De Nora Electrodic Package for Alkaline Water Electrolysis

advertisement

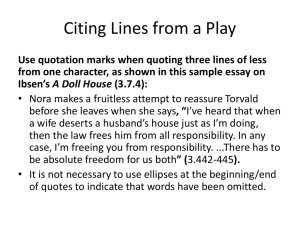

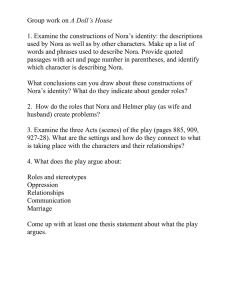

De Nora electrodic package for Alkaline Water Electrolysis “Hydrogen has the potential to be a powerful enabler of the world future energy transition “ (The Hydrogen Council – January 2017) The importance of long lasting energy storage technologies Discharge time (hours) Energy storage will become a key component of power systems in the next decades, as the share of intermittent renewables energy in the power mix continues to rise. Within the portfolio of storage technologies, hydrogen is widely recognized as a promising option for storing large quantities of renewable electricity over longer periods. For that reason, in a future where renewables energies (RES) will be the dominant power source, opportunities for Power to Hydrogen (P2H) in the long-term are acknowledged. But hydrogen is foreseeing to be not only a media for the longPower to Gas SNG 1000 100 Compressed Air Storage 10 Pumped Storage Power to Gas Hydrogen 1 The most established technology option for producing hydrogen from electrical power sources is water electrolysis. Water electrolysis will be in the future the viable alternative to steam methane reforming + carbon capture and storage (SMR + CCS) for green hydrogen generation. Month Day Hour Batteries 0,1 0,01 term energy storage, it can be also the energy vector for a more sustainable MOBILITY (through Fuel Cell Electric Vehicles - FCEV) and a renewable feedstock for a variety of CHEMICAL PRODUCTIONS (ammonia, methanol, green fuels, …). Energy Storage Technologies California Hydrogen Business Council Flywheel 0,001 AWE Stack – courtesy of McPhy Energy (2019) 1kWh 10kWh 1MWh 1GWh 1TWh 100TWh Storage size SNG = Synthetic Natural Gas (Power to Gas – Hydrogen plus methanation) Pumped Storage = Hydro electric Batteries = Lithium and Redox Flow About water electrolysis technologies and the contribution of De Nora electrodic package Alkaline electrolyzers offer the best economics and are likely to be dominant technology for renewable hydrogen production to 2020; (Bloomberg NEF: hydrogen the economics of production from renewables – 2019) Differently from SMR water electrolysis uses limited temperatures and less harmful catalysts for the hydrogen generation, with a substantial reduction of the risk level associated with this production and a strong simplification of the production processes (suitable for centralized of distributed generation and characterized by lower maintenance expenses). With a 100% RE power mix, water electrolysis can produce GREEN HYDROGEN with zero CO2 emissions. Three main electrolyzer technologies are used or being developed today: Alkaline (AWE) is well established and have been used by industry for nearly a century, proton exchange membrane (PEMWE) is commercially available today, while Solid Oxide (SOWE) are still in the development phase. Both AWE and PEMWE are suitable for centralized or distributed hydrogen (and oxygen) productions. De Nora in the recent years spent substantial R&D efforts on AWE to maximize its operating current density (CD) and reduce the overall power consumption, to push this technology toward the PEMWE performances but guaranteeing the lower CAPEX investment. AWE electrolyzers equipped with the electrodic De Nora package inside are able, today, to provide the lower total cost of hydrogen (TCH) for the Power to Hydrogen installation competitive with SMR+CCS. Intensification of alkaline water electrolysis – courtesy of Nouryon (2019) As alternative to the “package” De Nora could supply, eventually, the active electrodes only, realized following customers proprietary drawings and therefore easy to install inside the existing electrolysis cells / stacks. De Nora electrodic package In the last decade De Nora run, also through dedicated Joint Development Agreements with major partners, a structured project to close the main technological drawbacks of the alkaline water electrolysis as identified by SBC Energy Institute in the «hydrogen based energy conversion study» (see figure below from SBC EI 2017) and other referenced studies. The electrodic package design started from the necessity of guaranteeing a perfect and “live” ZERO GAP configuration, able to ensure anode and cathode contact to the diaphragm in any operating conditions and along the overall life of the package. In the electrodic package the cathode is always activated to reduce the hydrogen evolving over potential, while the anode can be In particular projects pursued the lower TCH through a activated or not, depending from the requested performances. reduction of the overall AWE plant footprint (maximizing the operating current density) and the optimization of the overall power consumption (increasing efficiency and De Nora can supply to customers different combinations operating pressure), while maintaining a low manufacturing of anode and cathode coatings as function of the electrolyzer operating conditions, the overall required performance in terms cost of the electrolyzer. of cell voltage and the availability to an higher CAPEX expenditure for obtaining the lower possible OPEX. Case by case De Nora SALES and BUSINESS DEVELOPMENT could assist customers in finding the electrodes combination capable to provide, given the specific boundary conditions, the lower TCH. Embedded into the package De Nora could supply in addition to the electrodes other cell internals such as: the cell bipolar plates, the anode/cathode separator (membrane or diaphragm) and the related gasketing system (between the separator and the cell frames). High Current Densities reduce the stack foot print, allowing a substantial CAPEX cost reduction to our customers that could also