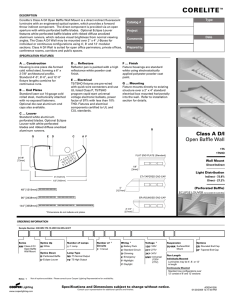

Defect and Diffusion Forum ISSN: 1662-9507, Vol. 401, pp 117-130 © 2020 Trans Tech Publications Ltd, Switzerland Submitted: 2019-05-24 Revised: 2019-10-02 Accepted: 2020-04-15 Online: 2020-05-28 Turbulent Heat Transfer Characteristics of a W-Baffled Channel Flow Heat Transfer Aspect Y. Menni1,a*, A.J. Chamkha2,b, O.D. Makinde3,c Unit of Research on Materials and Renewable Energies, Department of Physics, Faculty of Sciences, Abou Bekr Belkaid University, P.O. Box 119-13000-Tlemcen Algeria 1 Mechanical Engineering Department, Prince Sultan Endowment for Energy and Environment, Prince Mohammad Bin Fahd University, Al-Khobar 31952, Saudi Arabia 2 Faculty of Military Science, Stellenbosch University, Private Bag X2, Saldanha 7395, South Africa 3 a* menniyounes.cfd@gmail.com, bachamkha@pmu.edu.sa, cmakinded@gmail.com Keywords: Forced convection, Nusselt number, thermal enhancement, w-baffle, heat transfer aspect. Abstract. In this work, the thermal behavior of a turbulent forced-convection flow of air in a rectangular cross section channel with attached W-shaped obstacles is investigated. The continuity, momentum and energy equations employed to control the heat and velocity in the computational domain. The turbulence model of k-ε is employed to simulate the turbulence effects. The finite volume method with SIMPLE algorithm is employed as the solution method. The results are reported temperature, local and average Nusselt numbers, and mean velocity contours. The subject is relevant and important for industrial applications. Introduction The arrangement of obstacles, such as baffles, fins and ribs, within channels are among the effective methods used by many researchers and investigators in their numerical and experimental studies. Muszyński and Kozieł [1] carried out two-dimensional numerical investigations of the fluid flow and heat transfer for the laminar flow of the louvered fin-plate heat exchanger, designed to work as an air-source heat pump evaporator. The simulations were performed for different geometries with varying louver pitch, louver angle and different louver blade number. The maximum heat transfer improvement interpreted in terms of the maximum efficiency was obtained for the louver angle of 16° and the louver pitch of 1.35 mm. Park et al. [2] systematically presents the results of heat transfer and friction factor data measured in five short rectangular channels with turbulence promoters. They investigated the combined effects of the channel aspect ratio, rib angleof-attack, and flow Reynolds number on heat transfer and pressure drop in rectangular channels with two opposite ribbed walls. Their experimental results were also compared with literature values. Experimental and numerical studies were conducted by Wong et al. [3] to investigate the dynamic and thermal behavior of a turbulent airflow in a horizontal air-cooled rectangular duct, with inclined square-sectioned cross-turbulators mounted on its bottom surface. Effects of varying the angle formed by the cross-turbulators between 30° and 120° on the convective heat transfer and pressure drop were studied. An optimum range of angles formed by the cross-ribs corresponding to a maximum enhancement of forced convection was observed. According to the experimental and numerical results obtained, its value would be between 60° and 70°. Nasiruddin and Kamran Siddiqui [4] indicated that the convective heat transfer in a heat exchanger tube may be enhanced by placing a baffle inside the tube. The investigators considered a comparative study between three different baffle orientations. The first case examined a vertical baffle. The second case investigated a baffle inclined towards the upstream end, and the third one considered a baffle inclined towards the downstream end. The results suggested that a baffle inclined towards the downstream side with a smaller inclination angle (15° in their study) is a better choice as it enhances the heat transfer by a similar magnitude with a minimal pressure loss. Hwang and Liou [5] investigated heat transfer and loss friction in a rectangular channel with symmetrically mounted solid and fully perforated ribs on All rights reserved. No part of contents of this paper may be reproduced or transmitted in any form or by any means without the written permission of Trans