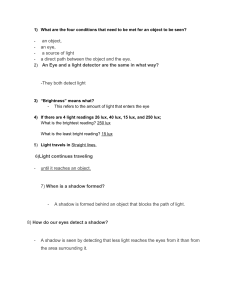

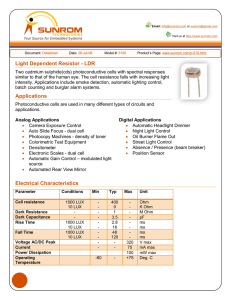

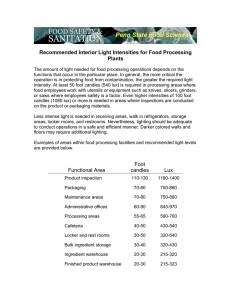

Work Environment Measurement (WEM) Refers to the determination of environmental stresses and their hazardous effects on worker’s health through direct measurement of hazards using IH equipment. Purposes of WEM • To evaluate the effectiveness of environmental control measures adopted to improve the workplace; • To maintain favorable environmental conditions. • To monitor worker’s exposure to harmful substances; WEM Equipment • • • • • • Lux Meter-Illumination Psychrometer-Humidity Anemometer-Air Movement Smoke Tester -Air Direction Globe Thermometer-Heat Sound Level Meter -Noise Permissible Noise Exposure (PNE) Level Duration/day Hours (Hr) 8 6 4 3 2 1½ 1 ½ ¼ Sound Level dB (A) 90 92 95 97 100 102 105 110 115 Recommended Illumination Levels • • • • A minimum of 50 lux – passageway, corridor, warehouse A minimum of 100 lux – engine and boiler rooms; toilets and washrooms A minimum of 200 lux – canning and preserving; planing of lumber and veneering A minimum of 300 lux – medium inspection; office deskwork with intermittent reading and writing for filing and mail sorting. No Entry An Oxygen Enriched Atmosphere Exists 23.5 % O2 Entry is Allowed Without Respiratory Protection if: • LEL 0% • Benzene < 0.5 ppm • Hydrogen Sulfide < 10 ppm • CO < 25 PPM • Total Hydrocarbons < 300 ppm • Temperature < 43.3 C (110 F) Entry with Supplied Breathing Air Providing: • LEL < 10% • Toxic vapours below their IDLH • Temperature < 43.3 C (110 F) No Entry Insufficient Oxygen to sustain life 19.5 % O2 16.5 % O2