International Journal of Trend in Scientific

Research and Development (IJTSRD)

International Open Access Journal

ISSN No: 2456 - 6470 | www.ijtsrd.com | Volume - 2 | Issue – 4

Effect of Load variation and thickness

on deflection and operating stress of wave spring

Hardik C. Tekwani, Dhruv D. Joshi

Assistant Professor, Mechanical En

Engineering Department,

Vadodara Institute of Engineering

Engineering, Gujarat, India

ABSTRACT

Wave springs are used for load bearing into

assemblies. When force applied to the spring, load is

gradual or abrupt. Typically wave spring will occupy

an extremely small space after compressions. In this

paper effect of change in thickness of wave spring oon

the deflection of spring and on operating stress is

studied. This study leads towards the impact of

thickness change under different load condition. The

result reveals that after increasing the thickness from

0.1181 to 0.23622 inch, drastically decrement noticed

in the deflection as well as operating stress for

different loading condition in wave spring. Study

shows the deflection for two different spring materials

(nickel and beryllium copper) considering different

parameters that help to choose best spring

ing material.

Keywords: wave spring thickness, Deflection, working

stress, Load on wave spring, etc.

1. INTRODUCTION

Spring is made up of elastic material as after getting

compressed it stored the energy. Generally springs are

made of steel. The spring constant of a spring can be

defined as the change in the force it exerts, divided by

the change in deflection, so spring rate is described by

unit N/m. in case of torsion spring, when it is twisted

about its axis by an angle, it produces a torque

proportional

nal to the angle and spring's rate having unit

Nm/rad. wave springs replaced helical springs

because wave springs required less height compare to

coil spring for the similar load application. Wave

springs were first discovered by Smalley industries of

USA in 1990’s. They manufacture wave spring of

many types. Small springs can be wound from pre

pre-

hardened stock, while larger ones are made from

annealed steel and hardened after fabrication. Some

non-ferrous

ferrous metals are also used including phosphor

bronze and titanium for parts requiring corrosion

resistance and beryllium copper for springs carrying

electrical current. Common spring materials include

stainless steel, alloy steels, carbon steels, non-ferrous

non

materials and some super-alloys

alloys which exist in the

market

ket

with

preparatory

designations

and

nomenclature. Each spring material has diverse

compositions, individual properties and also for a

particular type of spring, more than one feasible

alternative spring materials may be available in the

market.

1.1

Wave spring:

Among the many types of springs, wave springs have

attracted considerable attention this kind of long and

reliable source of long lasting durability and

considerable effectiveness than rest of the springs.

Wave springs are used to reduce the height of the

spring and to produce the same end effect end that of

a coil spring. Wave springs operate as load bearing

devices. They take up play and compensate for

dimensional variations within assemblies. A virtually

unlimited range of forces can be produced whereby

whe

loads build either gradually or abruptly to reach a

predetermined working height. This establishes a

precise spring rate in which load is proportional to

deflection. Functional requirements are necessary for

both dynamic and static spring applications.

applications Special

performance characteristics are individually built into

each spring to satisfy a variety of precise operating

conditions. Typically, a wave spring will occupy an

@ IJTSRD | Available Online @ www.ijtsrd.com | Volume – 2 | Issue – 4 | May-Jun

Jun 2018

Page: 684

International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470

extremely small area for the amount of work it

performs. The use of this product is demanded, but

not limited to tight axial and radial space constraints.

1.2 Wave spring types:

Gap type wave spring has gap between two ends.

Continued deflection causes the gap ends to move

closer together while the outer dia. presses against the

bore [fig. 1(a)]. Overlap type has overlapping ends

and ends are free to move circumferentially during

compression [fig. 1(b)]. Crest-to-Crest wave spring

has more numbers of turn. No need to use key

between springs because the spring is integrally

1.3 Spring materials and their properties:

For manufacturing of spring the material is selected

by considering many parameters like spring is made

of a material which having elasticity for storage of

energy after compression, higher yield strength, etc.

Also material must be compatible with the

environment and withstand effects of temperature and

formed. Crest springs replaced helical spring because

crest springs can develop similar forces so occupy less

the axial space and solid height [fig. 1(c)]. Nested

Wave Springs are pre-stacked in parallel from one

continuous filament of flat wire used for higher load.