Tech Publications Ltd, www.scientific.net. (#538950727, Stellenbosch University, South Africa-29/04/20,01:26:46) 118 Computational Analysis of Heat Transfer in Fluids and Solids II parallel broad walls (rib open-area ratio: β = 50%; rib pitch-to-height ratio: Pi/H = 5-20; rib heightto-channel hydraulic diameter ratio: H/De = 0.081 and 0.162; rib-to-channel height ratio: H/2B = 0.13 and 0.26; rib height-to-channel hydraulic diameter ratio: H/De = 0.081 and 0.162; Reynolds number: Re = 10,000-50,000). The results indicated that the perforated ribs had the advantages of eliminating the hotspots and providing a superior heat transfer performance. Karwa and Maheshwari [6] investigated fully (open area ratio of 46.8%) and half (open area ratio of 26%) perforated baffles covering Re values ranging from 2,700 to 11,150. The study showed an enhancement of 79-169% in Nusselt number over the smooth duct for the fully perforated baffles and 133-274% for the half perforated baffles while the friction factor for the fully perforated baffles are 2.98-8.02 times of that for the smooth duct and is 4.42-17.5 times for the half perforated baffles. In general, the half perforated baffles are thermo-hydraulically better to the fully perforated baffles at the same pitch. Of all the configurations studied, the half perforated baffles at a relative roughness pitch of 7.2 give the greatest performance advantage of 51.6-75% over a smooth duct at equal pumping power. Sahel et al. [7] presented a new baffle design to eliminate the formation of lower heat transfer areas (LHTAs), particularly in the downstream regions of solidtype baffles. This design concerns a perforated baffle having a row of four holes placed at three different positions. These positions are characterized by a ratio called the pore axis ratio (PAR) which is taken equal to 0.190, 0.425 or 0.660. In their study, the baffle perforated with PAR = 0.190 was found to be as the best design, which reduces significantly the LHTAs, since it ensures an increase in the thermal transfer rate from 2% to 65 %, compared with simple baffle. However, the pressure loss may decrease until 12 times compared with the simple baffle. Khan et al. [8] described experimental investigation of heat transfer with turbulent flow in a rectangular channel with inclined solid and perforated baffles combined with rib turbulators. Combining ribs with perforated and inclined baffles yielded an increase in average Nusselt number, albeit with a pressure drop penalty. In situations where rate of heat transfer is critical to the performance of a device, combining ribs with baffle is a viable solution. Se Kyung et al. [9] have done a numerical study on the heat transfer and frictional characteristics of airflow inside a rectangular channel fitted with different types of inclined baffles (type I: solid baffle; type II: 3 hole baffle; type III: 6 hole baffle; and type IV: 9 hole baffle). The numerical results of the flow field showed that the flow patterns around the different baffle configurations are entirely different and these significantly affect the local heat transfer characteristics. The heat transfer and friction factor characteristics are significantly affected by the perforation density of the baffle plate. It was found that the heat transfer enhancement of baffle type II has the best values. An experimental investigation was carried out by Ko and Anand [10] to measure the heat transfer coefficients and pressure loss in a uniformly heated rectangular channel with wall mounted staggered porous baffles. The experiments were conducted in Reynolds number range of 20,000-50,000. The use of porous baffles resulted in heat transfer enhancement as high as 300% compared to heat transfer in straight channel with no baffles. The experimental result analysis showed that the heat transfer enhancement per unit increase in pumping power was less than one for the range of parameters studied. Guerroudj and Kahalerras [11] simulated the influence of porous block shape on the laminar mixed convective heat transfer and airflow characteristics inside a two-dimensional parallel plate channel when the buoyant and forced flow effects are simultaneously present. The influence of the buoyancy force intensity, the porous blocks shape going from the rectangular shape to the triangular shape, their height, the porous medium