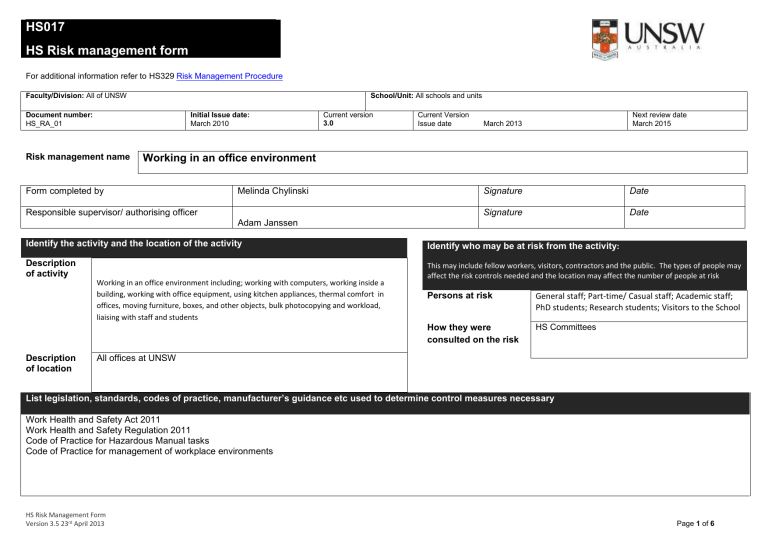

HS017 HS Risk management form For additional information refer to HS329 Risk Management Procedure Faculty/Division: All of UNSW School/Unit: All schools and units Document number: HS_RA_01 Initial Issue date: March 2010 Risk management name Current version 3.0 Current Version Issue date Next review date March 2015 March 2013 Working in an office environment Form completed by Melinda Chylinski Responsible supervisor/ authorising officer Signature Date Signature Date Adam Janssen Identify the activity and the location of the activity Identify who may be at risk from the activity: Description of activity This may include fellow workers, visitors, contractors and the public. The types of people may affect the risk controls needed and the location may affect the number of people at risk Working in an office environment including; working with computers, working inside a building, working with office equipment, using kitchen appliances, thermal comfort in offices, moving furniture, boxes, and other objects, bulk photocopying and workload, liaising with staff and students Description of location Persons at risk General staff; Part-time/ Casual staff; Academic staff; PhD students; Research students; Visitors to the School How they were consulted on the risk HS Committees All offices at UNSW List legislation, standards, codes of practice, manufacturer’s guidance etc used to determine control measures necessary Work Health and Safety Act 2011 Work Health and Safety Regulation 2011 Code of Practice for Hazardous Manual tasks Code of Practice for management of workplace environments HS Risk Management Form Version 3.5 23rd April 2013 Page 1 of 6 Identify hazards and control the risks. 1. An activity may be divided into tasks. For each task identify the hazards and associated risks. Also list the possible scenarios which could sooner or later cause harm. 2. Determine controls necessary based on legislation, codes of practice, Australian standards, manufacturer’s instructions etc. 3. List existing risk controls and any additional controls that need to be implemented 4. Rate the risk once all controls are in place using the matrix in HS329 Risk Management Procedure SHADED GREY AREAS If you need to determine whether it’s reasonably practicable to implement a control, based on the risk complete the shaded grey columns Feel free to resize the boxes to suit your situation/the amount of text you need to use Hazard Task/ Associated harm Existing controls Any additional controls required? Risk Rating C Working with computers Working with other office equipment e.g. photocopier s, printers, fax, electronic 1.Ergonomic: Poor posture Excessive duration in a seated position Incorrect setup of workstation Glare Repetitive movements 2. Electrical Exposure to Toner Electrical HS Risk Management Form Version 3.5 23rd April 2013 Physical injury to the wrists, arms, neck, shoulder or back. Eye strain All staff are provided with the UNSW Setting up your Workstation guide (HS705) and Workstation Checklist (HS114) to conduct their own workstation assessment All new staff complete online ergonomics course Adjustable chairs, desks and ergonomic accessories such as document holders are available for staff to use Individual staff are responsible for taking breaks and doing stretches Staff are advised to report any symptoms ASAP Inspection, Testing and Monitoring Procedure Testing and tagging program RCD’s on main switchboard checked by Facilities Individual RCD’s on specific equipment Regular workplace inspections Ensure photocopiers are located in well ventilated areas Inspection, Testing and Monitoring Procedure Testing and tagging program RCD’s on main switchboard checked by Facilities Individual RCD’s on specific equipment Regular workplace inspections Electrical shock , Fire , Burns, Physical injury from tripping over cords Irritation to skin, eyes Electrical shock Is this reasonably practicable Y/N Scenario Working with computers Cost of controls (in terms of time, effort, money) L R Page 2 of 6 Hazard Task/ Associated harm Existing controls Any additional controls required? Risk Rating Cost of controls (in terms of time, effort, money) Is this reasonably practicable Y/N Scenario C L R stapler, electronic paper folder, paper shaker, Scanner, binder Working with shredders, laminators, guillotines Using compactus Meetings/ face to face dealings with staff and students Telephone and email enquires and communicati on Sharp edges Moving parts Pinch points Hot parts Cuts Entanglement Physical injury Collisions with moving shelves Moving shelves Falling items Physical injury Physical /emotional intimidation Aggression towards staff members Physical or emotional injury to staff’ Malicious damage Aggression towards staff members Intimidation and harassment issues Emotional injury to staff HS Risk Management Form