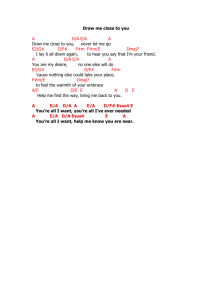

International Journal of Trend in Scientific Research and Development (IJTSRD) Volume 4 Issue 5, July-August 2020 Available Online: www.ijtsrd.com e-ISSN: 2456 – 6470 Computational Fluid Dynamics Analysis of Exhaust Heat Exchanger for TED Abhimanyu Pal1, N. V. Saxena2 1Research Scholar, 2Assistant Professor, 1,2Department of Mechanical Engineering, MIT, Bhopal, Madhya Pradesh, India ABSTRACT Lately with the headway of thermo-electric materials, direct change of warmth vitality into electrical vitality gets conceivable. Thermoelectric innovation is utilized for recuperating heat vitality loses from motor fumes gases. The force produced by thermoelectric innovation is called as thermoelectric force. In thermo-electric force age a fumes heat exchanger is utilized for recouping exhaust heat and a thermo-electric module is utilized for changing over warmth into power. The current examination was expected to improve the structure of fumes heat exchanger by expelling inside blades and changing the cross-sectional region of warmth exchanger to conquer issue of weight drop. The structures of fumes heat exchangers considered in the past exploration works recouped most extreme warmth from the fumes of a motor However issue of weight drop or back weight was watched affecting motor execution and working. Higher back weight can break down and harm motor bringing about stoppage of motor working. Computational liquid elements (CFD) was utilized in the recreation of the fumes gases streaming inside the warmth exchanger. The isothermal displaying strategy was utilized in recreation procedure of the warmth exchanger. The warm reenactment is done on heat exchanger to check the surface temperature, heat move rate, and weight drop in three distinctive test conditions (urban driving, rural driving and max. power driving) of a vehicle with 1.2 L petroleum motor. Rectangular molded warmth exchanger was utilized in ventilation system of interior burning motor (ICE) is demonstrated numerically to recoup the lost warmth from motor fumes. The examination uncovered that Rectangular molded warmth exchanger with progressively expanding cross sectional region limited weight drop and achieves higher temperature and warmth move rate at the surface. The mean surface temperatures acquired after CFD examination are 459K, 555K, and 791K for the three test conditions. The weight drop for the three test conditions are 24.14 Pa, 182.5 Pa and 5.413 Kpa and that is inside as far as possible. How to cite this paper: Abhimanyu Pal | N. V. Saxena "Computational Fluid Dynamics Analysis of Exhaust Heat Exchanger for TED" Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 2456-6470, Volume-4 | Issue-5, August 2020, pp.816IJTSRD33006 821, URL: www.ijtsrd.com/papers/ijtsrd33006.pdf Copyright © 2020 by author(s) and International Journal of Trend in Scientific Research and Development Journal. This is an Open Access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0) (http://creativecommons.org/licenses/by /4.0) KEYWORDS: Exhaust gases, waste heat recovery, Thermo-Electric power, Exhaust Heat Exchanger, Thermo-Electric module 1. INTRODUCTION In the present situation there are loads of issue with respect to vitality emergency and warm administration. The motor fumes the board is the significant subject of conversation for car ventures as of late and in Internal burning motors, loads of warmth is squandered as fumes gases and out of the absolute warmth vitality provided to the motor ignition chamber as fuel roughly 30-40% is been changed over into valuable work and the staying one is ousted as fumes gases and this fumes gases contains a ton of warmth that can be recouped by utilizing a waste warmth recuperation framework. The temperature of the fumes gases after the exhaust system is between 300-600ºcentigrade. Thermoelectric innovation assumes a crucial job in producing electrical force from heat, temperature contrasts and temperature inclinations. Thermo-electric force generators are little with no moving parts and they are generally productive at these temperatures so they are goals in such applications. @ IJTSRD | Unique Paper ID – IJTSRD33006 | In following fig the fuel vitality conveyance after ignition in gas motor is appeared. About 40% of the warm vitality of the fuel infused to an IC motor is dismissed as fumes gases as waste warmth. When contrasted with heat dismissed through coolant and greasing up oil a great deal of warmth is ousted through fumes gases at extremely high temperatures. In autos, large and overwhelming alternators are associated with the motors so as to fulfill the expanding electrical needs of various embellishments. An alternator which works at a productivity of 50 to 62% devours around 1 to 5% of the evaluated motor work yield. On the off chance that around 6% of waste warmth can be used from the motors fumes, it can satisfy the electrical necessities of our cars and it would have been conceivable to diminish the fuel utilizations about 10%. Along these lines a thermo-electric generator (TEG) can be utilized for changing over vitality from exhaust heat. TEG is like a warmth motor which is utilized believer the warmth vitality into electrical vitality and it essentially deals Volume – 4 | Issue – 5 | July-August 2020 Page 816 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 with the rule of Seebeck impact. In addition TEGs are natural benevolent, exceptionally dependable, work easily and discreetly, requires less support. Figure 1 Fuel Energy Distribution of Gasoline Engine. 