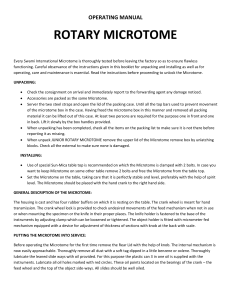

OPERATING MANUAL ROTARY MICROTOME Every Swami International Microtome is thoroughly tested before leaving the factory so as to ensure flawless functioning. Careful observance of the instructions given in this booklet for unpacking and installing as well as for operating, care and maintenance is essential. Read the instructions before proceeding to unlock the Microtome. UNPACKING: Check the consignment on arrival and immediately report to the forwarding agent any damage noticed. Accessories are packed as the same Microtome. Server the two steel straps and open the lid of the packing case. Until all the top bars used to prevent movement of the microtome box in the case. Having freed the microtome box in this manner and removed all packing material it can be lifted out of this case. At least two persons are required for the purpose one in front and one in back. Lift it slowly by the box handles provided. When unpacking has been completed, check all the items on the packing list to make sure it is not there before reporting it as missing. When unpack JUNIOR ROTARY MICROTOME remove the upper lid of the Microtome remove box by unlatching blocks. Check all the external to make sure none is damaged. INSTALLING: Use of special Sun-Mica table top is recommended on which the Microtome is clamped with 2 bolts. In case you want to keep Microtome on some other table remove 2 bolts and free the Microtome from the table top. Set the Microtome on the table, taking care that it is perfectly stable and level, preferably with the help of spirit level. The Microtome should be placed with the hand crank to the right hand side. GENERAL DESCRIPTION OF THE MICROTOME: The housing is cast and has four rubber buffers on which it is resting on the table. The crank wheel is meant for hand transmission. The crank wheel lock is provided to check undesired movements of the feed mechanism when not in use or when mounting the specimen or the knife in their proper places. The knife holder is fastened to the base of the instruments by adjusting clamp which can be loosened or tightened. The object holder is fitted with micrometer fed mechanism equipped with a device for adjustment of thickness of sections with knob at the back with scale. PUTTING THE MICROTOME INTO SERVICE: Before operating the Microtome for the first time remove the Rear Lid with the help of knob. The internal mechanism is now easily approachable. Thoroughly remove all dust with a soft tag dipped in a little benzene or oxlene. Thoroughly lubricate the leaned slide ways with oil provided. For this purpose the plastic can 3 in one oil is supplied with the instruments. Lubricate all oil holes marked with red circles. These oil points located on the bearings of the crank – the feed wheel and the top of the object side-ways. All slides should be well oiled. Starting up for the first time, crank the wheel for 20 or 30 revolutions clock wise, so that all the components get free motions. Keep the feed leading screw at the backward position with the help of feed handle by rotating in the clockwise direction as indicated. Pull the level back before operating the handle. Thus free the rachet wheel. CLAMPING THE SPECIMEN IN THE MICROTOME: The specimen on wooden block or metallic block is clamped in object holder by tightening adjusting screw jaw to orient the object adjust three tomy screw of the block holder. The clamping screw should be tightened well so as to eliminate vibration. The specimen should be well centered in the clapping screw. ADJUSTING SECTION THICKNESS: Section thickness is adjustable from 0-25 microns by turning knurled knob in front and indicated by a scale on rear with vernier. In supper 22 model. The 1 division on scale – 1 Micron. MOUNTING OF KNIFE: The knife holder is fastened to the base of the instrument by an adjusting clamp which is loosened by gripping of the clamping screw and turning counterclockwise or tightened by turning clockwise. To insert a knife in the holder, loosen the two thumb screw and insert knife literally. The inclination of the knife with respect to the object can be adjusted by loosening the two thumb screws and raising or lowering them. All set screws holding the specimen block, the knife, the knife holder to the base should be tightened before cutting sections. It is good practice to lower the object to the level of the knife edge before the first cut to make sure there is proper clearance, so as to avail all possible damage to the knife and specimen. The gap between the object and knife edge can be adjusted by turning the handle on the wheel. OPERATING THE MICROTOME: The Microtome is actuated by turning the crank wheel clockwise. A head locking arrangement is provided to look the wheel for preventing undesired movement of the feed mechanism. The Rotary Microtome should not be run faster than sixty cuts per minute. Each material sectioned on the Microtome has an optimum cutting speed depending on the nature of the material, the cutting edge of the knife and the thickness of the section. Sections should be made at the best speed for the best technical results. The distortions of the sections depends on the nature of the knife edge, the till of the knife, (clearance and rake angles) the temperature, material of sections embedding. POSITIONING THE KNIFE IN THE MICROTOME: The actual cutting facts of a knife kits very small in proportion to the knife. The angles between the two cutting facts is established by the honing back when the knife is on the microtome it must be tilled so that there is clearance between the cutting facet net to the block of tissue. If this till it is adequate, the surfaceof the block is forced down from the hedging effect of the cutting facet and no section results. The next time that knife passes over the tissue this compression is increased and a partial section or no section may be obtained. However, the tissue is soon so compressed that it suddenly explands and the next section is very thick, if the tilt is not adequate, alternate thick and thin section is usually due to insufficient or to excessive tilt. The tilt angle between the straight edge and the surface of block is the clearance angle. All of the material so far investigated suggest that the tilt angle ranges between 3 degree and 8 degree knife clearance angle. Also the angle between the outer facet and the line perpendicular to the block at the point of cutting, called the rake angle is also important. For hard tissues, rake angle is also important. For hard tissues, rake angles of 22 degree to 25 degree are used, and for soft tissues the rake angles may be increased to 45 degree. DIS-ENGAGE & RE-ENGAGE FEEDING MECHANISM: When the limit of the feed has been reached simply rotate the handle clockwise upto limit. Pull the level back before doing so to free the wheel and after that re-arrange the wheel with rachet dog. LUBRICATION: All slides should be kept well oiled with three in one oil provided. Never use strong or abrasive cleaners emery paper etc. When not in use: The Microtome should be cleaned with soft rag and cover put on it, so that dust may not spoil the fine.