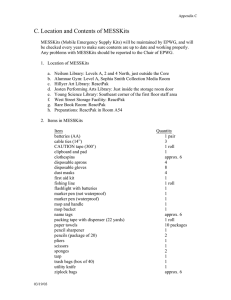

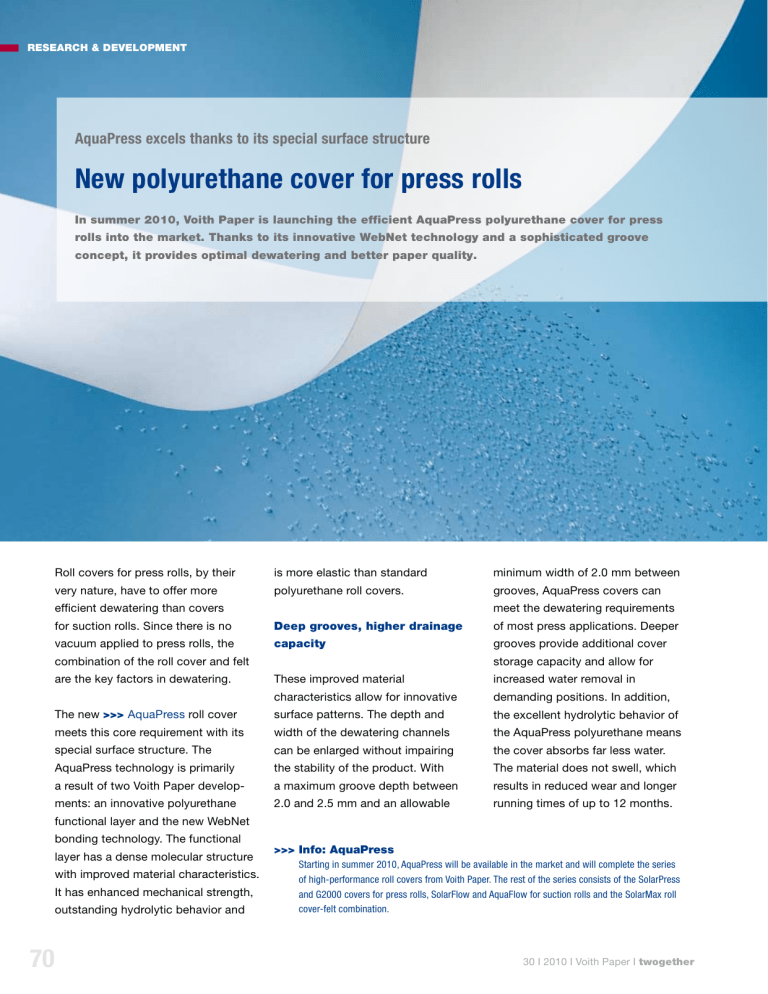

RESEARCH & DEVELOPMENT AquaPress excels thanks to its special surface structure New polyurethane cover for press rolls In summer 2010, Voith Paper is launching the efficient AquaPress polyurethane cover for press rolls into the market. Thanks to its innovative WebNet technology and a sophisticated groove concept, it provides optimal dewatering and better paper quality. Roll covers for press rolls, by their is more elastic than standard minimum width of 2.0 mm between very nature, have to offer more polyurethane roll covers. grooves, AquaPress covers can efficient dewatering than covers meet the dewatering requirements for suction rolls. Since there is no Deep grooves, higher drainage of most press applications. Deeper vacuum applied to press rolls, the capacity grooves provide additional cover combination of the roll cover and felt are the key factors in dewatering. storage capacity and allow for These improved material increased water removal in characteristics allow for innovative demanding positions. In addition, The new >>> AquaPress roll cover surface patterns. The depth and the excellent hydrolytic behavior of meets this core requirement with its width of the dewatering channels the AquaPress polyurethane means special surface structure. The can be enlarged without impairing the cover absorbs far less water. AquaPress technology is primarily the stability of the product. With The material does not swell, which a result of two Voith Paper develop- a maximum groove depth between results in reduced wear and longer ments: an innovative polyurethane 2.0 and 2.5 mm and an allowable running times of up to 12 months. functional layer and the new WebNet bonding technology. The functional layer has a dense molecular structure with improved material characteristics. It has enhanced mechanical strength, outstanding hydrolytic behavior and 70 >>> Info: AquaPress Starting in summer 2010, AquaPress will be available in the market and will complete the series of high-performance roll covers from Voith Paper. The rest of the series consists of the SolarPress and G2000 covers for press rolls, SolarFlow and AquaFlow for suction rolls and the SolarMax roll cover-felt combination. 30 I 2010 I Voith Paper I twogether RESEARCH & DEVELOPMENT Continuous operational temperature on the cover surface Hardness Primary applications AquaFlow 75 °C 5, 10, 15, 20, 25, 30 and 35 P&J SolarFlow 80 °C AquaPress Groove dimensions Groove width Web width Groove depth Suction roll 0.5-0.9 mm 2.0-2.5 mm 2.0-2.3 mm Roll cover for all current applications 5, 10, 15, 20, 25, 30 and 35 P&J Suction roll 0.4-0.9 mm 1.8-2.5 mm 2.5-3.0 mm Premium roll cover for high demanded applications 75 °C 5, 10, 15, 20, 25, 30 and 35 P&J Press rolls, smoothing press rolls, counter rolls in double felted shoe presses 0.5-0.9 mm 2.0-2.5 mm 2.0-2.5 mm Roll cover for all current applications SolarPress 80 °C 5, 10, 15, 20, 25, 30 and 35 P&J Press rolls, smoothing press rolls, counter rolls in double felted shoe presses 0.4-0.9 mm 1.8-2.5 mm 2.5-3.0 mm Premium roll cover for high demanded applications G 2000 85 °C 4 P&J Press rolls and counter rolls in double felted shoe presses Steel roll replacement 0.4-0.9 mm 1.8-2.5 mm 2.5-3.0 mm Premium roll cover for high demanded applications The right cover for each application: Voith Paper offers different polyurethane roll covers for the press section. AquaPress is available in three blind-drilled holes with the newly WebNet is based on the different surface designs: developed groove structures. interpenetrated network technology grooved, blind-drilled or a used in aircraft and automobile combination of grooved and blind- WebNet technology as the construction. The close cross-linking drilled. AquaPress can therefore be successor to AST of polymers in the bonding layer adapted to meet the dewatering results in improved temperature demands of the customer’s The WebNet layer is an additional resistance and increased stability application. It is also worth noting innovative component of AquaPress. of the roll cover against chemical that in some applications a high WebNet has an enhanced three- damage and high mechanical stress. void volume grooved surface pattern dimensional cross-linking of polymers may be used instead of grooved and provides an improved bond and blind-drilled. These patterns can between the polyurethane functional provide improved dewatering and layer and the base layer. WebNet eliminate the potential for nip flooding is an evolutionary advancement of and shadow marking. AquaPress the AST bonding layer developed compensates for the capacity of the by Voith Paper in the 1990s. Contact Michael Weinzettl michael.weinzettl@voith.com The grooved AquaPress roll cover (left) stands out due to the new WebNet technology (right). 30 I 2010 I Voith Paper I twogether 71