benefit of good OPEX costs; Product description Cathode Separator Anode DEA diaphragm electrode assembling composed by: Separator Diaphragm AGFA Zirfon Perl UTP 500/220 https://www.agfa.com/specialty-products/solutions/membranes/zirfon/ Flow Fields Elastic element for ZG configuration Ni mattress; (type and thickness/shape depend from the cell geometry and must be designed case by case by the DN’s team); Cathode Gaskets Flow Field De Nora’s electrodic package push Alkaline Water Electrolysis toward PEM Water Electrolysis performances, allowing the best TCH (Total Cost of Hydrogen) Activated mesh Ni Flynet activated NRG®; Proprietary De Nora coating originally developed for the membrane chlor alkali market, with whit a huge installed base (100.000 m2) and proven > 8 years lifetime; http://www.denora.com/products/cathodes.html Anode Nickel mesh Ni flynet non-activated; (the “standard” package uses a simple nickel net as electrode). Different types of anode coating are available and can be used to reach higher cell performances; Other parts Gaskets (between separator and cell frame); Bipolar plates (if requested); Operating Conditions Electrolyte KOH or NaOH (25 ÷ 30% w/w); Temperature 70 ÷ 80°C (design) or higher depending from the STACK / BOP (balance of plant) design temperature; Pressure Up to 60 bar(g) (design) depending from the STACK/BOP design pressure; Delta Pressure 0.2 bar (design) differential pressure between anodic and cathodic chambers; Circulation Forced or natural (gas lifting), depending from the design Current Density (CD), Cell Voltage, (CV) and the operating pressure; Normally the electrolyte circulation configuration and its flow rate are defined in collaboration with our experts to limit the ΔT (delta temperature) through the cell < 15°C; Current Density Up to 12 kA/m2 Performance (expected) Guaranteed performances on cathode HOV (Hydrogen Over Voltage) and anode OOV (Oxygen Over Voltage) will be provided specifically based on the customer plant configuration by our experts Electrodes coating life time : Electrodes coating life time: > 5 years (#, ##) (#) Electrodic package life time indicated above refers to a current density of 9 kA/m2. In case of a higher current density (up to 10 kA/m2) and / or a required lifetime period beyond 5 years, the subject should be discussed in detail with De Nora specialists; (##) The acceptable number of unprotected shut down (complete system shut down, no load fluctuation) per day should be discussed and agreed between the customer and De Nora because impacting on the coating solution choice; Electrodes coating performances drift: Cathode performance drift: < 0,5 % / Year Anode performance drift: < 0,5 % / Year Parameters affecting the cathode coating performances decay are: • Operating current density (CD); • Pollutants concentration in the electrolyte loop; • Number of starts / stop in unprotected (no polarized) conditions; Installation of De Nora package into an existing AWE cell architecture can increase the operating CD by more than two times, maintaining or even reducing the cell voltage Electrolyte LOOP quality Gas quality The table below shows the maximum allowable critical pollutants concentration to keep in the electrolyte loop to reach the higher performance and longer life of the package: Gas quality is impacted by three factors: oxygen and hydrogen permeation through the diaphragm, cross contamination through the diaphragm sealing system and gas dissolved in the electrolyte loop. The first point relates solely to the diaphragm performance, while the third to the system/BOP configuration: single or dual electrolyte circulation typically. Component (cations) Conc. Unit Iron 200 ppb (w/w) Chromium 5 ppm (w/w) Calcium/Magnesium 10 ppm Chloride 100 ppm (w/w) Carbonate 10.000 ppm (w/w) Silica 20 ppm (w/w) Sulphate 1.000 ppm (w/w) Demi water quality The table above indirectly determine the feed demi water quality. A simple material balance of the system, considering the initial KOH purity, the BOP material corrosion rate and the demi water feed quality, should close (at the end of the expected electrodes life) on the pollutants concentrations value reported in the table. More details on feed water quality and maximum allowable pollutants concentration in the electrolyte loop could be provided by our experts on request. The second point have been addressed by De Nora designing a dedicated gasketing system for the package able to strongly limit the cross of hydrogen and oxygen between the diaphragm and cell frame during normal operations. Services Thanks to its global footprint De Nora can guarantee the supply of new electrodes or electrodic packages and maintenance / refurbishment services, almost in any country around the world. Country References: De Nora Italy: Europe and Africa Asia and China Japan America Corporate (Italy) gaetano.porcino@denora.com simone.tremolada@denora.com De Nora China: andrea.cremonesi@denora.com De Nora Japan: andrea.cremonesi@denora.com De Nora North America: chuck.shultz@denora.com De Nora Corporate: michele.sponchiado@denora.com AWE Stack – courtesy of tkUCE (2020) AWE Stack – courtesy of McPhy Energy (2019) AWE Stack – courtesy of tkUCE (2020) WATER ELECTROLYSIS info.dnd@denora.com marketing@denora.com www.denora.com © Copyright 2016 Industrie De Nora S.p.A. - All rights reserved. De Nora, ON circle, Our research - your future, electrochemistry at your service (and any other trademark name) are trademarks or registered trademarks of Industrie De Nora S.p.A. in Europe and/or other countries. Other trademarks used herein are the registered trademarks of their respective owners. The information contained herein is offered for use by technically qualified personnel at their discretion and risk without warranty of any kind. DN-Etek-04/2016