permeability, the Reynolds number and the thermal conductivity ratio was analyzed. The results revealed essentially, that the shape of the blocks can alter substantially the flow and heat transfer characteristics. A computer code was developed by Kamali and Binesh [12] to study the turbulent heat transfer and friction in a square duct with various-shaped ribs mounted on one wall. The simulations were performed for four rib shapes, i.e., square, triangular, trapezoidal with decreasing height in the flow direction, and trapezoidal with increasing height in the flow direction. The results showed that features of the inter-rib distribution of the heat transfer coefficient are strongly affected by the rib shape and trapezoidal ribs with decreasing height in the flow direction provide higher heat transfer enhancement and pressure drop than other shapes. Defect and Diffusion Forum Vol.401 119 Sripattanapipat and Promvonge [13] simulated the laminar periodic flow and heat transfer in a two dimensional horizontal channel with isothermal walls and with staggered diamond-shaped baffles. They reported that the diamond shape of the baffle with different tip angles (5 to 35°) may enhance the heat transfer from 200 to 680% for Reynolds number ranging from 100 to 600. However, this intensification is associated with enlarged friction loss ranging from 20 to 220 times above the smooth channel. Saini and Saini [14] conducted an experimental prediction on the turbulent flow and convective heat transfer characteristics in a rectangular air channel with arc-shaped elements attached to the underside of a heated plate. The effects of various dimensionless parameters such as arc angle and height on the Nusselt number and friction factor were studied for Reynolds numbers ranging from 2,000 to 17,000. Their results suggested that a significant heat transfer coefficient enhancement in a solar air channel can be achieved by introducing arc-shaped ribs into the flow. The maximum enhancement in Nusselt number was obtained as 3.80 times corresponding to the relative arc angle of 0.3333 at relative roughness height of 0.0422, with the minimum pressure loss. Stehlik et al. [15] compared heat transfer and friction loss correction factors of an optimized segmental baffle heat exchanger to those of a helical baffle heat exchanger. In their studies, the correction factors for helical baffles were examined as a function of baffle inclination angle to gain an understanding of the underlying transport phenomena as well as to characterize the baffle for design purpose. An improved structure of ladder-type fold baffle was proposed by Wen et al. [16] in order to block the triangular leakage zones in original heat exchangers with helical baffles. They numerically showed that the distribution of shell-side velocity and temperature in improved heat exchanger are more uniform and axial short circuit flow is eliminated. The fluid flow and heat transfer characteristics of the improved heat exchanger and the original heat exchanger were also experimentally studied. They showed that the shell-side heat transfer coefficient and overall heat transfer coefficient are improved by 22.3-32.6% and 18.1-22.5%, respectively. A numerical investigation for fully developed turbulent flow in a square duct fitted with 45° in-line V-baffle pairs mounted on both upper and lower walls was conducted by Fawaz et al. [17] in order to examine the changes in flow structure and thermal performance, using air as the working fluid at Re ranging from 5,000 to 25,000. Effect of various baffle blockage ratios (BR = 0.2, 0.4 and 0.6) and baffles pitch ratios (PR = 0.5,1 and 1.5) on flow behavior and heat transfer were investigated. They found that the TEF of the V-baffle pointing upstream at BR = 0.2 is higher than that at larger BR and the TEF of this same baffle at PR = 0.5 is higher than that at higher PR, at the lowest Re value. Sriromreun et al. [18] reported experimental and numerical investigations of the heat transfer and flow friction characteristics for a solar air heater channel with in-phase and out-phase Z-shaped baffles in the turbulent regime from Re = 4,400 to 20,400. The Z-baffles inclined to 45° relative to the main flow direction are characterized at three baffle-to channel-height ratios (e/H = 0.1, 0.2 and 0.3) and baffle pitch ratios (P/H = 1.5, 2 and 3). The