Agric. Food Chem. 2004, 52, 1661–1668. [CrossRef] Derdelinckx, G.; Vanderhasselt, B.; Maudoux, M.; Dufour, J.P. Refermentation in bottles and kegs: A rigorous approach. Brauwelt Int. 1992, 2, 156–164. Vanderhaegen, B.; Neven, H.; Coghe, S.; Verstrepen, K.J.; Verachtert, H.; Derdelinckx, G. Evolution of chemical and sensory properties during aging of top-fermented beer. J. Agric. Food Chem. 2003, 51, 6782–6790. [CrossRef] Nizet, S.; Gros, J.; Peeters, F.; Chaumont, S.; Robiette, R.; Collin, S. First evidence of the production of odorant polyfunctional thiols by bottle refermentation. J. Am. Soc. Brew. Chem. 2013, 71, 15–22. [CrossRef] Saison, D.; De Schutter, D.P.; Vanbeneden, N.; Daenen, L.; Delvaux, F.; Delvaux, F.R. Decrease of aged beer aroma by the reducing activity of brewing yeast. J. Agric. Food Chem. 2010, 58, 3107–3115. [CrossRef] [PubMed] Ernest, C.-H.; Chen, A.; Jamieson, A.M.; Van Gheluwe, G. The release of fatty acids as a consequence of yeast autolysis. J. Am. Soc. Brew. Chem. 1980, 38, 13–17. Beverages 2019, 5, 39 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 11 of 11 Leroy, M.J.; Charpentier, M.; Duteurtre, B.; Feuillat, M.; Charpentier, C. Yeast autolysis during Champagne aging. Am. J. Enol. Vitic. 1990, 41, 21–28. Masschelein, C.A. The biochemistry of maturation. J. Inst. Brew. 1986, 92, 213–219. [CrossRef] Ormrod, I.H.L.; Lalor, E.F.; Sharpe, F.R. The release of yeast proteolytic enzymes into beer. J. Inst. Brew. 1991, 97, 441–443. [CrossRef] Neven, H.; Delvaux, F.; Derdelinckx, G. Flavor evolution of top fermented beers. MBAA Tech. Q. 1997, 34, 115–118. Gassenmeier, K.; Schieberle, P. Potent aromatic compounds in the crumb of wheat bread (French-type)influence of pre-ferments and studies on the formation of key odorants during dough processing. Z. Lebensm. Unters. Forsch. 1995, 201, 241–248. [CrossRef] Olsen, E. Brettanomyces: Occurrence, flavour effects and control. In Proceedings of the 23rd Annual New York Wine Industry Workshop, New York, NY, USA, 23–24 March 1994. Fugelsang, K.C. Wine Microbiology; The Chapman & Hall Enology Library: New York, NY, USA, 1997. Alvarez., P.; Malcorps, P.; Sa Almeida, A.; Ferreira, A.; Meyer, A.M.; Dufour, J.P. Analysis of free fatty acids, fusel alcohols, and esters in beer: an alternative to CS2 extraction. J. Am. Soc. Brew. Chem. 1994, 52, 127–134. [CrossRef] Lermusieau, G.; Bulens, M.; Collin, S. Use of GC−Olfactometry to identify the hop aromatic compounds in beer. J. Agric. Food Chem. 2001, 49, 3867–3874. [CrossRef] Licker, J.L.; Acree, T.E.; Henick-Kling, T. What is “Brett” (Brettanomyces) flavour? A preliminary investigation. In Chemistry of Wine Flavour; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 1998; pp. 96–115. Meilgaard, M. Flavor and threshold of beer volatiles. MBAA Tech. Q. 1974, 11, 87–89. Engan, S. Organoleptic threshold of some alcohols and esters in beer. J. Inst. Brew. 1971, 78, 33–36. [CrossRef] Saison, D.; De Schutter, D.P.; Uyttenhove, B.; Delvaux, F.; Delvaux, F.R. Contribution of staling sompounds to the aged flavor of lager beer by studying their flavor thresholds. Food Chem. 2009, 114, 1206–1215. [CrossRef] Ullrich, F.; Grosch, W. Identification of the most intensive volatile flavour compounds formed during autoxidation of linoleic acid. Z. Lebensm. Unters. Forsch. 1987, 184, 277–282. [CrossRef] Callemien, D.; Dasnoy, S.; Collin, S. Identification of a stale-beer-like odorant in extracts of naturally aged beer. J. Agric. Food Chem. 2006, 54, 1409–1413. [CrossRef] [PubMed] Chevance, F.; Guyot, C.; Dupont, J.; Collin, S. Investigation of the β-damascenone in fresh and aged commercial beers. J. Agric. Food Chem. 2002, 50, 3818–3821. [CrossRef] [PubMed] King, A.J.; Dickinson, J.R. Biotransformation of hop aroma terpenoids by ale and lager yeasts. FEMS Yeast Res. 2003, 3, 53–62. [CrossRef] [PubMed] © 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).