Defence Standard 61-12 Part 18: Equipment Wires, Fire Hazard

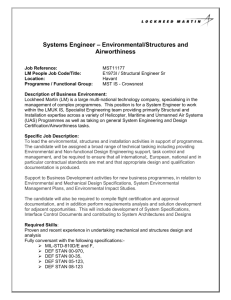

advertisement

Ministry of Defence Defence Standard 61-12 (Part 18)/Issue 4 WIRES, CORDS AND CABLES ELECTRICAL - METRIC UNITS PART 18: EQUIPMENT WIRES, LIMITED FIRE HAZARD This Defence Standard supersedes Def Stan 61-12(Part 18)/ Issue 3 dated 22 June 1990 6 January 1995 DEF STAN 61-12 (PART 18)/4 AMMENDMENTS ISSUED SINCE PUBLICATION AMD NO DATE OF ISSUE TEXT AFFECTED SIGNATURE & DATE Revision Note Issue 4 of this Standard incorporates user comments on the sheath temperature ratings and includes additional 85°C rated cables. Historical Record Issue 2 of this Standard included amendments and additions to bring the Standard more into line with Service requirements. Qualification Approval and certification clauses were amended to invoke Defence Standard 00-9 procedures. Issue 3 of this Standard removes the previous INTERIM status and specifies a reduced toxicity level for Table I items. Items having a toxicity level of greater than 0.2 and up to 1.5 remain in this Standard for maintenance purposes, Table II items. DEF STAN 61-12 (PART 18)/4 WIRES, CORDS AND CABLES ELECTRICAL, METRIC UNITS EQUIPMENT WIRES - LIMITED FIRE HAZARD PREFACE This Defence Standard supersedes Def Stan 61-12 (Part 18) Issue 3 dated 22 June 1990 i This Defence Standard specifies the requirements for, and also lists, equipment wires, having limited fire hazard (LFH) insulation, for Ministry of Defence use. ii It is a performance Standard, actual insulation material is not specified and tests are included to control materials offered for approval. With the development of new materials and/or constructions it is likely that additional tests will require to be devised. iii Tables I(A) to I(E) list the standard range of equipment wires and cables having a toxicity level as defined in 11.4. Tables II(A) to II(E) list the maintenance range of equipment wires and cables. They are manufactured to Issue 2 of this Standard and differ in certain significant features, including a higher toxicity level. iv The items listed in this Standard should only be purchased from those manufacturers holding a current Qualification Approval certificate applicable to the cable or wire required. A list of manufacturers holding approval to items specified in this Standard will be included in Def Stan 59-59 and the EPIC/CODUS data bank. v Users of this Standard are to note that these items may be claimed to be subject to patent rights in this or in other countries. vi This Standard has been agreed by the authorities concerned with its use and is intended to be used whenever relevant in all future designs, contracts, orders etc and whenever practicable by amendment to those already in existence. If any difficulty arises which prevents application of the Defence Standard, the Directorate of Standardization shall be informed so that a remedy may be sought. vii Any enquiries regarding this Standard in relation to an invitation to tender or a contract in which it is incorporated are to be addressed to the responsible technical or supervising authority named in that invitation to tender or contract. vii This Standard has been devised for the use of the Crown and its contractors in the execution of contracts for the Crown. The Crown hereby excludes all liability (other than liability for death or personal injury) whatsoever and howsoever arising (including but without limitation, negligence on the part of the Crown its servants or agents) for any loss or damage however caused where the Standard is used for any other purpose. 1 DEF STAN 61-12 (PART 18)/4 CONTENTS PAGE Preface 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Table Table Table Table Table Table Scope WARNING Related Documents Definitions Type Identification and Colours Materials Construction Testing General Electrical Tests Physical Tests Fire Hazard Tests Qualification Approval Procedures Quality Assurance Requirements Packaging and Labelling A B C D E F Table G Conductor Size and Guide to Current Ratings Details of Conductors Dimensions of Complete Equipment Wires and Cables Mass of Complete Equipment Wires and Cables List of Test Fluids, Additional Requirements Qualification Approval and Quality Assurance Test Applications Specific Test Requirements 4 5 6 7 7 8 8 12 13 13 18 20 21 21 5 10 11 12 15 19 20 Table I(A) ) ) ) ) Standard Range Table I(B) ) Toxicity Index < 0.2 ) ) ( ( ( ( ( ( ( Table I(C) Standard Range Toxicity Index < 0.2 Cables, Special Purpose, Electrical and Cables, Power, Electrical Types 1SB and 2SB Limited Fire Hazard Insulation, Screened 24 Table I(D) Standard Range Toxicity Index < 0.2 Cables, Special Purpose, Electrical and Cables, Power, Electrical Types 1SBM BT, 1SBM 120 and 2SBM Limited Fire Hazard Insulation, Screened and Sheathed 25 Table II(A)) ) ) ) Maintenance Range Table II(B) ) Toxicity Index ) > 0.2 < 1.5 ) ( ( ( ( ( ( ( Equipment Wires, Electrical Type 1 Limited Fire Hazard Insulation, Unscreened 22 Equipment Wires, Electrical Type 2 Limited Fire Hazard Insulation, Unscreened 23 Equipment Wires, Electrical Type 1 Limited Fire Hazard Insulation, Unscreened 26 Equipment Wires, Electrical Type 2 Limited Fire Hazard Insulation, Unscreened 27 2 DEF STAN 61-12 (PART 18)/4 CONTENTS (Contd) Table II(C) Table II(D) Table II(E) Annex A PAGE Maintenance Range Cables, Special Purpose, Electrical 28 Toxicity Index and Cables, Power, Electrical > 0.2 < 1.5 Types 1SB and 2SB Limited Fire Hazard Insulation, Screened Maintenance Range Cables, Special Purpose, Electrical 29 Toxicity Index and Cables, Power, Electrical > 0.2 < 1.5 Types 1SBM and 2SBM Limited Fire Hazard Insulation, Screened and Sheathed Maintenance Range Equipment Wires, Electrical Toxicity Index Type 1 Limited Fire Hazard > 0.2 < 1.5 Bicoloured Insulation Unscreened Type Designator Coding Structure 3 30 A-1 DEF STAN 61-12 (PART 18)/4 SPECIFICATION FOR WIRES, CORDS AND CABLES ELECTRICAL, METRIC UNITS PART 18: EQUIPMENT WIRES, LIMITED FIRE HAZARD 1 Scope 1.1 This specification describes the construction, identification and testing of wires and cables for the internal wiring of electronic or other equipment. 1.2 These wires and cables (ie screened wires) are also used as the cores of multicore cables. 1.3 The insulation of the wires and the sheathing of cables in this specification present a limited fire hazard and produce limited levels of noxious fumes, smoke and corrosive products when assessed by the methods of test in this specification. 1.4 The wires listed in this Standard are required to meet the Relative Thermal Life and Temperature Index Test of BS 2G 230, Appendix C for 40,000 hours at 120°C, and are suitable for continuous use within the temperature range -50°C to +120°C. 1.5 Cables Type 1SB, 1SBM 120, 2SB and 2SBM listed in this Standard are required to meet the Relative Thermal Life and Temperature Index Test of BS 2G 230, Appendix C for 40,000 hours at 120°C, and are suitable for continuous use within the temperature range -50°C to +120°C. 1.6 Cables Type 1SBM 85 shall have sheathing material qualified to Def Stan 61-12 (Part 31) and meet the Relative Thermal Life and Temperature Index Test of BS 2G 230, Appendix C for 40,000 hours at 85°C and are suitable for continuous use within the temperature range -50°C to +85°C. 1.7 These wires and cables have a voltage rating of 600 V rms or 800V DC. 1.8 These wires and cables are suitable for soldered or crimped terminations. They are not designed or necessarily suitable for solderless wrapped electrical connections. 1.9 Although these wires and cables may be subjected to test contamination by one or more of the fluids listed in Table E of this Standard, attention is drawn to 2.2.2 and 2.2.2.1. 1.10 Stranded conductors shall be used for flexing applications. fixed applications stranded or solid conductors may be used. For The following minimum bend radii shall be used within equipment: (a) for flexing applications, 10 times the overall diameter of the wire or cable; (b) for fixed applications, 4 times the overall diameter of the wire or cable. 