effects of e/H and P/H ratios were more significant for the in-phase Z-baffle than for the out-phase Z-baffle. In addition, numerical [19] and experimental [20-25] works on air baffled channels were conducted to analyze the heat transfer coefficient and pressure loss. In those studies, different structural parameters of the model and various operating parameters were used. In this paper, a computational thermal analysis of the turbulent forced-convection fluid stream behavior in the presence of two staggered, transverse, solid-type, double V-form baffles (or Wshaped obstacles) is conducted in order to improve the heat transfer phenomenon within thermal devices. The thermal aspect is shown for flow Reynolds numbers based on the hydraulic diameter of the channel ranging from 12,000 to 32,000. To perform a detailed analysis of the aerodynamic and thermal fields within this model of W-baffled channel, the finite volume approach, by means of Commercial CFD software FLUENT, for a steady-state, incompressible, and two-dimensional flow is used, and the SIMPLE-algorithm is implemented for all calculations. The analysis results are presented in terms of mean velocity, fields and profiles of temperature, local and average numbers of normalized Nusselt, and thermal enhancement factor for various axial and transverse channel 120 Computational Analysis of Heat Transfer in Fluids and Solids II stations. Small attack angle value (α = 45°) and high Reynolds number (Re = 32,000) values lead to the best functioning regime in a channel containing W-shaped obstacles. Problem Definition The particularity of this computational thermal analysis is the forced-convection heat transfer aspect. The main aim of this paper is to examine the turbulent flow field and convective heat transfer characteristics of a constant property Newtonian fluid inside a two-dimensional horizontal channel of rectangular form, containing two transverse, staggered, solid-type, double V-form (or Wshaped) baffles, where a constant surface temperature is applied on all solid boundaries of the duct, Fig. 1. Figure 1. Geometry under examination (dimensions in m). This channel section due to of their specific geometry, accelerate the flow disturbance and improve the heat exchange between the working fluid and the hot walls. The flow Reynolds number is varied between 12,000 and 32,000. The physical models for fluid flow in the rectangular cross section channel provided by double V-baffles were developed under the following assumptions: 1- Steady two-dimensional heat transfer and fluid flow; 2- Flow is turbulent and incompressible; 3- Physical properties of air fluid (Cp, μ, λf, ρ) and solid (λs) are constants; 4- Fluid is viscous Newtonian; 5- Temperatures applied to the lower and upper surfaces of the channel (Tw) are considered constants; 6- Velocity profile at the inlet of the channel is uniform; 7- Radiation heat transfer is not considered; 8- Thicknesses of the bottom and top wall surfaces of the channel are neglected; and 9- Standard k-ε turbulence model proposed by Launder and Spalding [26], by means of Commercial CFD software FLUENT is applied in this thermal analysis to simulate the fluid flow behavior. The governing flow equations, i.e., continuity, momentum and energy equations, used to simulate the incompressible steady fluid flow and heat transfer in the whole domain treated are given as [4, 29, 30] (1) ∇V = 0 , 2 (2) ρ V .∇V = −∇P + µ f ∇ V , ( ) ρc (V .∇T ) = k ∇ T . p f 2 (3) The standard k-ε model is defined by two transport equations, one for the turbulent kinetic energy, k and the other for its dissipation rate ε, as given below [26] ∂ (4) (ρkui ) = ∂ µ + µt ∂k + Gk − ρε σ k ∂x j ∂xi ∂x j and Defect and Diffusion Forum Vol.401 µt µ + σε The turbulent viscosity, μt is modeled as follows: ∂ (ρεui ) = ∂ ∂xi ∂x j ∂ε ε ε2 + C1ε Gk − C2ε ρ k k ∂x j 121 (5) k2 (6) ε In these equations, Gk represents the generation of turbulence kinetic energy due to the mean velocity gradients. The related constant parameters are [26] (7) C1ε = 1.44, C2ε = 1.92, Cµ = 0.09, σ k = 1.0, σ ε =1.3 µt = ρCµ The Reynolds number is defined as ρ U Dh µ The local Nusselt number, Nux which can be written as h D Nu x = x h Re = λf (8) (9) The average Nusselt number, Nu can be obtained by 1 (10) Nu = ∫ Nu x ∂x L where hx is the local convective heat transfer coefficient. In