Version 3.5 23rd April 2013 Ensure covers prevent people having access to moving parts during operation Do not insert items other than those allowed by the operating manual Do not operate with loose clothing or jewellery. People with long hair must tie it back. Safe work procedures Training and instruction given Never place objects on top of the unit Always place heavy objects on the lower shelves Check that aisles are clear Always use the hand wheel to move bays along if available Only move one bay a time Safe working procedure Training and instruction given Consultation with staff Procedures to minimise risk Workplace bullying policy communicated to all staff Equity unit advice and policies Conflict resolution training Security staff Workplace violence Prevention and management policy Consultation with staff Procedures to minimise risk Workplace bullying policy communicated to all staff Equity unit advice and policies Conflict resolution training Security staff Workplace violence Prevention and management policy Page 3 of 6 Hazard Task/ Associated harm Existing controls Any additional controls required? Risk Rating C Using kitchen appliances for preparing food & drinks Thermal comfort in offices Working after business hours or working alone Slips, trips and falls Fire in building Working after hours/ working alone Boiling water from urn Hot surfaces with sandwich maker/toaster Food getting caught in toaster Overheating food in microwave Using cleaning chemicals Excessive heat Lack of ventilation/air flow Walking to and from your vehicle /transport alone or in the dark HS Risk Management Form Version 3.5 23rd April 2013 Physical injury Burns and smoke inhalation Personal assault Burns from hot water or touching hot surfaces Severe scalding from superheated food & fluids Irritation to skin, eyes, chemical burns. Heat exhaustion Dehydration Headaches Fainting Dizziness Risk of being physically assaulted Is this reasonably practicable Y/N Scenario Working inside a building Cost of controls (in terms of time, effort, money) L R Building fire wardens Building fire safety Compliance with Emergency drills Making sure staff are aware of emergency procedures Workplace inspections to identify slip and trip hazards UNSW After hours guideline Swipe card access only after hours Signage put up in kitchen to remind people e.g. “Caution: Hot Water” etc. Follow instructions on label for cleaning chemicals Microwaves should not be placed at high levels Providing fans and opening doors, windows and vents where practical; Providing water Wearing lighter and loose fitting clothing during hot weather Monitor staff for signs of heat distress Use well-lit areas like the University Walk to access car/bus Try to walk in groups or pairs Contact Unibeat for a Security Escort from any lift phone or University Help Point Use free Security Shuttle Bus Service Page 4 of 6 Hazard Task/ Any additional controls required? Associated harm Existing controls Risk Rating Cost of controls (in terms of time, effort, money) Is this reasonably practicable Y/N Scenario C L R List emergency procedures and controls List emergency controls for how to deal with fires, spills or exposure to hazardous substances and/or emergency shutdown procedures Filing & storage hard copies of documents Repetitive movements involved in filing documents, reaching up/down to reach shelving in storage room/compactus , lifting & moving archive boxes Overuse injuries from extended periods of filing low or high cabinets/shelving Implementation Additional control measures needed: UNSW Hazardous Manual task procedure provided for all staff Manual Handling Training for all staff Rest breaks, exercise, and task rotation Manual handling aids provided e.g. Trolleys Early intervention when identified Resources required Responsible person Date of implementation REVIEW Scheduled review date: Are all control measures in place? HS Risk Management Form Version 3.5 23rd April 2013 Page 5 of 6 Are controls eliminating or minimising the risk? Are there any new problems with the risk? Review by: (name) Review date: Acknowledgement of Understanding All persons performing these tasks must sign that they have read and understood the risk management (as described in HS329 Risk Management Procedure). Note: for activities which are low risk or include a large group of people (e.g. open days, BBQ’s, student classes etc), only the persons undertaking the key activities need to sign below. For all others involved in such activities, the information can be covered by other methods including for example a safety briefing, induction, and/or safety information sheet (ensure the method of communicating this information is specified here) Risk management name and version number: Name HS Risk Management Form Version 3.5 23rd April 2013 I have read and understand this risk management form Signature Date Page 6 of 6