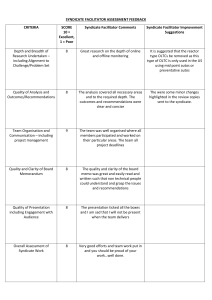

24th International Conference on Electricity Distribution Glasgow, 12-15 June 2017 Paper 1308 MANAGING ON-LOAD TAP CHANGER LIFE CYCLE IN TNB DISTRIBUTION POWER TRANSFORMERS Young Zaidey YANG GHAZALI Tenaga Nasional Berhad – Malaysia young@tnb.com.my ABSTRACT TNB has developed an Asset Management (AM) Framework in accordance with ISO 55001:2014. One of the key elements of the framework is the asset life cycle management. This paper presents TNB experience in managing the On-Load Tap Changers (OLTC) over their complete lifecycle to improve performance and reliability. Using failure mode, effect and criticality analysis (FMECA) based on the previous failure data, lifecycle management strategies for OLTC have been identified. It covers the main activities over the lifecycle stages namely design, operation and maintenance. Adoption of new technology in the design, enhancement in condition assessment and effective implementation of condition based maintenance were amongst the strategies implemented. Finally these strategies were validated through field evaluation and lifecycle cost analysis prior to the successful implementation throughout TNB. Most power transformers studies indicated that the main cause of power transformers failures is the OLTC [1] since it has mechanical parts that are in constant movement. In TNB distribution network, there are seven cases involving permanent damage of OLTC since 2005. In most failure cases, it has caused prolonged power interruption, often due to severity of damage and timely replacement, as the result of unavailability of spares and incompatibility with the existing design. The root causes of failures are often attributed to degradation and carbonization of oil as well as contact problems as illustrated in Fig 2. INTRODUCTION Presently, there are 1,260 power transformers rated upto 33kV with On-Load Tap Changer (OLTC), installed in TNB medium voltage distribution network with capacity ranging from 7.5 MVA up to 30 MVA. About 70% of the power transformers and their respective OLTC are aged between 15 and 25 years. Out of the total population, 95% of the OLTC is of in-tank oil-immersed selector switch type with transition resistors or also known as oil switch type OLTC as shown in Fig. 1, which combines both functions of tap selector and diverter switch in one oil-filled compartment. The typical number of tap change operation of the OLTC in TNB distribution ranged between 2000 and 5000 tap change per year. Fig. 1: In-tank oil-immersed selector switch type OLTC with transition resistors used in TNB distribution CIRED 2017 Fig. 2: Root cause analysis of typical OLTC failures in TNB distribution power transformers During normal tap change operation, switching arcs occur in oil due to the making and breaking of currents. These arcs cause degradation and carbonization that contaminate and reduce the dielectric strength of the oil [2]. The carbonization over time causes accumulation of carbon deposits on the surface of the fiberglass cylinder that resulted in the formation of electrical treeing. Fig. 3: Formation of electrical treeing on the cylinder’s surface resulted in tracking and arcing between phases 1/5 24th International Conference on Electricity Distribution Glasgow, 12-15 June 2017 Paper 1308 Without proper maintenance, the electrical treeing develops into tracking and finally phase-to-phase arcing in the OLTC. This is the common mode of failure found in most of the cases resulting in the permanent damage of the OLTC involved. On the other hand, coking or low conductivity film buildup was often observed on fixed and roller contacts during OLTC maintenance. This film consists of layer of pyrolytic carbon formation that bond to the oxide layer which was formed as the result of surface oxidation of the contacts [2]. In some cases, coking has led to erosion or contact ware and pitted marks can be visibly observed. This occurs as the result of continuous overheating, as coking worsen over time due to increased contact resistance [3]. Prolonged condition of such phenomenon may result in excessive arcing that could trip the transformer protection. Table I: FMECA based on common findings of OLTC failures Failure Mode Arcing between phases Excessive arcing between contacts Failure Effect Failure Failure P C Mechanism Consequence Tracking as • Permanent the result of tracking on Degradation & accumulation Transformer fibreglass trip by H carbonization of carbon cylinder protection H H of oil deposits on relays • Damage of the surface metal parts of cylinder Overheating • Damage of Transformer due to contact Coking of trip by M increased M M contacts protection • Contact contact relays wear off resistance S Failure Cause Note: S=Severity of failure, P=Probability C=Criticality, H=High, M=Medium, L=Low of failure, Based on the FMECA in