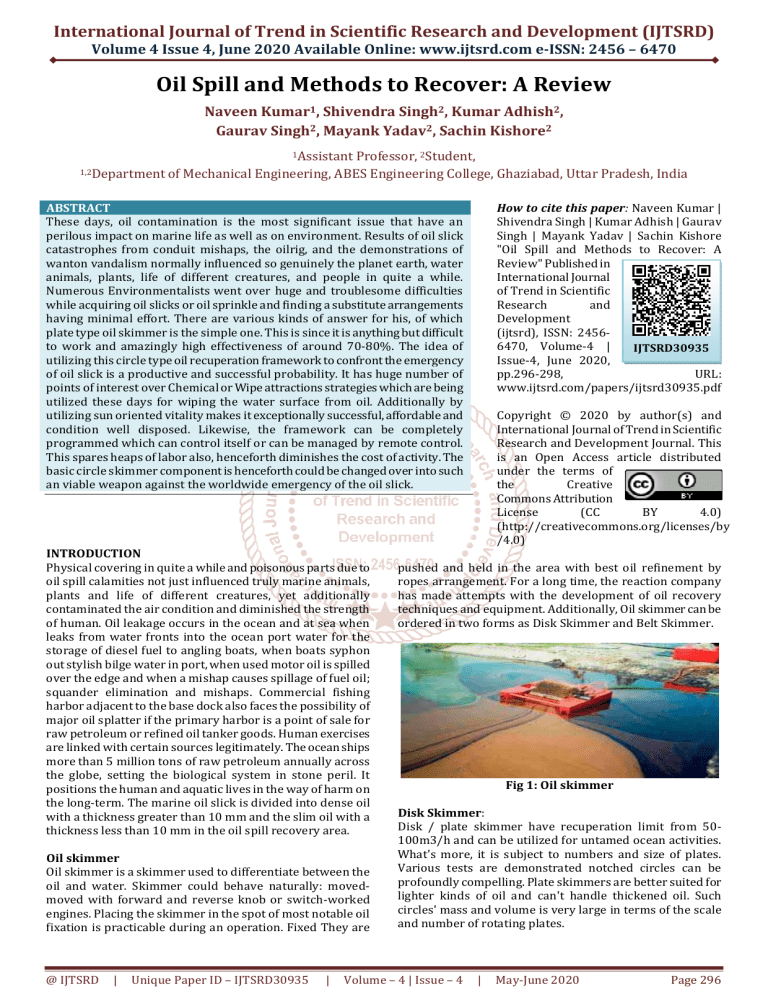

International Journal of Trend in Scientific Research and Development (IJTSRD) Volume 4 Issue 4, June 2020 Available Online: www.ijtsrd.com e-ISSN: 2456 – 6470 Oil Spill and Methods to Recover: A Review Naveen Kumar1, Shivendra Singh2, Kumar Adhish2, Gaurav Singh2, Mayank Yadav2, Sachin Kishore2 1Assistant Professor, 2Student, 1,2Department of Mechanical Engineering, ABES Engineering College, Ghaziabad, Uttar Pradesh, India How to cite this paper: Naveen Kumar | Shivendra Singh | Kumar Adhish | Gaurav Singh | Mayank Yadav | Sachin Kishore "Oil Spill and Methods to Recover: A Review" Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 24566470, Volume-4 | IJTSRD30935 Issue-4, June 2020, pp.296-298, URL: www.ijtsrd.com/papers/ijtsrd30935.pdf ABSTRACT These days, oil contamination is the most significant issue that have an perilous impact on marine life as well as on environment. Results of oil slick catastrophes from conduit mishaps, the oilrig, and the demonstrations of wanton vandalism normally influenced so genuinely the planet earth, water animals, plants, life of different creatures, and people in quite a while. Numerous Environmentalists went over huge and troublesome difficulties while acquiring oil slicks or oil sprinkle and finding a substitute arrangements having minimal effort. There are various kinds of answer for his, of which plate type oil skimmer is the simple one. This is since it is anything but difficult to work and amazingly high effectiveness of around 70-80%. The idea of utilizing this circle type oil recuperation framework to confront the emergency of oil slick is a productive and successful probability. It has huge number of points of interest over Chemical or Wipe attractions strategies which are being utilized these days for wiping the water surface from oil. Additionally by utilizing sun oriented vitality makes it exceptionally successful, affordable and condition well disposed. Likewise, the framework can be completely programmed which can control itself or can be managed by remote control. This spares heaps of labor also, henceforth diminishes the cost of activity. The basic circle skimmer component is henceforth could be changed over into such an viable weapon against the worldwide emergency of the oil slick. INTRODUCTION Physical covering in quite a while and poisonous parts due to oil spill calamities not just influenced truly marine animals, plants and life of different creatures, yet additionally contaminated the air condition and diminished the strength of human. Oil leakage occurs in the ocean and at sea when leaks from water fronts into the ocean port water for the storage of diesel fuel to angling boats, when boats syphon out stylish bilge water in port, when used motor oil is spilled over the edge and when a mishap causes spillage of fuel oil; squander elimination and mishaps. Commercial fishing harbor adjacent to the base dock also faces the possibility of major oil splatter if the primary harbor is a point of sale for raw petroleum or refined oil tanker goods. Human exercises are linked with certain sources legitimately. The ocean ships more than 5 million tons of raw petroleum annually across the globe, setting the biological system in stone peril. It positions the human and aquatic lives in the way of harm on the long-term. The marine oil slick is divided into dense oil with a thickness greater than 10 mm and the slim oil with a thickness less than 10 mm in the oil spill recovery area. Oil skimmer Oil skimmer is a skimmer used to differentiate between the oil and water. Skimmer could behave naturally: movedmoved with forward and reverse knob or switch-worked engines. Placing the skimmer in the spot of most notable oil fixation is practicable during an operation. Fixed They are @ IJTSRD | Unique Paper ID – IJTSRD30935 | Copyright © 2020 by author(s) and International Journal of Trend in Scientific Research and Development Journal. This is an Open Access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0) (http://creativecommons.org/licenses/by /4.0) pushed and held in the area with best oil refinement by ropes arrangement. For a long time, the reaction company has made attempts with the development of oil recovery techniques and equipment. Additionally, Oil skimmer can be ordered in two forms as Disk Skimmer and Belt Skimmer. Fig 1: Oil skimmer Disk Skimmer: Disk / plate skimmer have recuperation limit from 50100m3/h and can be utilized for untamed ocean activities. What's more, it is subject to numbers and size of plates. Various tests are demonstrated