the entrance region of the test section, 1- A uniform velocity profile is applied, u = Uin and v = 0; 2- At the bottom (y = -H/2) and top (y = H/2) channel walls, the non-slip and impermeability boundary conditions are implemented over the channel wall as well as the W-baffle surfaces, that is u = v = 0; 3- In the channel outlet (x = L) it is prescribed the atmospheric pressure, P = Patm; 4- The inlet temperature of air Tin is considered to be uniform at 300 K; 5- A constant temperature of Tw = 375 K is applied on the entire walls of the channel as the thermal boundary condition. CFD Solution The two-dimensional, incompressible Navier–Stokes equations and the turbulence model equations are discretized using the finite volume method, details of which can be found in Patankar [27]. For the momentum equations, the pressure and velocities are linked together based on the SIMPLE-algorithm [27]. Considering the characteristics of the flow, the Quick-scheme [28] was applied to the interpolations, while a Second-order upwind scheme [27] was used for the pressure terms. In order to verify the accuracy of numerical results obtained in this numerical study with the computer code Fluent, a validation of our analysis was made by comparing with the results of Demartini et al. [25] that are available in the literature. These authors studied a similar problem for the circulation of air through a rectangular channel but with simple baffles. Under the same conditions, we conducted a comparison in terms of the axial velocity profiles for a Reynolds number equal to Re = 8.73×104 at axial location x = 0.159 m from the entrance, shown in Fig. 2. The comparison of results by our numerical method and results of Demartini et al. [25] for steadystate flow conditions shows very good agreement as illustrated in the figure. 122 Computational Analysis of Heat Transfer in Fluids and Solids II Figure 2. Numerical validation of dimensionless axial velocity profiles at station x = 0.159 m for Re = 8.73×104. Results and Discussion Fig. 3 shows the contour plots of mean velocity fields for different Re numbers, i.e., Re = 12,000, 17,000, 22,000, 27,000, and 32,000. It is clearly noted that the fluid velocity values are almost negligible near the two W-obstacles, particularly in the downstream areas this is caused by the presence of the recirculation zones. Far from these regions, the current lines become parallel, which leads to the progressive development of the flow. It is also worth noticing that the velocity increases in the region extending from the end of each W-obstacle to the wall of the channel. This rise in velocity is caused by the presence of the W-obstacles and also by the presence of recycling; hence, an abrupt change in the direction of the flow comes out. One can also notice that the largest velocity values are found near the top of the channel. The flow starts accelerating just after the second W-obstacle. The velocity of the flow is also influenced by the Re number value. If the Re number is increased, then the flow accelerates in the vicinity of the W-obstacle faces, and this causes the convective heat transfer rate to rise. The analysis of the isotherms presented in Fig. 4 for various values of Reynolds number, shows that the fluid temperature significantly increases with the presence of the double V-baffles compared to that of the situation with no baffles. In the downstream region of the two double V-baffles, recirculation cells with relatively high temperatures are observed. In the space between the tip of each double V-baffle and the walls of the channel, the temperature is decreased. The total temperature profiles are shown in Fig. 5 (a) to (d) for different transverse sections of the channel. The numerical results show that the temperature of the air in the recirculation zone is substantially high compared to that obtained in the same region without baffles. This observation is confirmed by Nasiruddin and Kamran Siddiqui [4]. We also note that the hottest areas are, mostly, located near the solid boundaries of the test channel (lower and upper walls of the channel, and double V-baffle surfaces). It is also found that the temperature value at the heated wall level decreases with increasing the flow velocity. On the other hand, the results analysis allowed associating to the fluid temperature elevations, the