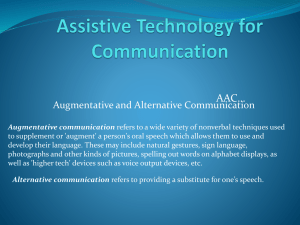

International Journal of Trend in Scientific Research and Development (IJTSRD) International Open Access Journal ISSN No: 2456 - 6470 | www.ijtsrd.com | Volume - 2 | Issue – 5 Beneficial Usage sage of Autoclaved Aerated Concrete Block Khin War Oo1, Su Nandar Hlaing2 1 Lecturer, 2Assistant Lecturer Department of Mechanical Engineering, Yangon Technological University University, Yangon, Yangon Myanmar ABSTRACT This paper is about the study of beneficial usage of AAC block production in Mother Industrial Co., Ltd (AAC and APC block factory). Autoclaved Aerated Concrete is one of such green materials. ials. It not only uses the waste material like fly ash but also provides adequate strength to structures. The main aim of this paper is to show the beneficial usage of AAC block instead of the use of conventional brick. For that, the beneficial usage of AAC C block is showed on many ways. The beneficial usage of AAC block shows the cost saving calculation of AAC block. As the next way, the beneficial usage of AAC block shows the weight saving calculation of AAC block. Quality control chart (x bar and R chart) use to prove the benefit of AAC blocks in checking the production process. The other way is the compressive strength calculation between conventional brick and AAC block to show the benefit of AAC block. Finally, the power consumption cost saving calculat calculation of AAC block compared with conventional brick is to show the benefit of AAC block. Keywords: aerated concrete block, beneficial usage, cost saving, compressive strength, weight saving, power consumption cost I. INTRODUCTION It is very essential for human beings to live in a building in the world. Man has used brick for building purpose for thousands of years. Bricks dated back to 7000 BC, which makes them one of the oldest known building materials. There were discovered in so southern turkey at the site of an ancient settlement around the city of Jericho. The first bricks were sun sun-dried mud bricks. Fired bricks were found to be more resistant to harsher weather conditions, which made them a much more reliable brick for use in permanent rmanent buildings, where mud bricks would not have been sufficient. Fired brick were also useful for absorbing any heat generated throughout the day, then releasing it at night. The autoclaved aerated concrete block has its obvious advantages of higher strength to weight ratio, better tensile strain capacity, lower coefficient of thermal expansion, and enhanced heat and sound insulation characteristics due to air voids in the concrete. [1] Autoclaved aerated concrete blocks can be applicable in construction ion engineering (compensation for the foundation, pipeline backfilling, roof insulation, etc.), but also get some application result in infrastructure facilities (such as bridge and culvert backfill, road widening, resolving bumping at bridge-head bridge of soft base embankment. [2] Brick are one of the most building materials in the India. In recent years, with expanding urbanization and increasing demand for construction materials, brick kilns have grown to meet the demand. It has directly or indirectly caused a series of environmental and health problems. At a global level, environmental pollution from brick- making operations contributes to the phenomena of global warming and climate change.[3] Brick which form an extremely important part of the Indian construction ction industry have many disadvantages. The brick kilns cause air pollution which not only affects humans but also vegetation and agriculture. Large amount of carbon dioxide and other harmful gases lead to the menace of global warming and climate change. Also lso the precious soil used for brick making could be better used for agriculture and thus providing food security to the increasing population [4]. @ IJTSRD | Available Online @ www www.ijtsrd.com | Volume – 2 | Issue – 5 | Jul-Aug Aug 2018 Page: 1961 International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470 The determination of using brick with optimal quality and energy saving is needed to be a strong building. This thesis is to study a comparison between conventional brick and the benefit of autoclaved aerated concrete block on the environment. II. MANUFACTURING AAC can be used as walls, partitions, floor and roof decks, and other building components, or as an integrated system for structures up to seven stories high. It is substantially unaffected by shrinkage, moisture, decay, termites and other common causes of building deterioration and it is environmentally “green” building material because it is easily recycled back into its own production process. AAC also appears to be a cost comparative building material and ease of cutting boots construction productivity. A. Equipment List The equipment list are sand ball mill (wet), jaw crusher (Lime Section), Fly-ash, slurry