Pickup & Delivery Terminal Case Study: Cost Analysis

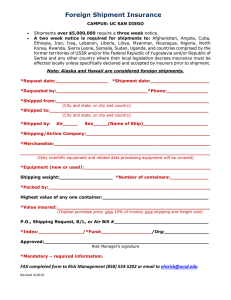

advertisement