4 DEF STAN 61-12 (PART 18)/4 2 WARNING 2.1 This Standard calls for the use of substances and/or procedures that may be injurious to health if adequate precautions are not taken. It refers only to technical suitability and in no way absolves either the designer, the producer, the supplier or the user from statutory and all other legal obligations relating to health and safety at any stage of manufacture or use. 2.2 Particular attention is drawn to the following hazards although the list may not necessarily be exhaustive: 2.2.1 Flammable and/or toxic fumes may be given off from the specimens when subjected to the fire hazard/flammability tests. Operators are to take appropriate precautions to avoid exposure to the evolved fumes. 2.2.2 Compliance with 10.2.8 (resistance to fluids test) provides no guarantee that the wires are suitable for continuous use in the specified fluids. 2.2.2.1 It should be noted that isopropyl alcohol and aircraft fuel are not specified for Type 2 wires and that certain Type 2 wire insulations are adversely affected by these fluids. 2.2.3 Due to the wide variety of insulants which may meet this Standard, particular attention is drawn to clause 5 especially with respect to selection of Type and size of wire to be used. Table A Conductor Size and Guide to Current Ratings SIZE NUMBER AND NOMINAL DIAMETER OF STRANDS IN CONDUCTOR MAXIMUM CONTINUOUS CURRENT (SEE NOTE BELOW) mm amps (b) (c) (a) 30 26 23 19 30 28 26 24 22 20 18 16 14 12 1/0.25 1/0.40 1/0.60 1/0.90 7/0.10 7/0.12 19/0.10 19/0.12 19/0.15 19/0.20 19/0.25 19/0.30 37/0.25 37/0.30 0.3 0.8 1.8 4.0 0.3 0.5 0.8 1.3 2.2 3.7 5.8 7.7 11.4 15.6 5 DEF STAN 61-12 (PART 18)/4 2.2.3 (Contd) NOTE: Current ratings will depend on circumstances but for general guidance the combination of conductor size and current shown in table A will give a temperature rise of about 15°C at an ambient temperature of 70°C. 3 Related Documents 3.1 Reference is made in this Standard to: IEC Publication 304 BS EN 29453 BS 2G 230 BS 2G 231 Def Stan 61-12 Part 0 Def Stan 59-59 Def Stan 61-12 (Part 31) Def Stan 91-4 CPU/AIS/300 Standard Colours for Insulation of Low Frequency Cables and Wires Soft Solder Alloys - Chemical Composition and Forms Specification for General Requirements for Aircraft Electrical Cables Specification for Conductors for General Purpose Aircraft Electrical Cables and Aerospace Applications Wires, Cords and Cables Electrical. General Requirements and Test Methods for Qualification Approval Electrical/Electronic Components for Defence Use. Services Qualified Products List Wires, Cords and Cables Electrical - Metric Units: Part 31 Sheaths, Limited Fire Hazard Fuel, Naval, Distillate: Dieso F-76 Agreed Industry Standard: Packaging of Wires, Cords and Cables, Electrical 3.2 Copies of documents referred to in 3.1 are obtainable from: DOCUMENT SOURCE Defence Standard Publications Directorate of Standardization Stan 1 Kentigern House 65 Brown Street GLASGOW G2 8EX British Standards British Standards Institution Sales Office Linford Wood MILTON KEYNES MK14 6LE Agreed Industry Standards CPU/AIS 300 Defence Packaging Authority Building 18 Royal Arsenal West Woolwich LONDON 6 DEF STAN 61-12 (PART 18)/4 3.3 Reference in this Defence Standard to any related document means, in any invitation to tender or contract, the edition and all amendments current at the date of such a tender or contract unless a specific edition is indicated. 4 Definitions 4.1 For the purpose of this Defence Standard the definitions given in BS 2G 230 shall apply together with the following: 4.1.1 Primary stage. For the purpose of this Defence Standard the primary stage will be taken as being the ‘buying in’ of the basic materials required to manufacture the complete wires and cables. 4.1.2 Wire, electrical. A single metallic conductor of solid, stranded or tinsel construction, designed to carry current in an electrical circuit. It may be bare or insulated, but does not have a metallic covering, jacket or shield. Refers to bulk quantities only. 4.1.3 Cable, power, electrical. Two or more insulated conductors (solid, tubular or stranded) contained in a common covering, or two or more insulated conductors twisted or moulded together without a common covering, or one insulated conductor with a metallic covering, shield or outer conductor. The rated working voltage of the item must be 250V or more and the size of each individual conductor must be size 18 or larger. 4.1.4 Cable, special purposes, electrical. Two or more individually insulated conductors (solid or stranded) contained in a common covering or two or more individually insulated conductors twisted or moulded together without a common covering, or one insulated conductor with a metallic covering or shield. 5 Type Identification and colours 5.1 Because of the differing physical nature of insulations which may be used in the construction of wires and cables to this Standard, the wires and cables have been divided into two categories to indicate their handleability for installation purposes. They are as follows: 5.2 Wire Type 1 Cable Type 1SB Cable Type 1SBM 85 Cable Type 1SBM 120 Wire Type 2 Cable Type 2SB Cable Type 2SBM Unscreened, Pliable, with Moderate Dynamic Cut Through Resistance Screened Type 1 Wire Screened and Sheathed Type 1 Wire, 85°C Rated Sheath Screened and Sheathed Type 1 Wire 120°C Rated Sheath Unscreened, Less Pliable than Type 1 Wire but having Higher Dynamic Cut Through Resistance Screened Type 2 Wire Screened and Sheathed Type 2 Wire 5.3 Test and limits to control dynamic cut through and pliability for the two categories, for Qualification Approval testing, are given in 10.2.6 and 10.2.12 respectively. 5.4 Colours. The colours in which the wire and cable shall be supplied are given in tables I(A) to II(E). 7 DEF STAN 61-12 (PART 18)/4 5.4.1 The colours shall be a reasonable match with the colours specified in IEC Publication 304. 6 Materials 6.1 Conductors. Conductors of the completed wires and cables shall be of tin coated annealed copper and shall comply with BS 2G 231 as applicable as well as with table B and 9.1 of this Standard. Tensile strength and elongation at break tests shall be in accordance with BS 2G 230, Test 7. 6.2 Insulation. The insulation shall meet all the relevant requirements of this Standard. 6.2.1 The dielectric constant of the insulation shall not be greater than 4 when measured at approximately 1 KHz. 6.3 Screens. Screens shall consist of a braid of annealed, tin plated, copper strands conforming to BS 2G 231 before braiding and constructed as detailed in 7.4 of this Standard. 6.4 Sheaths. The sheathing material for cable type 1SBM 85 shall be qualified to Def Stan 61-12 (Part 31). 6.4.1 The sheathing material for cable type 1SM 120 shall meet the requirements of this Standard. 6.5 It is required that all types of insulation and sheathing to this specification shall be mutually compatible and also be compatible with other types of insulation and sheath in general use. The Ministry of Defence reserve the right to verify this by selected compatibility (ageing) tests. The Ministry of Defence also reserve the right not to approve products which are incompatible with those in general use. 7 Construction 7.1 Mass of wires and cables. The mass of the complete equipment wires and cables shall not exceed the limits specified in table D. 7.2 Conductor stranding 7.2.1 Strands used for conductors shall be clean, bright and free from surface irregularities. The conductors shall be as specified in table B of this Standard. 7.2.2 The stranded conductor shall be of concentric construction as defined in BS 2G 230 2.3 or 2.4 and shall comply with 6.1 of this Standard. The lay of the strands within each layer shall be uniform throughout the conductor length. 7.2.3 Joints in single strands shall be brazed or hard soldered and there shall be not more than one such joint in any 50m of single strand. Joints in single strands shall not be within 300 mm of any other joint in the same layer. 7.2.4 Conductors consisting of single strands shall be not joined. 8 DEF STAN 61-12 (PART 18)/4 7.3 Insulation 7.3.1 The conductor shall be uniformly and continuously covered with one or more layers of insulation. 