storage mixer, mixer scale, pouring mixer, mould box, hydraulic frequency conversion, cutting cart, horizontal cutting machine, vertical cutting machine, reversal table, transporting crane or grouping crane, steam curing trolley, autoclave, boiler and separating machine. B. Raw Materials Used in the Manufacture of AAC Block Cement: Portland cements is generally preferred over other types of cements. Water: Portland water should be used which, must conform with the general requirements of the concrete. Sand: It is an important raw material in the manufacture of AAC Blocks. Quick Lime: Lime powder required for ACC production is obtained either by crushing limestone to fine powder at AAC factory or by directly purchasing it in powder from a vendor. Gypsum: Gypsum is easily available in the market and is used in powder form. It is stored in silos. Aluminium Powder C. Procedure Milling, Mixing, Pouring; Sand and water is milled by the Wet Ball Milland the slurry is put into the slurry pond and it is stored into the slurry tank and the slurry is put into the slurry tank and the slurry is put into the Pouring Mixer. Gypsum is crushed by Jaw Crusher and Gypsum ponder is stored into the silo and it is put into the Pouring Mixer. Sand and water and Gypsum is mixed into the Pouring Mixer for 40sec.Cement is stored into the silo and it is put into the Pouring Mixer. Lime is crushed by the Jaw Crusher and lime is milled by the Dry Ball Mill and it is stored into the silo and it is put into the Pouring Mixer. Cement and Lime is mixed into the Pouring Mixer and the time is for one min. To get the aluminium mixture. We have to open the temperature bar and adjust the temperature to 42℃ keep it about 15sec.Finally we mixed sand, water and gypsum mixture, Aluminium and water mixture. The mixture keep it about 40sec.We have the temperature must put to watch the temperature right to about 47℃ and is put into the mould and dry in the curing room where the temperature is about 50 to 55℃.Block must be lifted with a reversal crane. Block must be lifted with a reversal crane. Cutting and Distilling: The block is cut with a horizontal cutting machine and then cut with vertical cutting machine to get a suitable size and the extra art is cut with Bottom wipe off crane and the block must be distilled in autoclave. Separating: Block must be separated and we can get the block which we want to build. D. Size of AAC Block The photographic view of the AAC blocks (1) length600mm, height-200mm, thickness-200mm, Cost-1800 kyats and (2) Length-600 mm, Height-200 mm, Thickness-100 mm, Cost-950 kyats are shown in Figures 1 and 2. Fig.1. AAC block Fig.2.AAC block @ IJTSRD | Available Online @ www.ijtsrd.com | Volume – 2 | Issue – 5 | Jul-Aug 2018 Page: 1962 International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470 III. COMPARISONS 1. First is the cost saving calculation of AAC block compared with conventional brick for building a wall that have 100 ft2 to prove the benefit of AAC block. 2. Second is the weight saving of AAC block compared with conventional brick base on a wall that have 100ft2 to prove the benefit of AAC block. 3. Third is the compressive strength calculation between conventional brick and autoclaved Material Clay Brick Cement Sand Mason Worker AAC Block AAC Mortar Mason Worker aerated concrete block using method of sampling and testing. 4. Fourth is the power consumption cost saving calculation of AAC block compared with conventional brick 5. Fifth is calculating the cost saving of AAC block need the cost data of raw materials for AAC block and conventional brick and other requirement data. Following data got from Mother Industrial Co., Ltd (AAC and APC Block factory) and other constructional sides. TABLE I: COST SAVING CALCULATION OF AAC BLOCK Qty Price Total Grand Total Remark 490 Pieces 110 53900 (228.6× 101.6 × 76.2) 2.7 Bags 5,600 15,120 0.1 Sud 14,000 1,400 2 12,000 24,000 6hrs 4 8,000 32,000 6hrs 2 126420 126420(for 100ft ) 2 For 1ft of Clay brick=1264.2Kyats 70 Blocks 1,000 70,000 (600× 200 × 100)݉݉ 1 Bag 7,000 7,000 40kg/bag 1 12,000 12,000 2hrs 2 8,000 16,000 2hrs 105,000 105,000(for 100ft2) For 1ft2of AAC block=1050Kyats Difference Cost 21420(100ft2) Cost saving of AAC=1264.2-1050=214.2Kyats/ft2 6. Sixth is calculating the weight saving of AAC block need the weight data of raw materials for AAC block and conventional brick and other requirement data. Following data got from Mother Industrial Co., Ltd (AAC and APC Block factory) and other constructional sides. TABLE II: WEIGHT SAVING CALCULATION OF AAC BLOCK Material Qty Weight Total Grand Total Clay Brick 490 Pieces 2.5kg 1,225 kg Cement 2.7Bags 50kg 135kg Sand 0.1sud 3,500 kg 350kg Remark <12mm joint Thk 1,710kg(100ft2) 1,710 kg For 1 ft2 of Clay brick=17.1kg AAC Block 70 Blocks 9kg 630kg AAC Mortar 1 Bag 40kg 40kg 670kg (Wet Weight) <3mm Joint Thk 2 670kg(for 100ft ) 2 For 1 ft of AAC