notched circles can be profoundly compelling. Plate skimmers are better suited for lighter kinds of oil and can't handle thickened oil. Such circles' mass and volume is very large in terms of the scale and number of rotating plates. Volume – 4 | Issue – 4 | May-June 2020 Page 296 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 Solar Panel Fig 2: disk skimmer Belt Skimmer The slimmer belt oil makes use of a belt of treated steel. This belt is mixed with oil and immersed in the ocean water. The belt at that point goes through exceptional wiper cutting edges, which isolates the oil which is slicked on a superficial level. Fig 6: solar panal Skimming Disc and Belt Oil collecting tank Fig 7: oil collecting tank Bearings Floating Tube Fig 3: belt skimmer Literature Survey: Enormous number of research has been done and various paper was found during the writing study of this venture which lead to an extraordinary development. While writing this overview, it was guaranteed that the aftereffect of this exploration will be useful in contributing on this task. List of Components: DC Motor Zhu, Xueqing, Albert D Venosa, Makram T Suidan, and Kenneth Lee et al.,[2]The abridged strategies for recuperating and treating the oil slick from mishap, debacles were proposed. Every technique additionally included preferences and burdens. Consequently, it was important to complete the standards to assess targeting picking the most reasonable oil slick recuperation strategies. The rules ought to be unwavering quality, effectiveness, recuperation and recovery time, charge, water life impact, trouble level, capacity of oil recuperation, level of relying upon climate problems, level of impact on oil attributes of oil, level of further treatment subsequent to recouping. Fig 4: dc motor Chain drive for power transmission Shaft Battery Reynolds, John G, Paul R Coronado, and Lawrence W Hrubesh et al.[3] Reynolds, John G, Paul R Coronado, and Lawrence W Hrubesh et al.[3]Warm or in-situ expenditure technique was a fundamental and intelligent one involving oil spill or thick oil slick burned out of water. This approach has been used to minimize the risks and impacts of oil slick and oil spill on the organic in-water environment and marine state. By warm or in-situ expending technique, a 100-300 tons of oil spill and smooth could be collected every hour. This technique has been widely used since the 1960s, focusing on ousting oil spill, oil slick in / on ice, water, snow, the setbacks from broken pipeline, punctured / broken limit tank or pontoon accidents in the United States, Canada, Europe. Fig 5: battery @ IJTSRD | Unique Paper ID – IJTSRD30935 | Volume – 4 | Issue – 4 | May-June 2020 Page 297 International Journal of Trend in Scientific Research and Development (IJTSRD) @ www.ijtsrd.com eISSN: 2456-6470 Si-Zhong, YANG et al., [4] An in-situ consuming advanced its bit of leeway in oil slick cleanup while utilized in ice, cold water conditions or snow due to upkeep capacity of conditions preferring ignition for quite a while. Despite the fact that this strategy was a successful one to recuperation the oil slick, anyway the primary limitations of this technique were the capacity of happening auxiliary flames, the effect on the human wellbeing, the effect of consumed result on the earth. Zhang Yindong et al.,[5] The most widely used innovation in oil spill response capable of stripping waterborne oil using mechanical equipment called skimmer is mechanical recovery. Oil and water thickness is especially important so here we used the working rule that relies on the section of gravity type oil water. In which a delicacy force is expressed in view of the distinction in thickness where prepared to achieve separation of oil water. New technique of negative weight pull and twisted surface redirection is used to improve the division of oil water. Through this process, the skimmer-recovered oil water mix can be effectively pulled into a separator and obtain an upward base speed in the stream sector, so that the oil globules can provide greater separation across and float upward at higher speeds. Chunchang Zhang et al.,[7] water temperature and spill time are two fundamental factors that influence the thickness of the oil outwardly from the surface. Skimmer's pass will be as fast as time allows before oil thickness decreases, so oil recovery should be at a faster pace and high efficiency. Skimmer should be resigned when oil spill thickness starts to become brittle, and is not immune to skimmer mechanical recovery. Checking and identification on the spot is important for skimmer's mechanical recovery. Other than the thickness of oil, skimmer's pace and freeing width are notable segments for skimmer's recovery break point. The skimmer's speed and clearing width will usually be changed to support the skimmer's ampleness. Dhonde Dipak Panditrao et al.,[8] considered the use of both the plates and the belt for the methodology of oil separation. They went to a target in the wake of organizing and testing this effort that their contraction could isolate oil from water with 90 % efficiency for all purposes and purposes. Fingas, Mervin et al.