7.3.2 To permit satisfactory termination the insulation shall not be loose, but it shall be possible to remove the insulation completely without any insulation residue remaining. 7.3.3 The dimensions of the insulated conductor and the thickness and the concentricity of the insulation shall be measured in accordance with the methods specified in BS 2G 230 Test 5 and shall be within the limits stated in table C of this Standard. 7.4 Screens 7.4.1 Screens shall be of close fitting braided construction. Wherever the screened cable is cut it shall be possible to slide back the screen over a distance of 100 mm on a 600 mm length of cable, the other end of the cable being clamped. 7.4.2 There shall be no joints in the complete braid. Where breaks in the individual strands occur, the ends shall be brazed or tucked out of the braid and there shall not be more than one such break in any 300 mm length of cable or in any 10m of individual strand. Where renewal of spindles is necessary, the ends shall be tucked out of the braid and there shall not be more than one spindle renewal in any 300m length of cable. 7.4.3 The braid construction details shall be as follows: Diameter of braiding strands, maximum: (a) 0.11 mm for cables of conductor size up to and including 19/0.2 mm; (b) 0.13 mm for cables of conductor size of 19/0.25 mm and above. Ends per spindle minimum 3. Filling Factor, minimum 0.5. 7.4.3.1 The Filling Factor Kf is defined as: mnd 2π D ( 1 + π 2 ( ½ D2 ) L2 ) where D = mean diameter of braid = diameter over dielectric + 2.25d d = diameter of braiding strands in millimetres L = lay of braid in millimetres m = total number of spindles n = total number of ends per spindle 9 DEF STAN 61-12 (PART 18)/4 7.5 Sheaths 7.5.1 The sheaths shall be annular and free from defects. The overall diameter shall be measured in accordance with BS 2G 230, Test 6 and shall be within the limits specified in table C of this Standard. 7.5.2 The sheath shall not be loose but it shall be removable without damaging the metal screen. Table B Details of Conductor SIZE (a) 30 26 23 19 30 28 26 24 22 20 18 16 14 12 NUMBER AND NOMINAL DIAMETER OF STRANDS IN CONDUCTOR NOMINAL CROSS SECTIONAL AREA CONDUCTOR DIAMETER MINIMUM ELECTRICAL RESISTANCE AT 20°C Ω /km max MAXIMUM WIRE AND CABLE ALL TYPES mm m m2 mm mm ohms (b) (c) (d) (e) (f) 0.246 0.380 0.570 0.855 0.27 0.33 0.46 0.55 0.72 0.94 1.18 1.39 1.68 2.02 0.254 0.404 0.606 0.909 0.32 0.38 0.53 0.62 0.80 1.04 1.29 1.53 1.82 2.18 1/0.25 1/0.40 1/0.60 1/0.90 7/0.10 7/0.12 19/0.10 19/0.12 19/0.15 19/0.20 19/0.25 19/0.30 37/0.25 37/0.30 0.05 0.12 0.28 0.63 0.055 0.079 0.15 0.20 0.4 0.6 1.0 1.2 2.0 2.6 10 383.5 145.6 64.0 28.5 336.0 259.0 141.5 95.6 60.0 33.2 21.1 14.5 10.9 7.6 DEF STAN 61-12 (PART 18)/4 Table C Dimensions of Complete Equipment Wires and Cables WIRE CABLE TYPES SIZE (a) 30 26 23 19 30 28 26 24 22 20 18 16 14 12 1SB AND 2SB 1SBM 85, 1SBM 120 AND 2SBM OVER INSULATION OVER SCREEN OVER SHEATH 1 AND 2 NUMBER AND NOMINAL DIAMETER OF STRANDS IN CONDUCTOR DIAMETER RADIAL THICKNESS OF INSULATION NOMINAL MIN MIN MAX MIN MAX MIN MAX mm mm mm mm mm mm mm mm mm (b) (c) (d) (e) (f) (g) (h) (j) (k) 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.25 0.25 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.20 0.20 0.55 0.70 0.90 1.20 0.60 0.65 0.80 0.90 1.05 1.30 1.55 1.80 2.15 2.50 0.70 0.85 1.05 1.35 0.75 0.80 0.95 1.05 1.20 1.50 1.75 2.00 2.35 2.70 1.20 1.30 1.45 1.70 1.95 2.35 2.50 2.85 1.45 1.55 1.70 1.95 2.20 2.60 2.80 3.15 1.60 1.70 1.85 2.10 2.35 2.75 2.90 3.25 2.00 2.10 2.25 2.50 2.75 3.15 3.35 3.70 1/0.25 1/0.40 1/0.60 1/0.90 7/0.10 7/0.12 19/0.10 19/0.12 19/0.15 19/0.20 19/0.25 19/0.30 37/0.25 37/0.30 NOTE: - indicates that the column heading does not apply. 11 DEF STAN 61-12 (PART 18)/4 Table D Mass of complete Equipment Wires and Cables WIRE CABLE TYPE NUMBER AND NOMINAL DIAMETER OF STRANDS IN CONDUCTOR mm (a) MASS MAXIMUM kg/100m (b) (c) WIRE TYPES 1 AND 2 1/0.25 1/0.40 1/0.60 1/0.90 7/0.10 7/0.12 19/0.10 19/0.12 19/0.15 19/0.20 19/0.25 19/0.30 37/0.25 37/0.30 0.092 0.200 0.395 0.790 0.110 0.150 0.290 0.345 0.490 0.756 1.04 1.65 2.07 2.71 CABLE TYPES 1SB AND 2SB 19/0.10 19/0.12 19/0.15 19/0.20 19/0.25 19/0.30 37/0.25 37/0.30 0.576 0.720 0.911 1.27 1.77 2.5 3.03 3.81 CABLE TYPES 1SBM 85, 1SBM 120 AND 2SBM 19/0.10 19/0.12 19/0.15 19/0.20 19/0.25 19/0.30 37/0.25 37/0.30 0.829 0.988 1.20 1.60 2.13 2.92 3.48 4.31 8 Testing General Unless otherwise stated, cable and wire samples for Qualification Approval testing shall be size 22 (19/0.15) except for testing to 10.2.13 (Ageing Test) when either size 22 or 20 shall be tested and 11.4 (Toxicity Test) when sizes 30, 22 and 12 shall be tested. 12 DEF STAN 61-12(PART 18)/4 9 Electrical Tests 9.1 Electrical tests on wires types 1 and 2. Wires Type 1 and Type 2 shall be subjected to the following electrical tests. 9.1.1 Dry spark test. Def Stan 61-12 (Part 0) clause 13.13 or 13.14. test voltage shall be 5 kV rms for test 16b or 8 kV peak for test 16c. The 9.1.2 Conductor resistance test. In accordance with BS 2G 230, test 12. The conductor resistance shall be tested for compliance with the values stated in table B of this Defence Standard. 9.1.3 High voltage immersion test (on the insulation). Def Stan 61-12 (Part 0), clause 13.12, the test voltage shall be 2.5 kV rms. The number of specimens to be tested shall be 3 random samples per wire size. 9.1.4 Insulation resistance test. Def Stan 61-12 (Part 0), clause 13.11. The number of specimens to be tested shall be 3 random samples per wire size. The insulation resistance shall not be less than 1 MΩ /km. 9.1.5 Surface resistance test. Def Stan 61-12 (Part 0), clause 13.15. Two specimens per wire size shall be tested. 9.1.6 Dielectric constant test. Def Stan 61-12 (Part 0), clause 13.17. The dielectric constant shall not exceed the value given in 6.2.1. 9.2 Electrical tests on cables, types 1SB and 2SB. In addition to the tests detailed in 9.1, which take place before screening, the screened cable shall also be subjected to the following electrical test after screening. 9.2.1 Voltage test on screened cable. In accordance with BS 2G 230, test 16d, the test voltage shall be 2.5 kV rms between the conductor and the screen. 9.3 Electrical tests on cables, types 1SBM and 2SBM. In addition to the tests in 9.1 and 9.2 the completed screened and sheathed cable shall be subjected to the following electrical test after sheathing. 9.3.1 Dry spark test. voltage shall be 1 kV. Def Stan 61-12 (Part 0), clause 13.13, the test 9.3.2 High voltage immersion test on sheath. Def Stan 61-12 (Part 0), clause 13.12, the test voltage shall be 500 V rms. The number of specimens shall be 3 per wire size. 10 Physical Tests 10.1 Mechanical test on conductor and screen braid. Strands taken from the conductor of the completed wire, prior to screening if applicable and strands to be used for the construction of the screen braid shall be subjected to BS 2G 230 test 7 and shall meet the requirements of BS 2G 231, Table 3 which shall be considered to be extended to include conductor strands from 0.45 mm to 0.9 mm diameter, with the limits remaining as stated. Additional strands shall be subjected to and meet the requirements of BS 2G 231, clauses 4.4 and 4.5 (see also 6.1 and 6.3 of this Standard). 13 DEF STAN 61-12 (PART 18)/4 10.1.1 Solderability (conductor and screen). Def Stan 61-12 (Part 0), clause 13.2. The wetting time shall not exceed 1 second. The solder bath temperatures shall be 235°C ± 3°C and the solder shall be to BS EN 29453 1994 grade KP with a non activated flux. 10.2 Physical tests on completed wires. Wires Types 1 and 2 and cable/cores prior to screening, shall be subjected to the following physical tests. Def Stan 61-12 (Part 0), 10.2.1 Insulation thickness and concentricity. clause 13.7. The requirements shall be as table C of this Standard. 