Table 1, TNB has identified the key activities at various lifecycle stages that can contribute to mitigate the causes of failure and improve the performance and reliability of power transformers as a whole. The lifecycle management strategies for OLTC based on these key activities are further discussed in the following subchapters. Fig. 4: Erosion and pitted marks on the roller contacts (left) as well as carbon buildup on the fixed contacts (right) were observed during maintenance Realizing the needs to reduce the risk of OLTC failures, asset management strategies for OLTC have been proposed and implemented over its complete lifecycle. Thus, this paper describes TNB approach and experience in managing the lifecycle of OLTC in distribution power transformer to improve its performance and reliability. Fig. 5: Lifecycle activities of an asset FAILURE MODE EFFECT CRITICALITY ANALYSIS AND A failure mode effect and criticality analysis (FMECA) as shown in Table 1 has been used to determine the most appropriate asset lifecycle management strategy for OLTC based on the actual findings on OLTC failures [4]. FMECA evaluation on other components of the OLTC such as motor drive and oil surge relay are not discussed in this paper since severity of failure of these components are still low. In addition, these components follow the standard design based on the manufacturer and type of OLTC. Furthermore, the operation and maintenance requirement of these components only involve visual inspection and functional check which are very minimal. OLTC LIFECYCLE STRATEGIES MANAGEMENT The complete lifecycle of an asset in accordance with Asset Management requirements of ISO 55001:2014 is illustrated in Fig. 5, where the activities at every stage of the lifecycle are also shown. CIRED 2017 Improving Design and Specification Adoption of Vacuum Switch OLTC to Mitigate the Degradation and Carbonization of Oil in the OLTC Compartment as well as Coking of Arcing Contacts Degradation and carbonization of oil as described above are the most common causes of failure that has resulted in failure and permanent damage of the OLTC. In order to mitigate this problem, TNB has adopted the use of vacuum switch OLTC, shown in Fig. 6, that confines switching in interrupted vacuum bottles. As the results, this helps to prevent contamination of oil due to carbonization and hence lower the rate of oil degradation due to switching arcs. Furthermore, with the absence of oil inside the vacuum switch, formation of low conductivity film and deposition of carbon that lead to coking on the contacts’ surface will no longer occur. With the arc quenching property of the vacuum switch, contact erosion and thus contact wear is minimized and thus reduces maintenance costs. Prior to the adoption of the use of vacuum switch type OLTC in 2011, a field trial was conducted in 2007 to evaluate its performance. 2/5 24th International Conference on Electricity Distribution Glasgow, 12-15 June 2017 Paper 1308 validate and compare the net present value of the total lifecycle cost of using vacuum switch type OLTC together with self-dehydrating breather, and the oil switch type OLTC. The LCCA of the two systems shown in Table II reveals that the use of vacuum switch type OLTC together with self-dehydrating breather could generate saving of more than RM 600,000 a year for the entire transformer population, not including saving on the avoidance of loss revenue due to OLTC failure. Fig. 6: Vacuum switch type OLTC used in TNB distribution power transformers Adoption of Free Maintenance Self-Dehydrating Breather to Mitigate the Degradation of Oil in the OLTC Compartment Degradation of oil in the OLTC is not only influenced by the switching arcs that occur due to making and braking of currents during on-load tap change operation, but also affected by the presence of moisture in the oil. Even with the use of vacuum switch type OLTC, moisture can still be presence due to leakage or in most cases due to lack of maintenance of the OLTC dehydrating breather. Fig. 8: Use of maintenance free self-dehydrating breather Table II: Comparison of the net present value of the total lifecycle cost over the life span of 40 years per OLTC system Total OLTC System Operation & Initial Cost Lifecycle Maintenance (RM) Cost Cost (RM) (RM) Oil switch type OLTC & conventional 160,814.00 breather Vacuum switch type OLTC & self196,145.00 dehydrating breather 69,652.23 230,466.23 15,198.46 211,343.46 Enhancing Methods for Condition Assessment Fig. 7: Lack of maintenance of silica gel in the dehydrating breather of the OLTC In order to mitigate this problem, TNB has adopted the use of maintenance free self-dehydrating breather as depicted in Fig. 8. The breather has a heating element mounted within the container to heat the desiccant at selected intervals with temperature sensor to monitor the correct