effect of double V-baffles and fins. At the output of each free segment between the tip of each double V-baffle and the channel walls, the air in flow does not encounter any metal obstacles; its velocity decreases due to the sudden enlargement, and the lack of W-baffles constitutes a supplementary factor of local attenuation of the turbulence in these areas. However, the air temperature increases as soon as the fluid once again finds in contact with the double V-baffles, and this is repeated in an analogous manner from one cell to another. What was also noticed, the fluid temperature is inversely related with the increase in the Reynolds number. The graphical representations of the temperature variation as a function of Reynolds number (Re = 12,000; 22,000; and 32,000) in the transverse section situated between both the W-baffles at x = 0.255 m, is shown in Fig. 6. These results certify that the heat exchange between the heat transfer fluid and the heated walls in the channel with staggered 45° double V- Defect and Diffusion Forum Vol.401 123 baffles is more important with low flow Reynolds numbers. It is clear that for high Reynolds numbers, the fluid temperature significantly decreases i.e., there exists an inverse proportionality between increasing flow Reynolds number and the total temperature in each channel cross section. Additionally, according to analysis of our numerical results on the velocity profiles [see Fig. 6] and the total temperature profiles for different sections of the channel [see Figs. 5 and 6), it is found that the fluid temperature is related to the flow velocity. (a) (b) (c) (d) (e) Figure 3. Mean velocity fields for various values of flow rate: (a) Re = 12,000, (b) Re = 17,000, (c) Re = 22,000, (d) Re = 27,000, and (e) Re = 32,000. 124 Computational Analysis of Heat Transfer in Fluids and Solids II (a) (b) (c) (d) (e) Figure 4. Temperature fields for various values of flow rate: (a) Re = 12,000, (b) Re = 17,000, (c) Re = 22,000, (d) Re = 27,000, and (e) Re = 32,000. (a) Defect and Diffusion Forum Vol.401 125 (b) (c) (d) Figure 5. Profiles of fluid temperature (a) upstream of the first W-baffle at x = 0.159 m and x = 0.179 m, (b) between the first and the second W-baffles at x = 0.255 m and x = 0.285 m, (c) before the second W-baffle at x = 0.315 m and x = 0.335 m, and (d) near the channel outlet at x = 0.525 m, Re = 12,000. 126 Computational Analysis of Heat Transfer in Fluids and Solids II Figure 6. Variation of fluid temperature profiles with Reynolds number for x = 0.255 m. Figure 7. Distribution of normalized local Nusselt number along the bottom and top walls of the channel for Re = 12,000. The heat transfer rate, characterized by the normalized local Nusselt number, is then determined and shown along the lower and upper walls of the channel with Re = 12,000 in Fig. 7. These profiles present in all cases (bottom or top walls) a minimum and a maximum of the Nusselt number. It is found that the heat transfer rate minimums are observed at the level of base of these double V-baffles and that the Nusselt number increases along the baffle and reaches its maximum on its upper face. The effect of the Reynolds number on the normalized local Nusselt number evolution is seen in Fig. 8 (a) and (b) for both bottom and top walls of the channel, respectively. The results show that the heat transfer rate is increased with the increase of flow Reynolds number, because when the Re increases, the turbulence increases and the recirculation region become stronger and consequently the heat dissipation increases. If we think in terms of no-dimensional average Nusselt number, as shown in Fig. 9, there is increasing almost linearly Nusselt number as a function of Reynolds number. There is a linear increment between average heat transfer ratio and flow Reynolds number value. It may be generated by the augmentation of the flow acceleration causing by increasing the flow velocity. It is then found that the double V-baffles play an effective factor to dissipate the heat from the solid walls and the temperature of the flow increases in the regions occupied by the double V-baffles and between the W-deflectors. This enhances the heat transfer. Defect and Diffusion Forum Vol.401 127 (a) (b) Figure 8. Distribution of normalized local Nusselt number along the (a) bottom and (b) top walls of the channel for