Nested springs result in a spring rate that increases

proportionally to the number of turns [fig. 1(d)].

Wavo wave spring has round-section and used for

high load application and give accurate spring rate

[fig. 1(e)]. In linear wave spring forces act linearly or

radially depending on the installed position and axial

pressure is obtained by laying the spring flat in a

straight line [fig. 1(f)].

corrosion without an excessive loss in performance

because corrosion and temperature decrease spring

reliability. Engineer must analyze about the

compression rate of the spring and tensile strength for

fatigue frailer and life cycle of the spring. According

to the requirements of the material different materials

with their properties are shown in table 1.

@ IJTSRD | Available Online @ www.ijtsrd.com | Volume – 2 | Issue – 4 | May-Jun 2018

Page: 685

International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470

Table 1 spring material properties [6]

Density

(gm/cc)

Tensile Modulus

Strengt of

h (MPa) Elasticity

(GPa)

Design

Stress

percentage

Min.

Tensile (%)

Max.

Operatin

g Temp

(˚C)

Rockwe

ll

Hardne

ss

(HRC)

Materi

al Cost

($/Kg.)

High Carbon Steel (ASTM 7.85

A 228)

2168.5

207

45

121

50.5

35

Beryllium Copper

(ASTM B 197)

Alloy 8.26

1310

128

45

204

38.5

33

8.44

1241

179

40

288

29

55

Chrome Silicon Alloy Steel 7.85

(ASTM A 401)

1844.5

207

45

245

51.5

30

Stainless Steel (AISI 304)

7.92

1551.5

193

35

288

40

15

Inconel 600

8.47

1379

214

40

371

40

45

Nickel Alloy(ASTM A 286)

7.92

1241

200

35

510

38.5

32

Material

Monel K500

2. CALCULATION

Table 2 value of K corresponding to N [7]

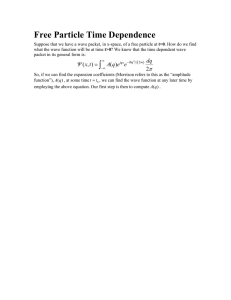

Deflection = f =

. .

. .

N

2.0

4.0

- 4.5

6.5

K

3.88

2.9

-

7.0-9.5

10.0+

2.3

2.13

Operating stress = S =

P = Load (lb.)

b = Radial Wall, in. [(O.D. - I.D.) ÷ 2]

L = Length, overall Linear (in.)

K = Multiple Wave Factor

t = Thickness of Material (in.)

H = Free height (in.)

I.D. = Inside Diameter (in.)

N = Number of Waves (per turn)

W.H. = Work Height (in.) [H-f]

O.D. = Outside Diameter (in.)

E1 = Modulus of Elasticity (psi) of E2 = Modulus of Elasticity (psi) of

Beryllium Copper Alloy (ASTM B

Nickel Alloy(ASTM A 286)

197)

Dm = Mean Diameter, in. [(O.D. + S1 = Operating Stress (psi) of Nickel S2 = Operating Stress (psi) of

Beryllium Copper Alloy (ASTM B

I.D.) ÷ 2]

Alloy(ASTM A 286)

197)

Z = Number of Turns

F1 = Deflection (in.)

Alloy(ASTM A 286)

of

Nickel F2 = Deflection (in.) of Beryllium

Copper Alloy (ASTM B 197)

@ IJTSRD | Available Online @ www.ijtsrd.com | Volume – 2 | Issue – 4 | May-Jun 2018

Page: 686

International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470

2456

Table 3 calculation of operating stress and deflection @ 600lbs

P

K

ID

OD

Dm

Z

b

t

N

E1

E2

S1 = S2

F1

F2

600

3.88

3.937

4.7244

4.3307

20

0.3937

0.1181

2.5

29007548

18564830

178391.8019

4.288643

6.701004947

600

3.88

3.937

4.7244

4.3307

20

0.3937

0.2362

2.5

29007548

18564830

44597.95048

0.536080

0.837625032

600

3.88

3.937

4.7244

4.3307

20

0.3937

0.3543

2.5

29007548

18564830

19821.31132

0.158838

0.248184384

600

3.88

3.937

4.7244

4.3307

20

0.3937

0.4727

2.5

29007548

18564830

11149.48762

0.067010

0.104703129

Deflection (Nickel v/s Beryllium copper)