2. LITERATURE SURVEY G. Murali , G. Vikram (2019)[1] - CFD models having strong field, liquid field and strong liquid field mix are produced for various warmth exchangers profile to animate disturbance and temperature forms working at same condition. Contrasting four distinctive warmth exchangers, the sequential plate has high pace of warmth move contrasted and other warmth exchangers. Sequential plate heat exchanger pushes the fumes gases to stream in reverse by going through puzzles expanding the pace of warmth move at the outside of warmth exchanger and expanding issue of weight drop. P M Meena (PhD-IITB) et al (2018)[2] - A hypothetical model of TEG will can be made dependent on thermodynamic hypothesis, semiconductor thermoelectric hypothesis, and law of protection of vitality, the conditions of intensity yield and flow of thermoelectric generator (TEG). As indicated by the examination the force yield per unit region is free of the thermo legs and of their cross sectional territory. The force yield is max. at a specific thermocouple length and relies upon different boundaries. Consequently to improve the presentation of TEGs by changing the boundaries and plan procedure. Rohan mathai chandy et al (2018)[3] - In this work a round warmth exchanger with blades connected with the TEGs for recuperating waste warmth from a vehicle exhaust pipe is broke down by performing CFD investigation. As the temperature builds voltage created likewise expanded as voltage is corresponding to the temperature contrast. It is investigated that the warmth exchanger connected among suppressor and exhaust system gives progressively uniform stream appropriation, lower back weight, and higher surface temperature. P. Mohamed Shameer et al (2017)[4] - In this examination work TEG is manufactured for a bike silencer. The presentation of the motor won't be influenced on the grounds that lone the surface warmth of the silencer is drawn out. The primary point of this examination is to move the surface fumes warmth to maintain a strategic distance from the mishaps (Burn-outs) brought about by the overheated silencers, and to move the recouped warmth to helpful electric vitality. The yield could be expanded by interfacing TEGs in arrangement, with the goal that the voltage gets included prompting expanded force. The vitality created from this framework is used in controlling any helper gadgets in a vehicle legitimately or it could be put away in a battery and afterward utilized later. 3. PROBLEM IDENTIFICATION A. As appeared by the writing audit, numerous analyses have been performed and models have been created to assess the presentation and plausibility of fumes heat exchangers for Thermo-electric force age. In light of the work and results from these tests and models, the accompanying perceptions are made: B. There is a need of advancing fumes heat exchanger for expanding the proficiency of thermoelectric force age. C. The Internal balances utilized in the fumes heat exchanger builds heat move rate however at the same time expands pressure drop which creates back weight that can weaken motor execution. D. Due to high weight drop there is an impediment of warmth exchanger to work under fast driving conditions. 4. RESEARCH OBJECTIVES The writing survey shows that the structures of Exhaust heat exchangers are not attempting to their ideal productivity due to the disadvantage of weight drop. The fundamental destinations of present examination work are as per the following: Optimizing the rectangular fumes heat exchanger configuration to conquer the issue of weight drop. CFD investigation to examine impact of upgrading the fumes heat exchanger. Calculating the force created by Thermo-electric generator module. 