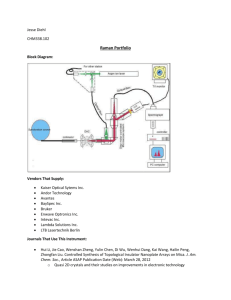

Predictive Stability in Pharmaceutical Development Helen Williams Drug Delivery and Formulation Summit, Berlin 14th March 2018 Overview ➢ Predictive stability tools ASAP Packaging predictions ➢ Case studies Phase I API and Tablet ASAP studies Phase III Tablet ASAP study NDA packaging predictions ➢ IQ Risk Based Predictive Stability Working Group ➢ Conclusions 2 Predictive Stability Tools 3 Accelerated Stability Assessment Program Studies Based on the Arrhenius equation modified for solid state degradation If measure how reaction rate changes with temperature & humidity, can determine Ea and ln (A) and B and via extrapolation determine the reaction rate at any given temperature and humidity. 4 D. Genton et al, J. Pharm. Sci. 66, 5 (1977) 676-680. K. Waterman and S.Colgan, Regulatory Rapporteur, 5 (2008) 9-14. K.Waterman et al, Pharm. Res., 24 (2007) 780-790. Packaging Predictions Depends on permeation of the barrier Difference in partial pressure of water between ambient environment and headspace Headspace Equilibrium between headspace and tablets is defined by the Gravimetric Vapour Sorption isotherm of the tablets 5 Predictive Stability - Applications ASAP and packaging predictions can potentially be utilised to reduce stability testing requirements for regulatory submissions….. ➢ In early clinical trial submissions to support initial shelf life/retest claim ➢ To support API route/process changes during development ➢ To support minor formulation changes during development ➢ To justify excipient selection ➢ To compare batch to batch stability characteristics ➢ For specification justification ➢ To support pack changes during development and post approval ➢ As supporting information in a marketing submission to then support changes post approval 6 Case Study 1 - Phase I API and Tablet ASAP Studies Applications of predictive stability tools 1. Drug substance retest period prediction - ASAP study 2. Drug product shelf life prediction – ASAP study 3. Regulatory Applications 7 Case Study 1 - Phase I API and Tablet ASAP Studies 1. Drug substance ASAP study Temperature (°C) Humidity (% RH) Storage Time (weeks) Initial Initial 0 (3 repeats), X 50 75 3, 6, S 60 30 3, 6, S 60 75 3 (5 repeats), 6, S 70 11 2, 3, S, X 70 75 2, 3, S, X 80 30 2, 3, S, X Impurities analysis by LC at all time points S = spare samples, X = XRPD sample, 8 No degradation was observed Case Study 1 - Phase I API and Tablet ASAP Studies 2. Drug product shelf life prediction – ASAP ASAP studies for 2 formulation strengths, 5 and 50 mg Protocol for impurities and appearance Temperature (°C) Initial 50 60 60 70 70 80 Humidity (%RH) Initial 75 30 75 11 75 30 S = spare sample 9 Storage Time (weeks) 0 3, 6, S 3, 6, S 3, 6, S 2, 3, 6, S 2, 3, 6, S 2, 3, 6, S Protocol for dissolution Temperature (°C) Initial 40 40 40 [ ] = optional Humidity Storage Time (%RH) (weeks) Initial 0 11 [4] 55 [4] 75 4 Case Study 1 - Phase I API and Tablet ASAP Studies 2. Drug product shelf life prediction – ASAP No change in dissolution profile or appearance during study “Good” model 10 Case Study 1 - Phase I API and Tablet ASAP Studies 2. Drug product shelf life prediction – ASAP Predictions at 25°C/60% RH support an initial shelf life of 12 months but suggest the product is likely to achieve 5 years 11 Case Study 1 - Phase I API and Tablet ASAP Studies 3. Regulatory Applications ➢ Drug substance and drug product ASAP data was presented in the Phase I regulatory submission to support an initial 12 month shelf life and retest period, in the absence of long term stability data but with a commitment to set down ICH compliant stability. ➢ Submitted to UK and USA ➢ Accepted with no related questions in USA. ➢ MHRA (UK) requested ICH compliant stability data ➢ Responded with 3 month ICH compliant stability data across drug substance and product to support 12 month shelf life/retest period. 