Digital Tachometer Report: Construction, Operation, Applications

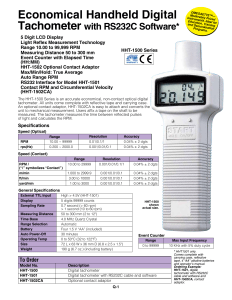

advertisement

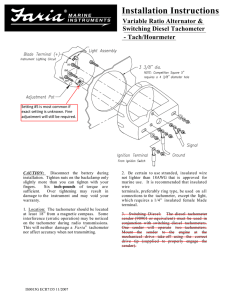

Arab Academy for Science and Technology and Maritime Transport College of Engineering and Technology Mechatronics Engineering Department EE218 Digital Tachometer Submitted by: Mohamed Amir EL Refaie محمد امير الرفاعي ID: 18104034 Supervised by Dr. Salwa 3/6/2020 Electrical and Control Engineering Department Arab Academy for Science and Technology and Maritime Transport Cairo 2020 CONTENTS CONTENTS.................................................................................................................................................. I LIST OF FIGURES .................................................................................................................................... II LIST OF TABLES ..................................................................................................................................... III 1.1 Construction ...................................................................................................................................... 1 2.1 Theory of Operation ...................................................................................................................... 1,2 3.1 Measurement Range (Span) ............................................................................................................. 3 4.1 Applications ....................................................................................................................................... 4 I. LED Tachometer ......................................................................................................................... 4 II. Non-Contact Tachometer ........................................................................................................ 4,5 III. Contact Tachometer .................................................................................................................... 5 5.1 Advantages and Disadvantages........................................................................................................ 6 6.1 Data Sheet Example ....................................................................................................................... 7,8 APPENDIX 1 ............................................................................................................................................... 8 APPENDIX 2 ............................................................................................................................................... 9 REFERNCES ............................................................................................................................................ 10 I LIST OF FIGURES Figure 1 Digital Tachometer Construction ................................................................................................... 1 Figure 2 Principle of operation of normal tachometer .................................................................................. 2 Figure 3 Principle of operation of digital tachometer………………………………………………………………………………3 Figure 4 LED Tachometer………………………………………………………………………………………………………………………..4 Figure 5 Non contact Tachometer………………………………………………………………………………………………………..5 Figure 6 Contact Tachometer…………………………………………………………………………………………………………………..5 II LIST OF TABLES Table 1 Ranges of different applications ...................................................................................................... 3 Table 2 Technical specification ................................................................................................................. 6,7 III 1.1 Construction This Digital Tachometer consists of optical sensor, signal conditioning, microcontroller, display, memory and external port (for the controller) as shown in Figure (1). The optical sensor transmits to the signal conditioning, the signal conditioning transmits to the microcontroller, the microcontroller transmits to display, memory and it transmits and takes back from the external port. Figure 1 Digital Tachometer Construction 2.1 Theory of Operation Pulses are taken care of by the tachometer at the frequency that should be measured. A scale factor is applied and connected to produce readings of a few types like flow rates, linear speed and so on. The voltage is created by means of a changeless magnet on the pole. There is a toothed wheel made of iron, which gets magnetized as the magnet passes the teeth. At that point, as the 1 magnet rotates away from the teeth, the wheel becomes de-magnetized. As these progressions happen, an electric field conforms to