[9]For the most part, physical methods were used as barriers to handling and preventing oil slick and oil spill from spreading but the physical oil and concoction qualities did not develop. For starters, blasts, skimmers, adsorbent materials aimed at controlling oil slicks and oil slicks were used in various boundaries.Boom: Boom is a typical sort of hardware used to forestall oil slick and smooth from spreading. Nonetheless, the viable activity of blasts relied upon the blast structure, yet additionally was unequivocally influenced by the qualities of the flows, wind heading, speed, and wave tallness. If current speed above 0.5 m / s may occur, wind speed above 5.6 m / s or wave tallness above around 1.23 m will convey sliced oil and oil slick below the impediment. G. Alaa El-Din et al.[10] examined oil detachment from water using banana strip as a tool. It has been discovered that different oil-type qualities, such as oil weight, oil film density, retention rates time, surface temperature, just as brininess, all affect oil intake cap. It can very well be seen that banana strip intake cap gives a decent result as another @ IJTSRD | Unique Paper ID – IJTSRD30935 | and ease farming waste for cleaning up the oil slick. Banana strip helps to minimize biological emissions along these lines, but it also helps to reduce the squandering of horticulture. CONCLUSION Solar panels based oil slick recovery frame however is quick, powerful and easy to use affordable and environment friendly framework to handle the worldwide emergency of the oil slick. It has numerous points of interest over till date innovations to clean oil leaked water. It will viably clean the water surface retrieving much of the oil back into functional structure. The framework can be mechanized and run on a near planetary system which makes it extremely capable of getting by all alone.Thus loads of human endeavors are disposed of and consequently oil slick recuperation can get quicker and effective reaction can be acquired. The dangerous impacts of oil slick are in this manner successfully diminished. Henceforth, solar based disk type oil slick recovery framework vows to be a significant instrument against worldwide emergency of oil spill. ACKNOWLEDGMENT The authors acknowledge Mr. Naveen Kumar Faculty of ABES Engineering College Ghaziabad, for supporting and guiding for this review paper. REFERENCES [1] Yin, Peihai, 2000. Prevention technology of ship pollution. Dailan: Dailan Maritime University Press. [2] Zhu, Xueqing, Albert D Venosa, Makram T Suidan, and Kenneth Lee. 2001. “Guidelines for the Bioremediation of Marine Shorelines and Freshwater Wetlands.” US Environmental Protection Agency. [3] Reynolds, John G, Paul R Coronado, and Lawrence W Hrubesh. 2001. “Hydrophobic Aerogels for Oil-Spill Cleanup–Synthesis and Characterization.” Journal of Non-Crystalline Solids 292(1): 127–37. [4] Si-Zhong, YANG et al. 2009. “Bioremediation of Oil Spills in Cold Environments: A Review.” Pedosphere 19(3): 371–81. [5] Zhang Yindong et al., (2014) The improvement of oilwater separation technology in oil spill mechanical recovery. International Conference on Logistics Engineering, Management and Computer Science. [6] Lingzhi Zhao et al., (2015) Research development and key scientific and technical problems on EMHD marine oil film recovery technology. International Oil Spill Response Technical Seminar, 02.223. [7] Chunchang Zhang et al., (2015) Modified assessment methodology for mechanical recovery capacity for oil spill response at sea. International Oil Spill Response Technical Seminar, 02.224. [8] Dhonde Dipak Panditrao et al., (2016) Sea oil separator with disc and belt skimmer. International Journal for Scientific Research & Development, Vol. 4, Issue 01. [9] Fingas, Mervin. 2016. Oil Spill Science and Technology. Gulf professional publishing. [10] G. Alaa El-Din et al., (2017) Study on the use of banana peels form oil spill removal. Alexandria Engineering Journal, 05.020. Volume – 4 | Issue – 4 | May-June 2020 Page 298