operation of the heater. A moisture sensor measure the humidity of the air to ensure only dehydrated air goes through the piping into the OLTC conservator. Both sensors are controlled by an electronic controller. The condensed moisture formed on the surface of the container will be expelled outward by gravity. A field trial on the use of the self-dehydrating breather was conducted in 2007 prior to its adoption in 2011. Lifecycle Cost Analysis Prior to the adoption on the use of vacuum switch type OLTC together with maintenance free self-dehydrating breather, a lifecycle cost analysis (LCCA) over the expected transformer life span of 40 years is performed to CIRED 2017 The adoption of vacuum switch OLTC is only applied for the new power transformers. Therefore, for the existing in-service power transformers, emphasis is given on the utilization (operation) and maintenance lifecycle stages which are discussed below. Condition Assessment Using Oil Quality Analysis to Detect Degradation of Oil in OLTC The implementation of the condition assessment for OLTC by means of oil quality analysis involved breakdown voltage & moisture content has started since 2007. Table III summarizes the oil quality indicator limits used for OLTC. Table III: Condition indicators for OLTC oil quality analysis Property Breakdown Voltage (kV) Water Content (ppm) Limits Good Fair Poor Bad > 50 40 to 50 30 to 39 < 30 < 15 15 to 30 31 to 45 > 45 3/5 24th International Conference on Electricity Distribution Glasgow, 12-15 June 2017 Paper 1308 Condition Assessment Using Dissolved Gas Analysis (DGA) to Detect Coking of Contacts DGA has been applied to assess the condition of the OLTC since 2007. However, the health condition of the OLTC then was not truly understood due to unavailable guide for interpretation of DGA results. In 2011, with the issue of IEEE Std. C57.139-2010 [5], a more enhanced condition assessment method using DGA data was formulated to interpret the health condition of the OLTC. The statistical model used follows the method described in Annex B of IEEE Std. C57.139-2010 to determine two types of condition indicator limits i.e gas concentration and gas ratio limits. The model was initially based on DGA data up to the year 2011 taken from 503 units of oil-immersed selector switch type OLTC classified as “ARAB” type OLTC in accordance with IEEE Std. C57.139-2010 classification scheme. The gas concentration limits is defined in terms of a statistical outlier limit identifying extreme values of gas concentration suspected to be the results of faults or unusual stresses. The gases that are used as indicators to discriminate between normal and faulty conditions are C2H2, C2H4 and CH4 together with the sum of CH4, C2H6 and C2H4 called the total dissolved heating gases (TDHG). The upper outlier limits U1, U2 and U3 were calculated for each set of gas concentration data. U3 is introduced to represent the most extreme values requiring the highest attention (U3 = Q3 + 4.5IQR where Q3: Third quartile, IQR: Interquartile range). Table IV summarizes the gas concentration limits for OLTC. Table IV: OLTC gas concentration limits Concentration (ppm) Generic CH4 C2H4 C2H2 TDHG C ≤ U1 C ≤ 2083 C ≤ 3522 C ≤ 14598 C ≤ 7000 U1 > C ≤ 2083 > C 3522 > C ≤ 14598 > C ≤ 7000 > C ≤ U2 ≤ 3254 5569 23004 11029 Condition Codes Normal (1) Caution (2) U2 > C ≤ 3254 > C 5569 > C ≤ 23004 > C ≤ 11029 > C ≤ Warning U3 ≤ 4423 7617 31410 15058 (3) C > U3 C > 4423 C > 7617 > 31410 > 15058 Danger (4) Note: C=gas concentration The gas ratios that are used as indicators to discriminate between normal and faulty conditions are C2H4/C2H2 and TDHG/C2H2. The gas ratio values of non-faulty OLTC operating under normal conditions are described by the percentiles of the lognormal distribution representing the nonoutlier gas ratios. The gas ratio limits calculated for the study are based on 90th (C090), 95th (C095), and 99th (C099) percentiles of the lognormal distribution with significance level of 0.1, 0.05 and 0.01 respectively. Table V summarizes the gas ratio limits for OLTC. CIRED 2017 It should be noted that, the ratio limits in Table V are applied only when any of the gas concentration has reached “Warning” limit or “Condition 3” in Table IV. Table V: OLTC gas ratio limits Ratio Generic C2H4 / C2H2 R ≤ C090 R ≤ 0.378 Condition Codes TDHG/C2H2 R ≤ 0.684 C090 > R ≤ C095 0.378 > R ≤ 0.480 0.684 > R ≤ 0.843 C095> R ≤ C099 0.480 > R ≤ 0.743 0.843 > R ≤ 1.234 R > C099 R > 0.743 R > 1.234 Normal (1) Caution (2) Warning (3) Danger (4) Note: R=gas ratio Table VI gives the overall interpretation to facilitate the understanding on the condition of the arcing contacts based on the results of the gas concentrations and ratios. Table VI: Interpretation of DGA results for OLTC Results Interpretation Condition Condition Codes Indicator R = 1 and Good Normal OLTC operation C≤2 Light