10.2.2 Strand adhesion test (stranded conductors}. (Part 0), clause 13.6. Def Stan 61-12 10.2.3 Insulation shrinkage test. Def Stan 61-12 (Part 0), clause 13.30, the retractions of the insulation shall not exceed 3 mm. 10.2.4 Insulation blocking. Def Stan 61-12 (Part 0), clause 13.31. Three samples of wire of 19/0.15 conductor size shall be tested. The mandrel diameter shall be 10 mm, the tension 5N. 10.2.5 Room temperature bend test. Def Stan 61-12 (Part 0), clause 13.19. A mandrel of a diameter which is 8 times the maximum specified diameter of the wire shall be used. The tensile force shall be as specified in table G, for each wire size. One specimen per wire size shall be tested. The test voltage shall be 2.5 kV rms. On completion of test, the insulation shall exhibit neither crazing nor cracking. 10.2.5.1 Cold bend test. Def Stan 61-12 (Part 0), clause 13.20. A mandrel of diameter which is 20 times the maximum specified diameter of the wire shall be used. The tensile force shall be as specified in table G for each wire size. The temperature of the chamber shall be -50°C ± 2°C and the time shall be 6 hours. The test voltage shall be 2.5 kV rms. One specimen per wire size shall be tested. 10.2.6 Dynamic cut-through test. Def Stan 61-12 (Part 0), clause 13.22. Three specimens per wire size shall be tested. The specimens shall be tested at a temperature of 120°C ± 5°C and the rate of loading shall be 6000 g/min at the sample. The minimum force required to achieve cut through to the conductor shall be as specified in table G. 10.2.7 Notch propagation test. Def Stan 61-12 (Part 0), clause 13.23. Three samples of wire of 19/0.15 conductor size shall be tested. The voltage shall be 2.5 kV rms. 10.2.8 Resistance to fluids test. Three samples of wire of 19/0.15 conductor size shall be tested in accordance with Def Stan 61-12 Part 0 clause 13.37. Additional test fluids and temperatures shall be as specified in table E of this Standard. Type 1 wires shall be subjected to all the fluids listed except trichloroethane. Type 2 wires shall be subjected to all the fluids listed with the exception of isopropyl alcohol, aircraft fuel and trichloroethane. The duration of immersion shall be 7 days for all fluids. The test voltage shall be 2.5 kV rms. 14 DEF STAN 61-12 (PART 18)/4 Table E List of Test Fluids, Additional Requirements FLUID TEMPERATURE °C TEST FLUID (c) (b) (a) Oil Detergent mineral oil OMD-113 Fuel Oil Dieso 47/20, NATO F-76 Def Stan 91-4 (or DERV) TIME (d) 100 ± 3 7 days 20 ± 3 7 days 50 ± 3 7 days Deionized Water Na Cl 3.5% (sea water) 10.2.9 Scrape abrasion test. Def Specimens shall be tested at 120°C force as specified in table G and than 500 cycles (1000 strokes) for Stan 61-12 (Part 0), clause 13.24. ± 5°C, the blade shall be loaded with a the specimens shall withstand not less both Types 1 and 2 wire. 10.2.10 Delamination test. Def Stan 61-12 (Part 0), clause 13.32. The ageing temperature shall be 135°C ± 3°C and the test temperature the wire rated temperature. 10.2.11 Pliability test. Def Stan 61-12 (Part 0), clause 13.26, except that the sample is to be straightened by hand. Samples of 19/0.15 conductor size shall be tested. The diameter of the mandrel shall be 5 mm and the force gradually applied, as specified, sufficient to bend the wire downwards through 89°. The specimen shall remain in this position for 5 minutes and the force recorded. After this time the force shall be removed and the specimen allowed to return towards its original position. At a time 5 minutes after removal of the force the recoil angle shall be recorded. The mean force required to bend the wire through 89° and the recoil angle shall not exceed: 7N and 35° for Type 1 wire 12N and 60° for Type 2 wire 15 DEF STAN 61-12 (PART 18)/4 10.2.11 (Contd) But in addition it is undesirable to have maximum force and recoil angle at the same time, Type 1 wires shall have a figure of less than 175 for the product of the force in newtons and the angle in degrees. 10.2.12 Thermal endurance test. Def Stan 61-12 (Part 0), clause 13.36. The upper temperature limit in this test relates to the maximum continuous temperature due to current flow. For Qualification Approval, samples of wire of conductor size 19/0.15 or 19/0.2 shall be tested. The wire shall be wrapped on a mandrel of 13 mm diameter with a weight of 400g for wire size 19/0.15, 700g for wire size 19/0.2. The Arrhenius plots so obtained are to form part of the submission to the Qualification Approval Authority when seeking Qualification Approval. It will be required to show that the insulation has a life exceeding 40,000 h at 120°C. 10.2.12.1 Accelerated ageing. Def Stan 61-12 (Part 0), clause 13.29. The mandrel diameters and tensile force to be applied to each end of the sample shall be as specified in table G of this Standard. To determine the test temperature for the Production Quality test requirements, a line is to be drawn through the 120°C - 40,000 hours point parallel to the Arrhenius plot. The temperature at which this line passes through 168 hours life is to be the minimum test temperature. 10.2.13 Colour fastness tests 10.2.13.1 Colour fastness to water test. A sample of wire about 100 mm long from which the conductor has been removed shall be cut into small pieces and then immersed in about 10 times its own volume of distilled water contained in a covered vessel, for a period of 48 hours at a temperature of 70°C ± 1°C. At the end of this period the water shall be examined and shall be free from colour. 10.2.13.2 Bleeding of colour test. A test sample shall consist of a bundle of wires, 300 mm long, made up of twisted pairs laid together and bound with glass fibre string or tape at 50 mm intervals so that the pairs cannot move in relation to each other. Each coloured wire is to be paired with a white wire with a lay of eight times the diameter of the wire. The test samples shall be stored in an air oven at 120°C ± 3°C for 72 hours. At the end of this period the sample shall be stripped down and the individual sample wires and control wires shall be examined for transfer of colour. There shall be no appreciable colour staining and no significant change in individual colours. 10.2.14 Colour durability test. 10.2.14.1 only. Application. This test is applicable to surface coloured wires 10.2.14.2 Test apparatus. A scrape abrasion test rig as described in BS 2G 230, test 30 shall be used. 16 DEF STAN 61-12 (PART 18)/4 10.2.14.3 Test procedure. A specimen of wire shall be mounted in the tester and the counter set to zero. Testing shall be carried out at a temperature of 120°C ± 5°C using a force of 2 N. The test shall be discontinued as soon as a continuous line is scored through the colour. To achieve a pass 100 cycles shall have been made. 10.2.15 Resistance to solder heat test. clause 13.35. Def Stan 61-12 (Part 0), 10.2.16 Flexure endurance test. Def Stan 61-12 (Part 0), clause 13.28. Three samples of wire of 19/0.15 conductor size shall be tested, at temperature of 20°C ± 3°C. The mass shall be 0.6 kg for Type 1 wire and 1 kg for Type 2 wire; (a) the insulation shall withstand the voltage test of 9.1.3; (b) the wire shall be capable of passing its full rated current given in table A, for 1000 cycles without any evidence of localized overheating. 10.3 Test applicable to 85°C completed cables 10.3.1 Cold bend. Def Stan 61-12 (Part 0), clause 15.6. 10.3.2 Thermal endurance. Def Stan 61-12 (Part 0), clause 13.36 after ageing for 28 days at a temperature of 110°C ± 2°C the cable is to be subjected to and meet the requirements of Def Stan 61-12 (Part 0), clause 13.20, the mandrel shall be 10 times the cable OD and the mass sufficient to ensure that the sample remains in intimate contact with the mandrel. 10.3.3 Sheath compatibility. Def Stan 61-12 (Part 0), clause 16.8. 10.4 Test applicable to 120°C completed cables 10.4.1 Cold bend. Def Stan 61-12 (Part 0), clause 15.6. 10.4.2 Thermal endurance. As 10.3.2 of this Standard. 10.4.3 Sheath Compatibility. 10.4.4 Flammability. Def Stan 61-12 (Part 0), clause 16.8. Def Stan 61-12 (Part 0), clauses 13.39 and 13.40. 10.4.4.1 Procedure 1. Five specimens per insulation type shall be tested and the flame shall be applied for 5 seconds. 10.4.4.2 Procedure 2. Five specimens per insulation type shall be tested and the flame shall be applied for 12 seconds. 