block=6.7kg Difference Weight=1040 kg The cost saving of AAC block=17.1-6.7=10.4 kg @ IJTSRD | Available Online @ www.ijtsrd.com | Volume – 2 | Issue – 5 | Jul-Aug 2018 Page: 1963 International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470 2456 7. Seventh is the compressive strength calculation comparison between conventional brick and autoclaved aerated concrete block need the size of AAC block and conventional brick. The following data got from Mother industrial Co., Ltd (AAC and APC block factory) and other construction shop. The compressive strength calculation of conventional brick Surface area= length ×width – (Hole’s surface) గ =220×100- ( ସ × ݀ ଶ × 10 =22000mm2- (/4 252×10) =17091.26mm2 Force is attained by testing the conventional brick. P= F A Where, P=compressive strength, F=force, A=area A=17091.26 mm2 TABLE III: COMPRESSIVE STRENGTH CALCULATION OF CONVENTIONAL BRICK Force Compressive= force No Area (mm2) (N) (N/mm2) area 1 75840 17091.26 4.437 2 72510 17091.26 4.2425 3 71920 17091.26 4.207 For Autoclaved aerated concrete block Dimension=100×100×100 Surface area=100×100×100=10000mm2 Force is attained by testing the autoclaved aerated concrete block. No 1 2 3 TABLE IV: COMPRESSIVE STRENGTH CALCULATION OF AAC BLOCK Compressive Force Area strength= force (N) (mm2) 2 (N/mm ) area 55600 10000 5.56 56100 10000 5.61 57200 10000 5.72 The bar graph of compressive strength calculating result between conventional brick and AAC block 10 5 0 1 2 Conventional brick 3 AAC block Fig3The bar graph of compressive strength comparison result E. Benefits of AAC Block The benefits of AAC block are workability, moisture resistance, water saver, less weight, acoustically absorbent and environment friendly, pest resistance, long lasting, weather and earthquake resistance, energy saving, faster construction and cost saving. 1. Workability Blocks can be easily cut, drilled, nailed, milled and grooved to fit individual requirement. It is also available in custom sizes subject to negotiation. 2. Moisture Resistance AAC blocks resist with moisture. Because AAC blocks have very less water absorption compared to other bricks. 3. Water Saver The properties of water are very good. In construction, AAC block require less water compare with clay brick and other traditional bricks during curing; plastering and laying process. 4. Less Weight AAC blocks have 1/3 density compared to clay bricks. Hence, AAC blocks are very light weight materials. V. CASE STUDY A case study is made at Mother Industrial Co., Ltd, AAC and APC block Factory, situated at Pa-Le-Road Pa (Opposite of MEC Tyre Factory), PhawtKan, Insein In Township, Yangon Division, Myanmar, which manufactures two different types of block. They are Autoclaved Aerated Concrete block (AAC block) and Autoclaved Pressed Concrete brick (APC).In many types of Autoclaved Aerated Concrete block productions, thiss paper only based on Autoclaved Aerated Concrete block production process. For a day, they can produce around 14112 blocks depending upon customer demand. The information and data are obtained from this factory for this paper. VI. CONCLUSION This paper is studied on the beneficial usage of AAC block Production Process from Mother Industrial Co., Ltd. (AAC and APC block factory).The cost of AAC block for building a wall that have 100ft2 is lower than the cost of conventional brick. The weight of AAC block to build a wall that have 100ft2 is less than the weight of conventional brick. The compressive strength of AAC block is higher than the compressive strength of conventional brick. So the quality of AAC block is better than the conventional brick. So, the use @ IJTSRD | Available Online @ www www. ijtsrd.com | Volume – 2 | Issue – 5 | Jul-Aug Aug 2018 Page: 1964 International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470 of AAC block instead of the use of conventional brick is more benefit. REFERENCES 1. T. M. Nahhas, “Flexural behavior and ductility of reinforced lightweight concrete beams with polypropylene fiber, “Journal of Construction Engineering and Management, vol.1, no.1, pp 410, 2013. 2. T. Wenling, L. Liyuan, Z. Xiaoyan, Z. Mingjie, and W. Nana, “Application of foamed concrete in road engineering,” in proc. International Conference on Transportation Engineering, 2009,pp. 2114-2119 3. Ankit Pahade, “Comparative Analysis of Water Consumption between AAC Blocks-Gypsum Plaster & Burnt Red Clay Bricks- Sand Cement Plaster, “International Journal on Recent and Innovation Trends in Computing and Communication”, Vol4 Issue7 pp 141-144 4. Prashant Gautam, Navdeep Saxena” “Comparison of Autoclaved Aerated Concrete Blocks with Red Bricks”,. Journal of Engineering Research Technology, Vol.2 Issue 10,October -2013,Page no-4130 5. Smith, G., Statistical Process Control and Quality Improvement.1991: p.170-175 @ IJTSRD | Available Online @ www.ijtsrd.com | Volume – 2 | Issue – 5 | Jul-Aug 2018 Page: 1965