coking or deterioration of arcing contacts, or R = 1 and Fair Unusually high frequency of tap 2<C≤4 change operation or high load current causing heating of transition resistors 1<R≤3 Coking or increased deterioration of and Poor arcing contacts 2<C≤4 R = 4 and Heavy coking or severe deterioration Bad 2<C≤4 of arcing contacts Table VII compares the outcome of the DGA results on 745 units of OLTC interpreted using the above method with the same DGA results using the Duval’s Triangle Method for Load Tap Changers [6]. Table VII: Comparison on the number of problematic OLTCs detected using TNB condition assessment method derived from IEEE Std. C57.139-2010 and Duval’s Triangle for OLTC TNB OLTC Assessment Method OLTC Duval’s Triangle Method 59 55 No. of severe thermal faults with moderate or heavy coking 41 22 No. of thermal faults in progress with light coking or heating of transition resistors 18 33 Fault Identification Total no. detected of possible faults 4/5 24th International Conference on Electricity Distribution Glasgow, 12-15 June 2017 Paper 1308 Effective Implementation of Condition Based Maintenance Based on the enhanced condition assessment method above, an overall health condition of the OLTC is derived as shown in Table VIII that provides recommended actions for mitigations as tabulated in Table IX. The assessment was validated through visual inspection of the OLTC condition. Fig. 9 shows typical observations found during maintenance. Validation of the assessment was also carried out by means of Dynamic Current Measurement using Dynamic Winding Resistance technique and it is discussed elsewhere [7]. Table VIII: Overall health condition of the OLTC DGA Results Overall Health Condition Oil Quality Analysis Results Good Fair Poor Bad Good 1 2 3 3 Fair 2 2 3 3 Poor 3 3 3 4 Bad 3 3 4 4 Table IX: Recommended mitigating actions based on the overall health condition of the OLTC Condition Condition Codes Indicator 1 2 3 4 Recommended Actions Continue oil sampling at 12 month interval Continue oil sampling at 6 month Caution interval Inspect for leaks & condition of silica gels. Conduct internal inspection on Warning arcing contacts. Perform overhaul & replace oil. Inspect for leaks & silica gels’ condition. Danger Possible replacement of arcing contacts. Perform overhaul & replace oil. Normal Table X: Example of maintenance planning sheet based on the criticality of the OLTC health condition Fig. 9: Surface erosion with pitted marks and coking of the roller contacts (left) and carbon deposits on the cylinder (right) were observed during OLTC maintenance at several sites CONCLUSIONS Managing asset lifecycle is the main focus of asset management system starting from the creation of the asset, utilization, maintenance up to its retirement. Thus, each aspect of the lifecycle activities must be strategized to optimize the usage of the asset and to strike a balance between cost, risk and performance of the asset. This paper has presented all possible mitigating actions that have become the OLTC asset management strategy at various stages of its lifecycle. Based on the FMECA, three main lifecycle activities have been identified for the implementation of the lifecycle strategy which includes design, operation and maintenance of OLTC. Finally, validation through field evaluation and lifecycle cost analysis was performed to evaluate for technical and economic feasibility of the proposed technologies and methodology, prior to the successful adoption of all the strategies throughout TNB since 2011. REFERENCES [1] [2] [3] [4] [5] [6] Based on the health condition and recommended mitigating actions, more effective maintenance planning can be executed where maintenance work can now be prioritized according to the criticality of the OLTC condition as shown in the example given in Table X. CIRED 2017 [7] R. Jongen, et. al., 2007, “A statistical approach to processing power transformer failure data”, CIRED 19th International Conference, Paper 546 J.J. Erbrink, E. Gulski, et. Al, 2008, “Advanced on-site diagnosis of transformer OLTC”, IEEE International Symposium on Electrical Insulation, 252-256 J.J. Erbrink, E. Gulski, et. al, 2010 “Condition assessment of OLTC using dynamic resistance measurements,” International Conference on HV Engineering, 433-436 BS 5760-5 “Guide to failure modes, effects and criticality analysis (FMEA and FMECA)” IEEE Std C57.139-2010, “IEEE Guide for Dissolved Gas Analysis in Transformer Load Tap Changers” M. Duval, 2008, “The Duval triangle for load tap changers, non-mineral oils and low temperature faults in transformers”, IEEE Electrical Insulation Magazine, Vol. 24, No. 6, 22-29 Mohd Shahril,Yasmin Hanum, Young Zaidey, et.al, 2013 “Diagnosis of OLTC via Duval Triangle Method and Dynamic Current Measurement”, Malaysian International Tribology Conference, Procedia Engineering 68, 477- 483 5/5