10.4.5 Critical oxygen index. Def Stan 61-12 (Part 0), clause 13.4.1. The critical oxygen index shall not be less than 29. 10.4.6 Smoke index. Def Stan 61-12 (Part 0), clause 13.4.2. Three test runs shall be performed. The smoke index is to be stated in terms of 1m of cable. The average of three runs is not to exceed 12 (20 for maintenance range). 17 DEF STAN 61-12 (PART 18)/4 10.4.7 Toxicity index. Def Stan 61-12 (Part 0), clause 13.43. The toxicity index shall not exceed 5.0 per 100g of sheathing material. Where the sheath contains more than one material the test sample is to contain all the constituent parts in the same concentration as the completed sheath. 10.4.8 Temperature index. Def Stan 61-12 (Part 0), clause 13.44. temperature index value shall not be less than 250°C. 10.4.9 Resistance to fluids. The As 10.2.8 of this Standard. 11 Fire Hazard Tests 11.1 Flammability tests. 13.40. Def Stan 61-12 (Part 0), clauses 13.39 and 11.1.1 Procedure 1. Five specimens per insulation type shall be tested and the flame shall be applied for 5 seconds. 11.1.2 Procedure 2. Five specimens per insulation type shall be tested and the flame shall be applied for 12 seconds. 11.2 Critical oxygen index test. Def Stan 61-12 (Part 0), clause 13.41. The Critical Oxygen Index shall be not less than 29. 11.3 Smoke index test. Def Stan 61-12 (Part 0), clause 13.42. Three test runs shall be performed. The smoke index is to be stated in terms of 1m of wire and the average of the 3 runs is not to exceed 12 (20 maximum for maintenance range). 11.4 Toxicity index test. Def Stan 61-12 (Part 0), clause 13.43. The toxicity index (the average value of the 9 samples) on a 100g insulation basis shall not exceed 0.2 when calculated to a 1m length of size 22 wire. The hydrochloric acid gas content shall not be greater than 10 cm3/m. 11.5 Temperature index test. Def Stan 61-12 (Part 0), clause 13.44. temperature index value shall not be less than 250°C. The NOTE: Wire samples for Qualification Approval shall be size 22 (19/0.15) except for testing to 10.2.13 when either size 22 or 20 shall be tested and 11.4 when sizes 30, 22 and 12 shall be tested. 18 DEF STAN 61-12 (PART 18)/4 Table F Qualification Approval and Quality Assurance Test Applications DESCRIPTION OF TEST CLAUSE NUMBER QUALIFICATION APPROVAL PRODUCTION QUALITY PRODUCTION ROUTINE DEF STAN 61-12 (PART 0) CLAUSE NO OR BS 2G 230 TEST NO NO OF SPECIMENS PER WIRE SIZE OR AS STATED Dry spark or dry impulse 9.1.1 x x x 13.13 All Production Conductor resistance 9.1.2 x x x BS 2G 230 Test 12 All Production High voltage immersion 9.1.3 x x - 13.12 3 Insulation resistance 9.1.4 x x - 13.11 3 Surface resistance 9.1.5 x - 13.15 2 Dielectric 9.1.6 x - - 13.17 9.2.1 x x x BS 2G 230 test 16d 1 All Production constant Voltage test, screened cable Dry spark test on sheath 9.3.1 x x x 13.13 All Production High voltage immersion, on sheath 9.3.2 x x - 13.12 3 Mechanical, conductor and 10.1 x x - 3 10.1.1 x x BS 2G 230 screen braid solderability test 7 3 13.2 Insulation thickness and 1 0.2.1 x x x 13.7 3 Strand adhesion 1 0.2.2 x x - 1 3.6 8 Insulation shrinkage 1 0.2.3 x x 1 3.30 1 Insulation blocking 1 0.2.4 x - - 1 3.31 3 Room temperature bend Cold bend 1 0.2.5 x x x x - 1 3.19 10.2.5.1 1 3.20 1 1 Dynamic cut through 1 0.2.6 x x - 1 3.22 2 Notch 1 0.2.7 x x - 1 3.23 3 Resistance to fluids 1 0.2.8 x - - 1 3.37 3 Scrape adhesion 1 0.2.9 x x - 1 3.24 2 Delamination 1 0.2.10 x - 1 3.32 3 Pliability 1 0.2.11 x x - - 1 3.26 1 Thermal x - Accelerated ageing 1 0.2.12 1 0.2.12.1 x 1 3.36 1 3.29 1 Colour fastness to water 1 0.2.13.1 x 1 0.2.13.2 x - - 1 per colour Bleeding of colour x - - Colour durability 1 0.2.14 x - - - 1 per colour Resistance to solder heat 1 0.2.15 x x 1 1 0.2.16 x - - 1 3.35 Flexure endurance 1 3.28 3 x 1 3.39 1 3.40 5 5 concentricity propagation endurance 4 1 per Procedure 2 1 1.1.1 1 1.1.2 x x x - Critical oxygen index 1 1.2 x - - 1 3.41 5 Smoke index 1 1.3 x - - 1 3.42 3 Toxicity index 1 1.4 x - - 1 3.43 3 T emperature index test 1 1.5 x - - 1 3.44 5 Flammability Procedure 1 19 colour DEF STAN 61-12 (PART 18)/4 Table F - Concluded DESCRIPTION OF TEST CLAUSE NUMBER Cold Bend Thermal Endurance QUALI- PRODUC- FICATION APPROVAL TION QUALITY PRODUCTION ROUTINE DEF STAN 61-12 N0 OF (PART 0) CLAUSE NO OR BS 2G 230 SPECIMENS PER TEST NO WIRE SIZE OR AS STATED 10.3.1 10.4.1 x x - 15.6 1 10.3.2 x - - 13.36 4 x - - 16.8 7 x x - 13.39 & 13.40 5 10.4.2 Sheath Compatibility 10.3.3 10.4.3 Flammability 10.4.4.1 10.4.4.2 Critical Oxygen Index 10.4.5 x - - 13.41 5 Smoke Index 10.4.6 x - - 13.42 5 Toxicity Index 10.4.7 x - - 13.43 3 - 13.44 3 - 13.37 3 Temperature Index 10.4.8 x - Resistance to Fluids 10.4.9 x - Table G Specific Test Requirements SIZE ACCELERATED ACCELERATED COLD SCRAPE DYNAMIC CUT AGEING AGEING BEND ABRASION THROUGH FORCE FORCE N ROOM AND TEMP FORCE TYPE BEND MANDREL N 1 MAX DIA FORCE N N mm TYPE 2 TYPE 1 TYPE 30 0.5 2.0 10.0 2.0 1.0 3.0 28 1.0 3.5 10.0 4.0 1.0 3.0 30.0 26 1.6 5.0 10.0 5.0 1.0 4.0 30.0 24 2.5 3.0 7.0 10.0 10.0 13.0 20.0 20.0 1.2 5.0 40.0 23 1.2 5.0 40.0 22 20 4.0 7.0 10.0 13.0 20.0 20.0 20.0 25.0 1.5 6.0 70.0 6.0 100.0 7.0 100.0 7.0 120.0 120.0 19 8.0 20.0 13.0 20.0 20.0 1.5 1.5 18 10.0 20.0 20.0 30.0 1.6 16 10.0 20.0 20.0 30.0 2.0 8.0 14 10.0 20.0 25.0 30.0 2.5 10.0 120.0 12 10.0 20.0 30.0 30.0 3.0 12.0 120.0 12 Qualification Approval Qualification Approval procedures should be as defined in Def Stan 61-12 (Part 0). 20 2 DEF STAN 61-12 (PART 18)/4 13 Quality Assurance Requirements 13.1 Procedure 13.1.1 The manufacturer shall ensure Quality of Conformance to the specified requirements by the following methods: (a) inspection of materials and wires and cables in the course of manufacture to ensure that the requirements of this Standard are met and the necessary standard of workmanship and process control is being maintained; (b) 13.2 subjection of all wires and cables to the tests specified in table F. Test and sampling levels on completed wires and cables 13.2.1 All wires and cables are to be subjected to Production Routine tests, specified in table F. 13.2.2 On satisfactory completion of Production Routine tests random samples shall be taken during cutting for dispatch and subjected to Production Quality tests. The number of random samples required shall be determined by the total production batch. 13.2.3 In a production run of 100 km or less, one random sample shall be taken and subjected to Production Quality tests. 13.2.4 In a production run between 100 and 500 km one random sample shall be taken from each of two separate factory drums and subjected to Production Quality tests. 13.2.5 In a production run greater than 500 km one extra sample shall be taken from each further 500 km and subjected to Production Quality tests. 13.2.6 The Quality Assurance Authority may at intervals select samples of wires and cables for Quality audit or check testing in their own laboratories. Samples shall be selected by the supervising representative of the Quality Assurance Authority. NOTE: The manufacturer may, if he wishes, submit an alternative sampling plan, covering the requirements of clause 13, for approval by the DELSC Cables and Wires Subcommittee. 14 Packaging and Labelling Packaging and labelling shall be in accordance with the requirements specified in Agreed Industry Standard CPU/AIS/300. Notes on Tables The definitions of tables I and II - items respectively are as follows: Table I. Standard items to be used whenever practicable in preference to all others. They may replace one or more non-standard items. Table II. Non-standard items for which there is no replacement. A non-standard item is to be provisioned only for maintenance of existing equipment. 