12 Case Study 1 - Phase I API and Tablet ASAP Studies 3. Regulatory Applications For drug product we included a comparison of the ASAP predictions with the ICH compliant stability data in the response. 25°C/60% RH 13 40°C/75% RH Case Study 2 - Phase III Tablet ASAP Study ➢ 200 mg tablet formulation, phase III ➢ Manufacturing change from wet granulation to roller compaction ➢ Chemically stable product, 2 years long term stability data on wet granulation product ➢ Reduction in dissolution rate observed when exposed to high humidity, so packed with desiccant in bottle Needed to quickly determine stability characteristics of the new roller compaction formulation …………. ASAP study 14 Case Study 2 - Phase III Tablet ASAP Study Temperature (°C) Humidity (% RH) Storage Time (weeks) Initial Initial 0 (3 repeats), X 50 75 4, 8, S 60 11 4, 8, S 60 75 4, 8 (5 repeats), S 70 11 4, 8, S, X 70 75 4, 8, S, X 80 30 4, 8, S, X Impurities analysis by LC at all time points S = spare sample, as optional additional time point X = XRPD sample 15 Case Study 2 - Phase III Tablet ASAP Study Dissolution Protocol Temperature (°C) Humidity (% RH) Storage Time (weeks) Initial Initial 0 40 30 6, S 40 55 6, S 40 75 6, S 24 tablets set down for each time point (n=6, two dissolution methods pH 1.2 and 4.5, and spares) 16 Case Study 2 - Phase III Tablet ASAP Study ➢ No degradants detected during the 8 week ASAP study ➢ No change in physical form of API detected (XRPD) ➢ No change in dissolution profile of tablets stored at 40°C/30% RH ➢ Evidence of dissolution rate slowing in tablets stored exposed to higher humidities ➢ All still pass specification (>75% dissolved at 30 minutes) 17 Case Study 2 - Phase III Tablet ASAP Study Conclusions ➢ Roller compacted tablets are chemically stable ➢ The tablets should be packed with desiccant to minimise the risk of a reduction in dissolution rate on storage ➢ Demonstrated equivalence with wet granulation tablet formulation ASAP data (impurities and dissolution) was included in the Phase III IND and IMPD submissions, as supporting information. 18 Case Study 2 - Phase III Tablet ASAP Study Regulatory Submission ➢ ASAP study on 200 mg roller compaction batch ➢ At time of IND submission 1 month ICH compliant stability data on 200 mg roller compaction development batch ➢ At time of IMPD submission 3 months stability data on 200 mg roller compaction development batch and 1 month on clinical batch ➢ Alongside 2 years stability data on 200 mg wet granulation batch ➢ Claimed a 12 month initial shelf for new 200 mg roller compaction formulation in the bottle packed with desiccant ➢ Submitted in Canada, US, Ukraine, Russia, Taiwan and Poland ➢ Accepted with no regulatory questions 19 Case Study 2 - Phase III Tablet ASAP Study Further ASAP study ➢ Six months later, a lower dose tablet was required for a different clinical trial (100 mg, roller compaction, common granule) ➢ No real time stability data on 100 mg formulation ➢ Performed a second, very similar ASAP study on 100 mg tablets ➢ Again no degradation was observed during the study and a small reduction in the dissolution rate was observed at 40°C/75% RH. ➢ Demonstrated equivalence between the 100 mg and 200 mg roller compaction formulations in terms of stability characteristics 20 Case Study 2 - Phase III Tablet ASAP Study ➢ No long term stability data on new 100 mg roller compaction tablets, ASAP study data only was presented for this formulation ➢ Alongside 2 years stability data on 100 mg wet granulation batch and 6 months stability data on two 200 mg batches roller compaction tablets. ➢ Claimed a 18 month initial shelf for new 100 mg roller compaction formulation in bottle pack with desiccant, based on equivalence with 200 mg roller compaction formulation. ➢ Committed to setting down ICH stability for 100 mg roller compaction formulation ➢ Submitted to Ukraine, Russia, Canada, US, Taiwan, Poland and Japan ➢ Accepted with no related regulatory questions 21 Case Study 2 - Phase III Tablet ASAP Study Packaging Predictions Predictions were also performed to determine the tablet water content and humidity inside the pack on storage at 25°C/60% RH for 3 years. 