5. METHODOLOGY By applying speculations of warm convection and violent stream, the three-dimensional model of rectangular warmth exchanger is changed by giving another plan. The equation of convective warmth move Q = h A Δ T, shows that heat convection increments by the warmth move region A. This is accomplished by giving an adequate conduction surface. Another methodology is to expand the convective warmth move coefficient h. Hypothesis of liquid elements proposes that under the state of Reynolds number Re >104, full scale violent liquid stream is a noteworthy factor for improving the pace of warmth move. In addition, the more noteworthy the convective warmth move coefficient h, the better the pace of warmth moves. The warm obstruction of fierce progression of convection generally exists in the limit layer. More alliance between the temperature field and speed field, greater improvement in the pace of warmth move. As indicated by both the speculations referenced over, @ IJTSRD | Unique Paper ID – IJTSRD33006 | Volume – 4 | Issue – 5 | July-August 2020 Page 817 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 the pace of warmth move can be expanded by including tempestuous gadgets or adjusting the geometry to build the liquid choppiness and harm the liquid limit layer. The warmth exchangers comprised of aluminum have gulf and outlet complex breadths as 80mm, the zone at channel as 110x110mm and at the outlet 165x165mm. The divider thickness is about 5mm. From delta of the warmth exchanger the cross segment is seen as expanding progressively to the outlet, which gives smooth communication of the fumes gas with the exchanger dividers. This causes the high temperature fumes gas to diffuse in the whole parallel zone as opposed to gathering in the focal area. Three dimensional perspectives and cross sectional perspective on the warmth exchangers are appeared in Fig.2. Figure 2: Three Dimensional View and Cross Sectional View of Rectangular Heat Exchanger. Figure 3: Meshing of Rectangular heat exchanger. 6. RESULTS AND ANALYSIS The temperature shapes shows that the fumes heat exchanger accomplishes surface mean temperature of 459K for urban driving cycle in fig 4, 555K for sub urban driving cycle in fig 5.3 and 791 K for greatest force driving cycle in fig 5. The chart in the fig 5, 6, 7 shows the variety of temperature along the length at a consistent rate for the three driving conditions. Figure 5: Surface Temperature contour of rectangular heat exchanger for urban driving cycle condition. @ IJTSRD | Unique Paper ID – IJTSRD33006 | Volume – 4 | Issue – 5 | July-August 2020 Page 818 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 TEMPERATURE ˚K 565 545 525 505 485 465 445 425 405 385 0 LENGTH (m) 0.1 0.2 0.3 0.4 0.5 0.6 Figure 6: Surface Temperature Graph for Urban Driving Condition. Figure 7: Surface Temperature contour of rectangular heat exchanger for sub urban driving cycle condition. TEMPERATURE ˚K TEMPERATURE GRAPH 665 645 625 605 585 565 545 525 505 485 LENGTH (m) 0.3 0.4 0.5 0.6 0 0.1 0.2 Figure 8: Surface Temperature Graph for Sub Urban Driving Condition. @ IJTSRD | Unique Paper ID – IJTSRD33006 | Volume – 4 | Issue – 5 | July-August 2020 Page 819 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 TEMPERATURE ˚K Figure 9: Surface Temperature contour of rectangular heat exchanger for Max. Power driving cycle condition. LENGTH (m) Figure 10: Surface Temperature Graph Max. Power Driving Condition. The Fig.5, Fig.6, and Fig.7 show the temperature circulation upon the warmth exchanger surface. From the reenactment it very well may be plainly observed that the rectangular warmth exchanger can give a uniform temperature appropriation, closer to the isothermal model methodology. 7. CONCLUSIONS In this examination rectangular formed fumes heat exchanger is demonstrated and enhanced utilizing PRO-E Software. The computational liquid elements (CFD) examination of the models was finished utilizing ANSYS V.14 FLUENT. The stream in the warmth exchanger was viewed as insecure and tempestuous and conventional divider law was applied. The administering conditions were settled by giving cycles with basic calculation. The weight, speed shapes and temperature circulation of the model are acquired in the wake of applying and fathoming the limit esteem conditions on CFD. CFD examination results uncovered that the plan streamlining of fumes heat exchanger has noteworthy impact on power created limit by TEG module. The @ IJTSRD | Unique Paper ID – IJTSRD33006 | temperature forms s*hows that the surface temperature achieved in rectangular molded fumes heat exchanger with progressively expanding cross sectional zone is uniform and better when contrasted with the past models. The improved rectangular fumes heat exchanger configuration gives mean surface temperature of 459K for urban driving cycle, 555K for sub urban driving cycle and 791 K for most extreme force driving cycle. By expelling the inside balances from the fumes heat exchanger the weight drop is decreased. The weight inclination is uniform all through with ostensible weight drop of 24.15 Pa for urban driving cycle, 182.5 Pa for sub urban driving cycle, 5.413 Kpa for most extreme force driving cycle. From the speed form it is extremely evident that in rectangular molded TEG the fumes is circulated consistently over the profile. The warmth move rate has been expanded as appeared by