21 Table I(A) Standard Range Equipment Wires, Electrical - Type 1 Limited Fire Hazard Insulation, Unscreened (Toxicity Index ≤ 0.2 NATO STOCK NUMBER 6145-99PAGE CONDUCTOR LINE SIZE RED BLUE GREEN YELLOW NO BLACK WHITE BROWN VIOLET ORANGE GREY PINK YELLOW Green (a) (b) (c) (d) (e) (f) (g) (h) (j) (k) (l) (m) (n) 1 1/0.25 891-9431 891-9432 891-9433 891-9434 891-9435 891-9436 891-9437 891-9438 891-9439 891-9440 891-9441 891-9442 2 1/0.40 891-9443 891-9444 891-9455 891-9446 891-9447 891-9448 891-9449 891-9450 891-9451 891-9452 891-9453 891-9454 3 4 1/0.60 891-9455 891-9456 891-9457 891-9458 891-9459 891-9460 891-9461 891-9462 891-9463 891-9464 891-9465 891-9466 1/0.90 891-9467 891-9468 891-9469 891-9470 891-9471 891-9472 891-9473 891-9474 891-9475 891-9476 891-9477 891-9478 5 7/0.10 891-9479 891-9480 891-9481 891-9482 891-9483 891-9484 891-9485 891-9486 891-9487 891-9488 891-9489 891-9490 6 7/0.12 891-9491 891-9492 891-9493 891-9494 891-9495 891-9496 891-9497 891-9498 891-9499 891-9500 891-9501 891-9502 7 19/0.10 891-9503 891-9504 891-9505 891-9506 891-9507 891-9508 891-9509 891-9510 891-9511 891-9512 891-9513 891-9514 8 19/0.12 891-9515 891-9516 891-9517 891-9518 891-9519 891-9520 891-9521 891-9522 891-9523 891-9524 891-9525 891-9526 9 19/0.15 891-9527 891-9528 891-9529 891-9530 891-9531 891-9532 891-9533 891-9534 891-9535 891-9536 891-9537 891-9538 10 19/0.20 891-9539 891-9540 891-9541 891-9542 891-9543 891-9544 891-9545 891-9546 891-9547 891-9548 891-9549 891-9550 11 19/0.25 891-9551 891-9552 891-9553 891-9554 891-9555 891-9556 891-9557 891-9558 891-9559 891-9560 891-9561 891-9562 12 19/0.30 891-9563 891-9564 891-9565 891-9566 891-9567 891-9568 891-9569 891-9570 891-9571 891-9572 891-9573 891-9574 13 37/0.25 891-9575 891-9576 891-9577 891-9578 891-9579 891-9580 891-9581 891-9582 891-9583 891-9584 891-9585 891-9568 14 37/0.30 891-9587 891-9588 891-9589 891-9590 891-9591 891-9592 891-9593 891-9594 891-9595 891-9596 891-9597 891-9598 NOTE: Base colour is indicated by capital letters. Table I(B) Standard Range Equipment Wires, Electrical - Type 2 Limited Fire Hazard Insulation, Unscreened (Toxicity Index ≤ 0.2) NATO STOCK NUMBER 6145-99PAGE CONDUCTOR LINE SIZE RED BLUE GREEN YELLOW BLACK WHITE BROWN VIOLET NO ORANGE GREY PINK YELLOW Green (a) (b) (c) (d) (e) (f) (g) 891-9601 891-9613 891-9602 891-9614 891-9603 891-9604 891-9605 891-9615 891-9617 891-9625 891-9626 891-9627 891-9616 891-9628 891-9629 (h) (k) (l) (m) (n) 891-9606 891-9607 891-9608 891-9609 891-9610 891-9618 891-9619 891-9620 891-9621 891-9622 891-9631 891-9633 891-9634 891-9643 891-9632 891-9644 891-9645 891-9646 891-9658 891-9670 (j) 1 1/0.25 891-9599 891-9600 2 1/0.40 1/0.60 891-9611 891-9623 891-9612 891-9624 1/0.90 891-9635 891-9636 891-9637 891-9638 891-9639 891-9640 891-9641 891-9630 891-9642 5 7/0.10 891-9647 891-9648 891-9649 891-9650 891-9652 891-9653 891-9654 891-9655 891-9656 891-9657 6 7/0.12 891-9660 891-9675 891-9680 19/0.12 19/0.15 891-9683 891-9685 891-9686 891-9689 891-9690 891-9667 891-9679 891-9691 891-9669 891-9681 8 891-9676 891-9688 891-9665 891-9677 891-9668 891-9672 891-9684 891-9662 891-9674 891-9666 19/0.10 891-9661 891-9673 891-9664 7 891-9659 891-9671 891-9651 891-9663 891-9692 891-9693 891-9695 891-9696 891-9697 891-9698 891-9699 891-9701 891-9702 891-9703 891-9704 891-9705 891-9706 19/0.20 891-9707 891-9708 891-9709 891-9710 891-9711 891-9714 891-9715 891-9716 891-9717 891-9718 11 19/0.25 891-9719 891-9720 891-9721 891-9722 891-9723 891-9726 891-9727 891-9728 891-9729 891-9730 12 19/0.30 891-9731 891-9732 891-9733 891-9734 891-9735 891-9724 891-9736 891-9713 891-9725 891-9737 891-9738 891-9739 891-9740 891-9741 891-9742 13 37/0.25 891-9743 891-9744 891-9745 891-9746 891-9747 891-9748 891-9749 891-9750 891-9751 891-9752 891-9753 891-9754 14 37/0.30 891-9755 891-9756 891-9757 891-9758 891-9759 891-9760 891-9761 891-9762 891-9763 891-9764 891-9765 891-9766 3 4 9 10 891-9687 NOTE: Base colour is indicated by capital letters. 891-9700 891-9712 891-9678 891-9682 891-9694 Table I(C) Standard Range Cables, Special Purpose, Electrical and Cables, Power, Electrical Type 1SB and 2SB Limited Fire Hazard Insulation, Screened (Toxixity Index ≤ 0.2) NATO STOCK NUMBER 6145-99PAGE LINE NO CONDUCTOR SIZE (a) ITEM NAME (b) TYPE 1SB TYPE 2SB PINK INSULATION WHITE INSULATION PINK INSULATION (c) (d) (e) WHITE INSULATION (f) 1 2 3 4 19/0.10 19/0.12 19/0.15 19/0.20 CABLE SPECIAL PURPOSE ELECTRICAL 891-9799 891-9803 891-9807 891-9811 891-9800 891-9804 891-9808 891-9812 891-9801 891-9805 891-9808 891-9813 891-9802 891-9806 891-9810 891-9814 5 6 7 8 19/0.25 19/0.30 37/0.25 37/0.30 CABLE POWER ELECTRICAL 891-9815 891-9819 891-9823 891-9827 891-9816 891-9820 891-9824 891-9828 891-9817 891-9821 891-9825 891-9829 891-9818 891-9822 891-9826 891-9830 NOTE: The NATO Stock numbers in columns (c), (d), (e) and (f) are only applicable to cables where the insulation is coloured pink or white (as applicable) and the sheath colour is black. Table I(D) Standard Range Cables, Special Purpose, Electrical and Cables, Power, Electrical Type 1SBM 85, 1SBM 120 and 2SBM Limited Fire Hazard Insulation, Screened and Sheathed (Toxicity index ≤ 0.2) NATO STOCK NUMBER 6145-99PAGE LINE NO CONDUCTOR SIZE ITEM NAME TYPE 1SBM 85 PINK INSULATION (a) (b) (c) WHITE INSULATION (d) TYPE 1SBM 120 TYPE 2SBM PINK INSULATION WHITE INSULATION PINK INSULATION (e) (f) (g) WHITE INSULATION (h) 1 2 3 4 19/0.10 19/0.12 19/0.15 19/0.20 CABLE SPECIAL PURPOSE ELECTRICAL 891-9767 891-9771 891-9775 891-9779 891-9768 891-9772 891-9776 891-9780 891-9769 891-9773 891-9777 891-9781 891-9770 891-9774 891-9778 891-9782 5 6 7 8 19/0.25 19/0.30 37/0.25 37/0.30 CABLE POWER ELECTRICAL 891-9783 891-9787 891-9791 891-9795 891-9784 891-9788 891-9792 891-9796 891-9785 891-9789 891-9793 891-9797 891-9786 891-9790 891-9794 891-9798 NOTE: The NATO Stock numbers in columns (c), (d), (e) and (f) are only applicable to cables where the insulation is coloured pink or white (as applicable) and the sheath colour is black. Table II(A) Maintenance Range Equipment Wires, Electrical - Type 1 Limited Fire Hazard Insulation, Unscreened (Toxicity Index > 0.2 ≤ 1.5) NATO STOCK NUMBER 6145-99PAGE CONDUCTOR LINE SIZE BLUE RED GREEN YELLOW BLACK WHITE BROWN VIOLET ORANGE GREY PINK NO YELLOW Green (a) (b) (c) (d) (e) (f) (g) (h) (j) (k) (l) (m) 771-6213 017-5526 771-6214 771-6215 771-6216 729-3026 017-5535 O17-5545 017-5554 017-5671 1 1/0.25 771-6206 771-6207 771-6208 771-6209 771-6210 771-6211 771-6212 2 1/0.40 017-5422 017-5431 017-5440 017-5449 017-5458 017-5508 (n) 3 1/0.60 017-5423 017-5432 017-5441 017-5450 017-5459 017-5509 017-5517 017-5518 017-5527 017-5536 017-5546 017-5555 017-5672 4 1/0.90 017-5424 017-5433 017-5442 017-5451 017-5460 017-5510 017-5519 017-5528 017-5537 017-5547 017-5556 5 7/0.10 771-6217 771-6218 771-6219 771-6220 771-6221 771-6222 771-6223 771-6224 771-6225 771-6226 771-6227 017-5673 729-3041 6 7/0.12 728-6125 771-6228 771-6229 771-6230 771-6231 771-6232 771-6233 771-6234 771-6235 771-6236 771-6237 729-3042 7 19/0.10 771-6238 771-6239 771-6240 771-6241 771-6242 771-6243 729-3043 017-5425 017-5443 017-5452 017-5502 017-5511 017-5538 017-5557 729-3025 9 19/0.15 017-5426 017-5434 017-5435 771-6247 017-5548 771-6248 19/0.12 771-6245 017-5529 771-6246 8 771-6244 017-5520 017-5444 017-5453 017-5503 017-5512 017-5521 017-5530 017-5539 017-5549 017-5558 017-5675 10 19/0.20 017-5427 017-5436 017-5445 017-5454 017-5504 017-5513 017-5522 017-5531 017-5540 017-5550 017-5559 017-5676 11 19/0.25 771-6249 771-6250 771-6251 771-6252 771-6253 771-6254 771-6255 771-6256 771-6257 771-6258 771-6259 729-3044 12 19/0.30 017-5428 017-5437 017-5446 017-5455 017-5505 017-5514 077-5523 017-5532 017-5541 017-5551 017-5560 017-5677 13 37/0.25 771-6260 771-6261 771-6262 771-6263 771-6264 771-6265 771-6266 771-6267 771-6268 771-6269 771-6270 729-3039 14 37/0.30 771-6271 771-6272 771-6273 771-6274 771-6275 771-6276 771-6277 771-6278 771-6279 771-6280 771-6281 729-3040 NOTE: Base colour is indicated by capital letters. Table II(B) Maintenance Range Equipment Wires, Electrical - Type 2 Limited Fire Hazard Insulation, Unscreened (Toxicity Index > 0.2 ≤ 1.5) NATO STOCK NUMBER 6145-99PAGE CONDUCTOR LINE NO SIZE RED BLUE GREEN YELLOW WHITE BROWN VIOLET ORANGE GREY PINK YELLOW Green (a) (b) (c) (d) (e) (f) (g) (h) 771-6282 771-6293 771-6283 771-6294 771-6284 771-6295 771-6285 771-6286 771-6297 771-6287 771-6288 771-6296 771-6298 771-6305 771-6306 771-6307 771-6318 771-6308 771-6309 771-6299 771-6310 771-6311 771-6319 771-6321 771-6332 771-6322 771-6330 771-6341 771-6320 771-6331 771-6312 771-6323 771-6342 1 1/0.25 2 1/0.40 3 1/0.60 