22 Case Study 2 - Phase III Tablet ASAP Study Packaging Predictions Predictions suggest that the humidity in the bottle will remain below 30% RH over 3 years stored at 25°C/60% RH. 23 Case Study 3 - NDA Packing Predictions The two proposed commercial packs are in HDPE bottles: 1. Existing bottle containing 30 capsules, 12 months stability data across 3 batches available 2. New bottle containing 60 counts, 6 months stability data available Packaging predictions were performed for the new bottle at 25°C/60%RH for 24 months. Compared the predictions to stability data for the existing bottle configuration. 24 Case Study 3 - NDA Packing Predictions Both bottle configurations offer similar moisture protection. These predictions were presented in the NDA and a 24 month shelf life was granted for both bottles configurations. 25 IQ Working Group - Risk Based Predictive Stability ➢ Risk Based Predictive Stability (RBPS) IQ Working Group was set up in 2015 ➢ A survey of all IQ member companies was conducted in 2016 ➢ 19 companies responded of which 16 used predictive stability studies ➢ 10 companies reported using predicted stability data in submissions, 6 in clinical and 5 in marketing submissions with 2 post approval changes ➢ 23 countries were reported to have accepted predicted stability data in clinical submissions and “worldwide” acceptance was reported in Marketing submissions. 26 H. Williams et al., "Risk-Based Predictive Stability–An Industry Perspective," Pharmaceutical Technology 41 (3) 2017 http://www.pharmtech.com/risk-based-predictive-stability-industry-perspective IQ Working Group - Risk Based Predictive Stability ➢ Currently working on harmonising how predicted stability data is presented in clinical submissions, with the aim of publishing both a template and a worked example during 2018 ➢ Collecting case studies of predicted stability data in clinical submissions for a further publication ➢ Comparing different predictive stability models across the industry 27 Conclusions ➢ Predictive stability tools can be used to support development. ➢ Zeneth and BDE tools can aid understanding of potential degradation mechanisms across both substance and product. ➢ ASAP and packaging predictions are powerful tools to predict chemical degradation, water content and pack humidity and can influence pack selection, pack configuration, storage conditions, shelf life/retest period claims, specification setting and control strategy. ➢ Pharma companies are working together through IQ Working Group to harmonise approaches and influence regulatory authorities. ➢ Regulatory acceptance of predicted stability data is growing. 28 Acknowledgements Confidentiality Notice Faye Turner Andrew Brookes Carolyn Gordon Jonathan Bright Emily Roddy Emily MacDougall Pam Harrison Magnus Fransson Johan Remmelgas Nadim Akhtar James Mann Anna Powell Keith Parker John Nightingale Angela Currie Darren Gore Andrew Phillips Ben McKeever-Abbas Andrew Poulton Paul Cronin Debbie Lane Edward Griffin Members IQ Working Group This file is private and may contain confidential and proprietary information. If you have received this file in error, please notify us and remove it from your system and note that you must not copy, distribute or take any action in reliance on it. Any unauthorized use or disclosure of the contents of this file is not permitted and may be unlawful. AstraZeneca PLC, 1 Francis Crick Avenue, Cambridge Biomedical Campus, Cambridge, CB2 0AA, UK, T: +44(0)203 749 5000, www.astrazeneca.com 29 Predictive Stability Tools ➢ ➢ ➢ ➢ 30 Determine risk of autoxidation ➢ Determine potential degradants Performed early in development ➢ Performed early in development Used to compare lead compounds before forced degradation studies If autoxidation