different flow Reynolds numbers. Figure 9. Variation of normalized average Nusselt number with Reynolds number. Fig. 10 shows the variations of the thermal enhancement factor (TEF) as a function of the Reynolds number at the lower and upper channel walls. In the figure, the TEF value tends to increase with augmenting the Re number for both channel surfaces. The upper wall containing the first 45° W-shaped baffle provides the highest TEF value while the lower wall fitted with the 128 Computational Analysis of Heat Transfer in Fluids and Solids II second 45° W-shaped baffle yields the lowest one. It is found that the TEF values vary between 0.853-1.037; and 1,277-1,644 for lower and upper walls of the channel, respectively, depending on the Re values. In the case of bottom surface, the TEF was found to be much larger than unity; its maximum value was around 1,644 for Re = 32,000. This value of TEF is decreased by 36,952 % in the case of the bottom channel wall at same Re number. Figure 10. Evaluation of thermal-aerodynamic performance for various Reynolds numbers. Conclusion The most important conclusions that can be drawn from this study are as follows: • The velocity of the flow is influenced by the Re number value. If the Re number is increased, then the flow accelerates in the vicinity of the W-obstacle faces, and this causes the convective heat transfer rate to rise; • The temperature of the air in the recirculation zone is substantially high compared to that obtained in the same region without baffles; • In the space between the tip of each double V-baffle and the walls of the channel, the temperature gradient is increased; • At the output of each free segment between the tip of each double V-baffle and the channel walls, the air in flow does not encounter any metal obstacles; its velocity decreases due to the sudden enlargement, and the lack of W-baffles constitutes a supplementary factor of local attenuation of the turbulence in these areas. • The fluid temperature is inversely related with the increase in the Reynolds number. • The heat transfer rate minimums are observed at the level of base of these double V-baffles and that the Nusselt number increases along the baffle and reaches its maximum on its upper face • The double V-baffles play an effective factor to dissipate the heat from the solid walls and the temperature of the flow increases in the regions occupied by the double V-baffles and between the W-deflectors. This enhances the heat transfer. • The TEF values vary between 0.853-1.037; and 1,277-1,644 for lower and upper walls of the channel, respectively, depending on the Re values. Defect and Diffusion Forum Vol.401 129 References [1] T. Muszyński, S. M. Kozieł, Parametric study of fluid flow and heat transfer over louvered fins of air heat pump evaporator, Archives of Thermodynamics, 37(3) (2016) 45-62. [2] J. S. Park, J. C. Han, Y. Huang, S. Ou, R. J. Boyle, Heat transfer performance comparisons of five different rectangular channels with parallel angled ribs, International Journal of Heat and Mass Transfer, 35(11) (1992) 2891-2903. [3] T. T. Wong, C. W. Leung, Z. Y. Li, W. Q. Tao, Turbulent convection of air-cooled rectangular duct with surface-mounted cross-ribs, International Journal of Heat and Mass Transfer, 46 (2003) 4629-4638. [4] Nasiruddin, M. H. Kamran Siddiqui, Heat transfer augmentation in a heat exchanger tube using a baffle, International Journal of Heat and Fluid Flow, 28 (2007) 318-328. [5] J. J. Hwang, T. M. Liou, Heat transfer in a rectangular channel with perforated turbulence promoters using holographic interferometry measurement, International Journal of Heat and Mass Transfer, 38(17) (1995) 3197-3207. [6] R. Karwa, B. K. Maheshwari, Heat transfer and friction in an asymmetrically heated rectangular duct with half and fully perforated baffles at different pitches, International Communications in Heat and Mass Transfer, 36 (2009) 264-268. [7] D. Sahel, H. Ameur, R. Benzeguir, Y. Kamla, Enhancement of heat transfer in a rectangular channel with perforated baffles, Applied Thermal Engineering, 101 (2016)156-164. [8] J. A. Khan, J. Hinton, S. C. Baxter, Enhancement of heat transfer with inclined baffles and ribs combined, Enhanced Heat Transfer, 9(3/4) (2002) 137-151. [9] O. Se Kyung, B. K. P. Ary, S. W. Ahn, Heat transfer and frictional characteristics in rectangular