1/0.90 771-6304 771-6315 771-6316 771-6317 7/0.10 771-6326 771-6337 771-6327 771-6328 771-6339 771-6329 4 5 BLACK (k) (l) (m) (n) 771-6289 771-6290 771-6291 771-6292 722-3157 771-6300 771-6301 771-6302 771-6313 771-6303 771-6314 729-3046 729-3027 771-6324 771-6325 729-3028 771-6334 771-6335 771-6343 771-6333 771-6344 771-6345 771-6336 771-6347 729-3030 729-3029 7 7/0.12 19/0.10 771-6348 771-6338 771-6349 771-6350 771-6351 771-6352 771-6353 771-6355 771-6356 771-6358 729-3031 8 19/0.12 771-6359 771-6360 771-6361 771-6362 771-6363 771-6364 771-6354 771-6365 771-6346 771-6357 771-6366 771-6367 771-6368 771-6369 729-3032 9 10 19/0.15 19/0.20 771-6370 771-6371 771-6372 771-6374 771-6375 771-6376 771-6377 771-6383 728-3148 728-3149 728-3150 728-3151 771-6379 728-3153 729-3033 771-6382 771-6378 728-3152 771-6380 771-6381 771-6373 728-3147 728-3154 729-3034 11 19/0.25 728-3155 728-3156 728-3157 728-3158 728-3159 728-3160 728-3161 728-3162 728-3163 728-3164 728-3165 729-3035 12 19/0.30 728-3166 728-3167 728-3168 728-3169 728-3170 728-3171 728-3172 728-3173 728-3174 728-3175 728-3176 729-3036 6 771-6340 (j) 13 37/0.25 728-3177 728-3178 728-3179 728-3780 728-3181 728-3782 728-3183 728-3184 728-3185 728-3186 728-3187 729-3037 14 37/0.30 728-3188 728-3189 728-3790 728-3191 728-3192 728-3193 728-3194 728-3195 728-3196 728-3197 728-3198 729-3038 NOTE: Base colour is indicated by capital letters. Table II(C) Maintenance Range Cables, Special Purpose, Electrical and Cables, Power, Electrical Type 1SB and 2SB Limited Fire Hazard Insulation, Screened (Toxicity Index > 0.2 ≤ 1.5) NATO STOCK NUMBER 6145-99PAGE LINE NO CONDUCTOR SIZE (a) ITEM NAME (b) TYPE 1SB TYPE 2SB PINK INSULATION WHITE INSULATION PINK INSULATION WHITE INSULATION (c) (d) (e) (f) 1 2 3 4 19/0.10 19/0.12 19/0.15 19/0.20 CABLE SPECIAL PURPOSE ELECTRICAL 770-8895 771-6178 771-6182 771-6186 771-6176 771-6180 771-6184 771-6188 771-6175 771-6179 771-6183 771-6187 771-6177 771-6181 771-6185 771-6189 5 6 7 8 19/0.25 19/0.30 37/0.25 37/0.30 CABLE POWER ELECTRICAL 771-6190 771-6194 771-6198 771-6202 771-6192 771-6196 771-6200 771-6204 771-6191 771-6195 771-6199 771-6203 771-6193 771-6197 771-6201 771-6205 NOTE: The NATO Stock numbers in columns (c), (d), (e) and (f) are only applicable to cables where the insulation is coloured pink or white (as applicable) and the sheath colour is black. Table II(D) Maintenance Range Cables, Special Purpose, Electrical and Cables, Power, Electrical Type 1SBM and 2SBM Limited Fire Hazard Insulation, Screened and Sheathed (Toxicity Index > 0.2 ≤ 1.5) NATO STOCK NUMBER 6145-99PAGE LINE NO CONDUCTOR SIZE (a) ITEM NAME (b) TYPE 1SBM TYPE 2SBM PINK INSULATION WHITE INSULATION PINK INSULATION WHITE INSULATION (c) (d) (e) (f) 1 2 3 4 19/0.10 19/0.12 19/0.15 19/0.20 CABLE SPECIAL PURPOSE ELECTRICAL 728-3199 017-5788 017-5789 017-5790 728-3200 728-3201 728-3222 728-3223 728-3202 728-3204 728-6126 728-3207 728-3203 728-3205 728-3206 728-6127 5 6 7 8 19/0.25 19/0.30 37/0.25 37/0.30 CABLE POWER ELECTRICAL 728-3208 017-5791 728-3214 728-3218 728-3209 728-3224 728-3215 728-3219 728-3210 728-3212 728-3216 728-3220 728-3211 728-3213 728-3217 728-3221 NOTE: The NATO Stock numbers in columns (c), (d), (e) and (f) are only applicable to cables where the insulation is coloured pink or white (as applicable) and the sheath colour is black. Table II(E) Maintenance Range Equipment Wires, Electrical - Type 1 Limited Fire Hazard Bicoloured Insulation, Unscreened (Toxicity Index > 0.2 ≤ 1.5) NATO STOCK NUMBER 6145-99PAGE CONDUCTOR LINE SIZE No RED GREEN RED WHITE RED ORANGE GREY GREEN WHITE BROWN ORANGE GREY blue red black red brown red red blue blue blue blue blue (b) (c) (d) (e) (f) (g) (h) 1/0.25 891-9024 891-9064 1/0.40 891-9040 017-5581 891-9056 2 3 891-9032 017-5572 891-9048 017-5563 017-5590 017-5608 1/0.60 017-5564 017-5573 017-5582 017-5591 017-5599 017-5600 4 1/0.90 017-5565 017-5574 017-5583 017-5592 (a) 1 (j) (k) (l) 891-9072 891-9080 891-9088 891-9096 891-9104 017-5617 017-5626 017-5635 017-5644 017-5653 017-5662 017-5609 017-5618 017-5627 017-5636 017-5645 017-5654 017-5663 017-5601 017-5610 017-5619 017-5628 017-5637 017-5646 017-5655 017-5664 891-9057 891-9065 891-9073 891-9081 891-9089 891-9097 891-9105 891-9113 (m) (n) 891-9112 5 7/0.10 891-9025 891-9033 891-9041 891-9049 6 7/0.12 891-9026 891-9034 891-9042 891-9050 891-9058 891-9066 891-9074 891-9082 891-9090 891-9098 891-9106 891-9114 891-9067 891-9075 891-9083 891-9091 891-9099 891-9107 891-9115 7 19/0.10 891-9027 891-9035 891-9043 891-9051 891-9059 8 19/0.12 891-9028 891-9036 891-9044 891-9052 891-9060 891-9068 891-9076 891-9084 891-9092 891-9100 891-9108 891-9116 017-5612 017-5621 017-5630 017-5639 017-5648 017-5657 017-5666 9 19/0.15 017-5567 017-5576 017-5585 017-5594 017-5603 10 19/0.20 017-5568 017-5577 017-5586 017-5595 017-5604 017-5613 017-5622 017-5631 017-5640 017-5649 017-5658 017-5667 891-9061 891-9069 891-9077 891-9085 891-9093 891-9101 891-9109 891-9117 017-5668 11 19/0.25 891-9029 891-9037 891-9045 891-9053 12 19/0.30 017-5569 017-5578 017-5587 017-5596 017-5605 017-5614 017-5623 017-5632 017-5641 017-5650 017-5659 13 37/0.25 891-9030 891-9038 891-9046 891-9054 891-9062 891-9070 891-9078 891-9086 891-9094 891-9102 891-9110 891-9118 14 37/0.30 891-9031 891-9039 891-9047 891-9055 891-9063 891-9071 891-9079 891-9087 891-9095 891-9103 891-9111 891-9119 NOTE: Base colour is indicated by capital letters. Table II (E) - Concluded Maintenance Range Equipment Wires, Electrical - Type 1 Limited Fire Hazard Bicoloured Insulation, Unscreened (Toxicity Index > 0.2 ≤ 1.5) PAGE CONDUCTOR LINE SIZE NO (a) 1 2 3 4 5 6 7 8 1/0.25 1/0.40 GREEN WHITE black green ORANGE green (b) (c) (d) (e) 891-9120 017-5680 891-9128 017-5689 891-9136 017-5698 017-5690 017-5691 017-5699 017-5700 1/0.60 017-5681 1/0.90 7/0.10 017-5682 7/0.12 19/0.10 19/0.12 9 10 19/0.15 19/0.20 891-9121 891-9122 891-9123 891-9124 017-5684 017-5685 891-9129 891-9130 891-9137 GREEN brown GREY ORANGE WHITE black black (f) (g) (h) (j) 891-9144 017-5707 891-9152 017-5716 891-9160 017-5725 017-5708 017-5717 017-5718 891-9153 017-5709 891-9145 891-9146 green WHITE WHITE GREY ORANGE orange grey brown brown (k) (l) (m) (n) 891-9168 891-9176 891-9184 891-9192 891-9200 017-5743 017-5744 017-5752 017-5753 017-5761 017-5762 017-5770 891-9208 017-5779 017-5726 017-5734 017-5735 017-5727 017-5736 017-5745 017-5754 017-5763 017-5771 017-5772 017-5780 017-5781 891-9154 891-9155 891-9161 891-9162 891-9163 891-9169 891-9170 891-9177 891-9178 891-9156 891-9164 891-9171 891-9172 017-5729 017-5738 017-5730 017-5739 891-9165 017-5731 891-9173 017-5748 891-9181 017-5740 017-5749 891-9131 891-9138 891-9139 891-9132 017-5693 891-9140 017-5702 017-5711 017-5694 017-5703 017-5712 017-5720 017-5721 891-9147 891-9148 brown WHITE 891-9179 891-9180 017-5747 891-9185 891-9193 891-9201 891-9209 891-9186 891-9187 891-9194 891-9195 891-9202 891-9203 891-9210 891-9211 891-9188 891-9196 891-9204 891-9212 017-5756 017-5757 017-5765 017-5774 017-5766 017-5775 017-5783 017-5784 891-9189 891-9197 017-5767 891-9205 891-9213 017-5758 017-5776 017-5785 11 19/0.25 891-9125 891-9133 891-9141 891-9149 891-9157 12 19/0.30 017-5686 017-5695 017-5704 017-5722 13 37/0.25 891-9126 891-9134 891-9142 017-5713 891-9150 891-9158 891-9166 891-9174 891-9182 891-9190 891-9198 891-9206 891-9214 14 37/0.30 891-9127 891-9135 891-9143 891-9151 891-9159 891-9167 891-9175 891-9183 891-9191 891-9199 891-9207 891-9215 NOTE: Base colour is indicated by capital letters. Blank Page DEF STAN 61-12 (PART 18)/4 ANNEX A Type Designator Coding Structure A.1 Scope A.1.1 This annex gives instructions for creating a designator which, when associated with this particular Defence Standard Number, will uniquely identify a specific item manufactured to the Standard’s requirements. A.1.2 Whilst the primary purpose of such a designator is NATO Stock Number (NSN) assignment, it may also be used by anyone else requiring a similar designator facility. A.2 Coding Structure for the Type Designator A.2.1 This consists of 3 or more elements separated from each other by oblique strokes. A.2.2 The first element is the relevant cable or