the permanent magnet. This field influences the electric charges in a wire coil that surrounds the magnet, generating both power and electricity. As the tooth moves toward the magnet, the current moves in one direction. As the tooth moves from the magnet, the current changes the direction oppositely. The tachometer reads the frequency with which the coil's current changes direction. Furthermore, if the engine turns all the more rapidly, the change in the magnetic field turns out to be increasingly radical, producing higher voltage. Motors with ignition systems, not always, utilize a little generator joined to the engine drive shaft. In such case, the tachometer becomes a voltage meter, meaning that it checks the pulsations of voltage within the ignition system. The output voltage is proportional to the shaft's speed so measuring voltage is changed over into an precise estimation in RPMs. Figure (2) shows the principle of operation of a normal tachometer. A tachometer that does not require any physical contact with the turning shaft is called a non-contact digital tachometer. In this sort, a laser or an optical disk is connected to the rotating shaft, and it can be studied by an IR beam or laser, which is coordinated by the tachometer. Figure (3) shows the principle of operation of a digital tachometer. Figure 2 Principle of operation 2 Figure 3 Principle of operation 3.1 Measurement Range (Span) The measurement range for the digital tachometer differs from an application to another. Digital Techometer has lots of applications but here are 3 measurement ranges for three different applications as shown in Table (1). Table 1 Ranges of different applications App name Display Range Accuracy Resolution Autoranging: Laser (LED 5 digits LCD 5 to 99,999 ±0.01% or ±1 0.001 to 1.0 light source) display RPM Digit RPM Fixed: ± 1 Digit RPM 0.1 RPM (2 to Non-Contact 5 digits LCD 1 to 99,999 ±(0.05%+1 999.9 RPM) 1 RPM display REV digits) RPM. (over 1000 RPM) Contact RPM 5 digits LCD 10.0 to display 19999RPM 3 0.001/0.01/0.1/1 ± (0.1% of rdg.+2 digit) 4.1 Applications I. Laser (LED light source) It is a battery-powered portable non-contact optical tachometer. It works with up to 36 inches from a reflective target. It uses an LED light source to transmit. Its design makes it safer, as the direct line of sight views both the rotating object and the screen at the same time while providing a non-slip rubber surface for a single hand operation as well as shown in Figure (4). Figure 4 LED Tachometer II. Non-Contact tachometer The digital tachometer gives fast and accurate non-contact RPM measurements of rotating objects. The tachometer uses the CPU technique and the photoelectrical technique as shown in Figure (5). 4 Figure 5 Non contact tachometer III. Contact tachometer It is widely used to measure rotational speed of engines, conveyer belts, and other rotating systems/objects as shown in Figure (6). Figure 6 contact tachometer 5 5.1 Advantages and Disadvantages Digital Tachometer has many advantages as: 1. It has linear relationships between output and rotational speed. 2. It is cheap. 3. It doesn’t require maintenance every now and then (Not often at all). 4. It gives free output. Although digital tachometer has those advantages, it also suffers from some disadvantages like: 1. Hard to calibrate with. 2. At high speed, it has no linear relationship between speed and output. 6.1 Data Sheet Example Table 2 Technical Specification Display 5 digits LCD display Accuracy Accuracy : ±(0.05%+1 digits) RPM Test Range 2 to 99,999 RPM Count Range 1 to 99,999 REV Resolution 0.1 RPM (2 to 999.9 RPM) 1 RPM. (over 1000 RPM) Sampling Time 0.5 sec. (over 120 RPM) Detecting Distance 50mm to 500mm 6 Time Base Quartz Crystal Power Consumption Approx 45mA Power Supply 9V Battery or 6V Exterior DC Operation Temp 0°C to 50°C Weight 151g Dimension 160mm × 58mm × 39mm 7 APENDIX 1 8 APPENDIX 2 9 REFERNCES https://www.youtube.com/watch?v=3l7EJMU_OGo https://www.slideshare.net/RohitChoudhury1/tachometer-66815270 https://www.elprocus.com/introduction-to-digital-tachometer-circuit-working-with-8051/ https://www.behance.net/gallery/24045013/Principle-Types-and-Application-of-Tachometer https://www.quora.com/What-is-the-working-principle-of-tachometers A. & M. College of Texas, 1952 https://www.globaltestsupply.com/pdfs/cache/www.globaltestsupply.com/monarch/tachomet er/6125_011/datasheet/monarch_6125_011_tachometer_datasheet.pdf 8. http://www.farnell.com/datasheets/1725281.pdf 9. http://content.amprobe.com/DataSheets/TACH-10%20Tachometer.pdf 10. https://www.youtube.com/watch?v=Kowv-nJnX7o 11. https://www.youtube.com/watch?v=_7dPJ5trYDo 1. 2. 3. 4. 5. 6. 7. 10