divider heat motion shapes. Volume – 4 | Issue – 5 | July-August 2020 Page 820 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 The determined force produced by TEG module ranges from 0.5 watt to 5.6 watt. Subsequently, it prompted the end that rectangular molded fumes exchanger could be utilized for thermoelectric force age. 8. SCOPE OF FUTURE WORKS In proposed philosophy, devoted innovative work is required for tackling the issue of vitality emergency for power age. And furthermore chip away at raising advancements by which we increment the pace of intensity age. More innovative work required in the segment of cost enhancement in the field of TEG. In future investigation, the technique for recreation displaying with infrared trial check should be joined with heat move hypothesis and material science to serve for additional auxiliary structure and streamlining of Exhaust heat exchanger, in order to improve the general fumes heat usage and upgrade the force age. More examination work is required on raising innovations by which we increment the pace of intensity age. More innovative work required in the area of structure and cost enhancement in the field of TEG. Innovation would have the option to improve the proficiency of the thermoelectric generators and we should work for improving the temperature of the hot side so we would get more force. This innovation will be advantageous for India as we are confronting the issue of vitality emergency and issue of a worldwide temperature alteration. The examination work could be proceeded with further to concentrate how thermoelectric innovation influences the fuel utilization rate and the other monetary parts of utilizing this innovation. REFERENCES [1] G. Murali , G. Vikram et al, A Study on Performance Enhancement of Heat Exchanger in Thermoelectric Generator using CFD, IJIRST –International Journal for Innovative Research in Science & Technology, ISSN: 2349-6010, Volume 2 Issue 10 , March-2019. [2] Krishna Purohit, P M Meena (PhD-IITB) et al, Review Paper on Optimizations of Thermoelectric System, International Journal of Innovative Research in Engineering & Management (IJIREM), ISSN: 23500557, Volume-3, Issue-4, July-2018. [3] Rohan mathai chandy, Rakesh rajeev et al, Design and analysis of heat exchanger for automotive basesd exhaust thermoelectric generators, IJIRST – International Journal for Innovative Research in Science & Technology, ISSN: 2349-6010, Volume 1 Issue 11 , April-2017. [4] Sugantha priya D, Varatharaj M, Thermoelectric power generator by recovering heat from engine exhaust, International Journal of research in Mechanical Engineering (IJRME), ISSN-2349-3860, Volume 2 Issue 03, March-2015. @ IJTSRD | Unique Paper ID – IJTSRD33006 | [5] P. Mohamed Shameer, D. Christopher, Design of Exhaust Heat Recovery Power Generation System Using Thermo-Electric Generator, International Journal of Science and Research (IJSR) ISSN: 2319-7064, Volume 4 Issue 1, January 2015 [6] Shengqiang Bai, HongliangLu et al, Numerical and experimental analysis for exhaust heat exchangers in automobile thermoelectric generators, journal homepage: www.elsevier.com/locate/csite, ISSN: 99– 112, Issue 4, 2014. [7] Dipak Patil, Dr. R. R. Arakerimath et al, A Review of Thermoelectric Generator for Waste Heat Recovery from Engine Exhaust, International Journal Of Research In Aeronautical And Mechanical Engineering, ISSN: 2321-3051, Issue.8 Vol.1, December 2013 [8] Hazli Rafis, Hamidon A.H et al, Design of DC-DC boost converter with thermoelectric power source, International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering, ISSN: 2278 – 8875, Vol. 2 Issue 9, September 2013. [9] Olle Högblom and Ronnie Andersson CFD Modeling of Thermoelectric Generators in Automotive EGR-coolers, International European conference for thermoelectrics, ISSN-497-500, 2012. [10] C. Ramesh Kumar, Ankit Sonthalia and Rahul Goel, Experimental Study on Waste Heat Recovery from an IC Engine Using Thermoelectric Technology, Center of Excellence for Automotive Research, VIT University, 2011. [11] Karri, M. A., Thacher, E. F., and Helenbrook B. T., Exhaust energy conversion by thermoelectric generator: two case studies, Energy Conversion and Management, in press, 2010. [12] Moran, M. J. and Shapiro, H. N., Fundamentals of Engineering Thermodynamics, Fifth Edition. John Wiley & Sons Inc., 2006. [13] Lee, P-S., Garimella, S. V., and Liu, D, Investigation of heat transfer in rectangular microchannels, International Journal of Heat and Mass Transfer, Volume 48, 2005. [14] DOE award DE-FC26-03NT41974, Hi-Z Technology, Inc., San Diego, California, January, 2004. Kusch, A. Hi Technology, Inc., personal communication, 2005. [15] Douglas T. Crane and Gregory S. Jackson, Optimization of Cross Flow Heat Exchangers for Thermoelectric Waste Heat Recovery. Energy Conversion and Management, 2004. Volume – 4 | Issue – 5 | July-August 2020 Page 821