wire type code from the following table: Table A Cable and Wire Type Coding TYPE Type Type Type Type Type Type Type 1 1SB 1SBM 85 1SBM 120 2 2SB 2SBM DESCRIPTION CODE No Screen or Sheath Screen only Screen and 85°C Rated Sheath Screen and 120°C Rated Sheath No Screen or Sheath Screen only Screen and Sheath 1 1SB 1SBM 85 1SBM 120 2 2SB 2SBM A-1 DEF STAN 61-12 (PART 18)/4 ANNEX A (Continued) A.2.3 The second is the relevant conductor size code letter from the following table: Table B Conductor Size SIZE (a) 30 26 23 19 30 28 26 24 22 20 18 16 14 12 NUMBER AND NOMINAL DIAMETER OF STRANDS IN CONDUCTOR NOMINAL CROSS SECTIONAL mm (b) 1/0.25 1/0.40 1/0.60 1/0.90 7/0.10 7/0.12 19/0.10 19/0.12 19/0.15 19/0.20 19/0.25 19/0.30 37/0.25 37/0.30 mm 2 (c) 0.05 0.12 0.28 0.63 0.055 0.079 0.15 0.20 0.33 0.59 0.93 1.34 1.82 2.50 CODE LETTER (d) A D G K B C E F H J L M N P A.2.4 The third element is the relevant insulation base colour code letters from the following table: Table C Insulation Base Colour COLOUR LETTER CODE RED BLUE GREEN YELLOW BLACK WHITE BROWN VIOLET ORANGE GREY PINK RE BU GR YE BL WH BR VL RG GY PK A-2 DEF STAN 61-12 (PART 18)/4 Annex A (Concluded) A.2.4.1 Bicolours. When a bicolour wire requires to be coded, codes for each individual colour are used separated by an oblique stroke (see example below). A.3 Diagram of Coding Structure 1st element 2nd element 1S E 3rd element YE Subsequent element (if required) GR ISSUE NO 4 Issue No Bicolour Insulation base colour Conductor size Wire or Cable Type A.4 Example of Type Designators A.4.1 ISBM 85/P/WH/3: This is a screened and sheathed Type 1 cable having a conductor of 37 strands, each of 0.30 mm diameter and insulation base colour white to Issue 3, suitable for continuous use in the temperature range -50°C to +85°C. A.4.2 2/D/VL/3: This is a non-screened, no sheathed Type 2 wire, having a single solid conductor with a diameter of 0.40 mm and insulation base colour violet to Issue 3. a.4.3 1SB/E/YE/GR/3: This is a screened Type 1 cable having a conductor of 19 strands each of 0.10 mm, with insulation base colour yellow and secondary colour green to Issue 3. NOTE: In all cases the type designator shall be preceded by ‘Def Stan 61-12 (Part 18)’. A-3 DEF STAN 61-12 (PART 18)/4 © Crown Copyright 1994 Published by and obtainable from: Ministry of Defence Directorate of Standardization Kentigern House 65 Brown Street GLASGOW G2 8EX Tel No: Fax: 041-224 2531/2 041-224 2503 This Standard may be fully reproduced except for sale purposes. The following conditions must be observed: 1 The Royal Coat of Arms and the publishing imprint are to be omitted. 2 The following statement is to be inserted on the cover: ‘Crown Copyright. Reprinted by (name of organization) with the permission of Her Majesty’s Stationery Office.’ Requests for commercial reproduction should be addressed to MOD Stan 1, Kentigern House, 65 Brown Street, Glasgow G2 8EX The following Defence Standard file reference relates to the work on this Standard - D/D Stan 372/7/19. Contract Requirements When Defence Standards are incorporated into contract users are responsible for their correct application and for complying with contract requirements. Revision of Defence Standard Defence Standards are revised when necessary by the issue either of amendments or of revised editions. It is important that users of Defence Standards should ascertain that they are in possession of the latest amendments or editions. Information on all Defence Standards is contained in Def Stan 00-00 (Part 3) Section 4, Index of Standards for Defence Procurement - Index of Defence Standards and Specifications published annually and supplemented periodically by Standards in Defence News. Any person who, when making use of a Defence Standard encounters an inaccuracy or ambiguity is requested to notify the Directorate of Standardization without delay in order that the matter may be investigated and appropriate action taken. 92/70002 DEF STAN 61-12 (PART 18)/4 - 6 JANUARY 1995 WIRES, CORDS AND CABLES, ELECTRICAL METRIC UNITS PART 18: EQUIPMENT WIRES LIMITED FIRE HAZARD AMENDMENT 1 1. Page 13, Clause 9.1.4, line 3 Delete: 1 M Ω /Km Insert: 0.2 M Ω/Km 2. Make a note of this amendment on the amendment record. D/D Stan/372/07/19 92/70002 30 June 1995 Ministry of Defence Directorate of Standardization Stan 7b Kentigern House 65 Brown Street GLASGOW G2 8EX DEF STAN 61-12 (PART 18)/4 WIRES, CORDS AND CABLES, ELECTRICAL METRIC UNITS PART 18: EQUIPMENT WIRES LIMITED FIRE HAZARD AMENDMENT 2 1. 2. Page 25 Table I(D) Delete: Table I(D) Insert: New Table I(D) Make a note of this amendment on the amendment record. D/D Stan/372/07/19 92/70002 23 October 1996 Ministry of Defence Directorate of Standardization Stan Ops 2b Kentigern House 65 Brown Street GLASGOW G2 8EX Table I(D) Standard Range Cables, Special Purpose, Electrical and Cables, Power, Electrical Type 1SBM 85, 1SBM 120 and 2SBM Limited Fire Hazard Insulation, Screened and Sheathed (Toxicity Index ≤ 0.2) NATO STOCK NUMBER 6145-99PAGE LINE NO CONDUCTOR SIZE ITEM NAME TYPE 1SBM 85 PINK INSULATION (a) (b) (c) WHITE INSULATION (d) TYPE 1SBM 120 TYPE 2SBM PINK INSULATION WHITE INSULATION PINK INSULATION WHITE INSULATION (e) (f) (g) (h) 1 2 3 4 19/0.10 19/0.12 19/0.15 19/0.20 CABLE SPECIAL PURPOSE ELECTRICAL 053-5000 053-5001 053-5002 053-5003 053-5008 053-5009 053-5010 053-5011 891-9767 891-9771 891-9775 891-9779 891-9768 891-9772 891-9776 891-9780 891-9769 891-9773 891-9777 891-9781 891-9770 891-9774 891-9778 891-9782 5 6 7 8 19/0.25 19/0.30 37/0.25 37/0.30 CABLE POWER ELECTRICAL 053-5004 053-5005 053-5006 053-5007 053-5012 053-5013 053-5014 053-5015 891-9783 891-9787 891-9791 891-9795 891-9784 891-9788 891-9792 891-9796 891-9785 891-9789 891-9793 891-9797 891-9786 891-9790 891-9794 891-9798 NOTE: The NATO Stock numbers in columns (c), (d), (e) and (f) are only applicable to cables where the insulation is coloured pink or white (as applicable) and the sheath colour is black. Amdt.2 DEF STAN 61-12 (PART 18)/4 WIRES CORDS AND CABLES, ELECTRICAL METRIC UNITS PART 18: EQUIPMENT WIRES LIMITED FIRE HAZARD AMENDMENT 3 1 Page 22 Table 1(A), column (n), Page Line No 13 Delete: 891-9568 Insert: 891-9586 2 Make a note of this amendment on the amendment record D/DStan/372/07/19 92/70002 25 April 1997 Ministry of Defence Directorate of Standardization Stan Ops 2b Kentigem House 65 Brown Street Glasgow G28EX Procurement Executive, Ministry of Defence Directorate of Standardization Room 1138, Kentigern House, 65 Brown Street, GLASGOW, G2 8EX Telephone: 0141-224 2595 (Direct Dialling) 0141-248 7890 (Switchboard) Internet e-mail address: t.leaver@dstan.mod.uk Fax: 0141-224 2503 Your Reference : Our Reference : D/DStan/11/2 Date : 9 November 1998 Removal of Product Qualification Approval IMPORTANT ANNOUNCEMENT 1. This Standard contains a Product Qualification Approval (PQA) scheme. iMOD policy requires that all PQA schemes are removed from Defence Standards called up in contracts placed after 1st January 1998. 2. Users of this Standard are to contact the Project Manager (PM), Equipment Support Manager (ESM) or Technical Service Authority (TSA) named in the contract or order, to identify whether there is a continuing need for an approvals scheme. ii 3. Product Conformity Certification (PCC) is a risk based process that replaces PQA. Once a risk has been identified PCC can be included as a contract clause. In exceptional circumstances agreement can be sought from AD/Stan for PCC to be included in a Defence Standard. 4. At the next revision of this Standard the PQA scheme will be removed. T R Leaver Head of Standards Programme Management Tel: 0141 224 2595 FAX: 0141 224 2503 i Defence Council Instruction (General) 197/97; Quality Temporary Memorandum 5/98; Chief of Defence Procurement Instruction CDPI/TECH/250 (draft) ii PCC is certification that a product meets its specification. When PC is required by the contract, the contractor is responsible for obtaining the necessary PCC. Certification shall be provided from a NAMAS accredited laboratory when appropriate. PCC shall apply where a Risk Assessment has been identified by the PM; ESM or TSA.