channel with inclined perforated baffles, World Academy of Science, Engineering and Technology, 3(1) (2009) 13-18. [10] K. H. Ko, N. K. Anand, Use of porous baffles to enhance heat transfer in a rectangular channel, International Journal of Heat and Mass Transfer, 46 (2003) 4191-4199. [11] N. Guerroudj, H. Kahalerras, Mixed convection in a channel provided with heated porous blocks of various shapes, Energy Conversion and Management, 51 (2010) 505-517. [12] Kamali, A. R. Binesh, The importance of rib shape effects on the local heat transfer and flow friction characteristics of square ducts with ribbed internal surfaces, International Communications in Heat and Mass Transfer, 35 (2008) 1032-1040. [13] S. Sripattanapipat, P. Promvonge, Numerical analysis of laminar heat transfer in a channel with diamond-shaped baffles, International Communications in Heat and Mass Transfer, 36 (2009) 32-38. [14] S. K. Saini, R. P. Saini, Development of correlations for Nusselt number and friction factor for solar air heater with roughened duct having arc-shaped wire as artificial roughness, Solar Energy, 82 (2008) 1118-1130. [15] P. Stehlik, J. Nemcansky, D. Kral, L. W. Swanson, Comparison of correction factors for shelland-tube heat exchangers with segmental or helical baffles, Heat Transfer Engineering, 15 (1994) 55-65. [16] J. Wen, H. Yang, S. Wang, Y. Xue, X. Tong, Experimental investigation on performance comparison for shell-and-tube heat exchangers with different baffles, International Journal of Heat and Mass Transfer, 84 (2015) 990-997. 130 Computational Analysis of Heat Transfer in Fluids and Solids II [17] H. E. Fawaz, M. T. S. Badawy, M. F. Abd Rabbo, A. Elfeky, Numerical investigation of fully developed periodic turbulent flow in a square channel fitted with 45° in-line V-baffle turbulators pointing upstream, Alexandria Engineering Journal 57(2) (2018) 633-642. [18] P. Sriromreun, C. Thianpong, P. Promvonge, Experimental and numerical study on heat transfer enhancement in a channel with Z-shaped baffles, International Communications in Heat and Mass Transfer, 39 (2012) 945-952. [19] K. Boukhadia, H. Ameur, D. Sahel, M. Bozit, Effect of the perforation design on the fluid flow and heat transfer characteristics of a plate fin heat exchanger, International Journal of Thermal Sciences, 126 (2018) 172-180. [20] R. Ben Slama, The air solar collectors: comparative study, introduction of baffles to favor the heat transfer, Solar Energy, 81 (2007) 139-149. [21] R. K. Karwa, Experimental studies of augmented heat transfer and friction in symmetrically heated rectangular ducts with ribs on heated wall in transverse, inclined, v-continuous and vdiscrete pattern, International Communications in Heat and Mass Transfer, 30 (2003) 241250. [22] S. Tamna, S. Skullong, C. Thianpong, P. Promvonge, Heat transfer behaviors in a solar air heater channel with multiple V-baffle vortex generators, Solar Energy, 110 (2014) 720-735. [23] R. Kumar, A. Kumar, R. Chauhan, M. Sethi, Heat transfer enhancement in solar air channel with broken multiple V-type baffles, Case Studies in Thermal Engineering, 8 (2016) 187-197. [24] F. Wang, X. Chen, J. Chen, Y. You, Experimental study on a debris-flow drainage channel with different types of energy dissipation baffles, Engineering Geology, 220(30) (2017) 4351. [25] L. C. Demartini, H. A. Vielmo, Q. V. Möller, Numeric and experimental analysis of turbulent flow through a channel with baffle plates, Journal of the Brazilian Society of Mechanical Sciences and Engineering, 26 (2004) 153-159. [26] B. E. Launder, D. B. Spalding, The numerical computation of turbulent flows, Computer Methods in Applied Mechanics and Engineering, 3(2) (1974) 269-289. [27] S. V. Patankar, Numerical heat transfer and fluid flow, McGraw-Hill, New York, (1980). [28] B. P. Leonard, S. Mokhtari, ULTRA-SHARP nonoscillatory convection schemes for highspeed steady multidimensional flow, NASA TM 1-2568, NASA Lewis Research Center, (1990). [29] M. Sankar, S. Kiran, G.K. Ramesh, O.D. Makinde, Natural convection in a non-uniformly heated vertical annular cavity, Defect and Diffusion Forum, 377 (20187) 189-199. [30] O. D. Makinde, Z.H. Khan, R. Ahmad, W. A. Khan, Numerical study of unsteady hydromagnetic radiating fluid flow past a slippery stretching sheet embedded in a porous medium, Physics of Fluids, 30 (2018) 083601 (7pages).