risk identified, and method development followed up with EPR ➢ Used to identify possible excipient spectroscopy analysis to monitor incompatibilities to support for radical formation formulation development Predictive Stability Tools ➢ Used throughout development to predict drug substance or product stability 31 ➢ ➢ ➢ ➢ Used to support pack selection Determine the need for desiccant Set water content specifications Used to support pack changes during development ➢ Used to support pack changes post approval Bond Dissociation Energy Tool The BDE values can be accurately calculated for hydrogen atoms in a molecule using relatively fast DFT methods1. The risk of autoxidation can then be estimated. Initiation Propagation Termination BDE < 87 kcal/mol = risk for autoxidation 32 1T. In principle, the chain reaction can be fast as long as the breaking CH-bond is weaker than the OH bond (87 kcal/mol) that is formed in the hydrogen transfer. Andersson, A. Broo, E. Evertsson, J. Pharm. Sci. 103, (2014), 1949-1955 Bond Dissociation Energy Tool c b b a a 3 types of non-equivalent protons Septet of septet of quartets (196 lines!) a a b b c a b BDE = 96 kcal/mol c a b BDE==72 72 kcal/mol BDE kcal/mol Electron Paramagnetic Resonance spectroscopy performed to monitor for free radical formation 33 Simulation based on coupling constants from 2 P. Brovetto, G. Bussetti, Rendiconti del Seminario della Facoltà di scienze dell'Università di Cagliari, 39 (3-4) p.387 Zeneth Zeneth is designed to predict potential degradants of a compound from the chemical structure. ➢ 446 known and validated transformations (version 7.0, 2016 knowledge base) ➢ Data from published sources and data donated by a consortium of member organisations ➢ Drug Substance and Drug Product stability Benefits of Zeneth3: ➢ Provides degradation information when no experimental data is available ➢ Data generated can be used to support regulatory submissions ➢ Assist in the selection of excipients, highlighting potentially problematic ones ➢ Helps in assignment of structure to forced degradation work ➢ Prevents the overlooking of possible pathways through unbiased application of transformations ➢ Presence or absence of conditions (light, water, oxygen, radical initiators, peroxides, metal, temperature, pH) ➢ Relative likelihood of competing reactions 34 3 http://www.lhasalimited.org/products/zeneth.htm Zeneth Example query compound Zeneth predictions displayed in a tree layout. Zoom out for high level view & zoom in for compound specific detail Transformation description and references to supporting literature Simplified tree view of results 35 Zeneth also includes a list of common excipients and is able to predict whether they are likely to interact with the query compound Table to show all degradants generated. Can be filtered upon molecular formula or molecular mass Phase I formulation development - tablet 2. Drug product shelf life prediction – ASAP ➢ When comparing both strengths of tablets, it can be seen that the error for the 50mg tablets is much larger than for the 5mg ➢ This is because the 50mg tablets did not degrade as much as the 5mg, therefore increased extrapolation required to reach specification 36 Phase III Tablet ASAP Study Protocol 37 Temperature (°C) Humidity (% RH) Initial Initial 50 75 60 11 60 75 70 11 70 75 80 30 Phase III Tablet – ASAP Study Set down ➢ The tablets were set down in glass jars, with inserts containing the tablets and a further insert containing the relevant salt solution. ➢ Salt solutions were used to control the humidity - lithium chloride 11% RH, magnesium chloride 30% RH, sodium chloride 75% RH and Amebis humidity capsule (U036) for 55% RH. ➢ Coated tablets are usually allowed to pre-equilibrate with humidity for at least 24 hours before exposure to high temperatures ➢ The jars were then placed in ovens ➢ 44 tablets for the initial analysis were placed in the fridge, also stored in the same inserts. 38