8

7

6

5

Nickel

4

Beryllium

Copper

3

2

1

0

0.1181

0.2362

0.3543

0.4727

Table 4 calculation of operating stress and deflection for 1000lbs

P

K

ID

OD

Dm

Z

b

t

N

E1

E2

S1 = S2

F1

F2

1000

3.88

3.937

4.7244

4.3307

20

0.3937

0.1181

2.5

29007548

18564830

297319.6698

7.147737916

11.16834093

1000

3.88

3.937

4.7244

4.3307

20

0.3937

0.2362

2.5

29007548

18564830

74329.91745

0.893467239

1.396042615

1000

3.88

3.937

4.7244

4.3307

20

0.3937

0.3543

2.5

29007548

18564830

33035.51887

0.264731033

0.413642255

1000

3.88

3.937

4.7244

4.3307

20

0.3937

0.4727

2.5

29007548

18564830

18582.47936

0.111683404

0.174505325

Deflection (Nickel v/s Beryllium copper)

12

10

8

Nickel

6

Beryllium

Copper

4

2

0

0.1181

0.2362

0.3543

0.4727

@ IJTSRD | Available Online @ www.ijtsrd.com | Volume – 2 | Issue – 4 | May-Jun

Jun 2018

Page: 687

International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470

2456

2.1 Comparison of deflection for 600 lbs and 1000 lbs load on the wave spring of nickel & Beryllium

copper

12

10

8

F1 @ 600 lbs

6

F2 @ 600 lbs

F1 @ 1000 lbs

4

F2 @ 1000 lbs

F2 @ 1000 lbs

F1 @ 1000 lbs

F2 @ 600 lbs

2

0

0.1181

0.2362

F1 @ 600 lbs

0.3543

0.4727

2.2 Comparison of operating stress for 600 lbs and 1000 lbs load on the wave spring

350000

300000

250000

200000

150000

100000

50000

0

0.1181

0.2362

0.3543

0.4727

Operating stress for 600lbs

Operating stress for 1000lbs

3. CONCLUSION

For the wave spring calculation conclude that as

the wave increase the frequency of the spring will

decrease and also chart shows the frequency

versus wave of spring for two different load. Here

rapid decrement of frequency from 1000lbs to 600

lbs.

For nickel and beryllium copper wave spring, the

result shows that the deflection occur at maximum

level in the case beryllium copper having

havi value

11.16834093 on load of 1000 lbs

For better properties metal matrix composite can

be preferred for the future scope.

For the helical spring,

ng, frequency versus no. of

active coil chart shows that as the no. of active

coil decrease frequency also decrease.

@ IJTSRD | Available Online @ www.ijtsrd.com | Volume – 2 | Issue – 4 | May-Jun

Jun 2018

Page: 688

International Journal of Trend in Scientific Research and Development (IJTSRD) ISSN: 2456-6470

REFERENCES

1. E. Dragoni, July 1, 1988, A Contribution to Wave

spring, The Journal of Strain Analysis for

Engineering Design, vol. 23 no. 3 pp.145-153

2. P.P.Mohan, T.L.Kishore, Dec, 2012, Design and

analysis of a shock absorber, International Journal

of Engineering Research and Technology, vol.1,

Issue 4, pp. 578-592

3. Youli Zhu *, Yanli Wang, Yuanlin Huang. Failure

analysis of a helical compression spring for a

heavy vehicle’s suspension system, CC BY-NCND, Published by Elsevier Ltd.

4. Animesh das and Awinash kumar, “Selection of

Spring Material Using PROMETHEE Method”

IOSR Journal of Mechanical and Civil

Engineering, vol. 12, Issue 5

5.

Puvvala Raju and Mrs.N .Venkata Lakshmi

“Design and Analysis of Wave Spring for

Automobile Shock

6. Absorber”, international journal & magazine of

engineering, technology, management and

research I December 2016, vol. 3, Issue 12

7. Hardik C. Tekwani, “Effect of waves in wave

spring” International journal of advance research

and innovative ideas in education vol. 4 Issue 2.

@ IJTSRD | Available Online @ www.ijtsrd.com | Volume – 2 | Issue – 4 | May-Jun 2018

Page: 689